Matte background and glossy pattern glazed tile manufactured by using polished slag and preparation method of matte background and glossy pattern glazed tile

A technology of polishing waste residue and soft light mirror, which is applied in the field of glazed tile preparation, can solve the problems of not being able to move it back indoors for long-term appreciation, scarcity of high-grade stone, and high price, and achieve unique decorative effects, good glaze quality, and no pinholes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

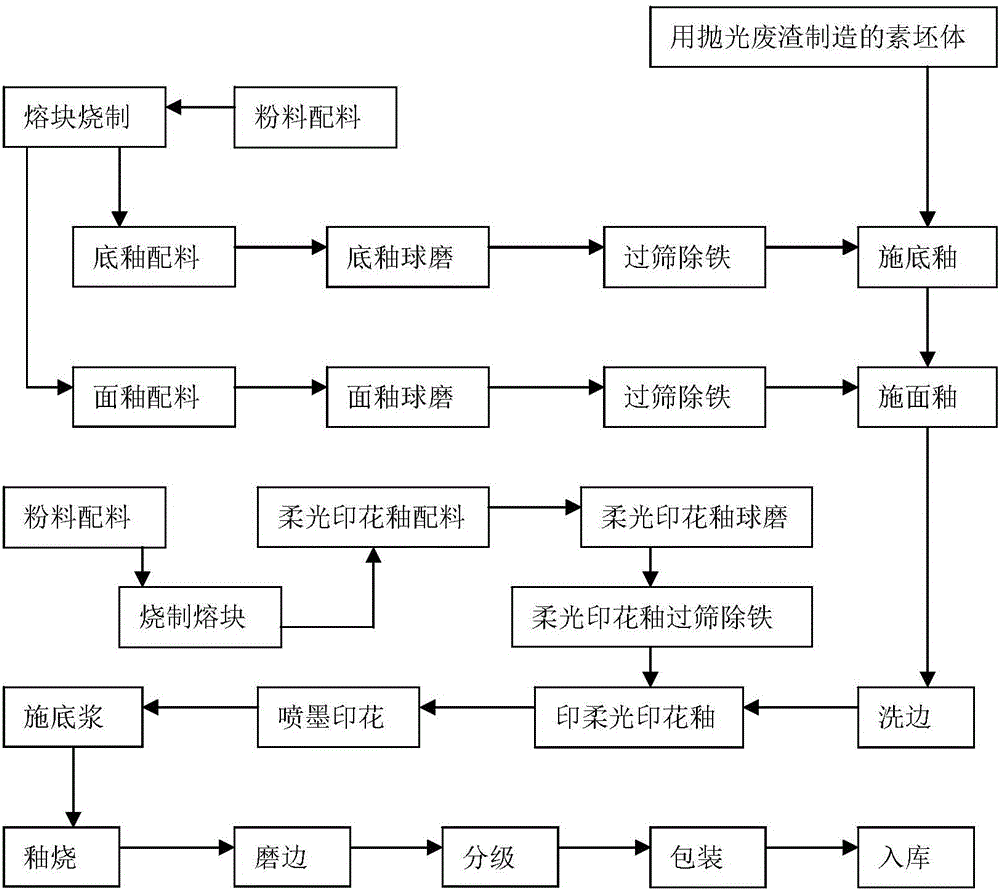

[0051] The method for the soft-light mirror pattern glazed tile manufactured with polishing waste slag, it comprises the following steps:

[0052] A, prepare bottom glaze:

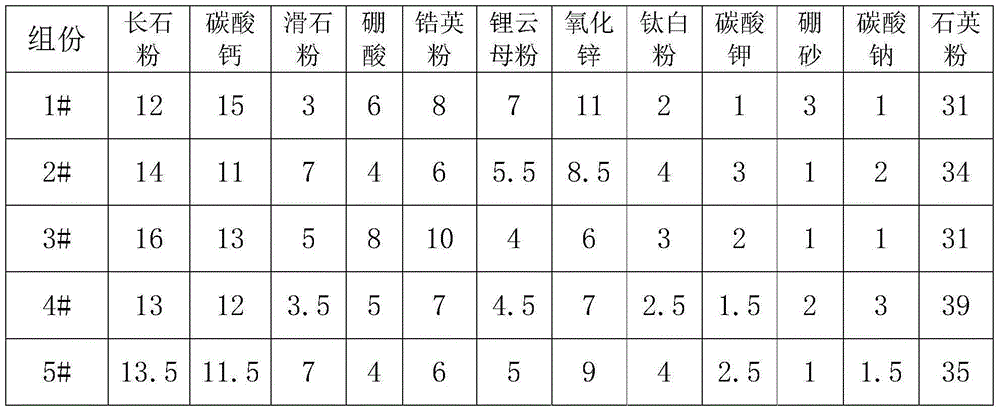

[0053] Prepare frit a, the formula composition of frit a is as follows table 1

[0054] Table 1, the formula composition table (parts by weight) of frit a

[0055]

[0056] The above-mentioned raw materials with a particle size of less than 150 mesh are mixed according to weight parts in Table 1, mixed evenly, and melted in a frit furnace. block a;

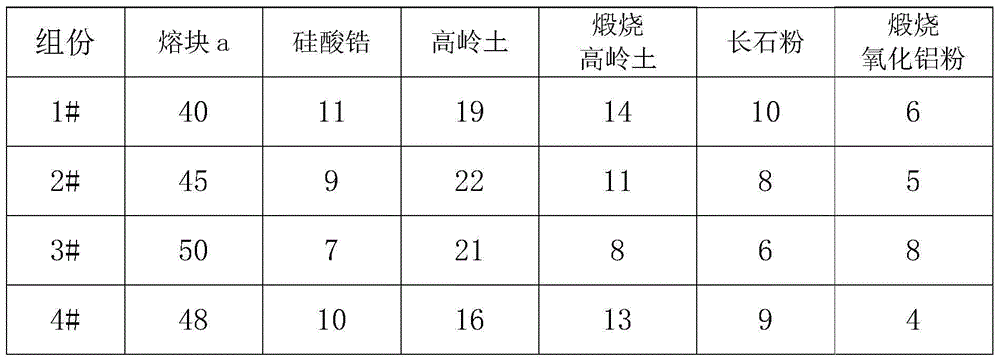

[0057] Prepare bottom glaze, the formula composition of bottom glaze is shown in Table 2:

[0058] Table 2, the formula composition list (parts by weight) of the bottom glaze

[0059]

[0060] According to the formula composition of the bottom glaze in Table 2, take the frit a, zirconium silicate, kaolin, calcined kaolin, feldspar powder, and calcined alumina powder prepared in the above steps, and add 0.02 to 0.04 parts of carboxymethyl cellulose, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com