Pure black glazed tile produced by using waste glaze slip and preparation method of pure black glazed tile

A technology of glazed tiles and glaze slurry, which is applied in the field of manufacturing pure black glazed tiles by using waste glaze slurry and its preparation, which can solve the problems of difficult production of pure black glaze, bluish, grayish, etc., and achieve decorative effects and strong artistic beauty , strong universality, good glaze quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

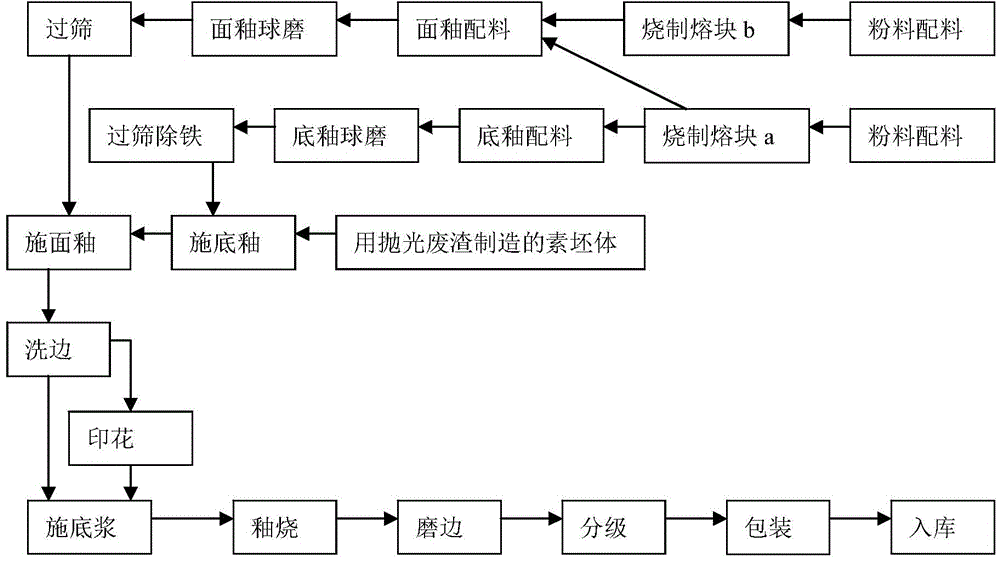

[0050] The method for making pure black glazed tiles by utilizing waste glaze slurry, it may further comprise the steps:

[0051] A, prepare bottom glaze:

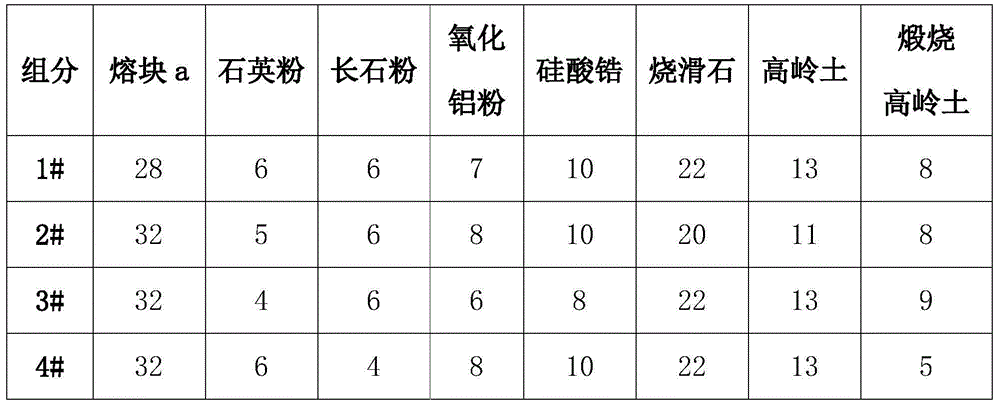

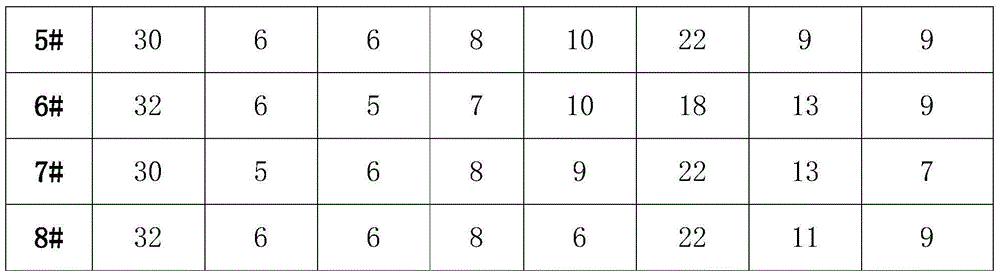

[0052] Prepare frit a, the chemical composition of frit is shown in Table 1:

[0053] Table 1, the chemical composition list of frit a (weight percent, %)

[0054] components

SiO 2

al 2 o 3

CaO

MgO

K 2 o

Na 2 o

TiO 2

ZnO

SrO

ZrO 2

B 2 o 3

P 2 o 5

1#

61.5

4.7

7.9

1.7

2.6

0.5

2.5

6.8

1.0

6.4

3.8

0.6

2#

61.4

4.6

7.6

2.2

2.6

0.5

2.8

7.1

1.1

6.1

3.2

0.8

3#

61.2

4.6

7.8

1.6

3.2

0.2

2.6

7.4

1.2

6.4

3.2

0.6

4#

61.2

5.0

8.2

1.7

2.9

0.6

2.2

7.4

0.8

6.2

3.2

0.6

5#

61.5

5.1

7.7

1.9

3.0

0.4

2.2

7.2

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com