Fine stoneware brick made from recovered ceramic solids and its preparation method

A technology of recycled materials and ceramic polished tiles, which is applied in the field of preparation of fine stoneware bricks. It can solve the problems that affect the product's internal quality and appearance quality, pinholes, glaze bubbles, product deformation, etc., and achieve industrial scale and good flatness. , fine texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of preparation method of the unglazed fine stoneware brick that reclaimed ceramic solid comprises the following steps:

[0058] A. Prepare the green body:

[0059] The chemical composition of the green body is shown in Table 1:

[0060] Table 1, the chemical composition list of green body (weight percent, %)

[0061] Component SiO 2

Al 2 o 3

CaO MgO K 2 O+Na 2 o 3

Fe 2 o 3 +TiO 2

1# 70 20 3 2 3 2 2# 71 19 4 1 4 1 3# 72 19.5 2 1.5 3.5 1.5 4# 71.5 18 3.5 2 3.8 1.2

[0062] Prepare the green body: select the corresponding proportion of potassium feldspar, albite and quartz mixed sand, clay, talc, porcelain stone, ceramic solid recyclate and 1% to 2% by weight according to the chemical composition in Table 1. Auxiliary raw materials are used for batching; add an appropriate amount of water and finely crush it into a slurry with a fineness of 250 mesh sieves with a mass perce...

Embodiment 2

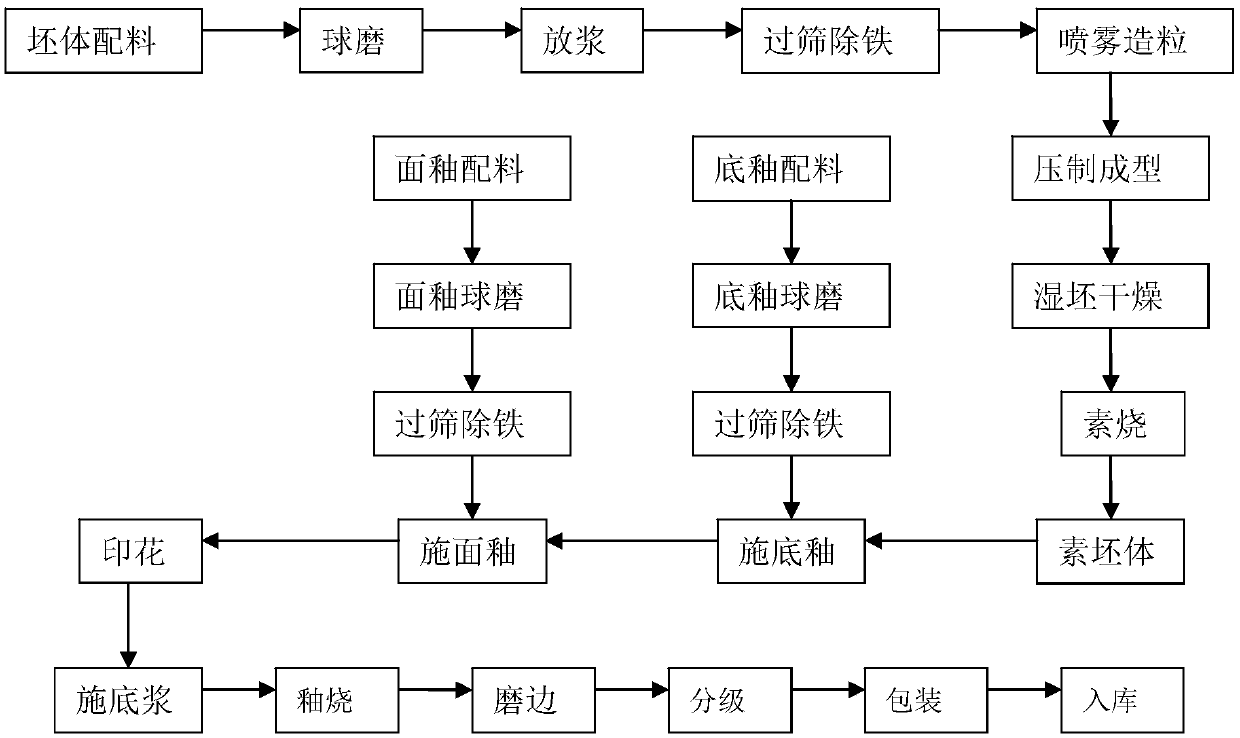

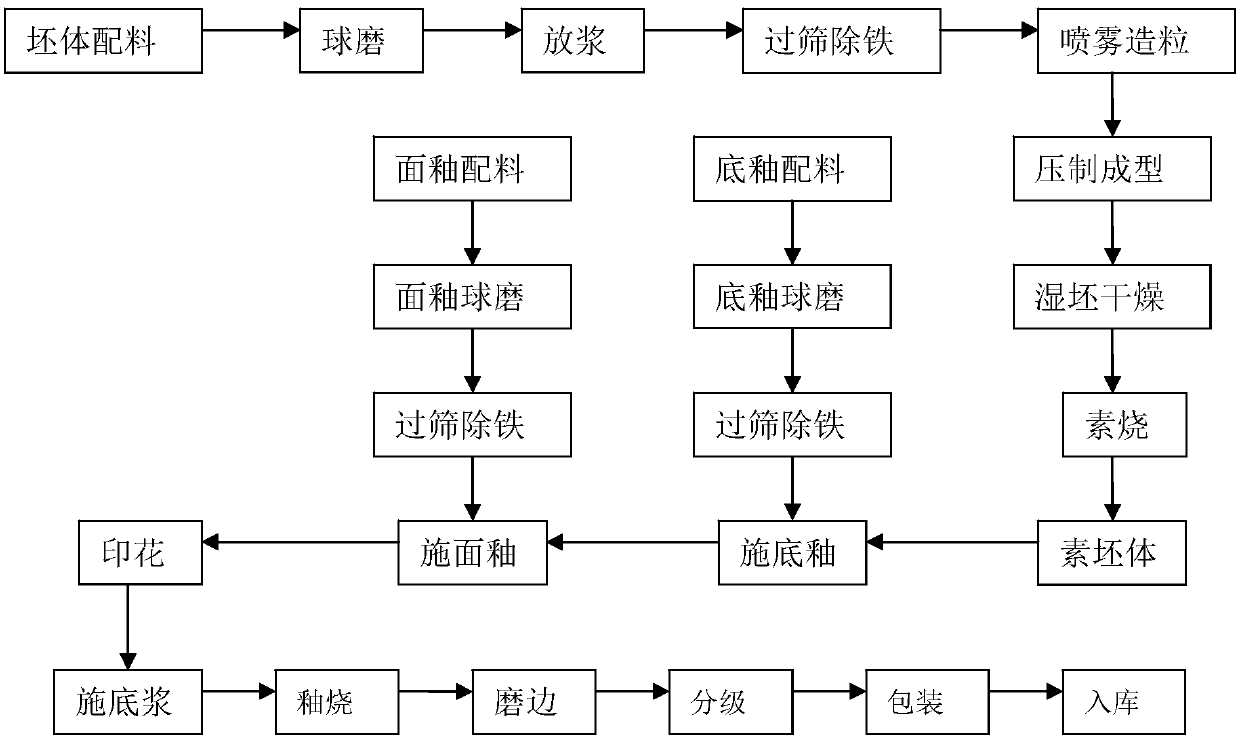

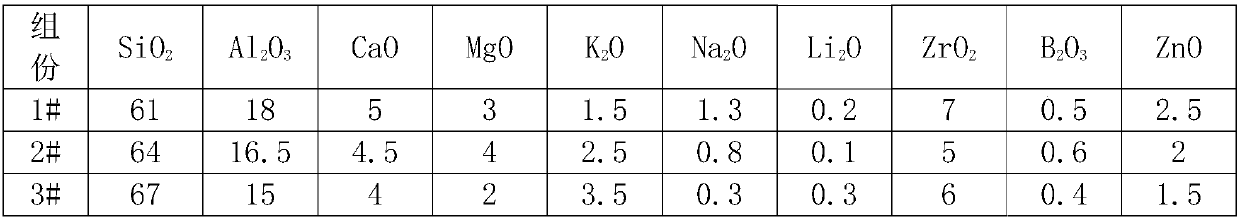

[0068] A preparation method of glazed fine stoneware bricks manufactured from ceramic solid reclaimed materials, comprising the following steps:

[0069] A. Prepare the green body:

[0070] The chemical composition of the green body is shown in Table 2:

[0071] Table 2, the chemical composition list of green body (weight percent, %)

[0072] Component SiO 2

al 2 o 3

CaO MgO K 2 O+Na 2 o 3

Fe 2 o 3 +TiO 2

1# 70 20 3 2 3 2 2# 71 19 4 1 4 1 3# 72 19.5 2 1.5 3.5 1.5 4# 71.5 18 3.5 2 3.8 1.2

[0073] Prepare the green body: select the corresponding proportion of potassium feldspar, albite and quartz mixed sand, clay, talc, porcelain stone, ceramic solid recyclate and 1% to 2% by weight according to the chemical composition in Table 1. Auxiliary raw materials are used for batching; add an appropriate amount of water and finely crush it into a slurry with a fineness of 250 mesh sieves with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com