Method for preparing biological diesel oil using nano solid acid or alkali catalyst

A biodiesel, solid acid technology, applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of poor repeated use performance, catalysts cannot be recycled and reused, environmental pollution, etc., and achieves improved repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

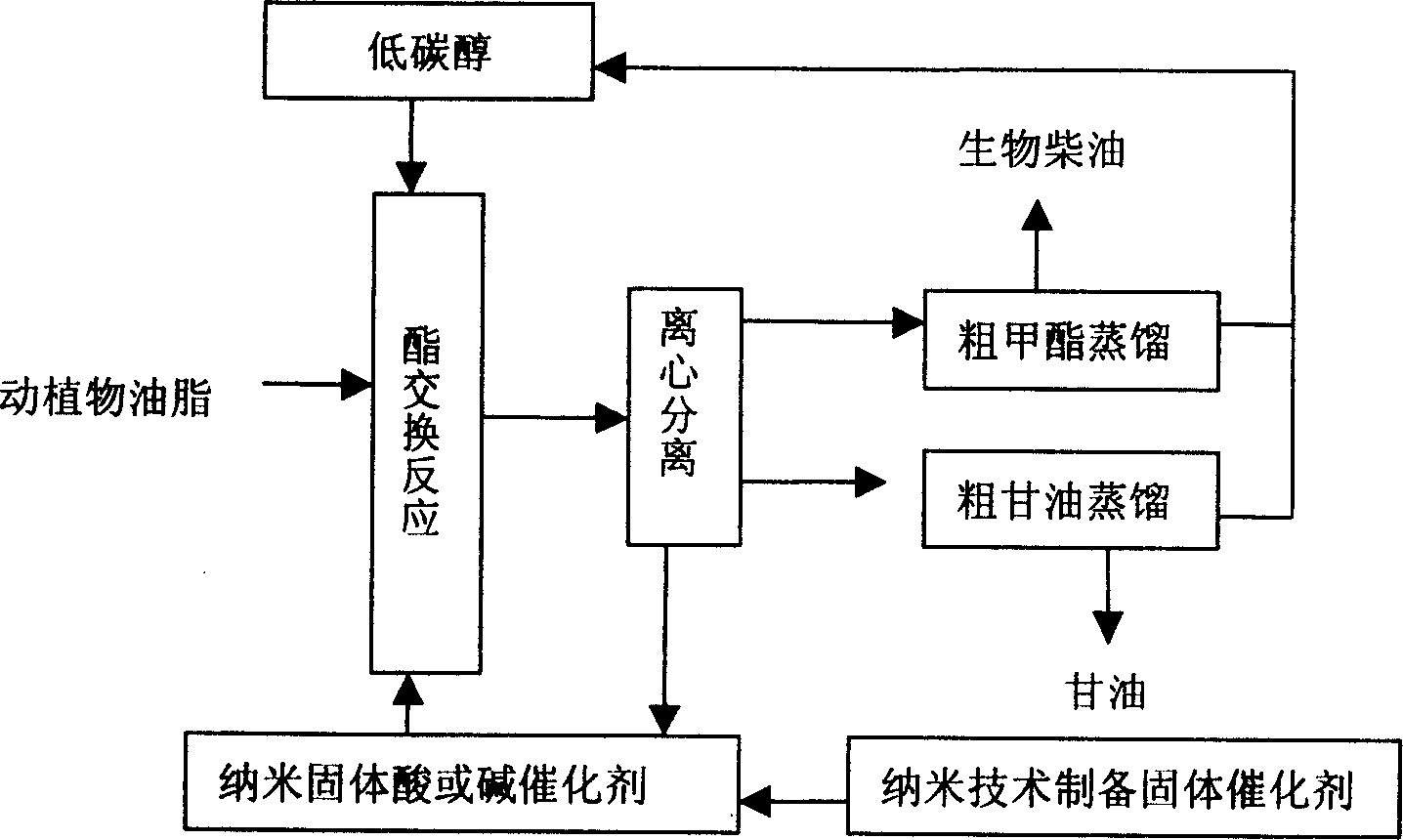

Image

Examples

Embodiment 1

[0019] Raw materials: cold-rolled rapeseed crude oil, methanol, nano hydrotalcite (MgAl(O) / MgFe 2 o 4 );

[0020] Add 200g of cold-rolled rapeseed crude oil and 60g of methanol by weight into a 500ml three-neck round-bottomed flask, place in an electric heating thermostat, stir evenly, and then add 5g of nanometer hydrotalcite (MgAl(O) / MgFe 2 o 4 ), heated to 70°C, methanol was refluxed and stirred for 5 hours, then stopped heating and stirring. Then the reactant was poured into a centrifuge cup, and the crude methyl ester and crude glycerin were separated by centrifugation, and the methanol was removed by rotary distillation under reduced pressure to obtain 198.67g of biodiesel, with a yield of 99.34%, and 19.87g of glycerin, which was measured by GB / T 13216.6-91 The glycerol content is 98%, and the theoretical glycerin yield is 20g, that is, the biodiesel conversion rate is above 97.36%. The absolute content of fatty acid methyl ester in the biodiesel product was determi...

Embodiment 2

[0025] Raw materials: degummed soybean oil, methanol, K + / nano-Al 2 o 3 , K + / Common Al2 o 3 ;

[0026] Put 200g of degummed soybean oil and 60g of methanol into a 500ml three-neck round-bottomed flask by weight, place it in an electric heating thermostat, stir evenly, and then add 5g of nanometer solid catalyst: K + / nano-Al2O3, heated to 70°C, methanol was refluxed and stirred for 5 hours, then stopped heating and stirring. Then the reactant was poured into a centrifuge cup, and the crude methyl ester and crude glycerin were separated by centrifugation, and the methanol was removed by rotary distillation under reduced pressure to obtain 199.50 g of biodiesel, with a yield of 99.75%, and 19.69 g of glycerin, which was measured by GB / T 13216.6-91 The obtained glycerol content is 97.98%, and the theoretical glycerin yield is 20g, that is, the biodiesel conversion rate is 96.46%. The absolute content of fatty acid methyl ester in the biodiesel product was determined by g...

Embodiment approach 3

[0031] Raw materials: waste cooking oil with an acid value of 24mgKOH / g, methanol, nano-solid superacid: ZrO 2 / SiO 2 , ordinary solid superacid: ZrO 2 / SiO 2

[0032] The waste cooking oil collected by weight is first settled and filtered to obtain raw oil with an impurity content of less than 0.1%, and its acid value is measured to be 24 mgKOH / g. Add 200g of treated waste cooking oil and 60g of methanol into a 500ml three-neck round bottom flask, stir evenly, then add 5g of nano-solid superacid: ZrO 2 / SiO 2 , heated to methanol reflux temperature, stirred and reacted for 5 hours, then stopped heating and stirring, poured out the reactant and centrifuged, obtained crude methyl ester and crude glycerol to remove methanol, obtained biodiesel product 199.86g, yield 99.93%, by-product glycerin 19.81g , the glycerol content is 97.08%, and the biodiesel conversion rate is 96.16%. The absolute content of methyl esters in biodiesel products was determined by gas chromatography...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com