Ceramic glaze with infrared reflection, light glazed exterior wall tile and preparation method of light glazed exterior wall tile

A ceramic glaze, lightweight technology, applied in the field of architectural ceramics, can solve the problems of yellowing glaze, inability to prepare high-quality glazed tiles, etc., to reduce indoor temperature rise, solve glaze yellowing, prevent glaze The effect of pinholes and glaze cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

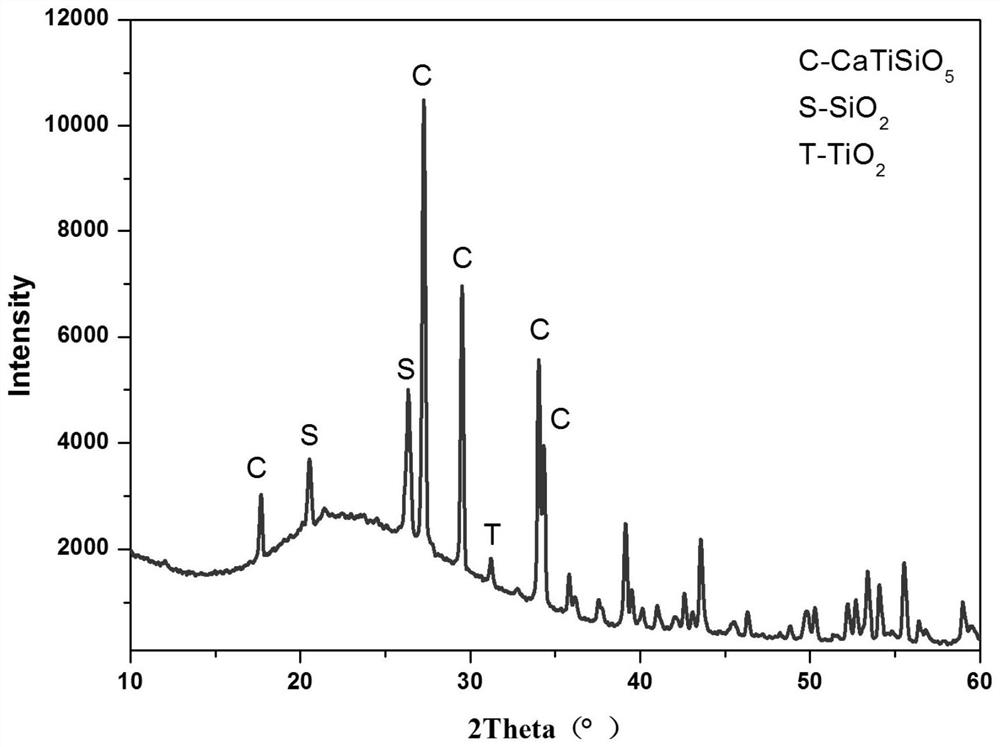

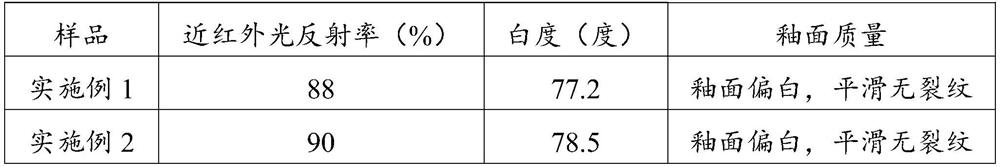

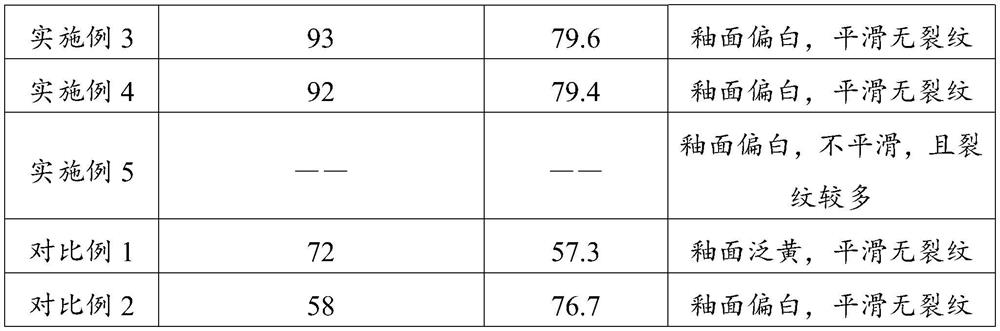

[0044] A kind of ceramic glaze, this ceramic glaze comprises by weight: 29 parts of feldspar, 22 parts of quartz, 22 parts of calcite, 7 parts of kaolin, 4 parts of talc, 11 parts of titanium dioxide, 12 parts of titanite frit . Among them: the raw material composition of titanite frit includes, by weight, 22 parts of calcite, 15 parts of titanium dioxide, 17 parts of quartz, 8 parts of wollastonite, and 48 parts of flux; The coefficient of thermal expansion is 7.7×10 -6 / °C.

[0045] A preparation method for ceramic glaze, comprising the following steps:

[0046] (1) mixing the raw materials for preparing titanite frit, melting at 1500° C., pouring into water and quenching to obtain titanite frit;

[0047] (2) Mixing the titanium titanite frit obtained in step (1) with other raw materials of the ceramic glaze and wet grinding to obtain the slurry of the ceramic glaze (ceramic glaze slurry).

[0048] A light-weight glazed exterior wall brick. The light-weight glazed exteri...

Embodiment 2

[0054] A kind of ceramic glaze, this ceramic glaze comprises by weight: 28 parts of feldspar, 22 parts of quartz, 22 parts of calcite, 6 parts of kaolin, 4 parts of talc, 13 parts of titanium dioxide, 12 parts of titanium titanite frit . Among them: the raw material composition of titanium titanite frit includes, by weight, 22 parts of calcite, 17 parts of titanium dioxide, 17 parts of quartz, 6 parts of wollastonite, and 48 parts of flux; The coefficient of thermal expansion is 7.7×10 -6 / °C.

[0055] A preparation method for ceramic glaze, comprising the following steps:

[0056] (1) mixing the raw materials for preparing titanite frit, melting at 1450° C., pouring into water and quenching to obtain titanite frit;

[0057] (2) Mixing the titanium titanite frit obtained in step (1) with other raw materials of the ceramic glaze and wet grinding to obtain the slurry of the ceramic glaze (ceramic glaze slurry).

[0058] A light-weight glazed exterior wall brick. The light-we...

Embodiment 3

[0063] A kind of ceramic glaze, this ceramic glaze comprises by weight: 30 parts of feldspar, 20 parts of quartz, 23 parts of calcite, 6 parts of kaolin, 4 parts of talc, 15 parts of titanium dioxide, 10 parts of titanite frit . Among them: the raw material composition of titanite frit includes, by weight, 20 parts of calcite, 18 parts of titanium dioxide, 15 parts of quartz, 8 parts of wollastonite, and 49 parts of flux; The coefficient of thermal expansion is 7.7×10 -6 / °C.

[0064] A preparation method for ceramic glaze, comprising the following steps:

[0065] (1) mixing the raw materials for preparing titanite frit, melting at 1450° C., pouring into water and quenching to obtain titanite frit;

[0066] (2) Mixing the titanium titanite frit obtained in step (1) with other raw materials of the ceramic glaze and wet grinding to obtain the slurry of the ceramic glaze (ceramic glaze slurry).

[0067] A light-weight glazed exterior wall brick. The light-weight glazed exteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com