Decorative thin film and decorative glass

A decorative film and microstructure technology, applied in decorative arts, decorative structures, glass/slag layered products, etc., can solve the problems of difficulty in processing limited glass materials, single effect, high cost, and improve visual uniqueness. The effect of environmental protection in the process and high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

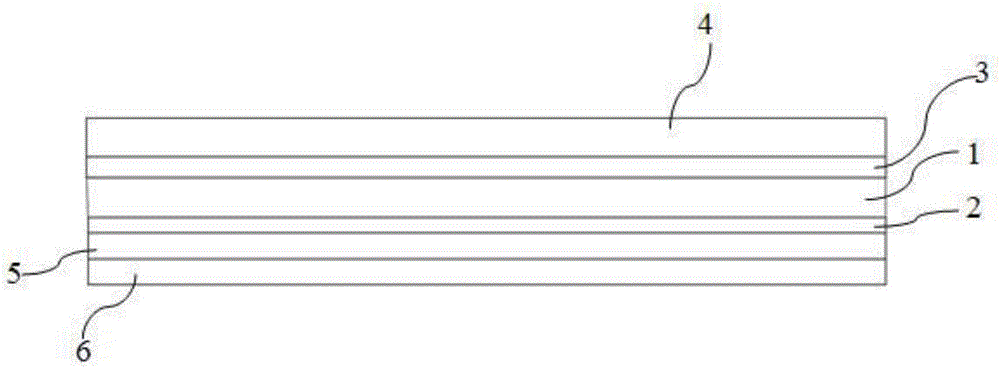

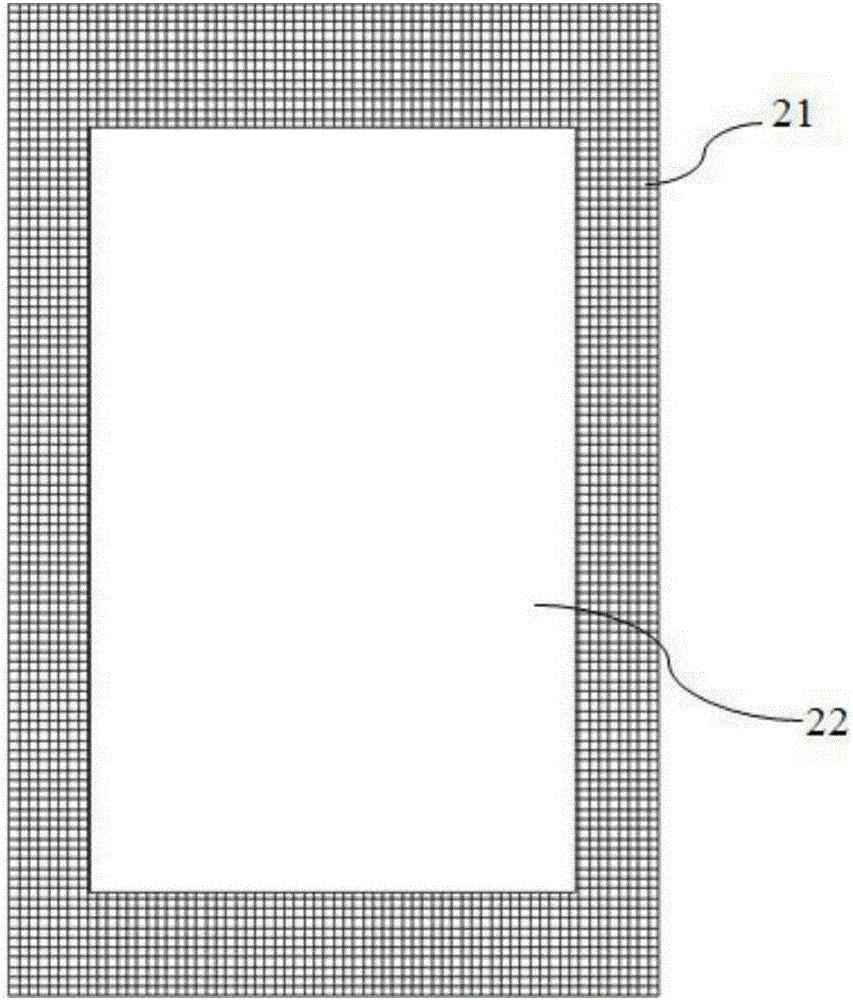

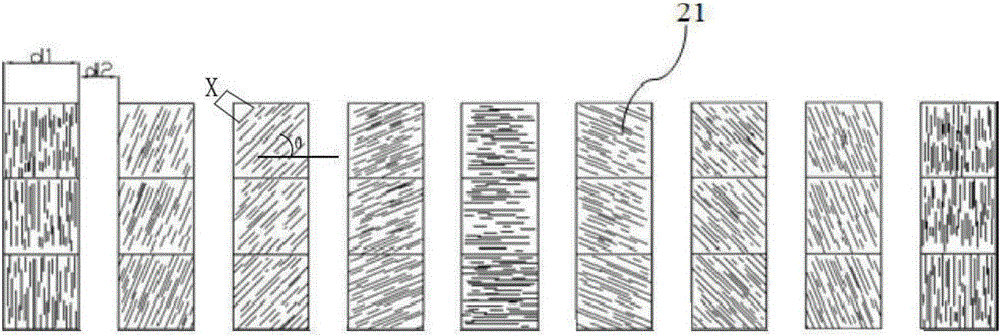

[0033] refer to Figure 1 to Figure 5 As shown, a decorative film of the present invention includes: a substrate layer 1 , a pattern layer 2 and an adhesive layer 3 . The substrate layer 1 is a transparent film layer, and its optical transmittance can be >90%, so as to ensure the overall light transmittance of the film. The pattern layer 2 is arranged on one side of the substrate layer 1, and the adhesive layer 3 is arranged on the substrate layer. 1 On the side away from the pattern layer 2, that is, on the other side of the substrate layer 1 opposite to the pattern layer 2, the adhesive layer 3 may be a transparent glue layer with adhesive properties. A glass layer 4 is arranged on the side of the adhesive layer 3 away from the substrate layer 1 , and the decorative film of the present invention and the glass layer 4 are tightly bonded tog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com