Patents

Literature

92results about How to "Unique decorative effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glaze and preparation of embossment phantom glazed brick

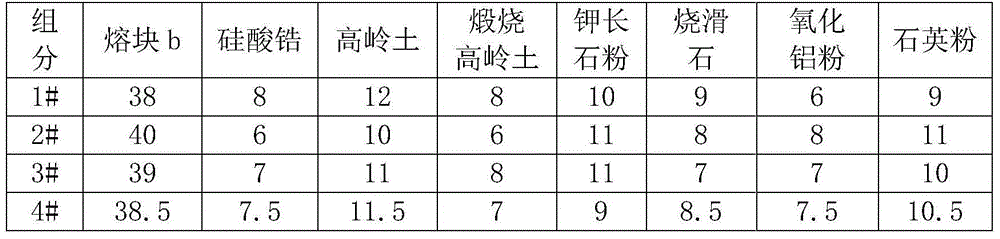

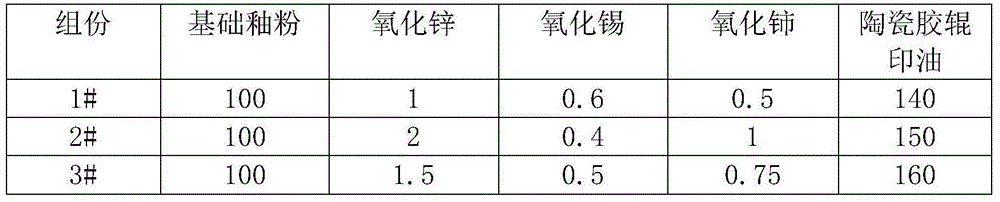

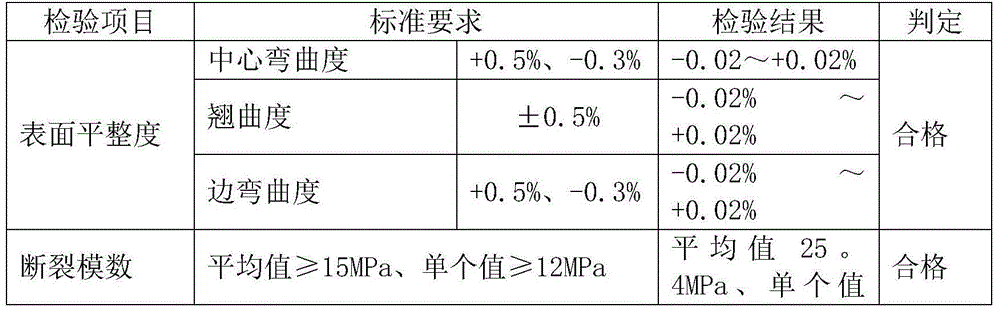

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

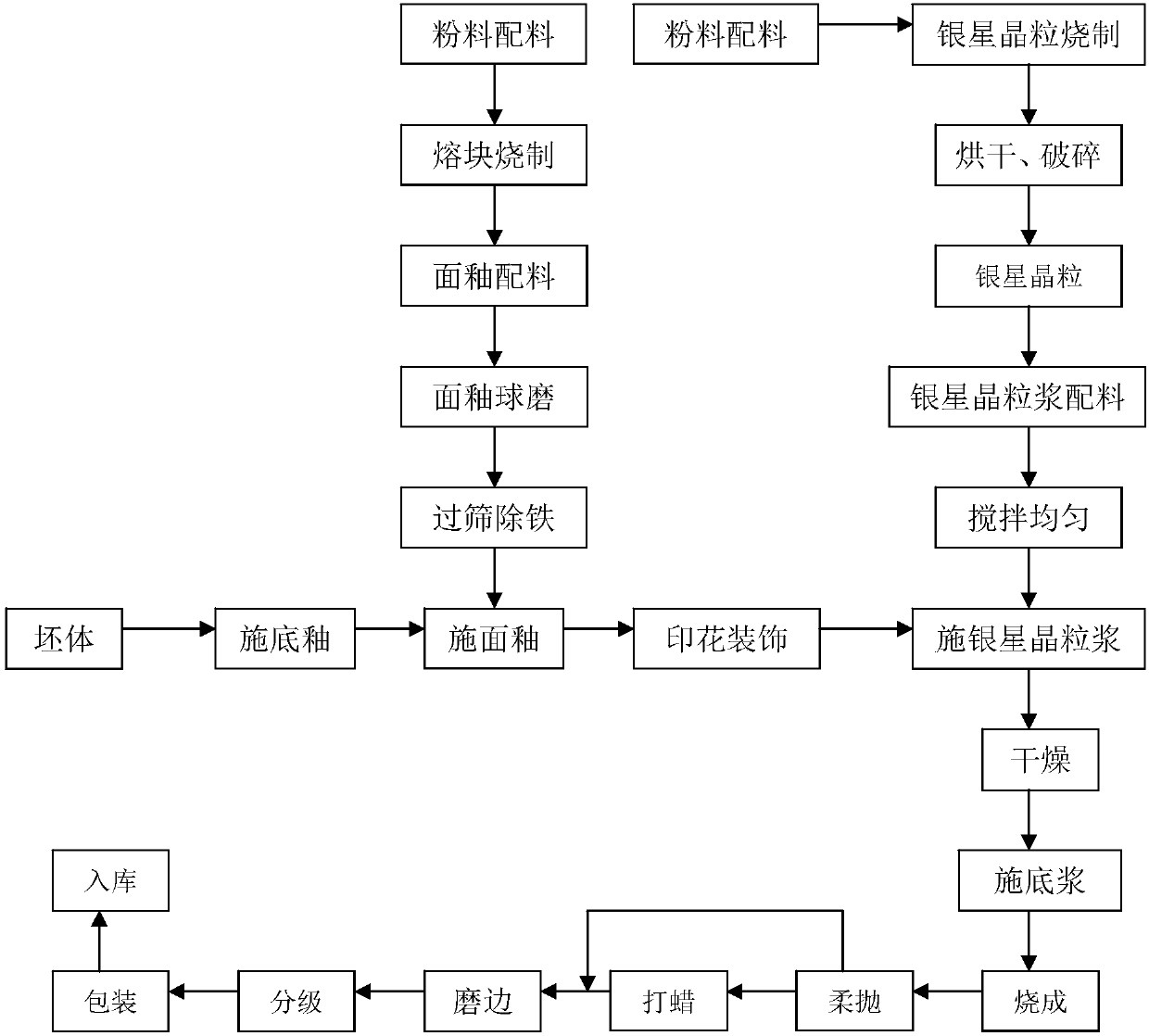

Magic star stone glazed brick with surface aventurine effect and preparation method thereof

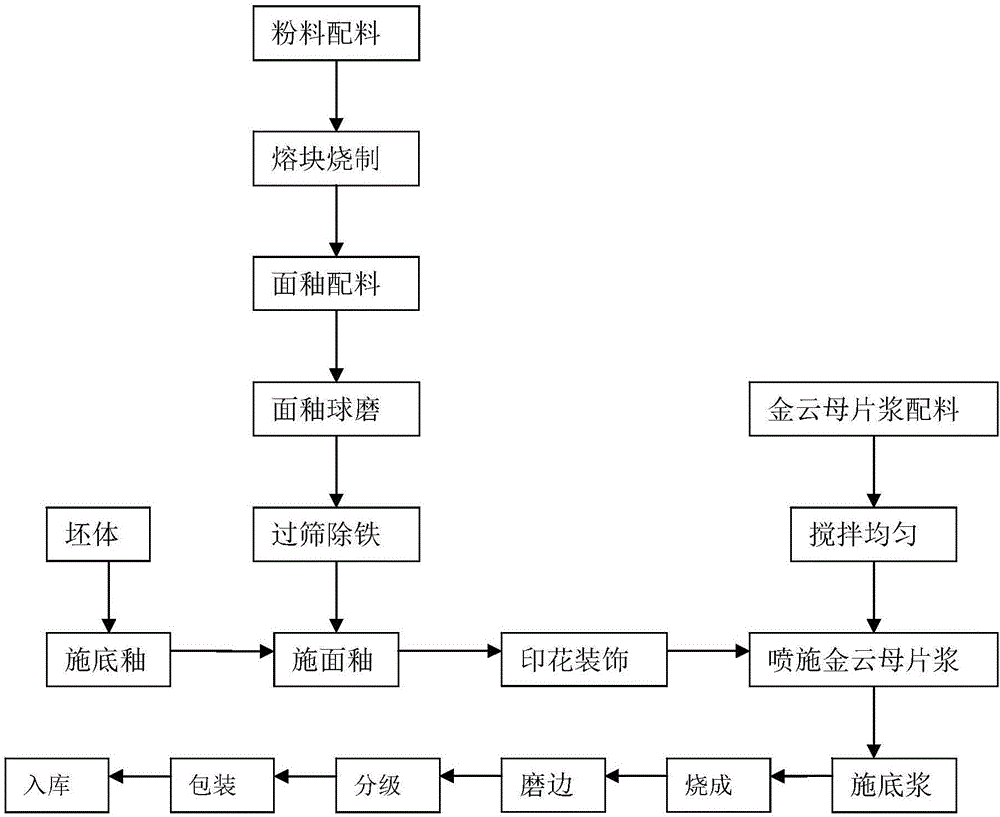

The invention relates to a magic star stone glazed brick with surface aventurine effect, and provides a magic star stone glazed brick with surface aventurine effect and a preparation method thereof. The magic star stone glazed brick comprises a frit, a surface glaze and a gold mica sheet slurry. The magic star stone glazed brick has the advantages that on the basis of not performing major change on the production technology of the existing glazed brick, the formula composition of the frit, the formula composition of the surface glaze, the formula composition of the gold mica sheet slurry, the optimum selection of granularity of gold mica sheet, the glaze applying technique, the slurry applying technique and the like are adjusted and optimized, so that the surface of the prepared magic star stone glazed brick is matte, and the luster of the surface of the product is measured by a WGG60-E4 luster meter and is 8 to 12; under the light radiation condition, the gold mica sheet at the surface of the product, such as mica or hematite small sheets in the aventurine, is glittering, magic and elegant, so that the special decorativeness and artistry are realized; the technique has higher universality, and is suitable for being popularized in industry.

Owner:GUANGDONG WINTO CERAMICS +3

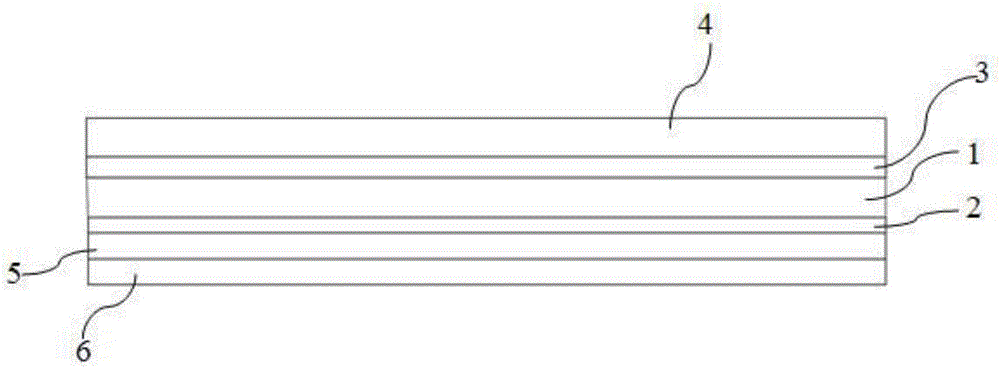

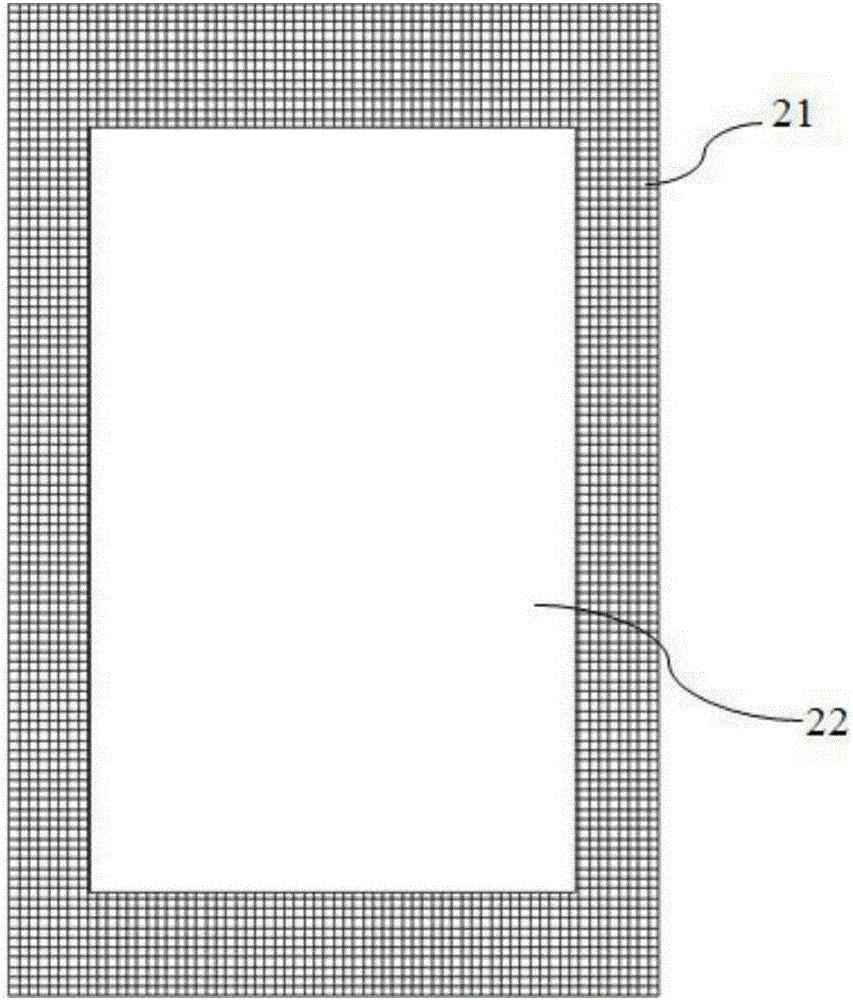

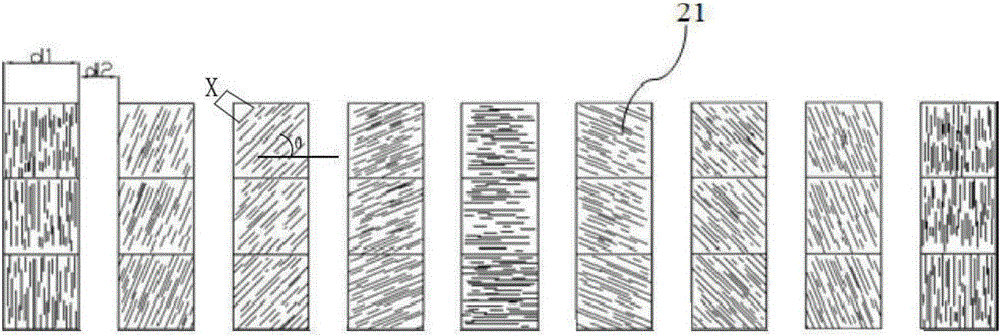

Light-permeable tile and preparation method thereof

The invention relates to a light-permeable tile and a preparation method thereof. The light-permeable tile comprises a semi-light-permeable green body with light-impermeable colored particles inside, color emitting assistant clear glaze and patterns sequentially from bottom to top. Due to the light-impermeable colored particles in the green body of the light-permeable tile and in combination with appropriate colorful patterns, a ceramic product with a special hazy effect and strong stereoscopic impression can be formed. Moreover, with the color emitting assistant clear glaze, the emitted color of the patterns is brighter, and the color development effect is better. Compared with the non-transparency of common polished tiles and rustic tiles, the light-permeable tile provided by the invention can form a unique decoration effect in combination with certain light.

Owner:MONALISA GRP CO LTD

Pearlescent magic color aluminum powder pigment and preparation method thereof

InactiveCN102260421ASimple processSimple equipmentInorganic pigment treatmentElectrically conductiveTitanium dioxide

The invention discloses an aluminum powder pigment with iridescent pearl luster and a preparation method thereof. The method uses aluminum powder with an average particle size of 10 μm to 150 μm and a surface coated with SiO2 film as the substrate raw material. The SiO2 film is inert, acid-resistant, heat-resistant, and transparent. The pH of the solution is 1.5-2.5 and the temperature is 60 Under the condition of ℃~80℃, deposit a layer of nano-titanium dioxide film on the transparent SiO2 film by chemical liquid phase deposition, wash and dry, and bake the pigment at 500℃~600℃ under the protection of inert gas 0.5~1.0 h, the high-gloss pearlescent aluminum powder pigment with TiO2 / SiO2 / Al-based composite film was obtained. The pigment also has excellent comprehensive properties such as the illusion interference effect of pearlescent pigments and the conductivity, high hiding power, shielding and non-toxic environmental protection of metallic aluminum powder pigments. It has unique decorative effects and can be widely used in high-end automotive topcoats and high-end decorations. Products, surface coating of high-end instruments, ink printing, children's toys, etc. The method of the invention is simple and feasible, and has industrial feasibility.

Owner:SICHUAN UNIV

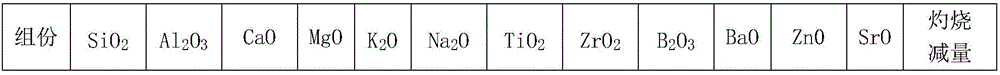

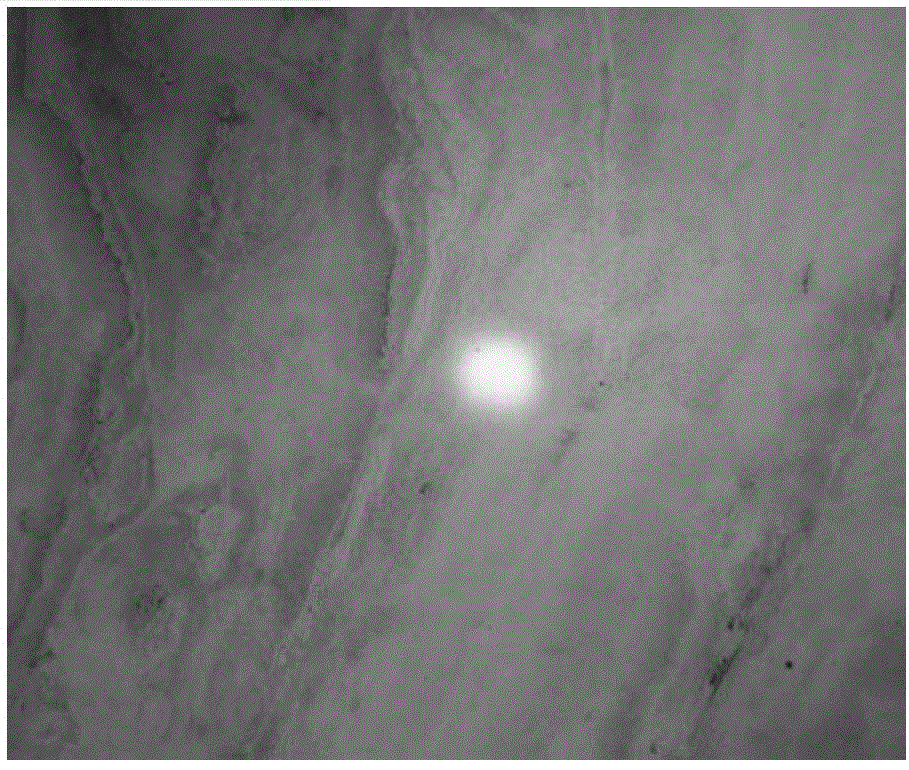

Matte background and glossy pattern glazed tile manufactured by using polished slag and preparation method of matte background and glossy pattern glazed tile

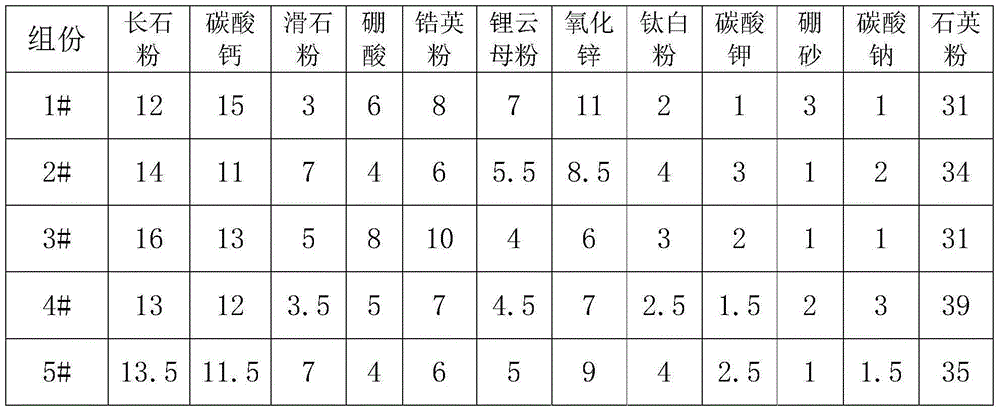

A prepared matte background and glossy pattern glazed tile product is enabled to have a surface with two special decorative effects, i.e., soft matte and highlight mirror-like effects, at the same time critically by virtue of optimization of types of biscuits, optimization of composition of a ground coat frit and a surface coat frit, optimization of composition of a ground coat and a surface coat, optimization of composition of a matte printing glaze frit, optimization of composition of matte printing glaze, adjustment and optimization of a pattern printing process and optimization of number of screen printing plates of the matte printing glaze and carving modes of an offset print roll on the basis of not significantly changing a conventional glazed tile production process. With organic combination with pattern design, the patterns at the soft matte parts and the highlight mirror-like parts of the tile are enabled to represent two different visual decorative effects at the same time. The difference of glossiness measured at the soft matte parts and the highlight mirror-like parts by using a WGG60-E4 gloss meter is greater than or equal to 50, so that the tile has a very unique visual effect and is strong in integral art aesthetic feeling. At the same time, the technology disclosed by the invention is good in universality and is easy to popularize in the industry.

Owner:GUANGDONG HONGHAI CERAMIC IND DEV +3

Manufacture method of solid wood and solid wood composite baking floor

The invention discloses a manufacture method of a solid wood and a solid wood composite baking floor, aiming at providing a manufacture method for utilizing solid wood floor blank with the levels of B, C and D or utilizing the blank of the solid wood composite floor to manufacture the solid wood and solid wood composite baking floor with low cost, beautiful texture and good decorative effect. The manufacturing method comprises the following steps: arranging tongue-and-groove boards on the floor blank, baking the surface of porous plates of the floor, and carrying out surface treatment and surface coating treatment. The invention uses carbonized effect generated by flame baking so as to mask the defects of the surfaces of inferior materials, and is beneficial to different sparse and compact materials which are natural to the wood after fiber drawing treatment, thus presenting rugged wood texture and leading the whole floor to be very beautiful; the decorative effect is distinctive and very novel, the applications are extreme wide, various quality indexes can reach or exceed the indexes of existing similar products, so that the value of the inferior wood with the levels of B, C and D is greatly improved, therefore, the manufacturing method has great economical and social benefits.

Owner:张高荣

Matt porcelain glaze prepared by using waste porcelains and production method thereof

The invention discloses a matt porcelain glaze prepared by using waste porcelains and a production method thereof. The matt porcelain glaze is prepared from the following components in percentage by weight: 10 to 40 percent of waste porcelain powder, 0 to 30 percent of quartz, 20 to 40 percent of feldspar, 18 to 25 percent of barium carbonate, 2 to 6 percent of limestone and 6 to 10 percent of kaolin. The matt porcelain glaze can be produced by using the waste porcelains to reduce pollutions caused by the waste porcelains to the environment and reduce the production cost; and the prepared porcelain glaze is well combined with a body to ensure that the matt effect on a glazed surface of a product is obvious, and has a unique decorative effect.

Owner:WEIYE CERAMICS CO LTD

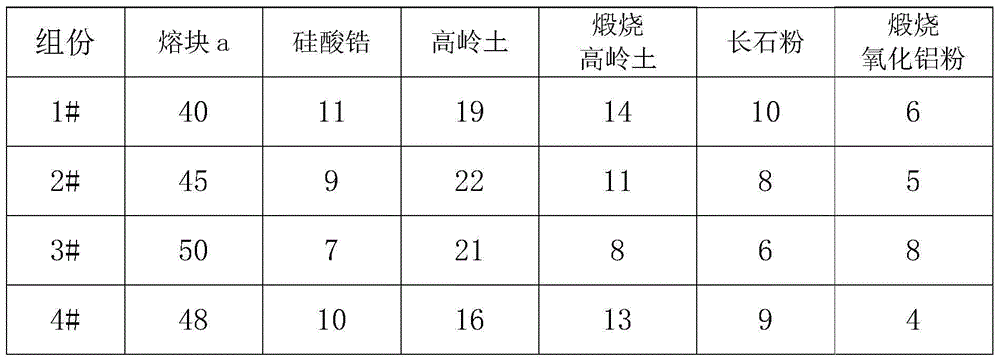

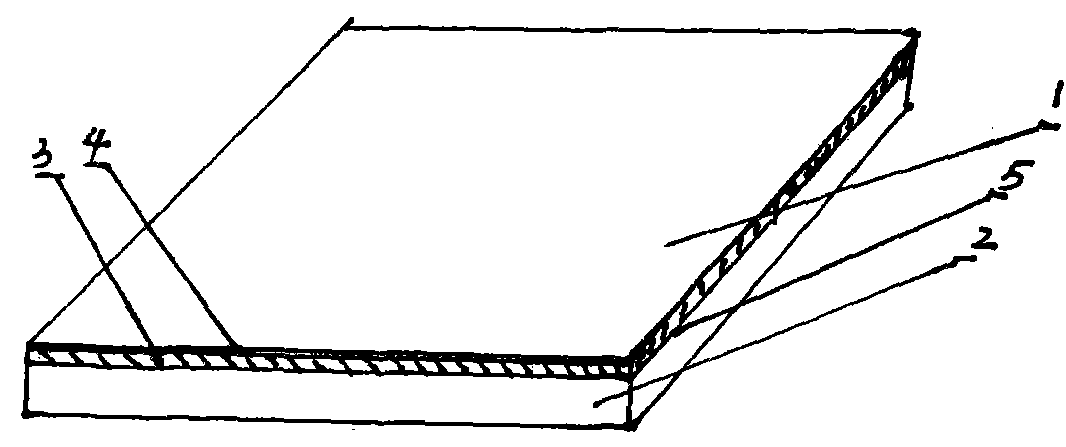

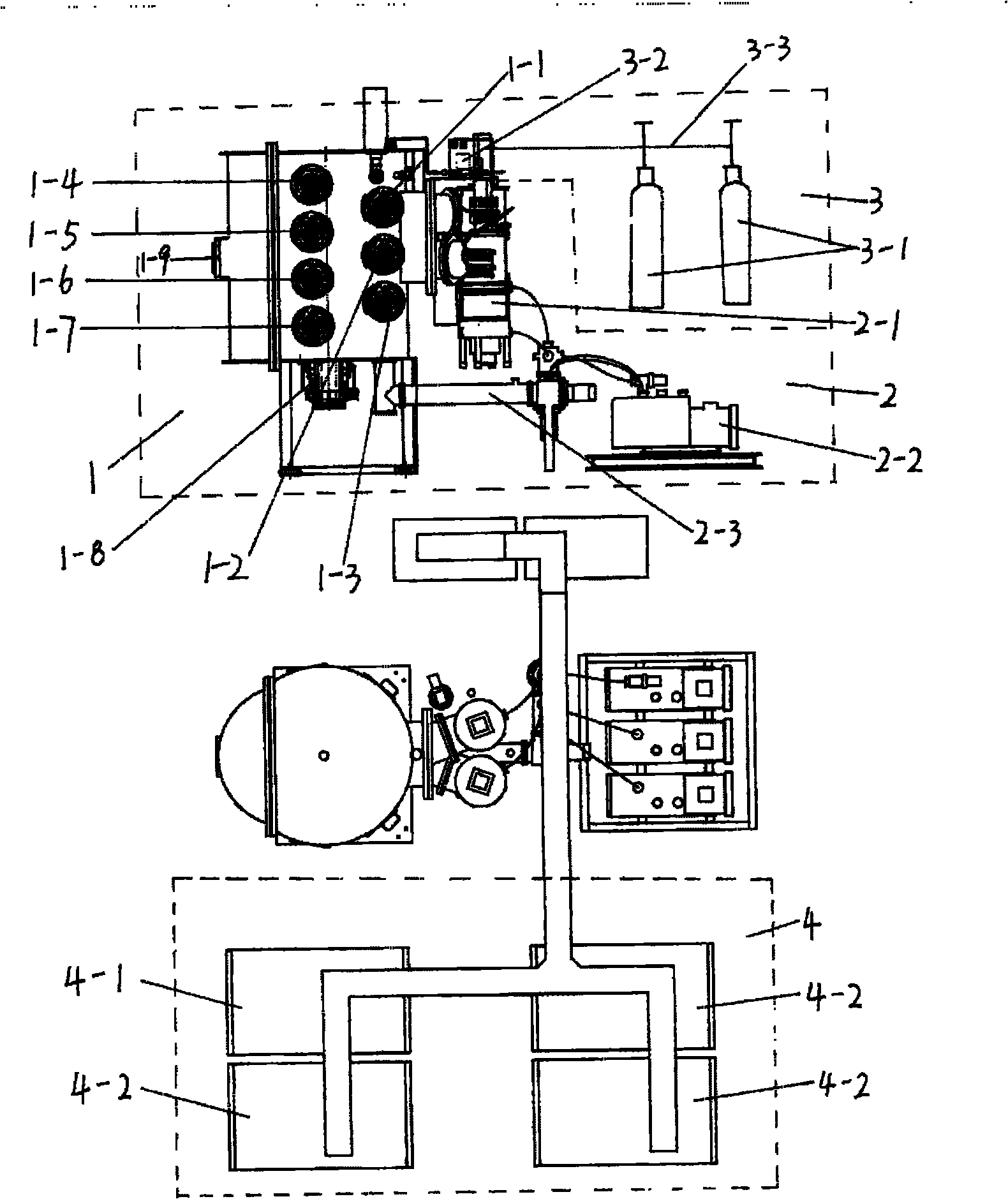

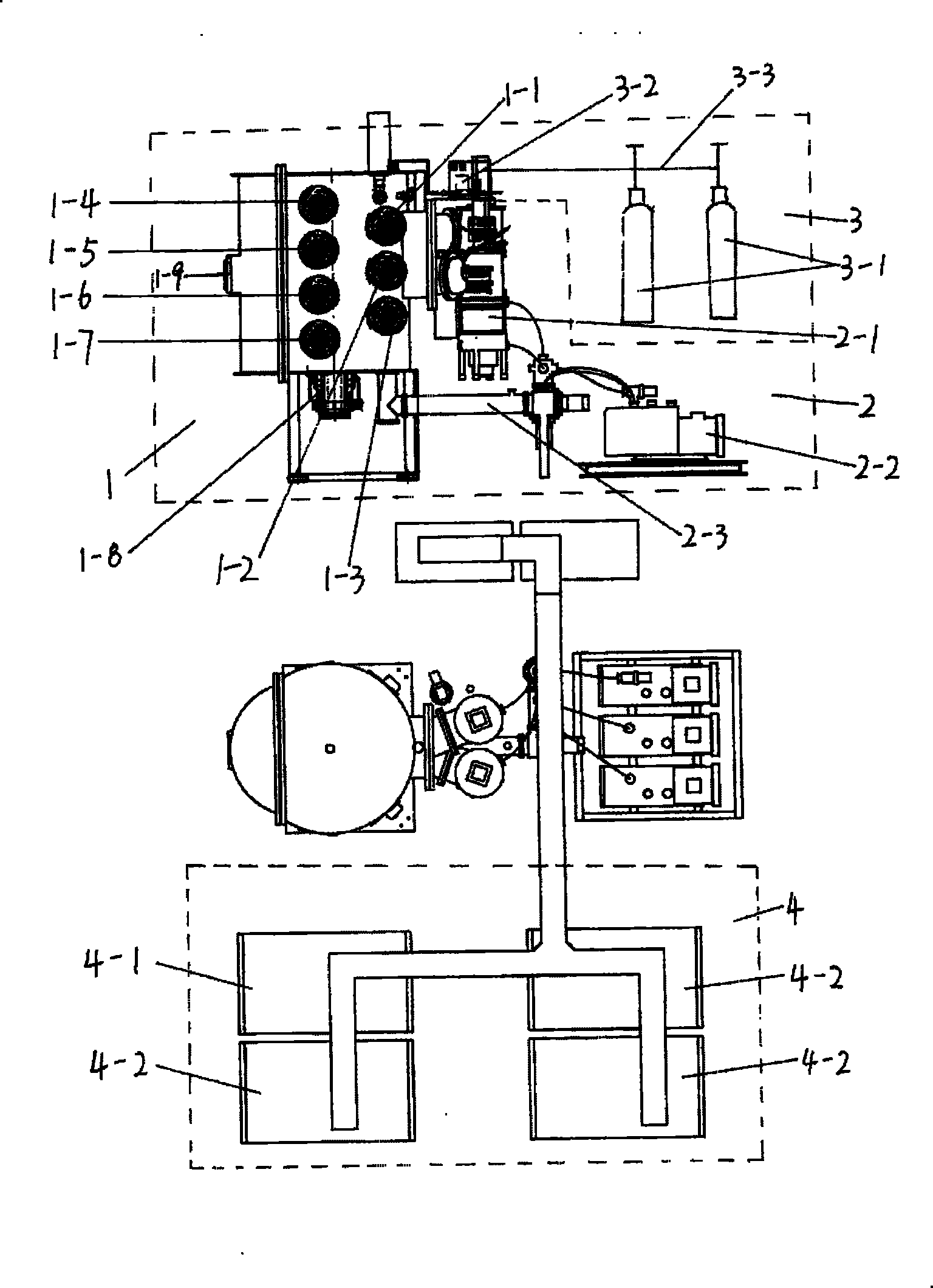

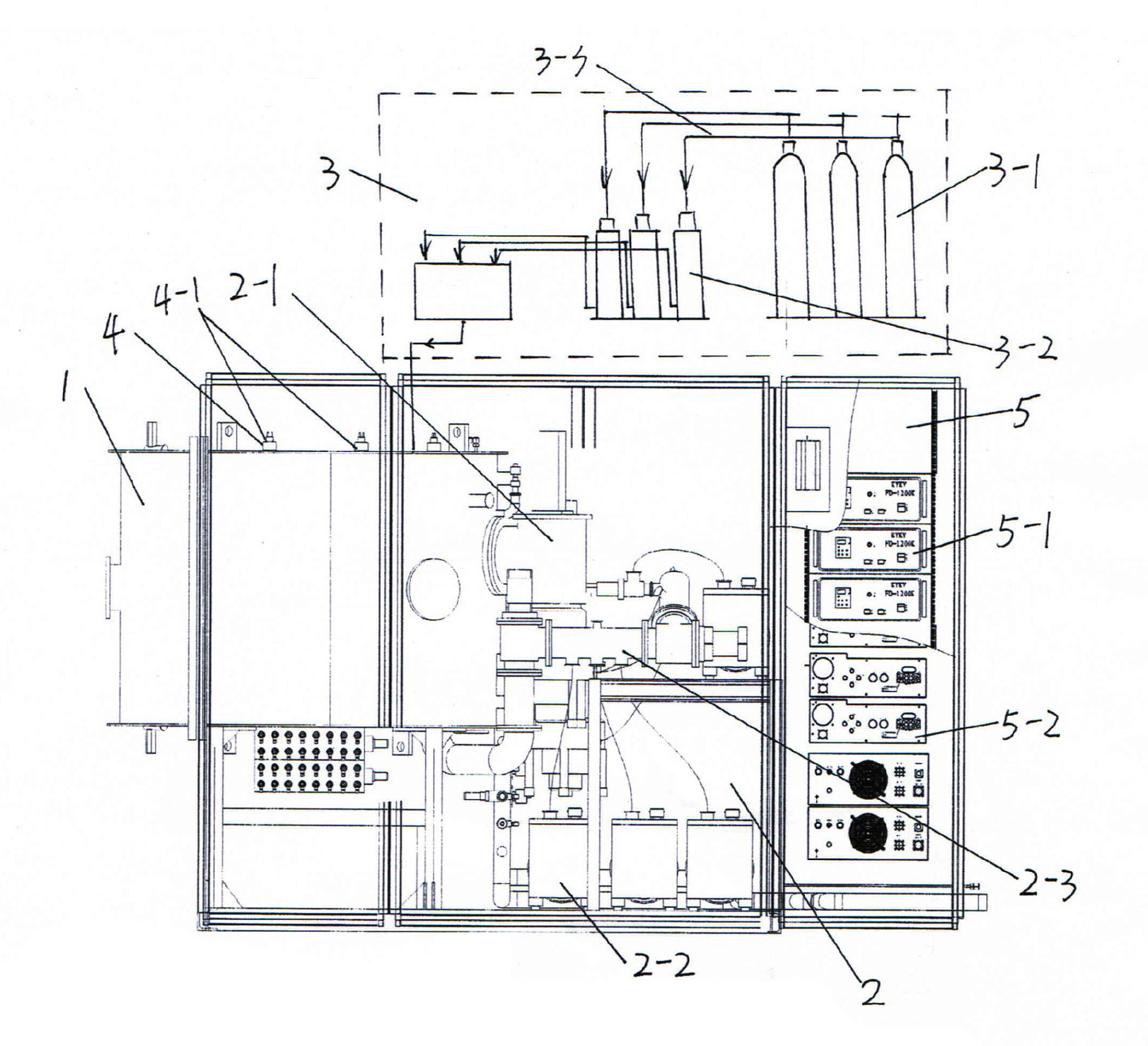

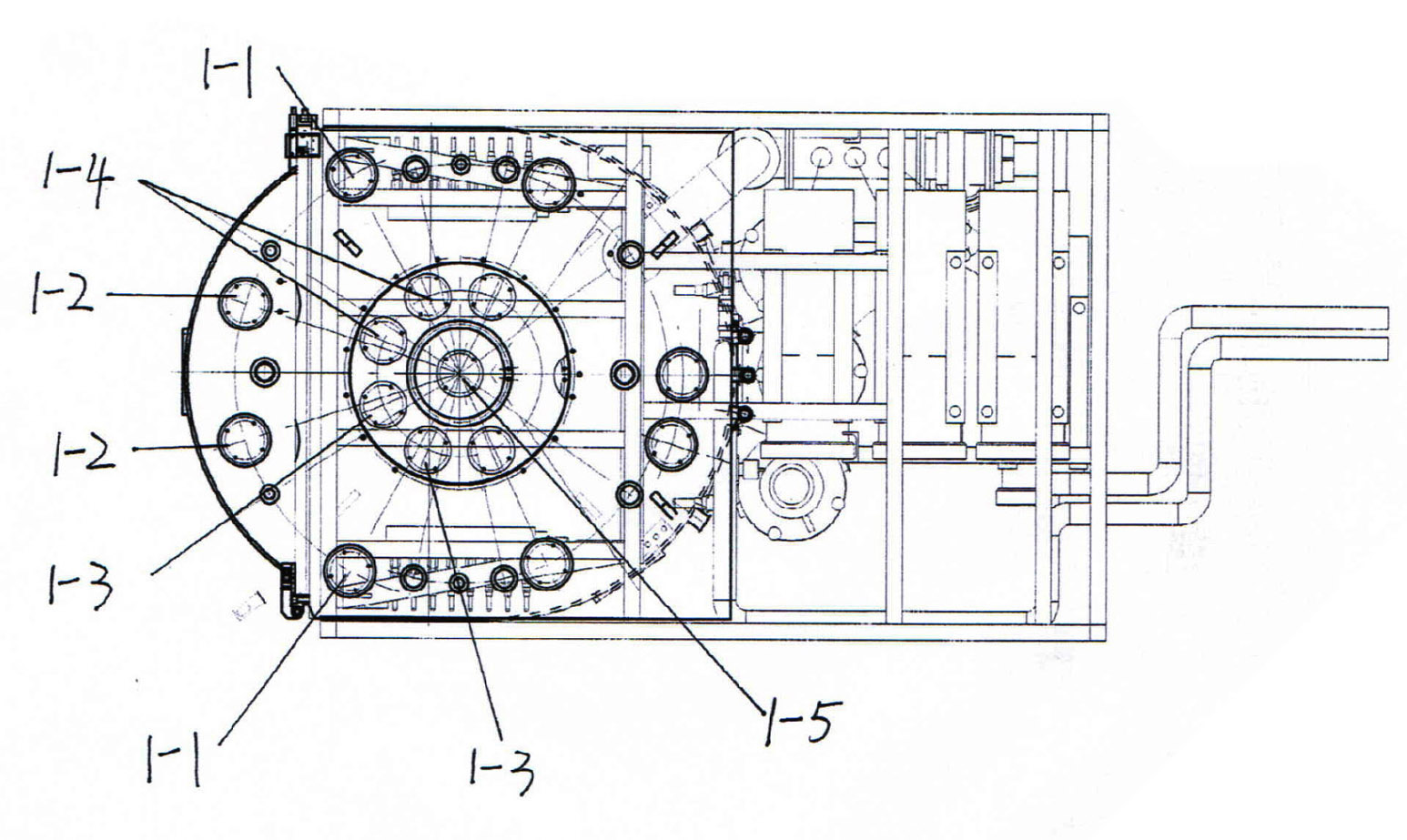

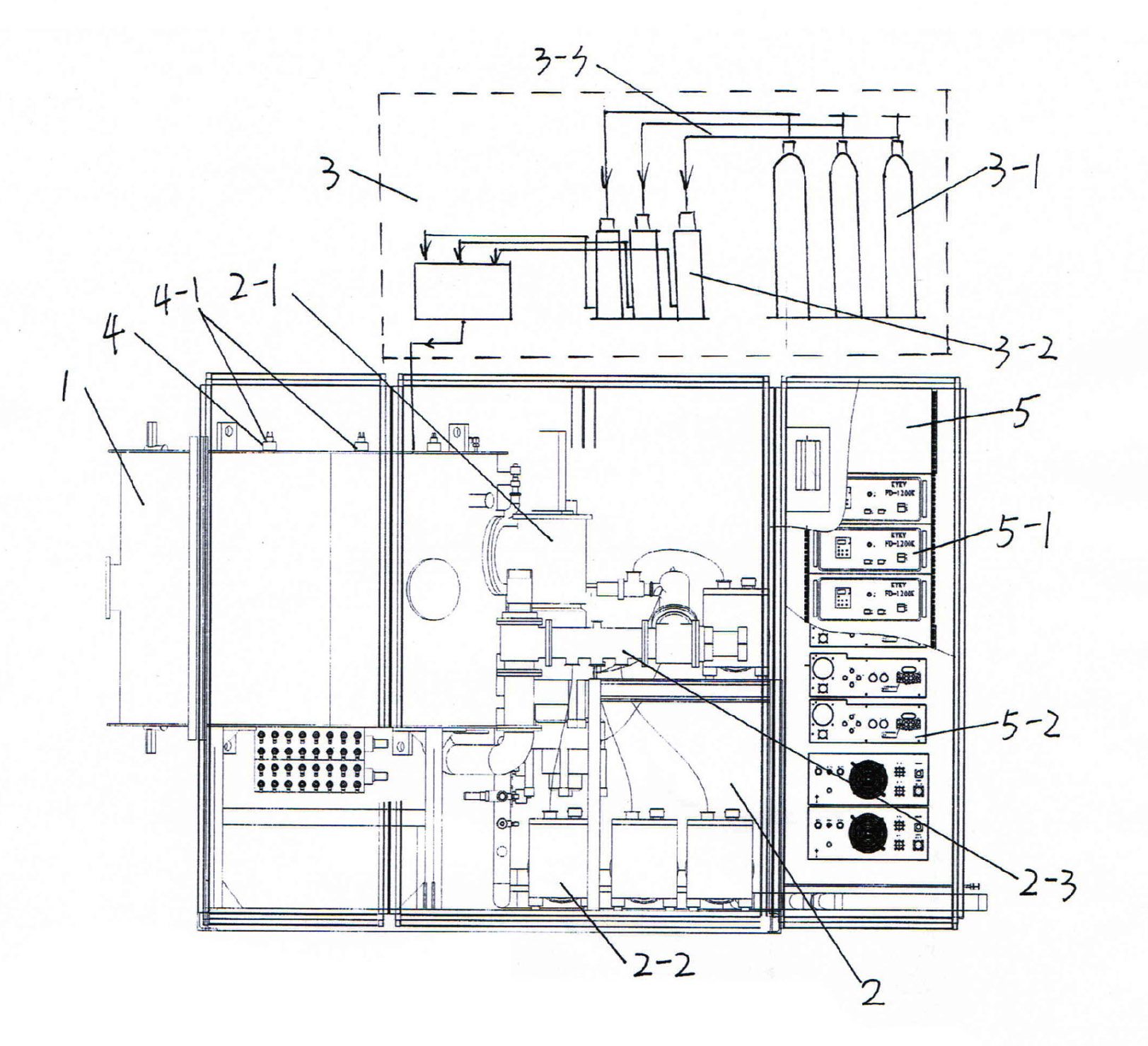

Aluminium plastic composite board manufacture equipment and technique thereby

InactiveCN101214749AEnvironmental pollutionNo pollution in the processLamination ancillary operationsControlling laminationCross cutEngineering

The invention discloses an aluminum and plastic composite plate manufacturing equipment, which comprises a control cabinet, an electric case, a hot pressing compound device, a blower, an inspection table, a plate edge trimming equipment and a cross cut equipment. The plate edge trimming equipment is connected with the cross cut equipment through a delivery device and a towing device. The invention is characterized in that the input port of the hot pressing compound device is provided with a plastic extrusion unit consisting of a main machine extrusion device, a three-roller press finishing device, a trimming device and a pressure diverting device. An adjustable aluminum coil frame and an uncoiling device are arranged between the hot pressing compound device and the blower. The hot pressing compound device is arranged on the output port of the plastic extrusion unit. The equipment disclosed by the invention takes up little space, is installed and operated conveniently and simply. The equipment can produce plates of different thicknesses and widths. The production of the equipment is free from the influence of the external environment and can go on without failure under all external environments. Without pollution to the environment, the equipment is an environmentally protective equipment with obvious energy-saving effect, and can reduce the production cost to the maximum extent.

Owner:魏宝华

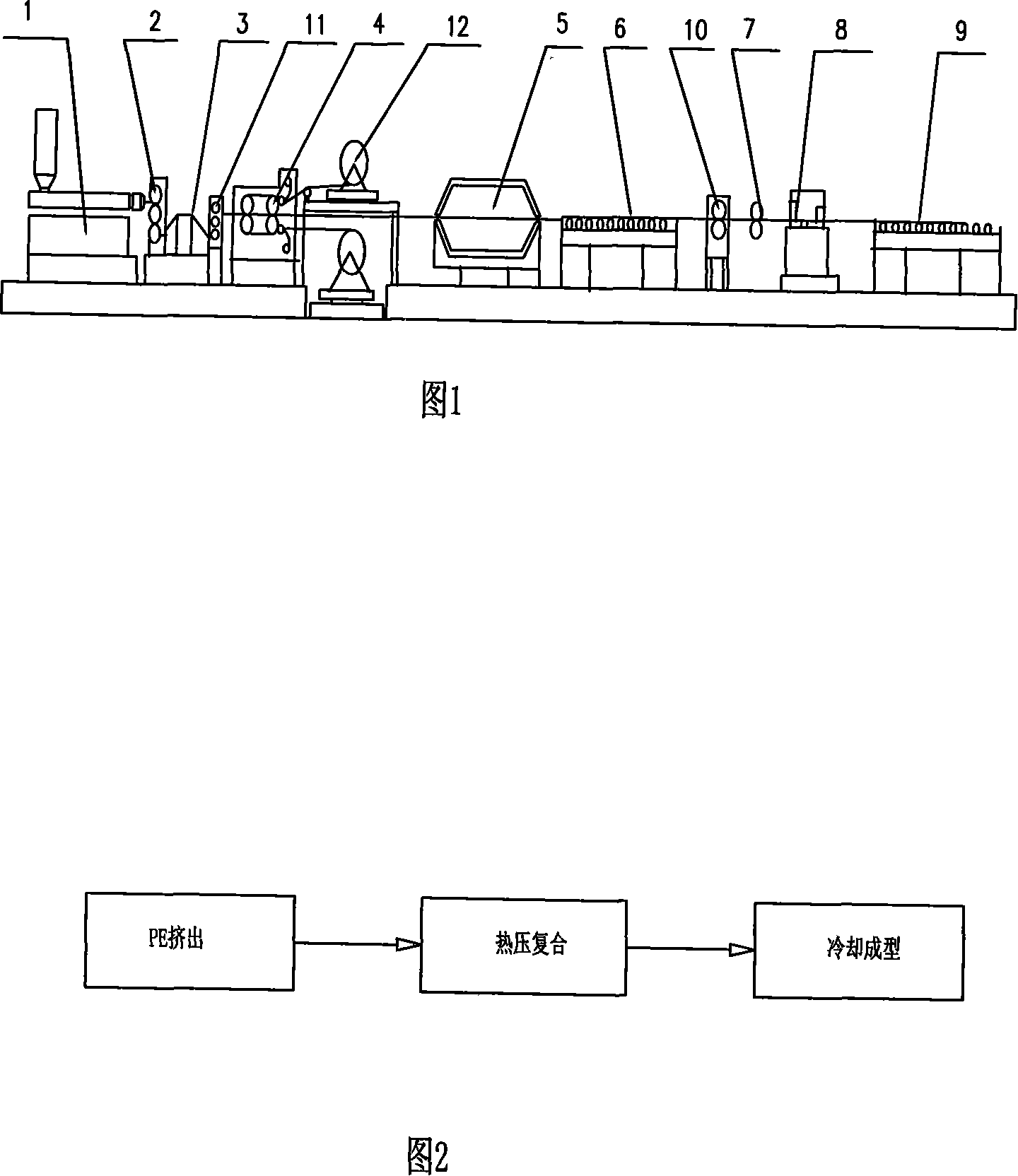

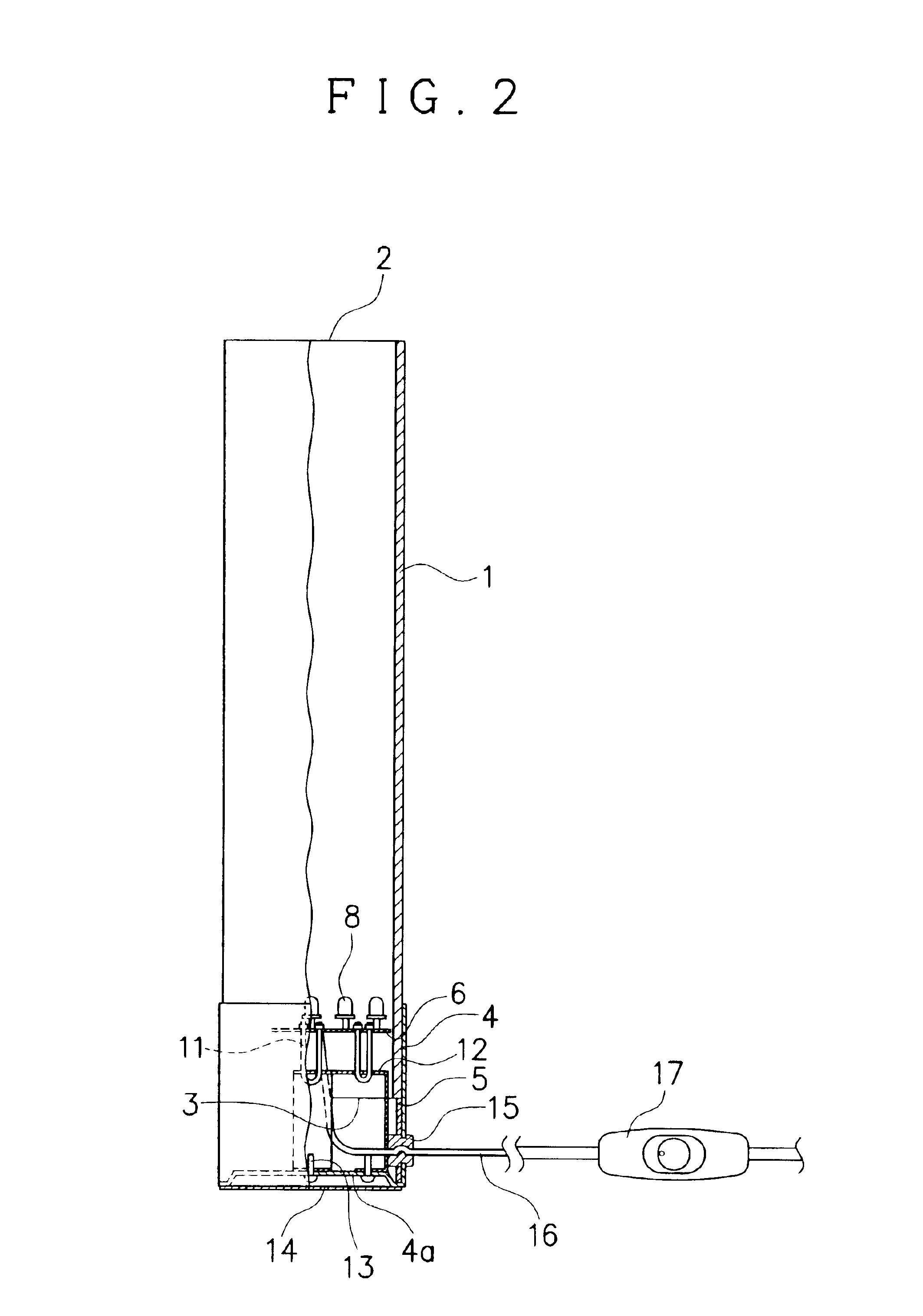

Display device and display method

InactiveCN101825865AStrong sense of modernityUnique decorative effectVisual indicationsCathode-ray tube indicatorsDisplay deviceComputer science

The invention provides a display device and a display method. According to the display method, a time identifier is annularly displayed around a display unit of the display device; and the current time can be obtained by checking the time identifier corresponding to a current pointer, and other contents such as pictures, audios, texts and the like also can be displayed when the current time is displayed; therefore, a user can see vivid time display patterns when viewing the contents. The display method ensures that the structure of the pattern has a strong contemporary feeling, and has a unique aesthetic and adornment effect on the display device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Zisha pottery inlay technology

InactiveCN102285294ARich types of decorationElegant temperamentDecorative surface effectsCeramicSmooth surface

The purple sand pottery inlay process belongs to the technical field of purple sand pottery decoration. On the decorative part of the semi-finished purple sand pottery clay blank, a groove is carved with a carving knife. There is an expansion section on the inner periphery of the groove. In the groove, and along the groove, gently tap the gold and silver wires with tools. After the knocking, the gold and silver wires deform and expand in the groove and get stuck in the groove, and then file flat the purple sand pottery products inlaid with gold and silver wires. The surface part makes the surface of the purple sand pottery smooth and flat and integrated with the inlaid gold and silver threads. The gold and silver threads are caught by the grooves and are not easy to fall off. When the grooves are carved, various patterns can be laid out on the purple sand pottery, which enriches the purple sand pottery decoration. This kind of decoration method makes Zisha pottery elegant, exquisite and luxurious, and has good artistic effect, which complements the commonly used decoration methods of Zisha pottery.

Owner:胡洪明 +1

Non-cracking soft-polishing glazed tile with wavellite effect on surface and preparation method thereof

The invention discloses a non-cracking soft-polishing glazed tile with a wavellite effect on a surface and a preparation method thereof. The non-cracking soft-polishing glazed tile comprises a frit, acover glaze, wavellite crystal particles and wavellite crystal particle pulp. On the basis of no significant change for an existing glazed tile production technology, the key points are the optimization of the formula composition of the frit, the formula composition of the cover glaze, the formula compositions of the wavellite crystal particles and wavellite crystal particle pulp and the particlesize of the wavellite crystal particles, regulation and optimization of glazing and pulping technologies, optimization of soft-polishing abrasive bricks and a soft-polishing technology and the like,so that the spherical and columnar wavellite crystal particles on the surface of the prepared glazed tile product are of strong difference with those of lusterless cover glaze in glossiness, shiny starlight like wavellite, which looks like a starry sky in fairy tales and a dream, is emitted under the irradiation of lamplight, and the glazed tile has unique decoration and artistry; through the result of the fitness test of an A.H.Harcourt glaze body, the product is judged that unconditional safety is provided in days without cracking at room temperature, and the disadvantage that an existing glazed tile is cracked after long-term use is solved.

Owner:GUANGDONG WINTO CERAMICS +3

Fireproof plate with wooden decorative surface

InactiveCN102312535AImprove waterproof performanceImprove moisture resistanceCovering/liningsCeramic layered productsSingle plateFireproofing

The invention relates to a fireproof plate with a wooden decorative surface. The fireproof plate uses a wooden single plate as a surface plate and a ceramic plate plain plate as a baseplate, wherein the wooden single plate and the ceramic plate plain plate are connected by an adhesion agent, and the surface of the wooden single plate is sprayed with paint. The fireproof plate with the wooden decorative surface has a wooden decoration effect, also has favorable fireproofing performance, meets the double requirements of the indoor wall decoration of public building places such as grogshops, conference halls, singing halls, movie theaters, emporiums and the like on fireproofing safety and the wooden decoration effect, and has significant application prospect.

Owner:唐晓迪

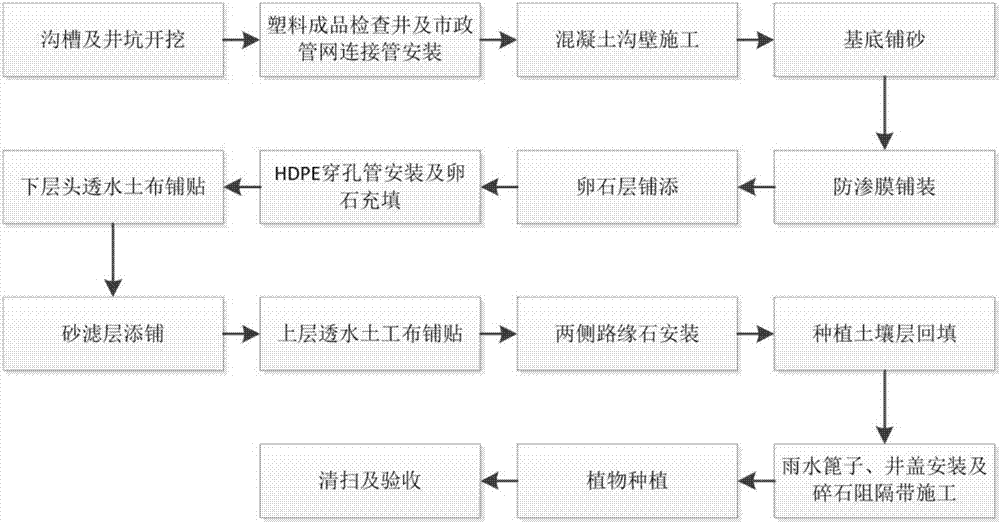

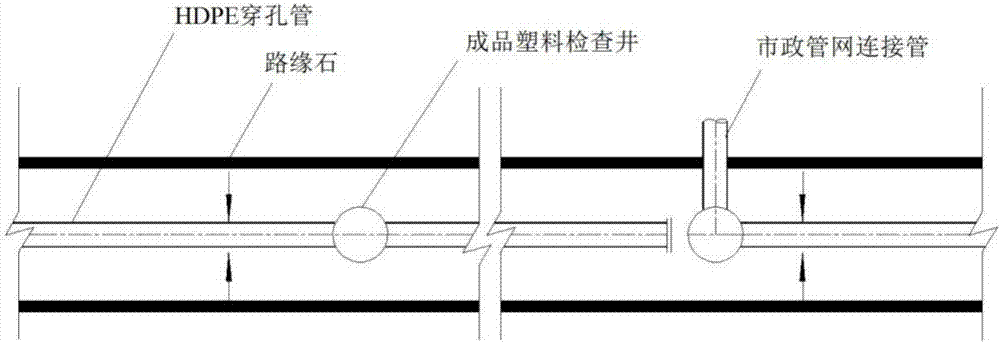

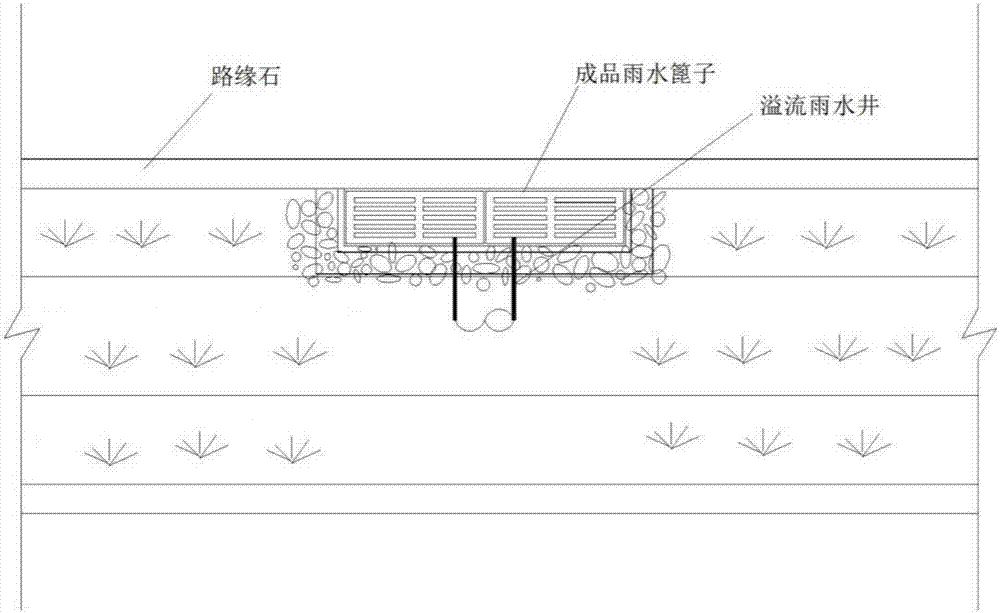

Urban road greenbelt LID (low impact development) bioretention trough construction method

ActiveCN107100227AReduce the amount of engineering constructionReduce O&M requirements and costsSewerage structuresGeneral water supply conservationBioretentionEnvironment of Albania

The invention provides a urban road greenbelt LID (low impact development) bioretention trough construction method. The construction method sequentially comprises the following steps: excavating grooves and pits; installing a plastic product inspection well and a municipal pipe network connecting pipe; implementing concrete trench wall construction; paving sand on a basement; paving an impermeable membrane; paving and adding a pebble bed; installing an HDPE (high-density polyethylene) perforated pipe and filling the perforated pipe with pebbles; paving and illuminating a permeable geotextile on lower layer; adding and paving a sand filter bed; paving and illuminating a permeable geotextile on upper layer; installing curbs at two sides; implementing back-filling with a planting soil layer; installing rainwater grates and well coves and implementing construction of a gravel block belt; planting plants; and implementing cleaning as well as acceptance and inspection. According to the construction method provided by the invention, a conventional drainage mode, adopted by urban roads, of direct discharging at a source and centralizing at an end, is changed, and a problem on drainage is solved; meanwhile, by planting the rainwater-cultivated plants in the bioretention trough in normal times, rainwater is utilized; and a urban heat island effect is solved and effects of lighting urban and beautifying environment are achieved.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

Machining method of wood stair solid wood stand pillar with dual-rectangular-shaped patterns

ActiveCN106827131AUnique decorative effectHigh technology contentBalustersWood treatment detailsSolid woodEngineering

The invention discloses a machining method of a wood stair solid wood stand pillar with dual-rectangular-shaped patterns. Firstly, broad-leaf ring-porous wood is selected, and the wood is cut into wood sections after bark is removed; secondly, the wood sections are dried, pressurized and soaked in phenolic resin, bags cover the two ends of each wood section and are tied, and drying and curing are carried out; thirdly, the cured dipped wood sections are perpendicularly fixed to a rotary plate of a wood stair stand pillar line processing device and subjected to sand blasting treatment with a combined sprayer, and after the dual-rectangular-shaped patterns appear on the surfaces of the wood sections, the angle of the wood sections is adjusted and then the sand blasting treatment continues; and finally, the wood sections with the dual-rectangular-shaped patterns appearing on the side faces are subjected to secondary sand blasting treatment, mending, machining formation and painting, and the finished wood stair solid wood stand pillar with the side faces having the dual-rectangular-shaped patterns is obtained. The machining technique is simple and easy to implement, the raw material is low in cost, and the finished wood stair solid wood stand pillar with the side faces having the dual-rectangular-shaped patterns is obtained through special technical treatment. The machining method can comprehensively improve the technological content and added value of the wood stair stand pillar and has broad development prospects.

Owner:芽米科技(广州)有限公司

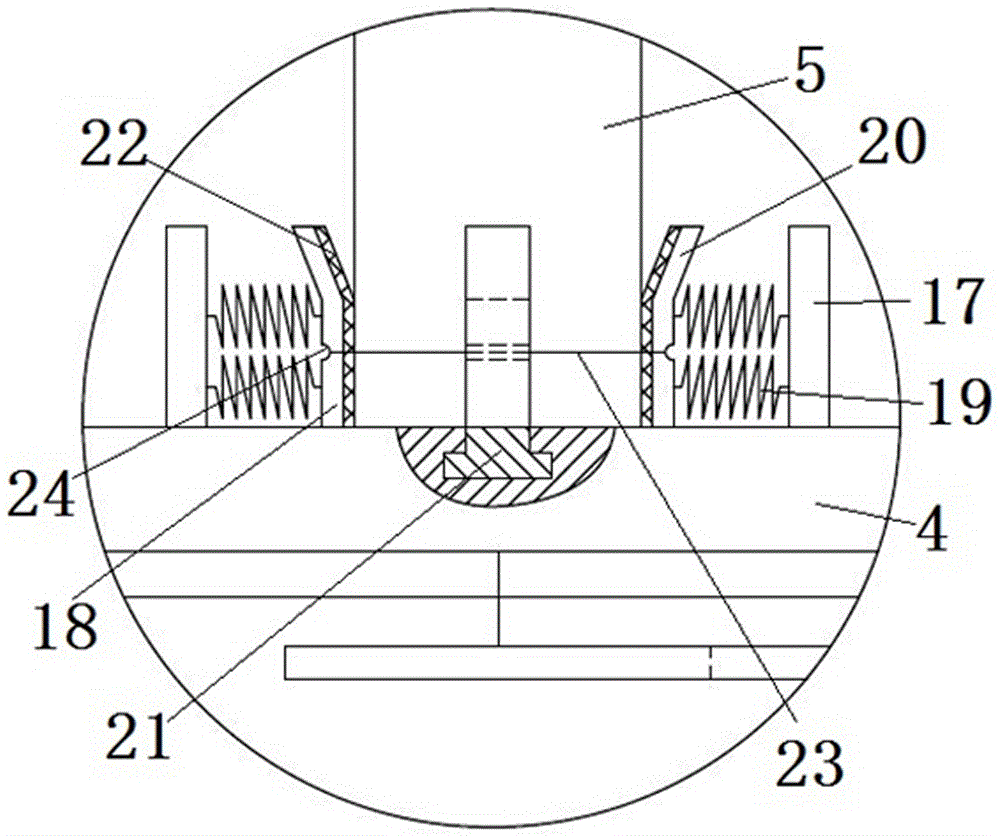

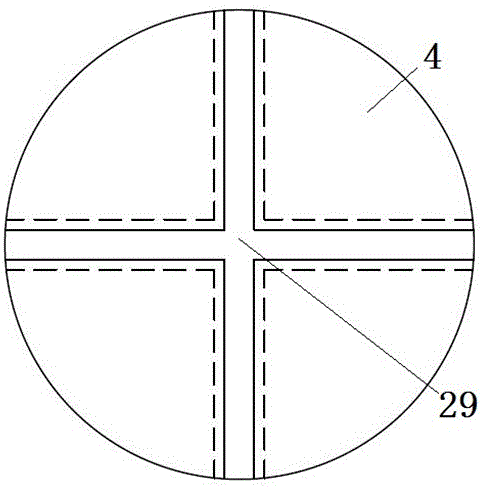

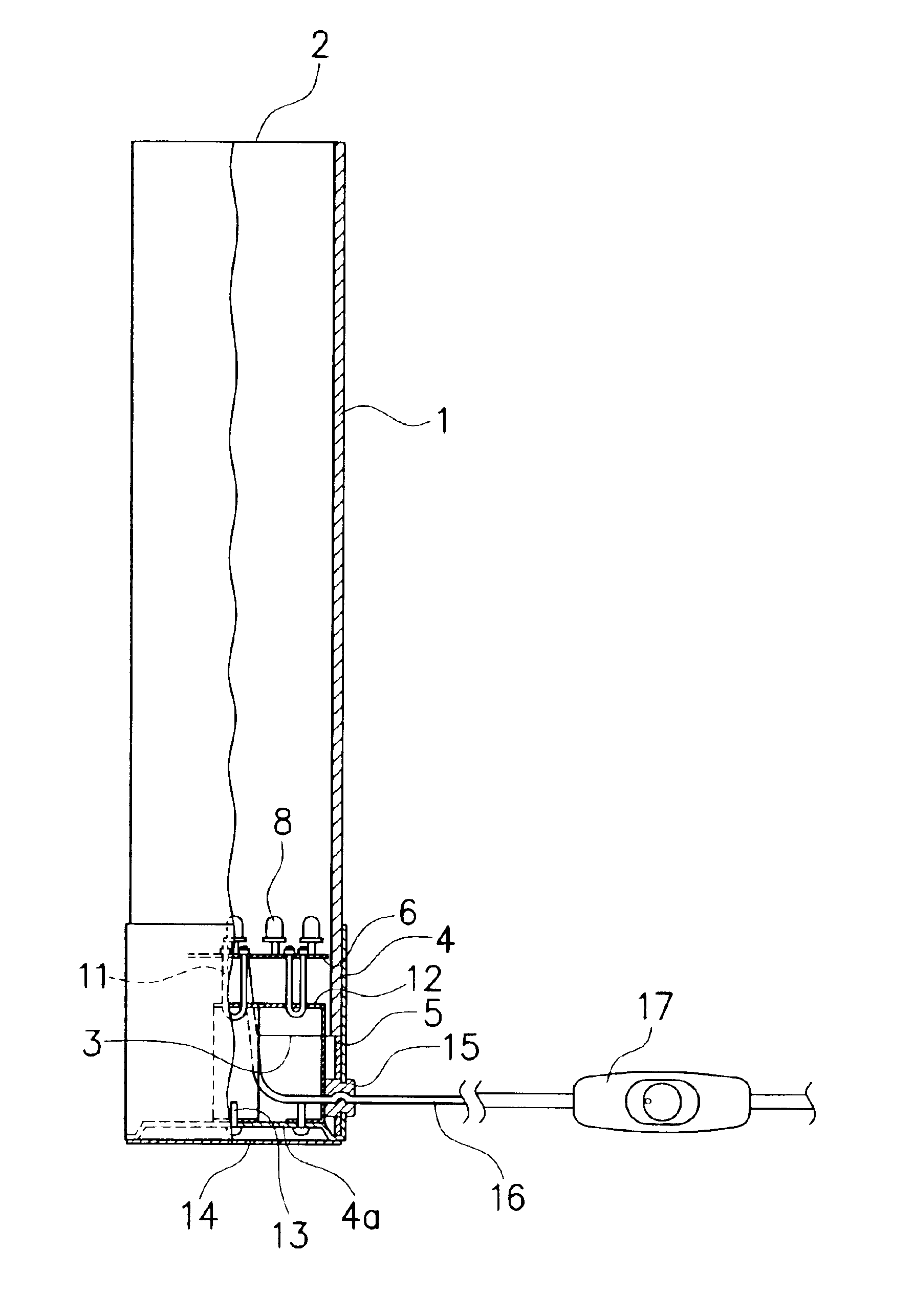

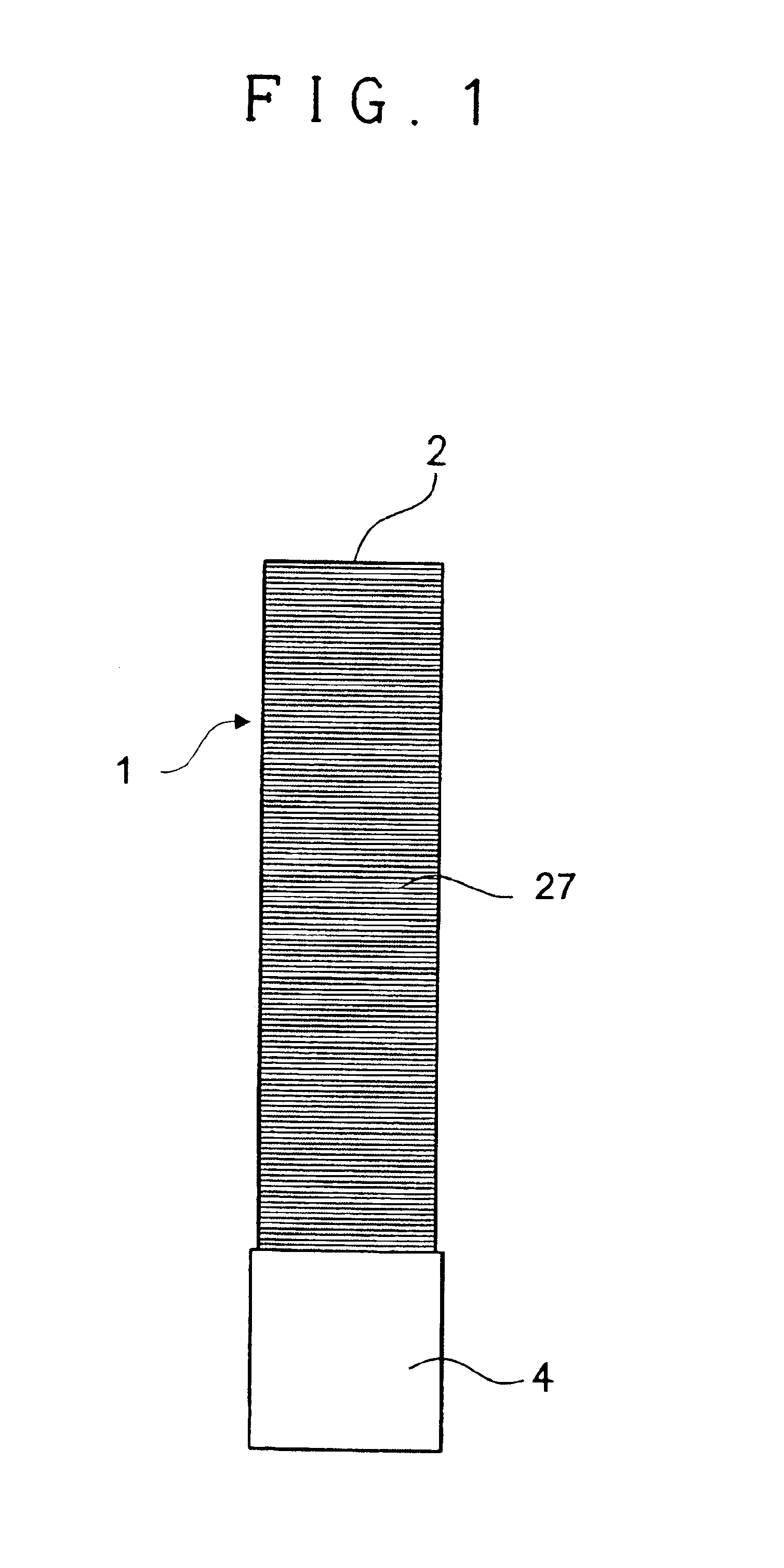

Decorative lighting equipment

InactiveUS6857765B2Effective displayImprove visual effectsPoint-like light sourceWith electric batteriesLight equipmentLight flux

A decorative lighting equipment includes a shade that is transparent or translucent and formed into a tube with opposite ends, a light source for emitting a directional light flux, the light source being placed at one end of the opposite ends of the shade so that the directional light flux is transmitted within the shade toward another end of the shade, and the shade forming thereon hairlines which extend in a direction crossing the direction along which the directional light flux emitted from the light source is transmitted.

Owner:KISHIMA

Method for performing surface treatment on golf head by aluminium -titanium nitride composite coating

ActiveCN101979703ASimple processGood repeatabilityVacuum evaporation coatingSputtering coatingTitanium nitrideTitanium alloy

The invention discloses a method for performing surface treatment on a golf head by an aluminium-titanium nitride composite coating. The method comprises the following steps of: gasifying aluminium-titanium alloy under a vacuum condition, forming plasma, and forming a composite coating of aluminium-titanium alloy and aluminium-titanium nitride on the surface of the golf head by a physical vapour deposition method. The treated golf head has good wear resistance, solvent resistance, salt and fog corrosion resistance and a vivid rosy appearance colour. The coating has good comprehensive mechanical performance, certain hardness and certain toughness. Therefore, the golf head has good impact resistance and good adhesion firmness with a golf head base material and completely meets the requirements on the surface quality of the golf head.

Owner:范文波

Method for performing surface treatment on golf head by forming carbon, nitrogen, titanium, chromium composite coating

ActiveCN102031483AReduce coefficient of frictionMeet quality requirementsVacuum evaporation coatingSputtering coatingGas phaseGolf Ball

The invention discloses a method for performing surface treatment on a golf head by forming a carbon, nitrogen, titanium and chromium composite coating. Under the vacuum condition, the pure metal such as titanium and chromium, and graphite are gasified and argon, nitrogen and acetylene gas are introduced so as to form plasma, and the carbon, nitrogen, titanium and chromium composite coating is formed on the surface of the golf head by a physical vapor deposition method according to an alloying principle. The golf head treated by the method has a pearlescent glossy black appearance, and high solvent resistance, corrosion resistance, impact resistance and metal adhesion firmness. Simultaneously, the coating has high comprehensive mechanical property, and certain hardness and toughness and completely meets the surface quality requirement of the golf head.

Owner:范文波

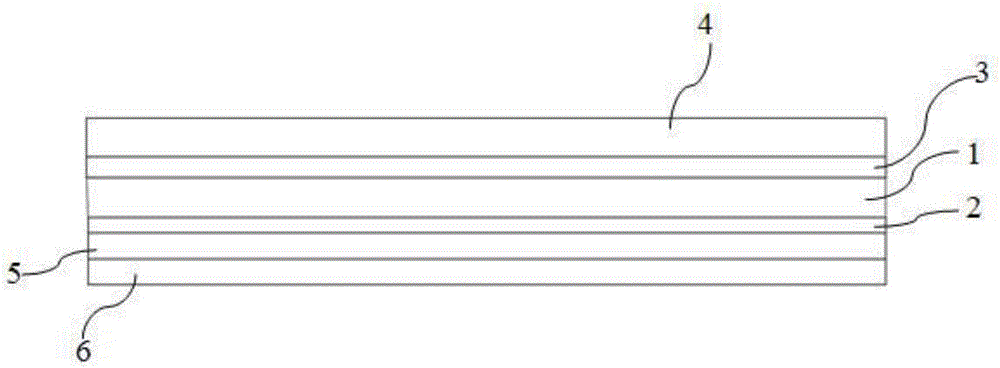

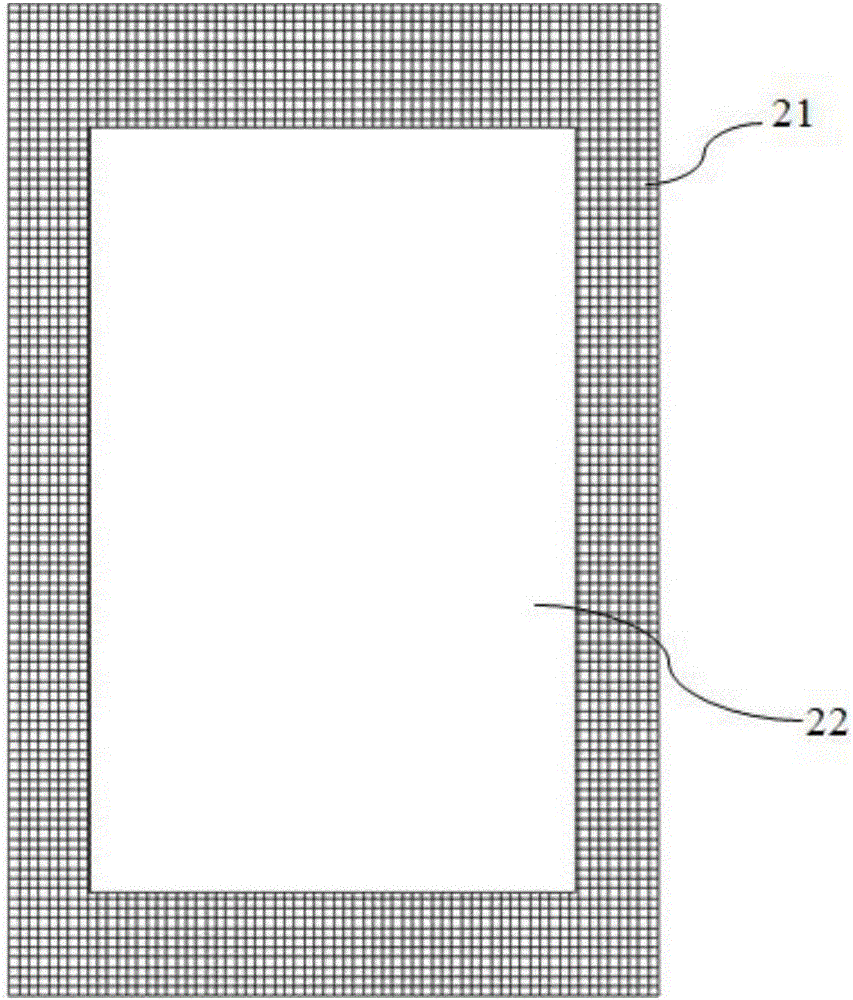

Decorative thin film and glass

PendingCN107433816ADoes not change hueChange color single effectOrnamental structuresSynthetic resin layered productsDiffraction effectEngineering

The invention discloses a decorative thin film. The decorative thin film comprises a base material layer, a pattern layer and an adhesive layer, wherein the pattern layer is arranged on one side of the base material layer and provided with evenly arranged microstructure units, and the microstructure units are provided with a plurality of parallelly arranged periodic cylindrical surface structures; and the adhesive layer is arranged on the other side of the base material layer relative to the pattern layer. At the same time, the invention further discloses decorative glass. According to the decorative thin film and glass, compared with the prior art, the decorative thin film can obtain a special dynamic light discoloration effect; by forming a microstructure on the thin film, the decorative thin film has the special visual effect on the macroscopic effect, the more shiny effect on the visual effect, and the higher diffraction effect; and the decorative thin film and the decorative glass are applied to the surface of a product and play roles on all aspects of decorative, brand protecting, cost controlling and environmental protecting.

Owner:苏州迈塔光电科技有限公司

Production method of portoro glaze ceramic

The invention relates to the technical field of ceramic production, in particular to portoro glaze and a production method of ceramic with a light emperador glaze effect. The portoro glaze is characterized by comprising black ground glaze and portoro glaze, a special raw material formula is selected, unique glazing and firing processes are used according to characteristics of glaze, the fired portoro glaze ceramic has a basic black tone on the surface, has golden yellow grains intermittently and uniformly distributed in a stripe shape like bright yellow golden flowers scattered on black satin,gives people sense of steadiness and nobleness, has unique decoration and artistic effects and can be used as a creation carrier of home decoration and artwork, so that use of natural stone can be reduced, the production cost can be reduced, stone resources can be saved, and the portoro glaze ceramic has positive social and economic benefits.

Owner:FUJIAN DEHUA LONGNAN CERAMICS CO LTD

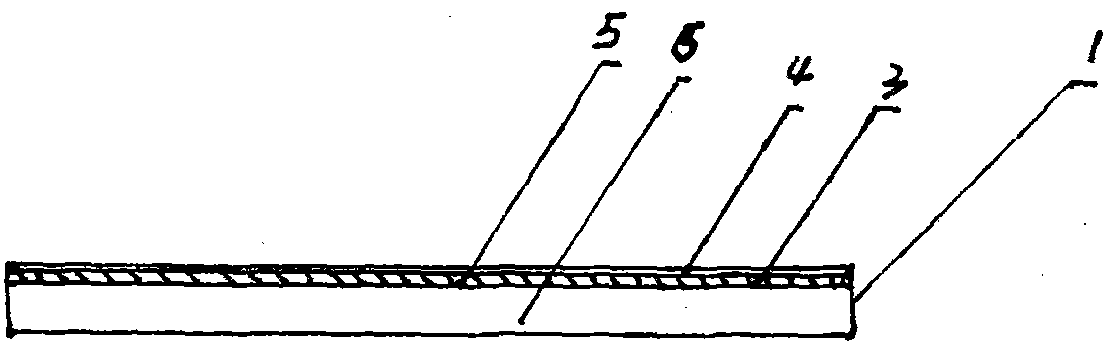

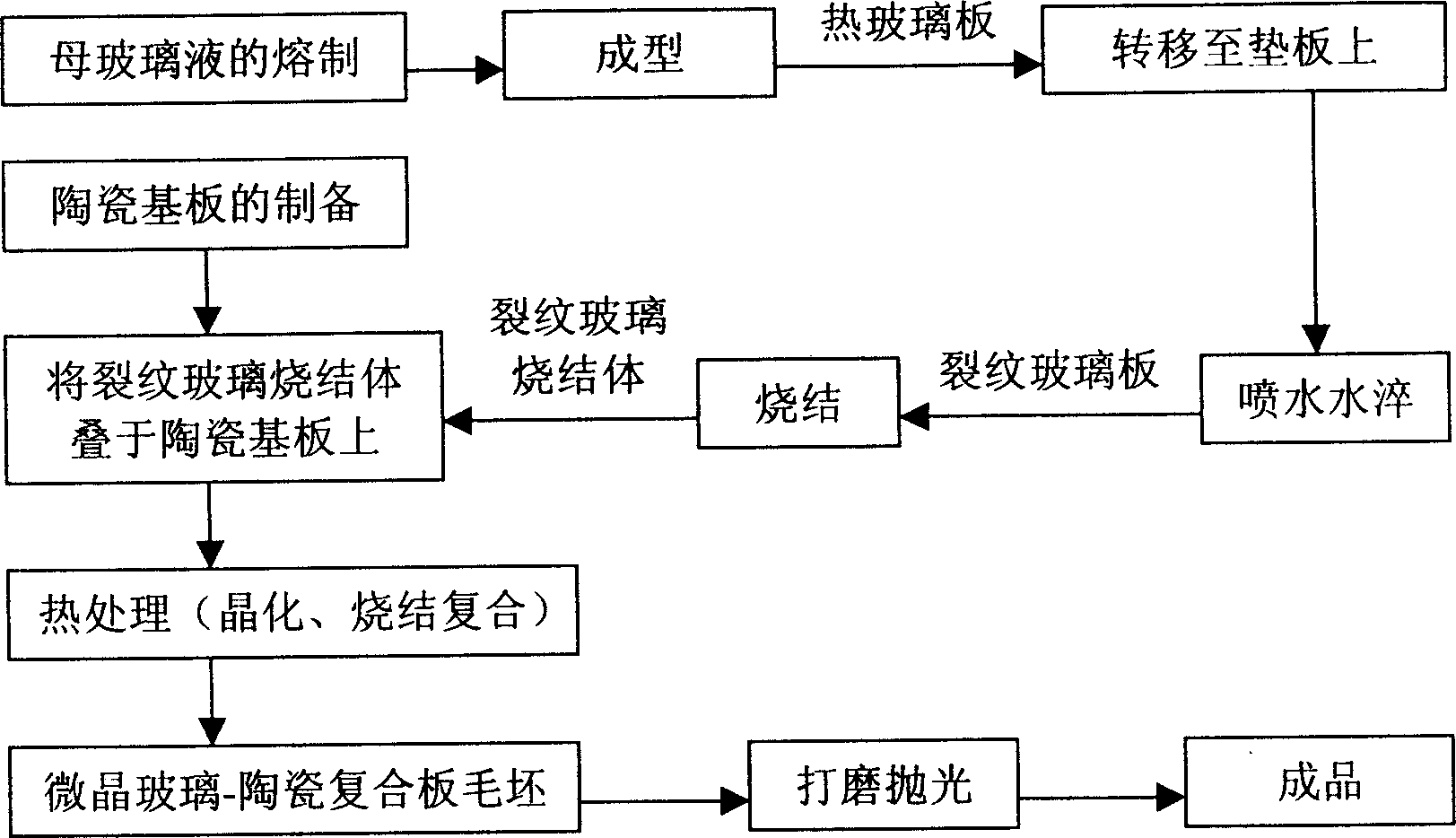

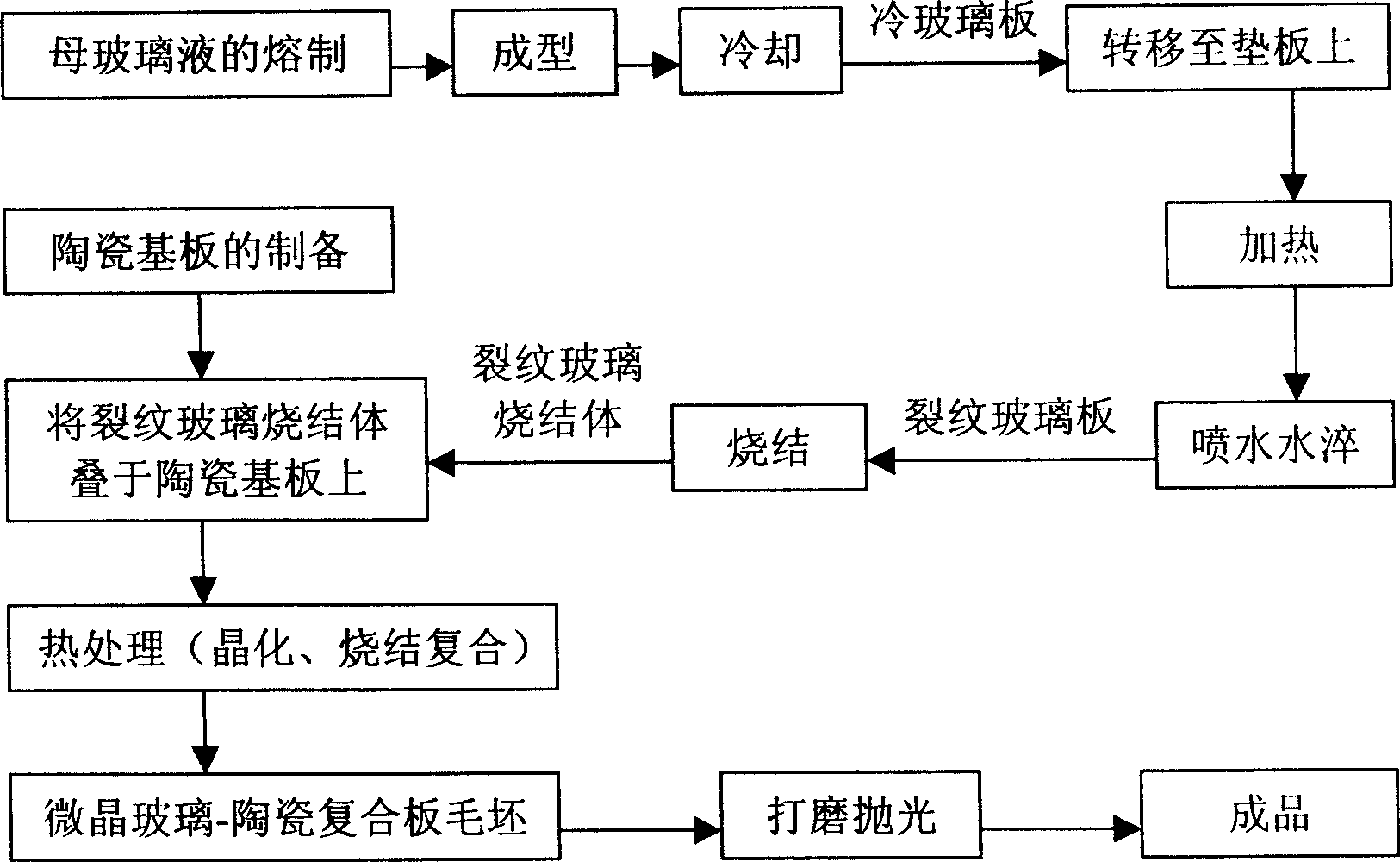

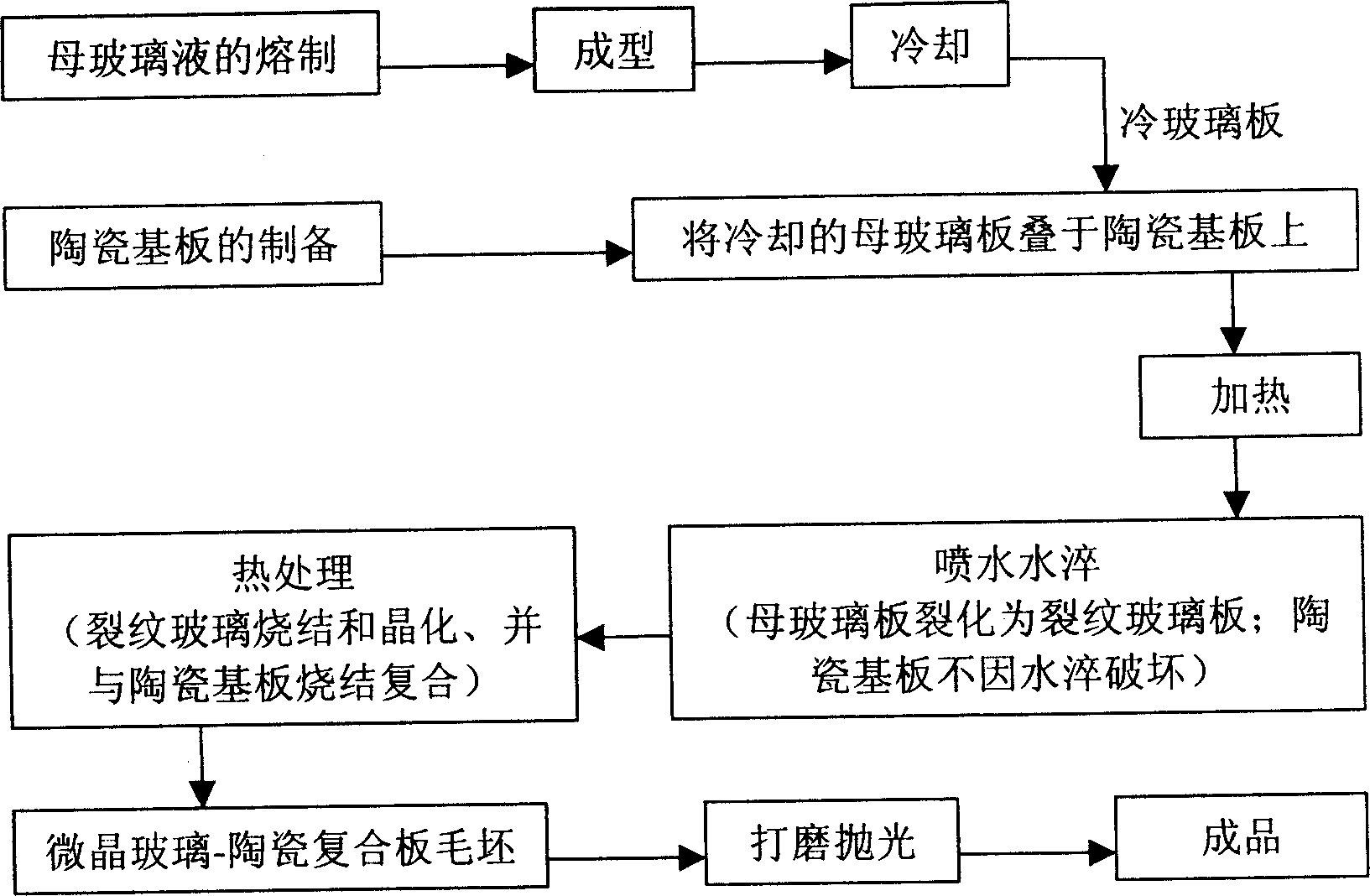

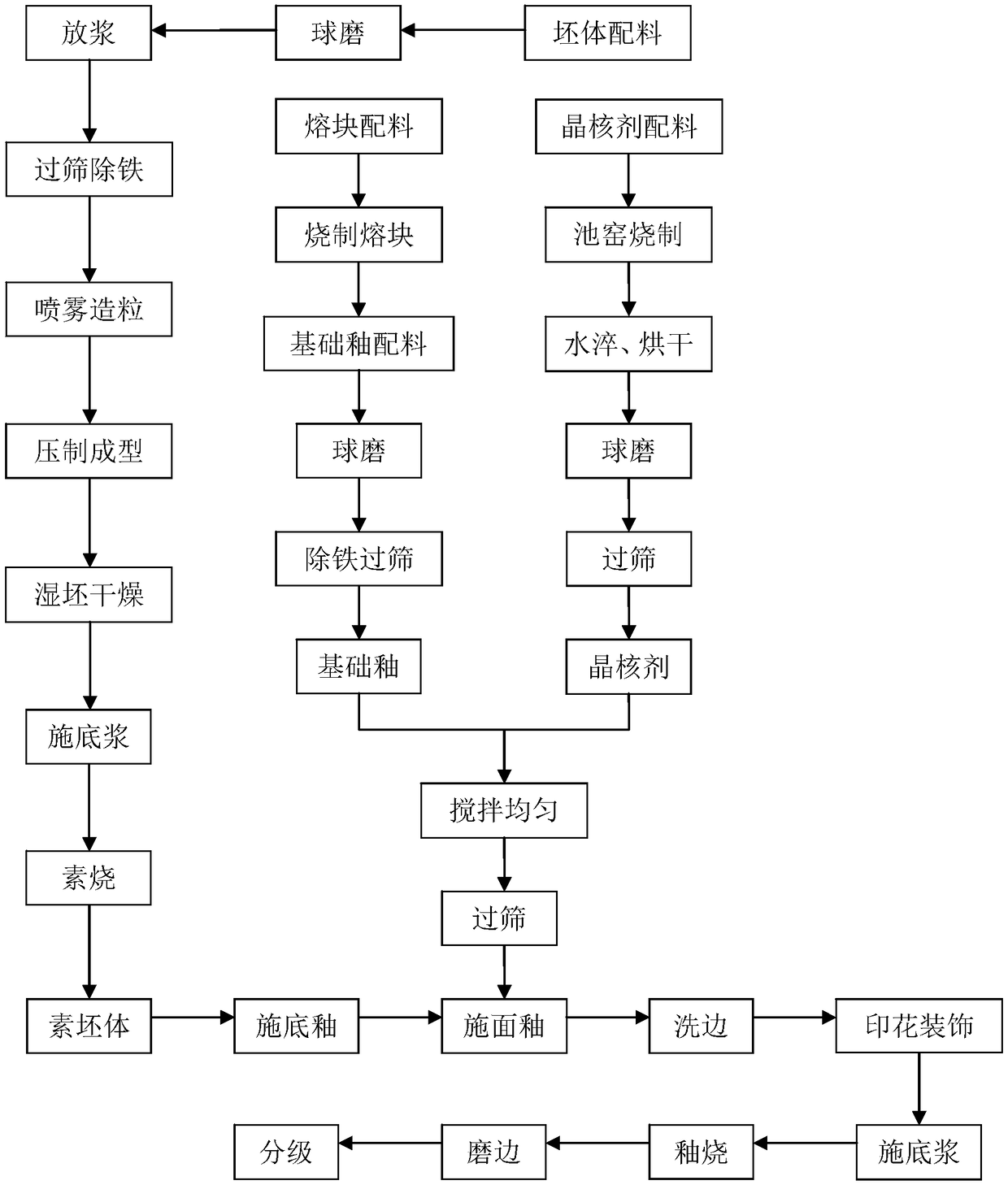

Process for preparing microcrystal glass-ceramic compounded plate

The invention discloses a preparing method of architectural decorative microcrystalline glass-ceramic composite board, which comprises the following steps: 1) preparing ceramic base; 2) preparing mother glass board; 3) preparing composite board from the following schemes: (1) transmitting the moulded mother glass board on the bearing plate; cooling to do crack disposal; heating again to sinter into integral to obtain the crack sintered bulk; overlapping the crack glass sintered bulk on the ceramic base to obtain the product; (2) transmitting the moulded and cooled mother glass board on the bearing plate; heating again to do crack disposal; (3) overlapping the moulded and cooled mother glass board on the ceramic base directly; 4) polishing to obtain the product.

Owner:浙江中地大科技有限公司

Warm sound-proof decorative materials and prepn. method

This invention is attributed to the field of building materials, concretely speaking, relates to a kind of decoration materials with heat preservation and sound absorption functions and its preparation method. The heat-preserving and sound-absorbing decoration materials comprise a hear-preserving layer, a decoration layer and a mask layer. The heat-preserving layer is made of polybenzene particles, water glass, cement, silica fume, slag powders, fly ash and sand. The decoration layer is made of polybenzene, rubber powders, pigment, cement, silica fume, slag powders and sand. The mask layer is made of organosilicon series of waterproof materials. By the technique of spray stir, layered moulding, compression molding and vapor conservation, the polybenzene particles and the porous structure can help realize highly effective heat preservation. The sound-absorbing structure can be fabricated by compression molding. Fascinating stereo patterns can be organized by alternation of mould shape and pigment. Besides, thanks to the mask layer, wear and decoration properties can be promoted. The product performs excellent heat-preserving, sound-absorbing and decorative functions.

Owner:TONGJI UNIV

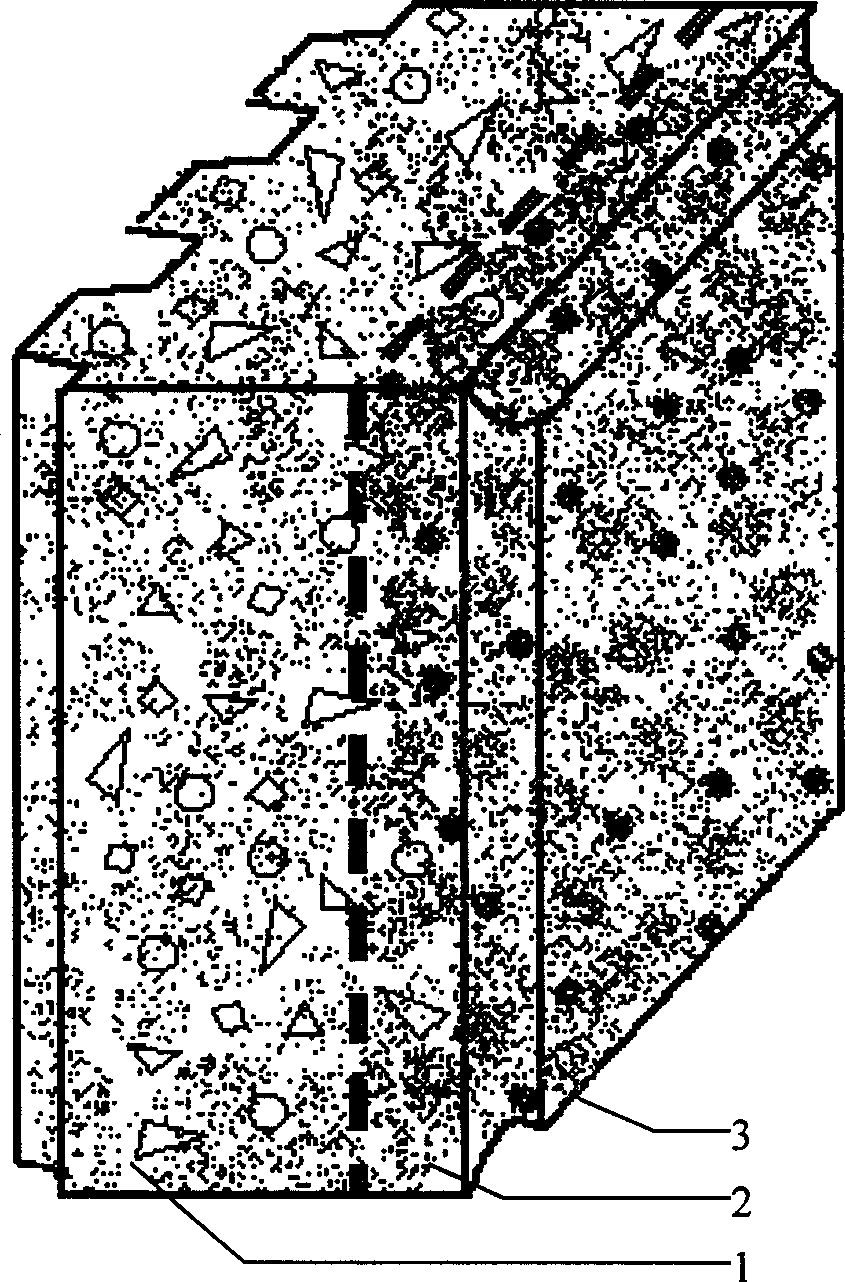

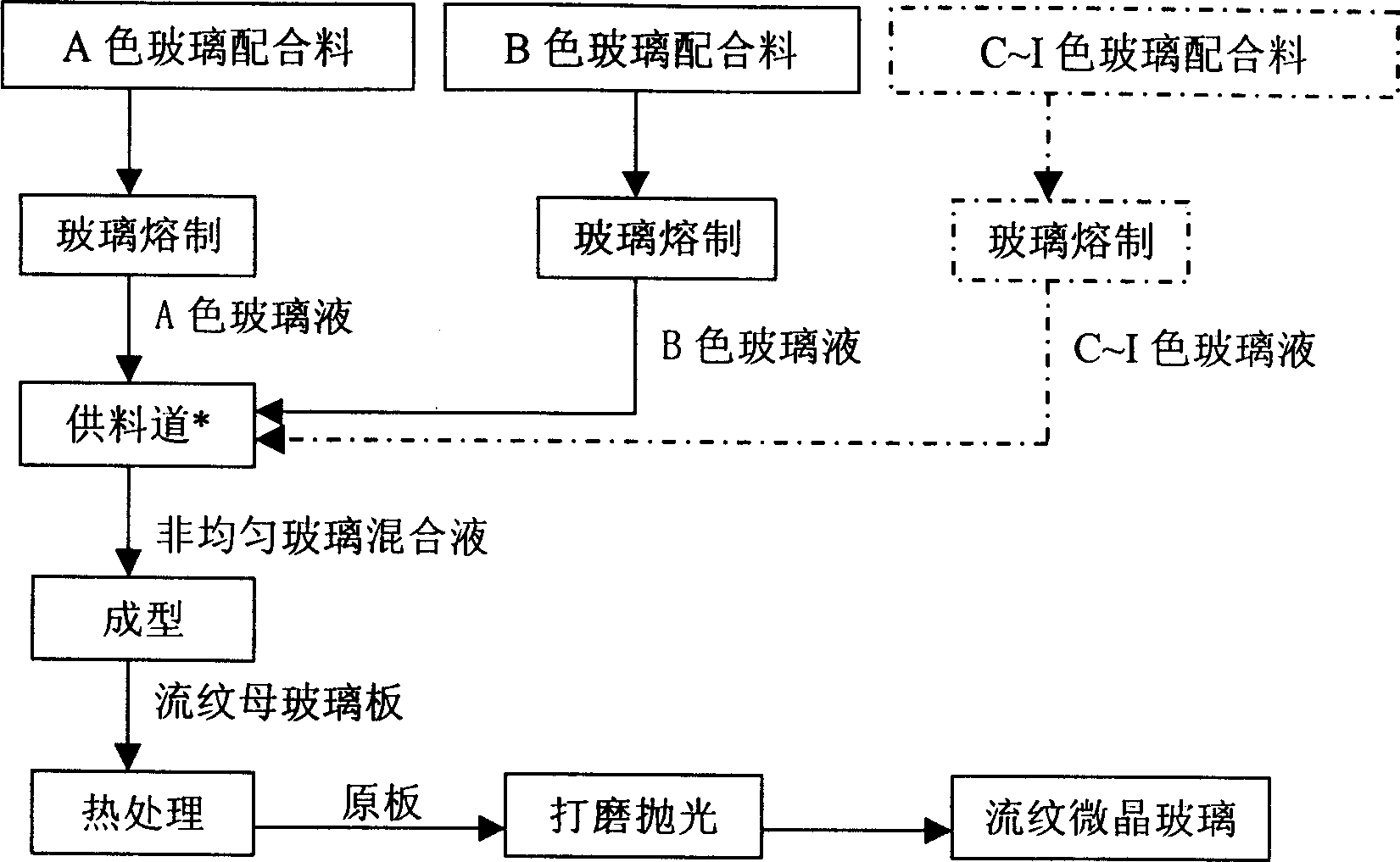

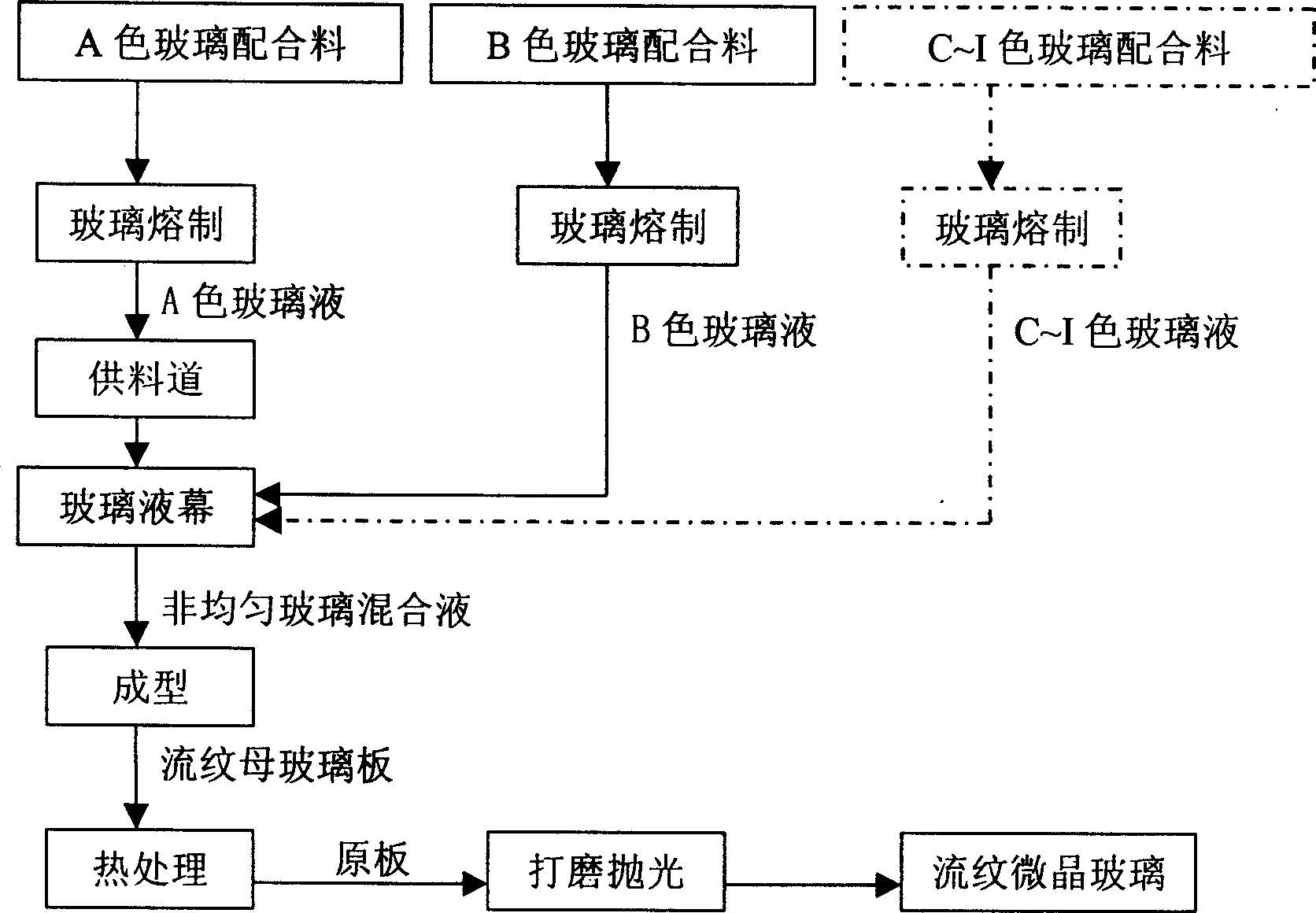

Preparation method of flow liner crystallite glass

InactiveCN1807303ARich types of texture and morphologyIncrease flexibilityGlass pressing apparatusGlass rolling apparatusCrystalliteThermal treatment

The invention relates to a preparation method for the decorative microcrystal glass, which comprises: fusing glass liquid with different color; leading the liquid into another glass liquid with different color; on uneven mixing state, forming the mixed glass liquid into the rhyolitic mother glass plate with calendering or poring or pressing method; then, taking crystallization and thermal treatment to obtain the final product with two or more colors combined naturally. This invention has well decorative effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Water-in-water colorful stone simulated paint

InactiveCN102181196AProtection wallExtended service lifeMulticolor effect coatingsCelluloseSodium Bentonite

The invention provides a novel water-in-water colorful stone simulated paint, and belongs to the technical field of coating preparation. In the process of preparing a dispersion phase, a surface treated calcium carbonate is added, and the dispersion phase prepared from the calcium carbonate can be obviously separated from the aqueous phase; the protective glue component mainly consists of cellulose, water, water-soluble resin, defoaming agent, dispersant and preservative; by adding the protective glue component, the dispersion phase is coated by the protective glue, so that the prepared colorful paint has good stability and the dispersion phase is obviously separated from the dispersion medium; and the aqueous dispersion medium mainly consists of water, organic bentonite, aluminum sulfate and magnesium chloride. On the process design, secondary reaction of base paints is adopted to improve the viscosity of the base paints and the strength of cohesion; and on the formula design, protective solution with polarity is added among the base paints of different colors, and granules are uniformly distributed in the protective solution under mechanical action.

Owner:张兴艺

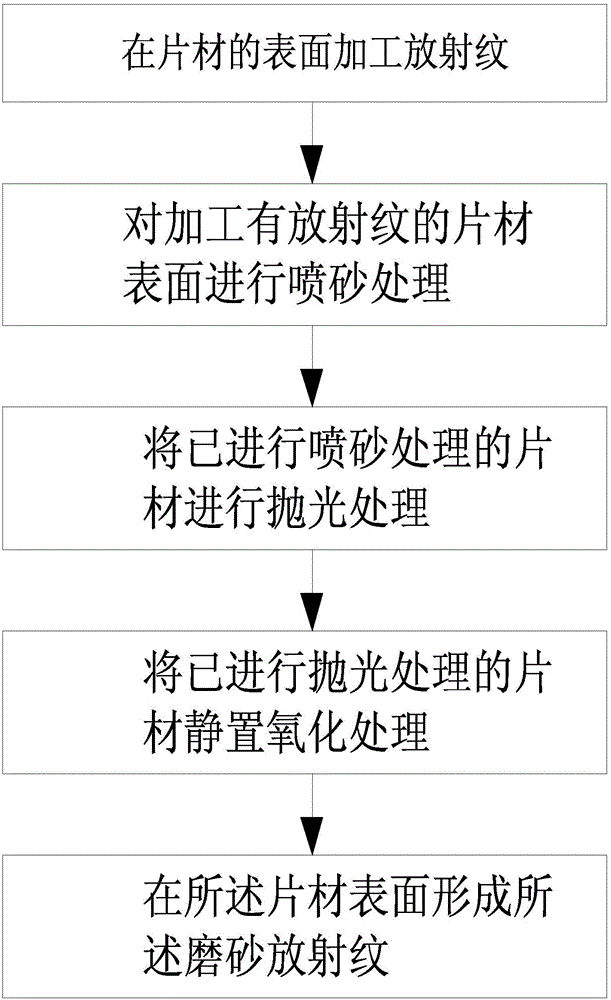

Dull polish radiation grain manufacturing technology and shell of terminal equipment

InactiveCN106364251AEliminate grainImprove appearance decoration effect and yield rateCasings/cabinets/drawers detailsSpecial ornamental structuresEngineeringRadiation

The embodiment of the invention provides a dull polish radiation grain manufacturing technology. Radiation grains are machined on the surface of a sheet; the surface of the sheet with the radiation grains is subject to sand blasting treatment; the sheet subject to sand blasting treatment is polished; the polished sheet is subject to standing oxidation treatment; dull polish radiation grains are formed on the surface of the sheet; the embodiment of the invention further provides a shell of terminal equipment. In conclusion, the grain effect that the radiation grains and dull polish are overlapped is formed, the decoration effect is novel and unique, and the texture decoration can be effectively improved; the dull polish radiation grains are good in vision effect and soft in reflected light, the grains have the regularity and smooth hand feeling, and use experience of a user is effectively improved; particularly, the grains manufactured through the manufacturing technology are applied to the metal shell of a terminal, and the use effect of the grains is more prominent; meanwhile, the technology is simple in step and short in manufacturing procedure, and the production efficiency is effectively improved.

Owner:VIVO MOBILE COMM CO LTD

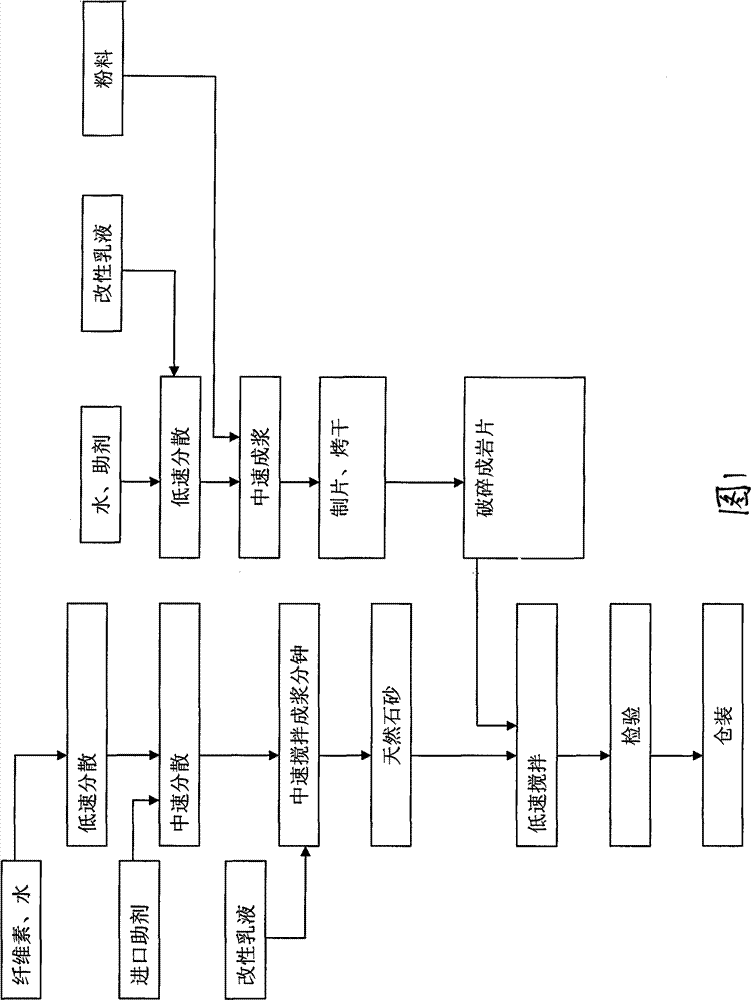

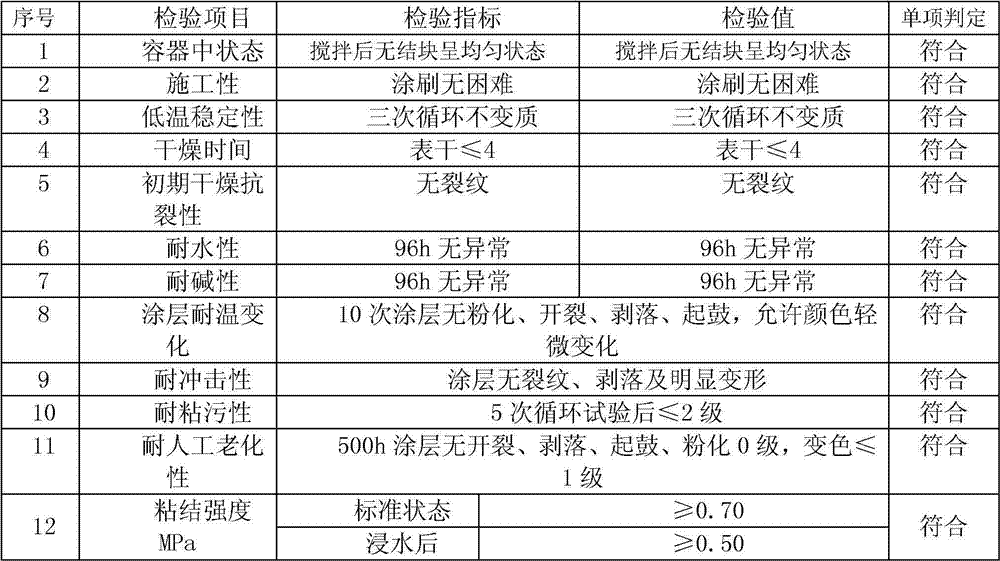

Natural rock slice paint and preparation method

The invention discloses natural rock slice paint and a preparation method, and belongs to the technical field of decoration paint. The natural rock slice paint is characterized in that the natural rock slice paint is formed by mixing sheet mica with an adhesive at a weight ratio of 1:(1-3), wherein the adhesive comprises the following raw materials by weight proportioning: 50-60% of a silicone-acrylate emulsion, 15-25% of an aluminum solution, 1-3% of a silane coupling agent, 1-3% of a coupling agent, 2-4% of a coalescing agent, 10-20% of water, and the balance of a thickener. With the adoption of the technical scheme, the natural rock slice paint has the benefits that compared with the artificially synthesized rock slice paint in the existing market, the natural rock slice paint has a unique decoration effect; the added natural mica has a good heat preservation effect; the use cycle of the natural mica is longer; and the color brightness is better.

Owner:临海市百佳涂料厂(普通合伙)

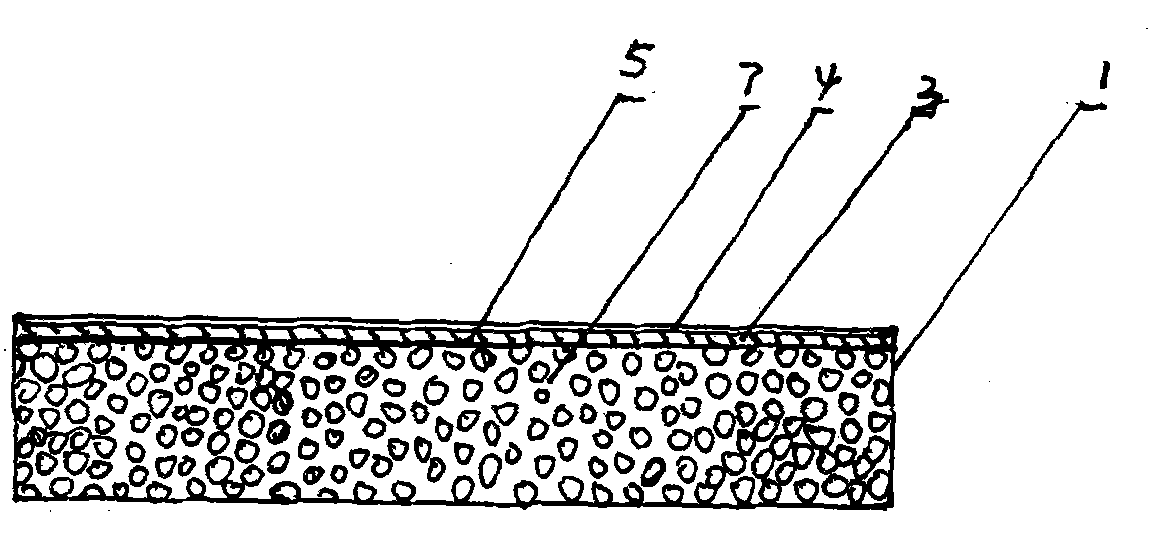

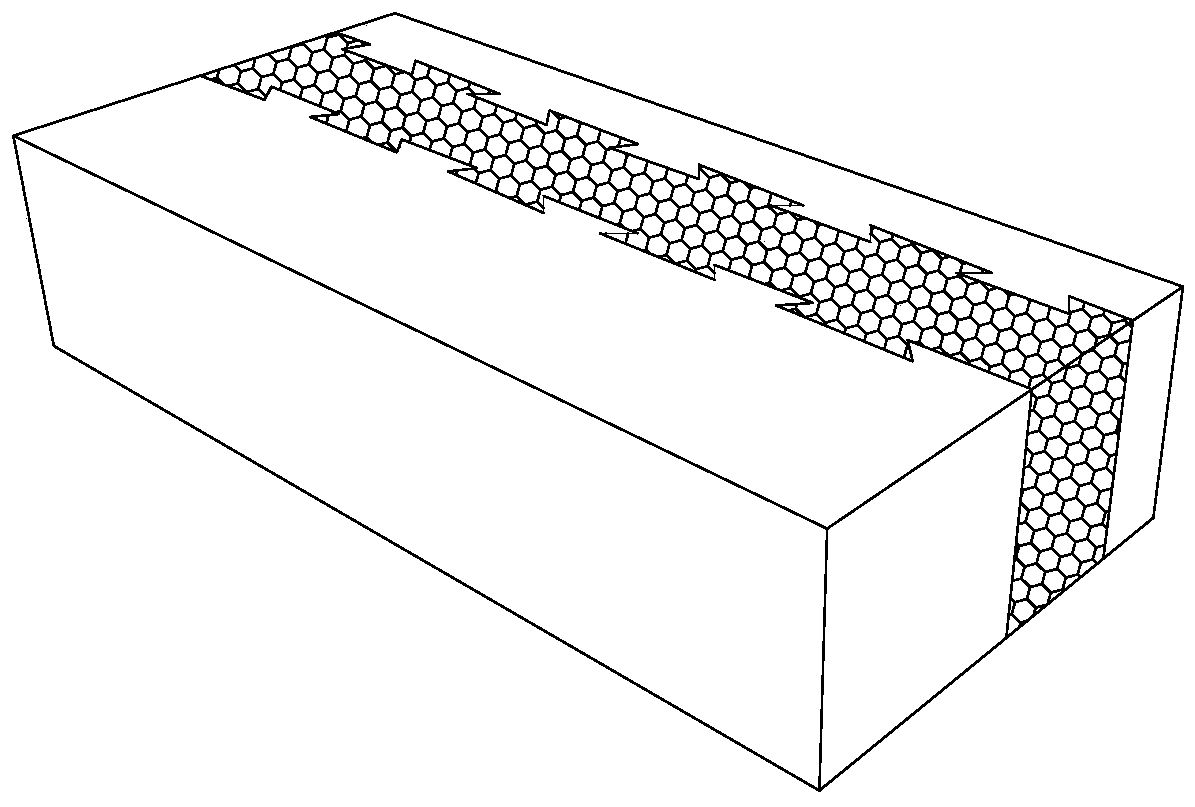

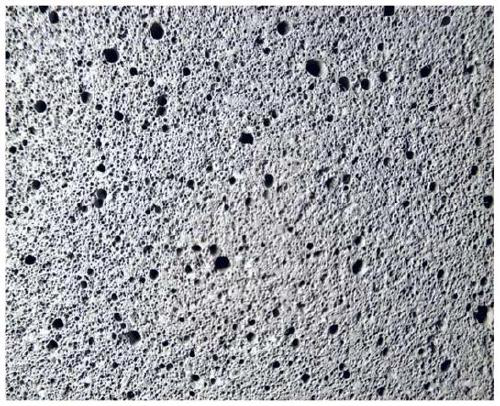

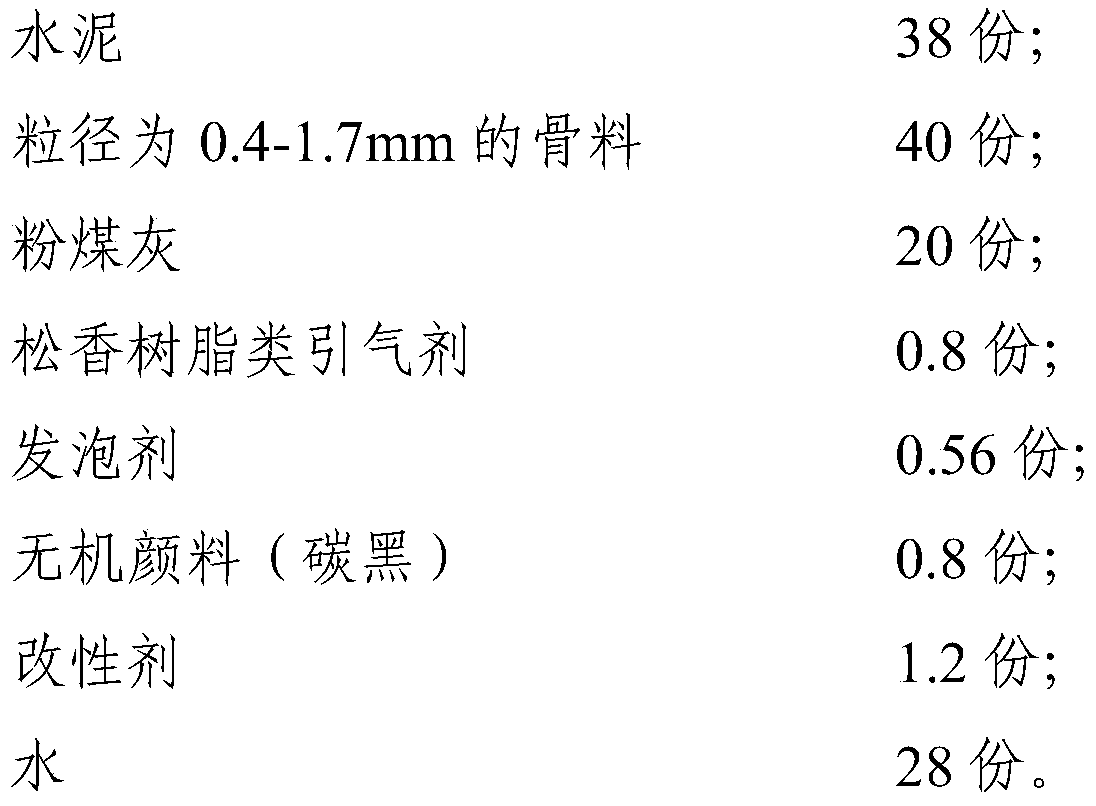

Scoria-imitated light heat-preservation composite building block and processing method thereof

InactiveCN110372275AHigh strengthGood insulation performanceConstruction materialCeramicwareOptoelectronicsPore diameter

The invention provides a scoria-imitated light heat-preservation composite building block and a processing method thereof. The scoria-imitated light heat-preservation composite building block comprises two independent and mutually-parallel light porous concrete matrixes and a heat-preservation core layer arranged between the two light porous concrete matrixes in a clamped mode, each light porous concrete matrix is of a natural-scoria-imitated structure prepared through a chemical foaming-curing process and provided with irregular pores in a distributed mode, and each light porous concrete matrix is prepared from the raw materials: cement, aggregate, an active admixture, a foaming agent and an air entraining agent; and the processing method comprises the steps that the heat-preservation core layer is fixedly arranged in a pouring mold, then the raw materials of the light porous concrete matrixes are evenly mixed according to the ratio and then injected, demolding is conducted after chemical foaming, and the scoria-imitated light heat-preservation composite building block is obtained through curing, surface processing and drying. The scoria-imitated light heat-preservation compositebuilding block is prepared through the chemical foaming-curing process, meanwhile by combining adjusting of the pore size and pore diameter distribution, the surface of the scoria-imitated light heat-preservation composite building block has a unique and realistic natural-scoria-imitating effect; and the scoria-imitated light heat-preservation composite building block is light, high in strength, good in heat-preservation performance, excellent in comprehensive performance and wide in actual application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

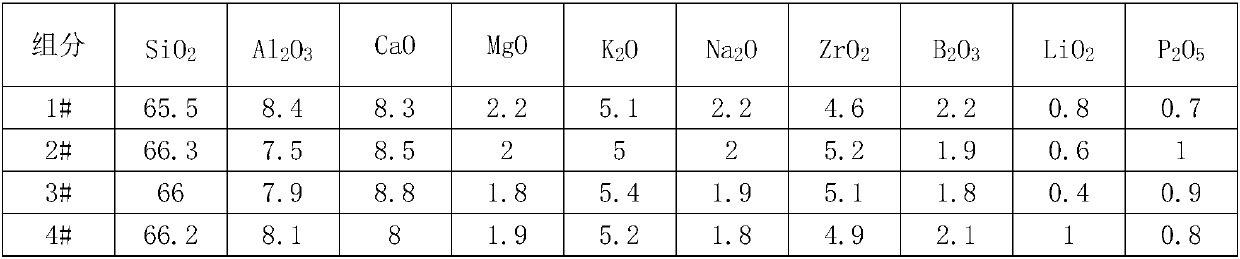

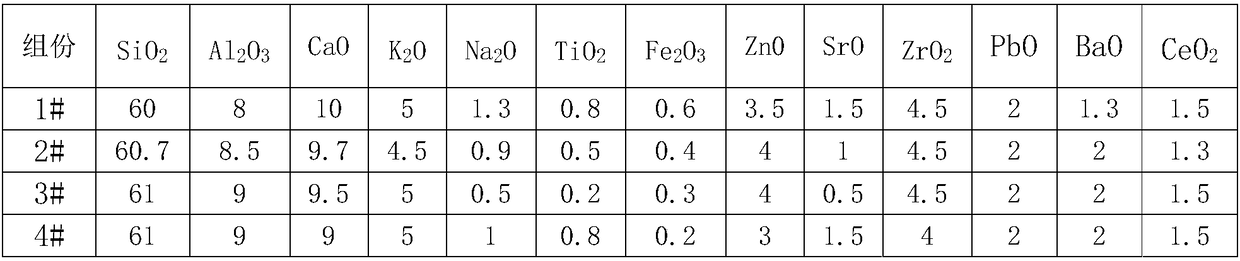

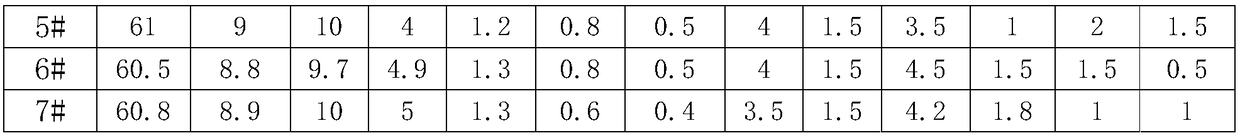

Crystalline glazed tile capable of durably producing negative ions and preparation method thereof

The invention provides a crystalline glazed tile capable of durably producing negative ions and a preparation method thereof. In the invention, without significant change on a production process of glazed tiles in the prior art, the method mainly pays attention to formulas and compositions of a frit, a basic glaze, a nucleation agent and a surface glaze, fineness of the basic glaze and the nucleation agent, and optimization on a sintering process and the like, so that a large number of silver crystals, in the size of a rice grain, are formed on the surface of the glaze tiles, wherein the crystals emit a bright silver light under irradiation by oblique light or lamp light, while the glaze base surrounding the crystals are matte, so that the whole tile looks like a starry night. In addition,there are a plurality of photo-catalytic semiconductor microcrystalline mineral, which cannot be seen by naked eyes, such as SrTiO3 and CaO.TiO2, in the surface glaze, wherein the minerals can be reacted with oxygen in air to generate oxygen negative ions durably, quantity of the inductively generated negative ions in air reaching 538 / s*cm<2>. The product is a decorative material which integratesdecorative and artistic properties and health-functional effects.

Owner:GUANGDONG WINTO CERAMICS +3

Sand-in-water stone-like paint

InactiveCN107163721AWith natural sand texture effectUnique decorative effectCoatingsNatural sandEmulsion

The invention provides sand-in-water stone-like paint. Sand-in-water wall paint is prepared from the following raw materials: water, cellulose, a dispersing agent, an antifoaming agent, ethylene glycol, a sterilizing agent, titanium dioxide, barium sulfate, a multifunctional auxiliary, a film forming auxiliary, acrylic emulsion, natural sand and tourmaline powder; the raw materials are proportionally mixed to obtain sand-in-water type paint. According to the scheme provided by the invention, the prepared sand-in-water wall paint has natural sand texture and can release anions and thus has unique decoration property, is widely applicable and is suitable for being used as a wall decoration material.

Owner:啄木鸟漆业集团有限公司

Decorative thin film and decorative glass

PendingCN107433817AElegant colorDoes not change hueOrnamental structuresSynthetic resin layered productsCost ControlsOptoelectronics

The invention discloses a decorative thin film. The decorative thin film comprises a base material layer, a pattern layer and an adhesion layer, wherein the pattern layer is arranged on one side of the base material layer; micro-structure units are uniformly distributed on the pattern layer; interval regions are arranged between the adjacent micro-structure units; an embossed microstructure is arranged on each micro-structure unit; the embossed microstructure is provided with plural directional non-periodic grating set lines; and the adhesion layer is arranged on the other side of the base material layer relative to the pattern layer. The invention further discloses a decorative glass. Compared with the prior art, the decorative film can obtain special dynamic photochromic effect; the microstructures are formed on the thin film, so that a special visual effect is achieved on the macroscopic effect; and the decorative thin film is applied to the surface of a product and has the effects of decoration, brand protection, cost control and environmental protection.

Owner:苏州迈塔光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com