Microcrystal-reinforced transparent leadless fritted glaze and preparation method thereof

A lead-free frit and transparent technology, which is applied in the field of ceramic glaze processing, can solve the problems of unsatisfactory glaze hardness performance, insufficient thermal stability, and high glaze firing temperature of western tableware, and achieve good glaze quality and glaze surface Good gloss and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of microcrystalline reinforced transparent lead-free frit glaze comprises the following steps:

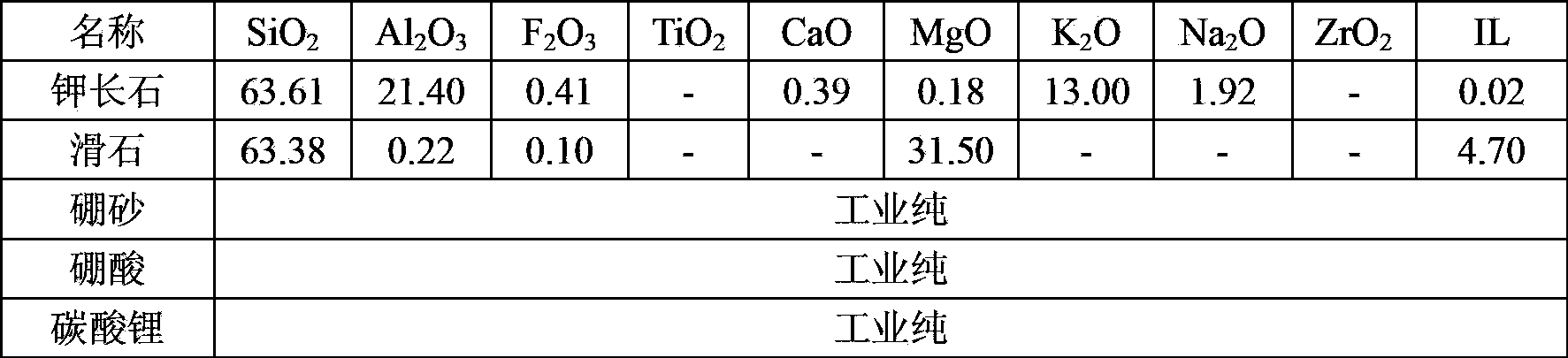

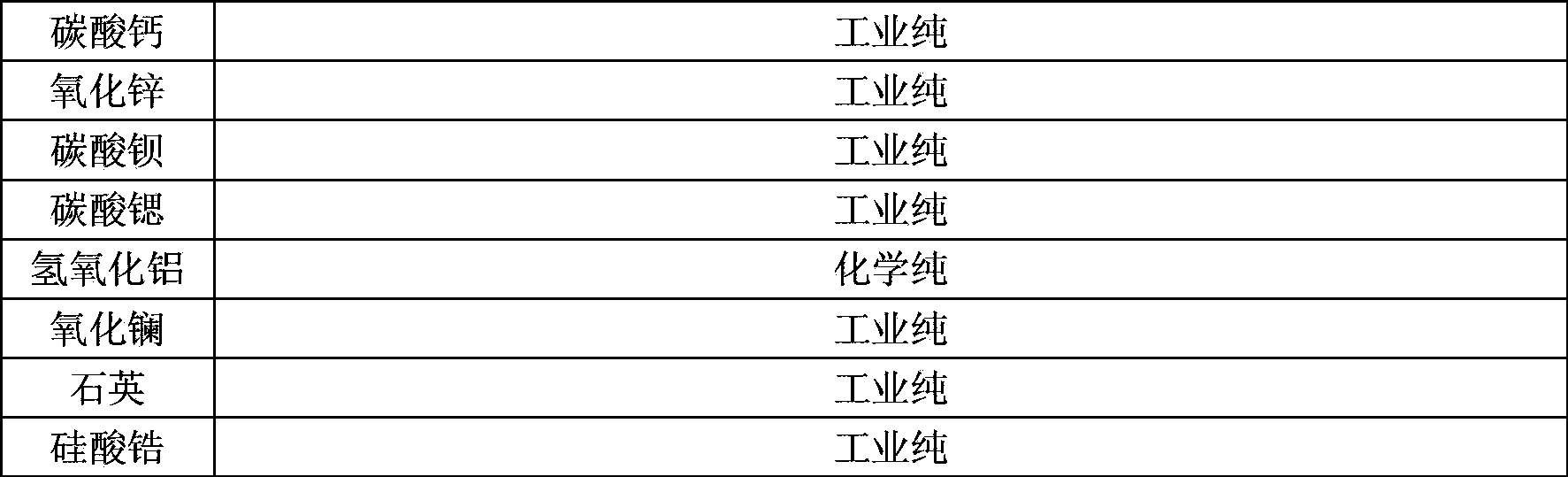

[0030] Microcrystalline reinforced transparent lead-free frit glaze, the following raw materials are weighed according to mass percentage: potassium feldspar 18.06%, borax 6.83%, talc 3.17%, boric acid 3.23%, lithium carbonate 2%, strontium carbonate 3.03%, calcium carbonate 15.92%, 7% zinc oxide, 4.53% barium carbonate, 4.18% aluminum hydroxide, 0.5% lanthanum oxide, 4.57% zirconium silicate, 28.42% quartz;

[0031] Mix the raw materials of each component evenly, melt in a frit furnace at a melting temperature of 1400°C for 180 minutes, and make a lead-free frit glaze after water quenching;

[0032] Using water as the medium, add 0.15% polyacrylamide of the quality of lead-free frit glaze, and ball-mill the lead-free frit glaze in a ball mill to make glaze slurry. )0.02~0.05%;

[0033] The glaze slurry is applied to the high-temperature biscuit-fire...

Embodiment 2

[0035] The preparation method of microcrystalline reinforced transparent lead-free frit glaze comprises the following steps:

[0036] Weigh the following raw materials according to mass percentage: potassium feldspar 20.06%, borax 5%, talc 3.17%, boric acid 8.97%, lithium carbonate 2%, strontium carbonate 3.03%, calcium carbonate 15.92%, zinc oxide 7%, barium carbonate 4.53%, aluminum hydroxide 1%, lanthanum oxide 0.5%, zirconium silicate 4.57%, quartz 24.25%;

[0037] Mix the raw materials of each component evenly, melt in a frit furnace at a melting temperature of 1450°C for 250 minutes, and obtain a frit after water quenching;

[0038] Using water as the medium, add 0.20% polyacrylamide of lead-free frit glaze quality, and ball-mill the frit in a ball mill to make a glaze slurry, and the fineness of the glaze slurry is controlled at 0.02-0.05% over a million-hole sieve.

[0039] The glaze slurry is applied to the bone china biscuit that has been fired at high temperature, ...

Embodiment 3

[0041] The preparation method of microcrystalline reinforced transparent lead-free frit glaze comprises the following steps:

[0042] Weigh the following raw materials according to mass percentage: potassium feldspar 25.06%, borax 1%, talc 3.17%, boric acid 14.65%, lithium carbonate 6%, strontium carbonate 3.03%, calcium carbonate 3.86%, zinc oxide 7%, barium carbonate 4.53%, aluminum hydroxide 1%, lanthanum oxide 0.5%, zirconium silicate 6.84%, quartz 26.15%;

[0043] Mix the raw materials of each component evenly, melt them in a frit furnace at a melting temperature of 1450°C, and make a frit after water quenching;

[0044] Using water as the medium, add 0.25% polyacrylamide of lead-free frit glaze quality, and ball-mill the frit in a ball mill to make glaze slurry, and the fineness of the glaze slurry is controlled at 0.02-0.05% over a million-hole sieve.

[0045]The glaze slurry is applied to the bone china biscuit that has been fired at high temperature, and then fired t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com