Machining method of wood stair solid wood stand pillar with dual-rectangular-shaped patterns

A processing method and stair technology, applied in the field of wood processing, can solve problems such as shortage of raw material sources, high cost, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

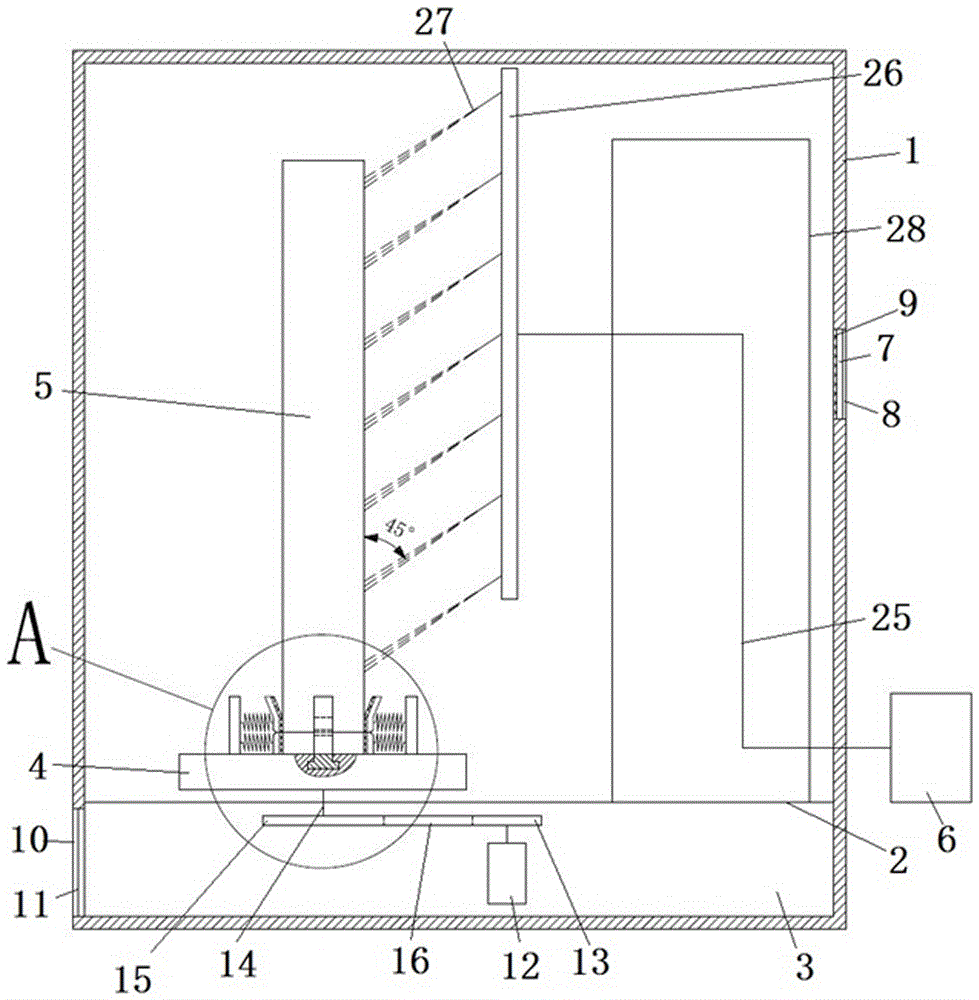

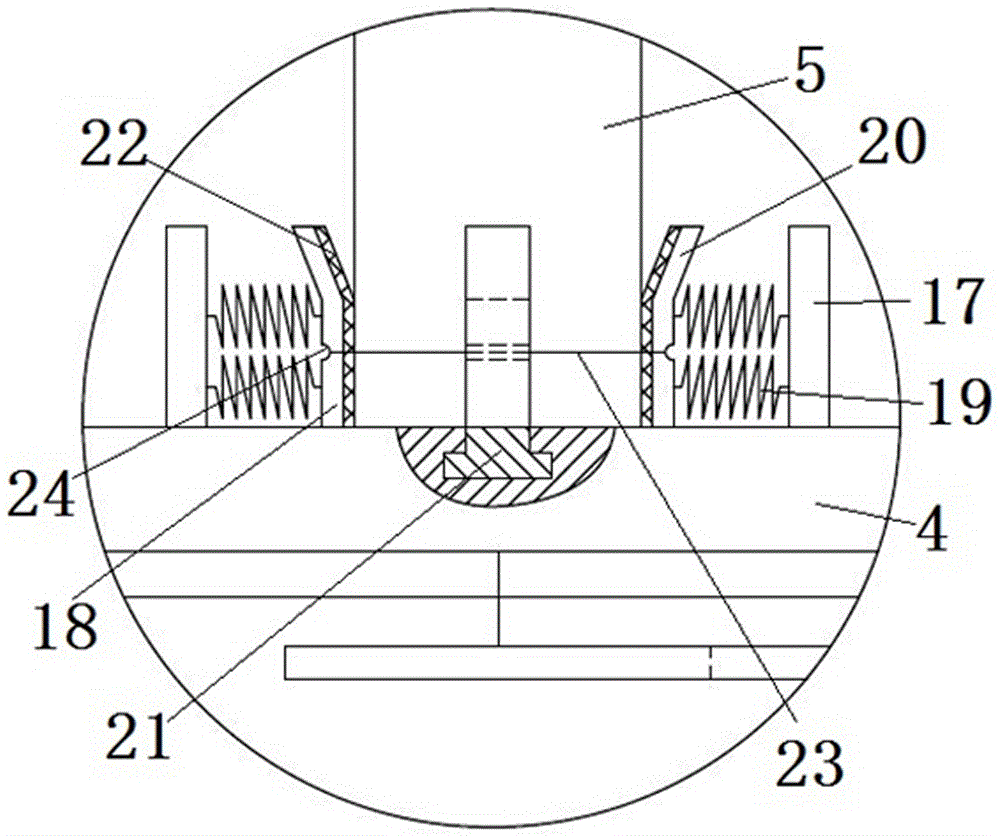

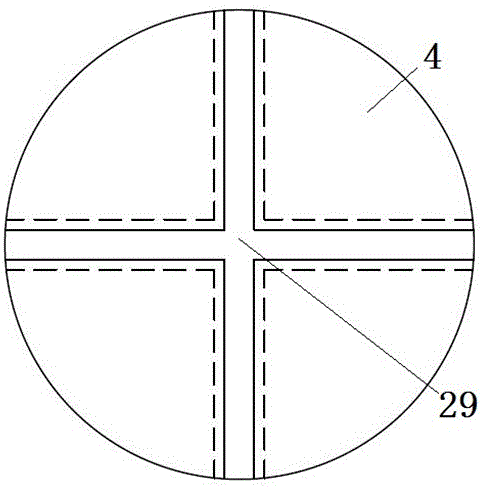

Method used

Image

Examples

Embodiment 1

[0037] A method for processing a solid wood column of a wooden staircase with a pattern, the method comprises the following steps:

[0038] Step 1: harvest the fresh wood of Sassafras tree with a diameter of 20cm, remove the bark and other debris, and cut it into a certain length of wood;

[0039] Step 2: Put the cut wood section into a wood drying kiln for drying, the drying temperature is 80°C, the drying time is 120 hours, and the moisture content of the wood section after drying is controlled at 8wt%;

[0040] Step 3: Place the dried wood sections horizontally in the metal tank, fix the wood sections on the surface with iron wires and iron nails, press the weights on the top layer of the stack of wood sections, and mix the water-soluble phenolic resin and water in a volume ratio of Dilute at 1:2.2, mix thoroughly and pour into the metal tank. The liquid level of the glue should be 20cm higher than the top layer of the wood stack, and close the opening of the metal tank;

...

Embodiment 2

[0053] A method for processing a solid wood column of a wooden staircase with a pattern, the method comprises the following steps:

[0054] Step 1: harvest fresh wood of Mandshurica mandshurica with a diameter of 20 cm, remove the bark and other sundries, and cut it into a certain length of wood;

[0055] Step 2: put the cut wood section into a wood drying kiln for drying, the drying temperature is 100°C, the drying time is 60 hours, and the moisture content of the wood section after drying is controlled at 10wt%;

[0056] Step 3: Place the dried wood sections horizontally in the metal tank, fix the wood sections on the surface with iron wires and iron nails, press the weights on the top layer of the stack of wood sections, and mix the water-soluble phenolic resin and water in a volume ratio of Dilute at 1:3, mix thoroughly and pour into the metal tank, the liquid level of the glue should be 20cm higher than the top layer of the wood stack, close the opening of the metal tank;...

Embodiment 3

[0069] A method for processing a solid wood column of a wooden staircase with a pattern, the method comprises the following steps:

[0070] Step 1: Harvesting fresh jujube wood with a diameter of 20cm, removing the bark and other debris, and cutting it into a certain length of wood;

[0071] Step 2: put the cut wood section into a wood drying kiln for drying, the drying temperature is 90°C, the drying time is 90 hours, and the moisture content of the wood section after drying is controlled at 9wt%;

[0072] Step 3: Place the dried wood sections horizontally in the metal tank, fix the wood sections on the surface with iron wires and iron nails, press the weights on the top layer of the stack of wood sections, and mix the water-soluble phenolic resin and water in a volume ratio of Dilute at 1:2.6, mix thoroughly and pour into the metal tank, the liquid level of the glue should be 20cm higher than the top layer of the wood stack, close the opening of the metal tank;

[0073] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com