A kind of antibacterial glaze and its preparation method and application

An antibacterial glaze and glaze technology, which is applied in the field of ceramic glaze, can solve the problems of poor antibacterial effect of antibacterial sanitary ceramics, less than 85%, and poor durability of silver ion antibacterial agents, so as to improve the quality of glaze surface and glaze surface. Gloss boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. An antibacterial glaze according to an embodiment of the present invention is composed of a bottom glaze and a top glaze; wherein,

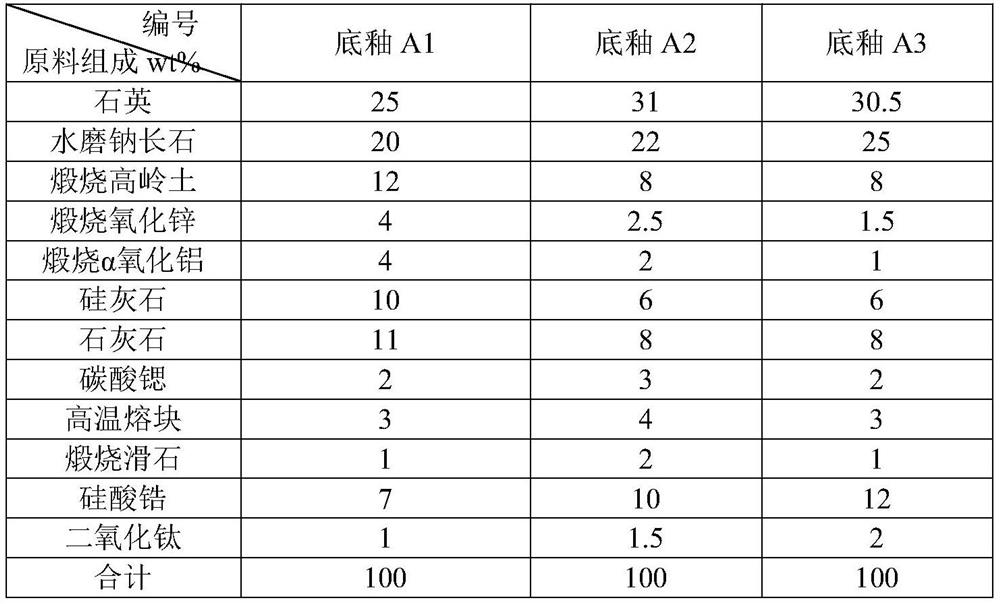

[0025] The raw material composition of the bottom glaze is 25-35wt% of quartz, 20-28wt% of terrazzo albite, 8-12wt% of calcined kaolin, 1.5-4wt% of calcined zinc oxide, 1-4wt% of calcined α-alumina, and 6-4wt% of wollastonite. 10wt%, limestone 8-12wt%, strontium carbonate 2-6wt%, high-temperature frit 3-6wt%, calcined talc 1-3wt%, zirconium silicate 7-12wt%, titanium dioxide 1-2wt%.

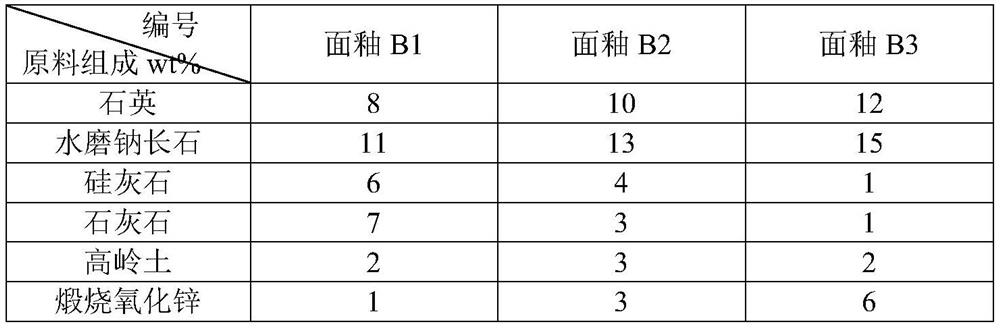

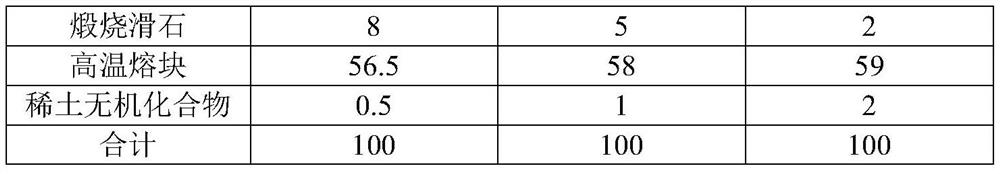

[0026] The raw material composition of the surface glaze is 8-12wt% of quartz, 11-15wt% of terrazzo albite, 1-6wt% of wollastonite, 1-7wt% of limestone, 1-5wt% of kaolin, 1-6wt% of calcined zinc oxide, calcined Talc 2-8wt%, high-temperature frit 40-60wt%, rare earth inorganic compound 0.5-2wt%.

[0027] The raw material compositions of the bottom glaze and the top glaze used in the embodiment of the present invention are shown in Table 1 and Table 2.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com