Liquid metal fluid containing phase-change microcapsules

A phase change microcapsule and liquid metal technology, applied in the field of cooling fluids, can solve the problems such as the inability to meet the thermal control requirements of high heat flux chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

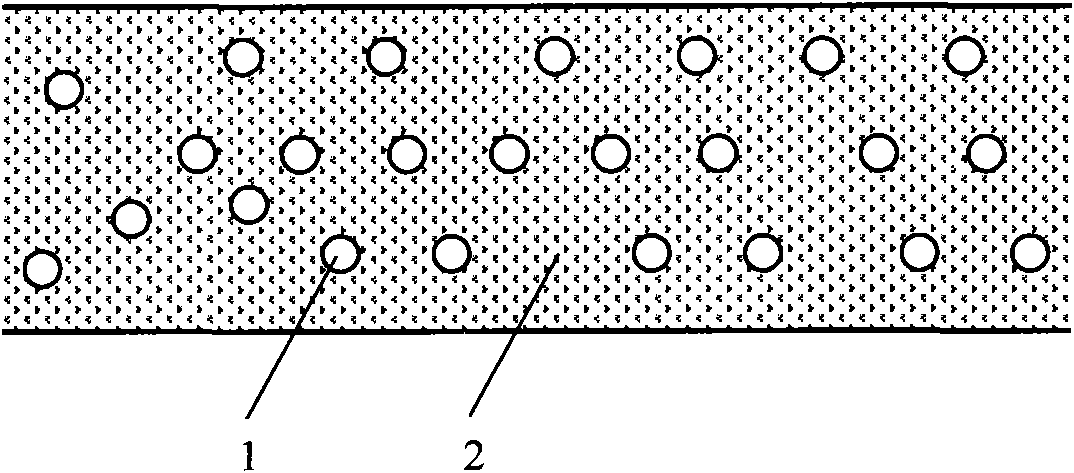

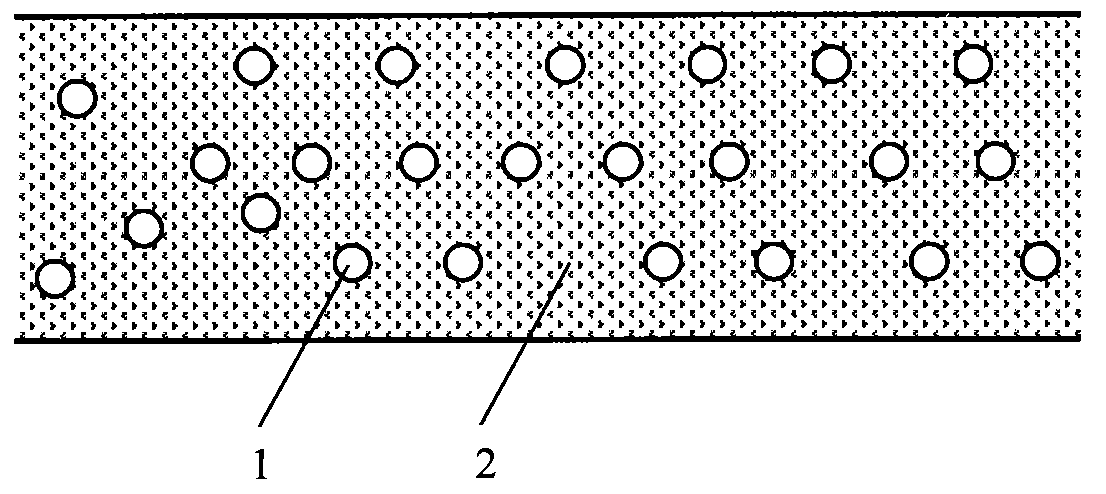

Embodiment 1

[0023] The liquid metal 2 used as a solvent is mercury (melting point -38.72°C), gallium (melting point 29.8°C), gallium-indium alloy (such as 62.5wt% Ga, 21.5wt% In, 16wt% Sn, melting point 10.7°C); or Is other metals with low melting points at medium or low temperatures, including lead (melting point 327.5°C), bismuth (melting point 271.4°C), tin (melting point 232.0°C) or chromium (melting point 321.1°C); or forms of at least two of the above metals alloys, or alloys of the above metals with other metals. The ratio of the composition in the liquid alloy can be selected according to actual needs, so that the melting point of the alloy is lower than the working temperature.

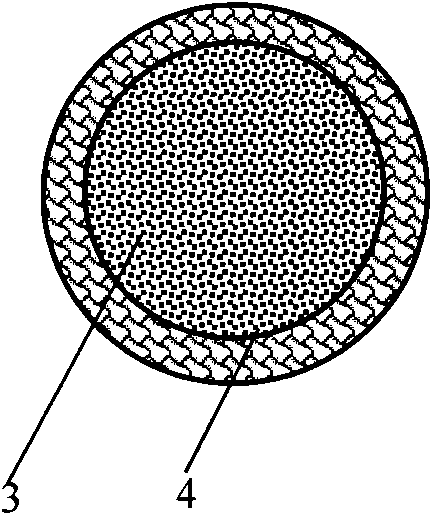

[0024] The phase change material 3 has a very high phase change heat, and can be selected from solid-liquid or liquid-gas hydrated inorganic salts, higher fatty alcohols, higher fatty acids, hydrocarbons, polyethers, aliphatic polyesters and polyester ethers, etc. The heat of phase change per unit weigh...

Embodiment 2

[0026] The phase-change material 3 of the present invention is a combination of two or more of the above-mentioned phase-change materials, forming phase-change microcapsules 1 with multiple phase-change temperatures, and realizing enhanced heat exchange in multiple different temperature regions. The shell 4 and the liquid metal 2 are the same as those of the first embodiment.

Embodiment 3

[0028] The shell 4 of the present invention is a combination of two or more materials such as inorganic or organic polymers described in Example 1, so as to improve the airtightness or heat-humidity stability of the shell. The phase change material 3 and the liquid metal 2 are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com