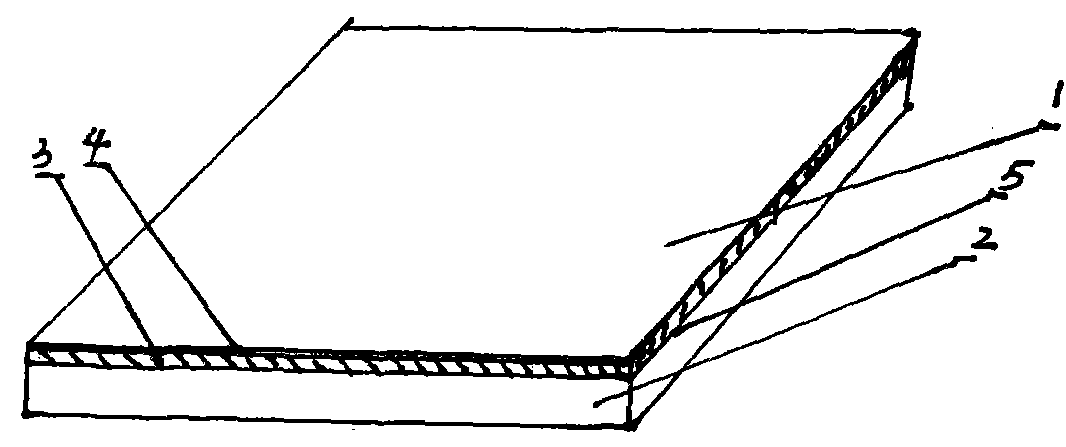

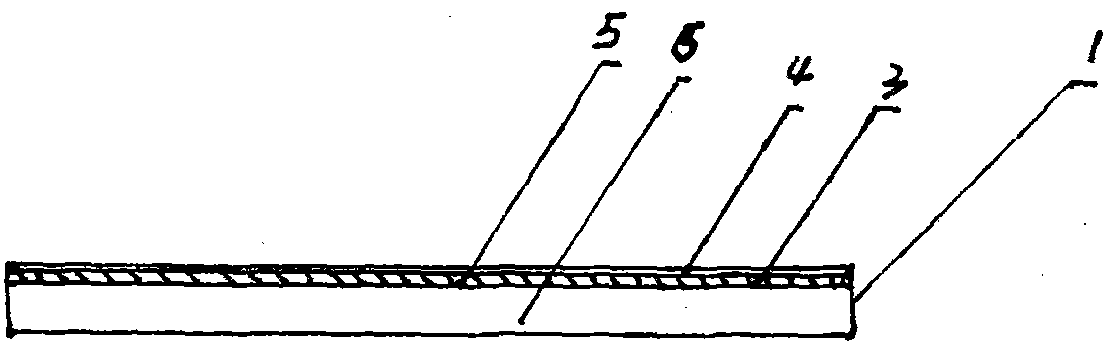

Fireproof plate with wooden decorative surface

A fire-proof board and wood veneer technology, which is applied in fire prevention, wood layered products, building components, etc., can solve the problems affecting the yield and decoration effect, poor bonding strength, poor fire resistance and flame retardancy, etc., and achieve excellent industrial production Process operation performance and value, improved firmness and durability, good fire and flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Wood veneer fireproof board, which is composed of a surface wooden decorative veneer and a base plate ceramic plate, the surface of the wooden decorative veneer is coated with transparent paint, and two-component polyurethane is used between the wooden decorative veneer and the ceramic plate plain plate Adhesive glued connection.

Embodiment 2

[0039] Embodiment 2: Others are the same as Embodiment 1, but the wooden decorative veneer and the ceramic plate are glued and connected with foamed polyurethane adhesive.

Embodiment 3

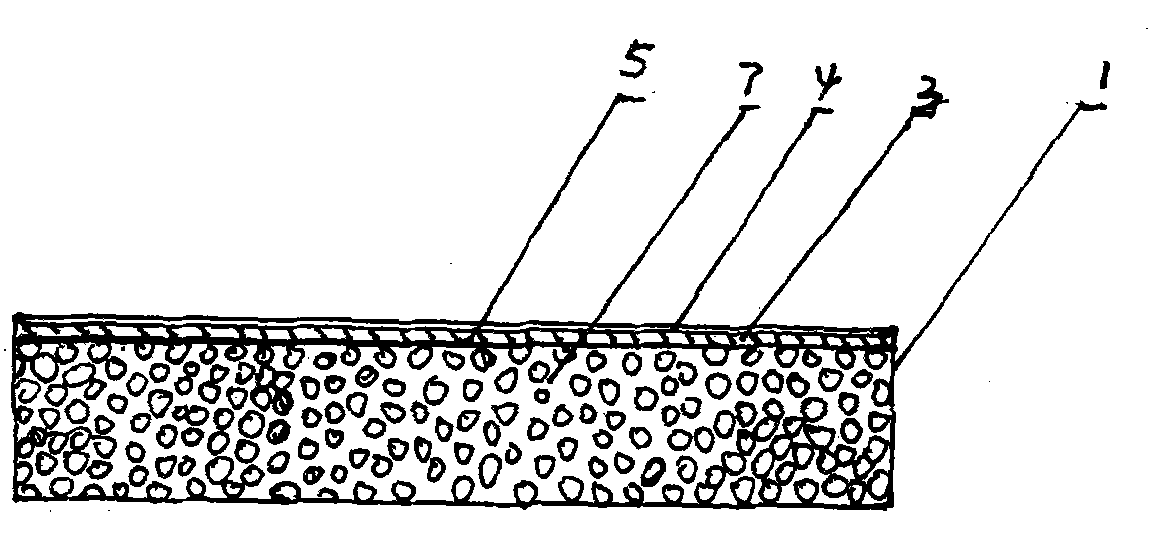

[0040] Embodiment 3: Others are the same as Embodiment 1, but the substrate ceramic plate is a fiber ceramic plate, 1-3m long, 0.8-1.6m wide, and 2.5-10mm thick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com