Patents

Literature

97results about How to "Elegant color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

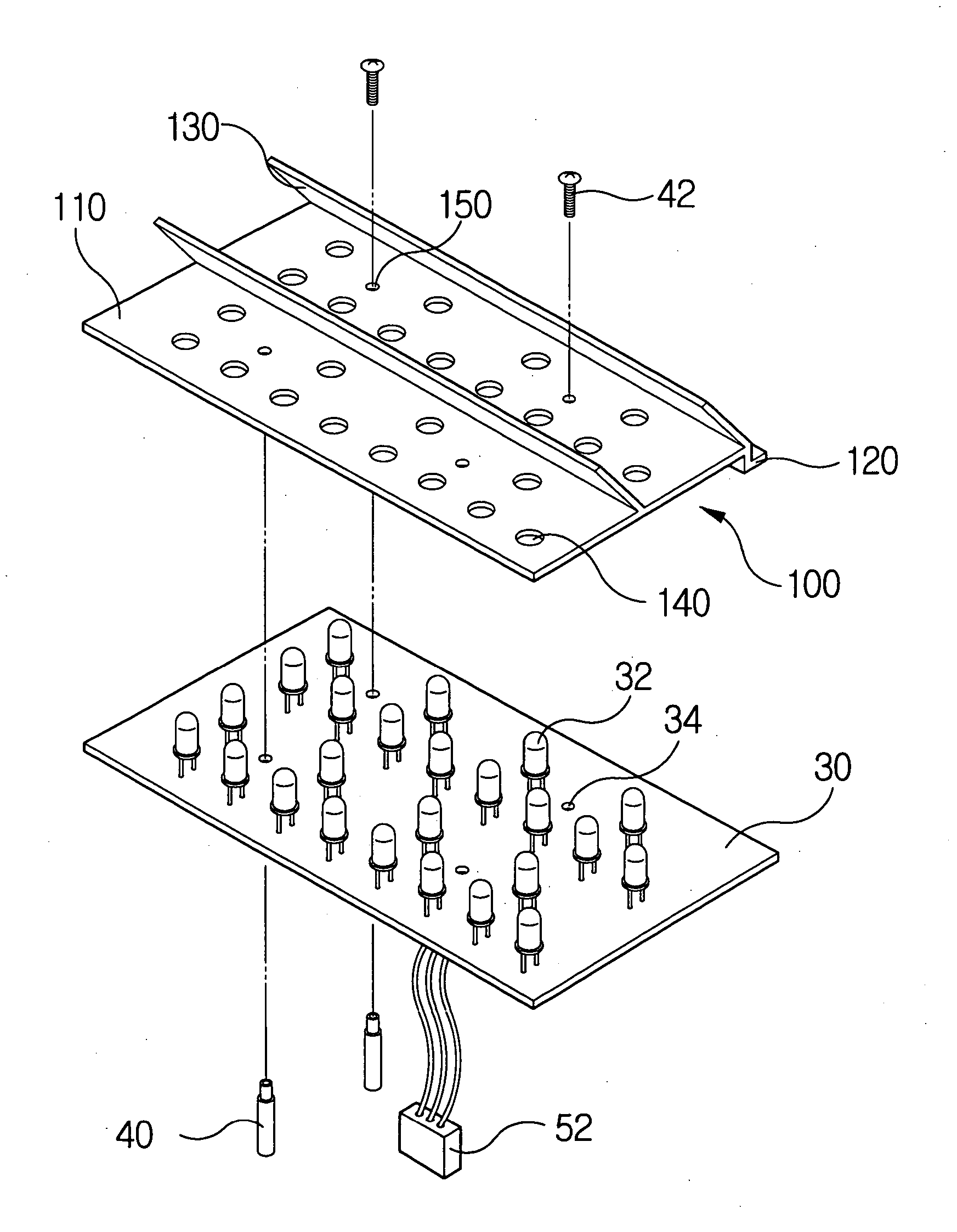

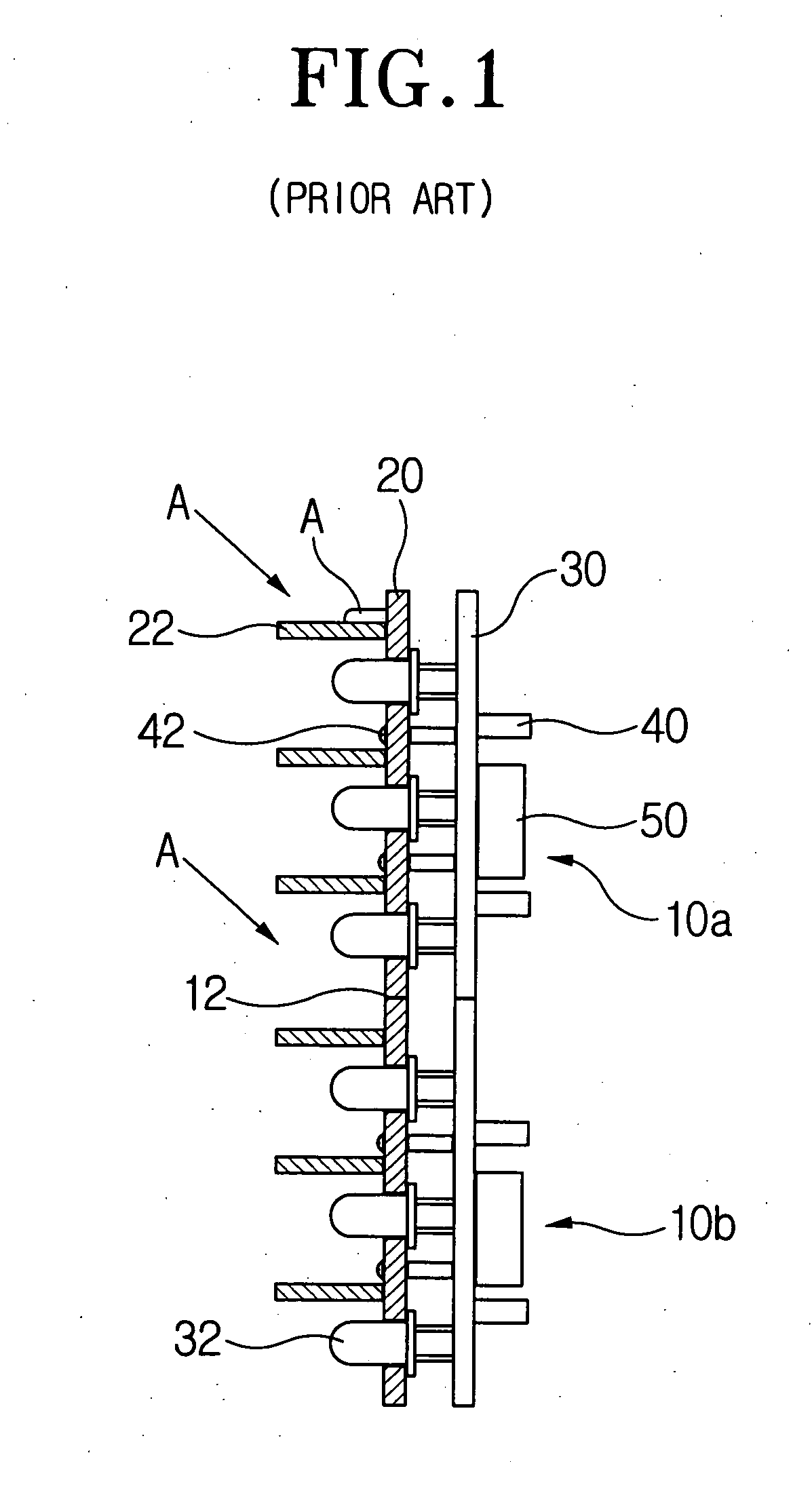

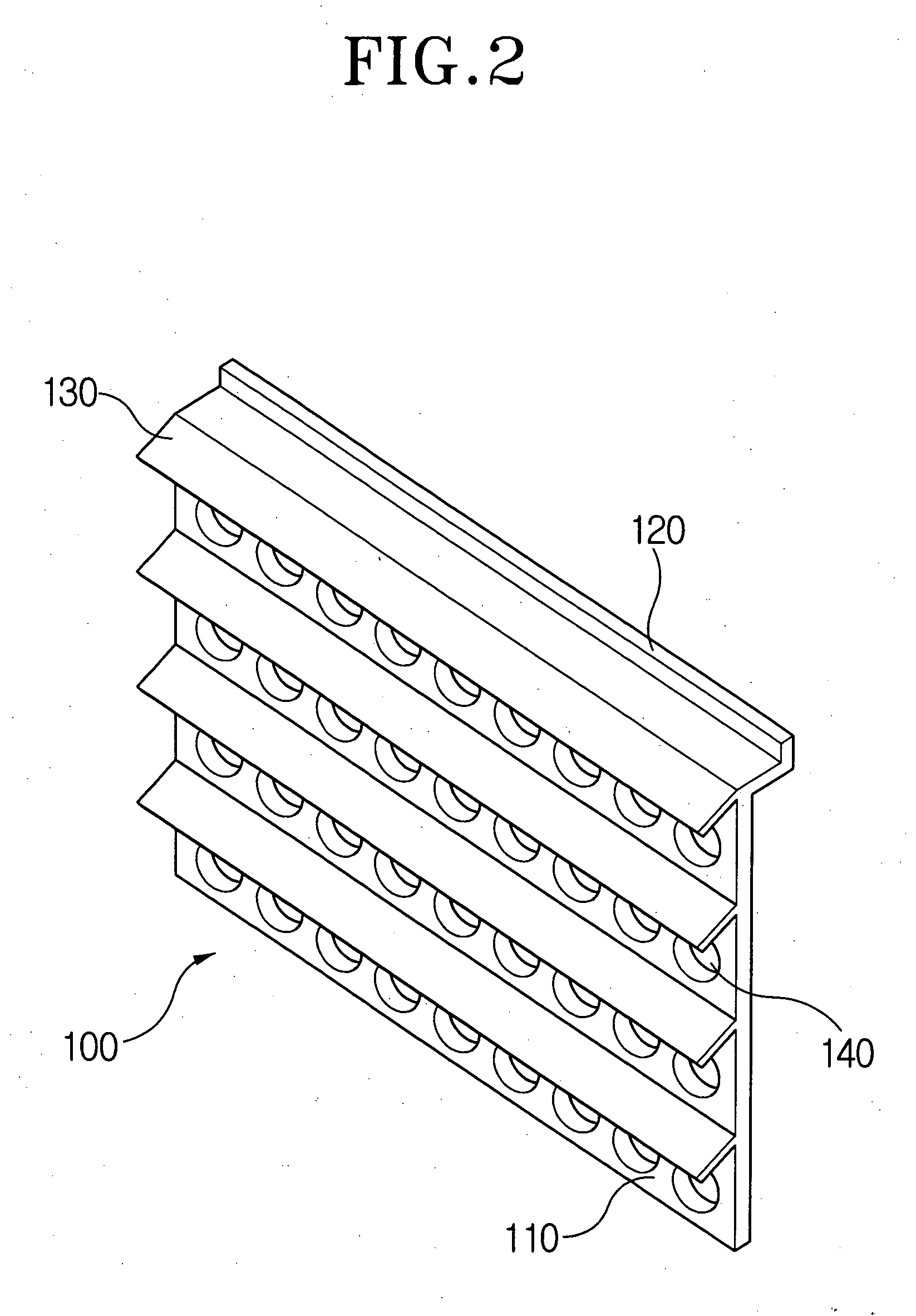

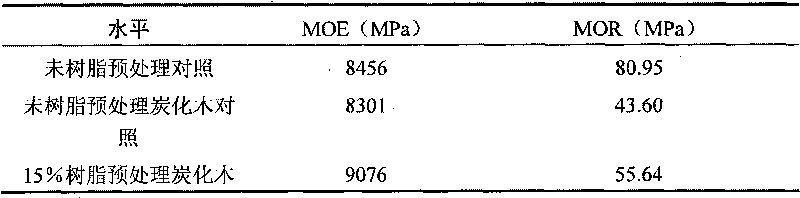

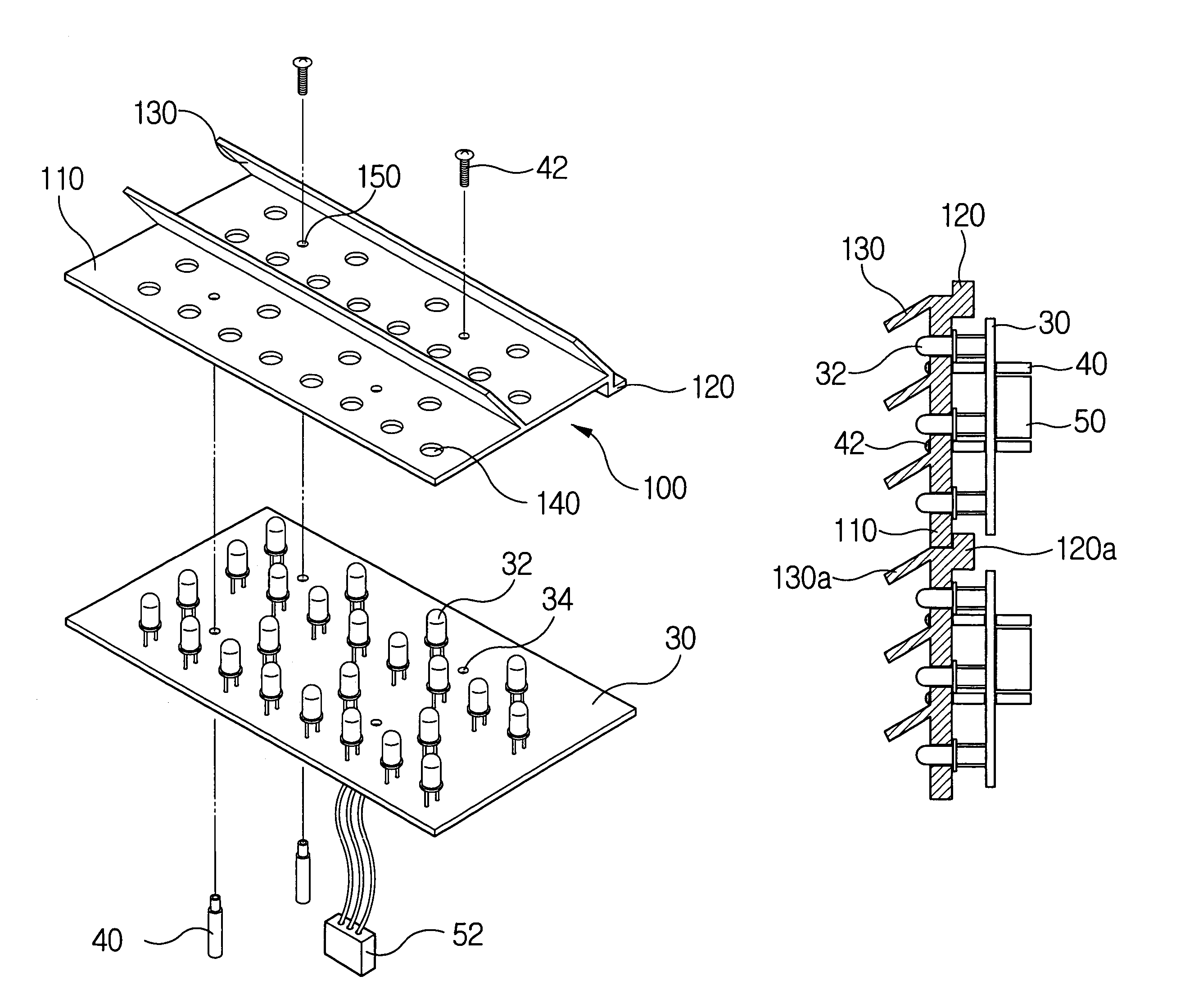

Led fixing device of a pixel module and method for manufacturing the same

InactiveUS20050231949A1Prevent lowering of intensity of lightReduce manufacturing costPlanar light sourcesLighting support devicesEngineeringDriving circuit

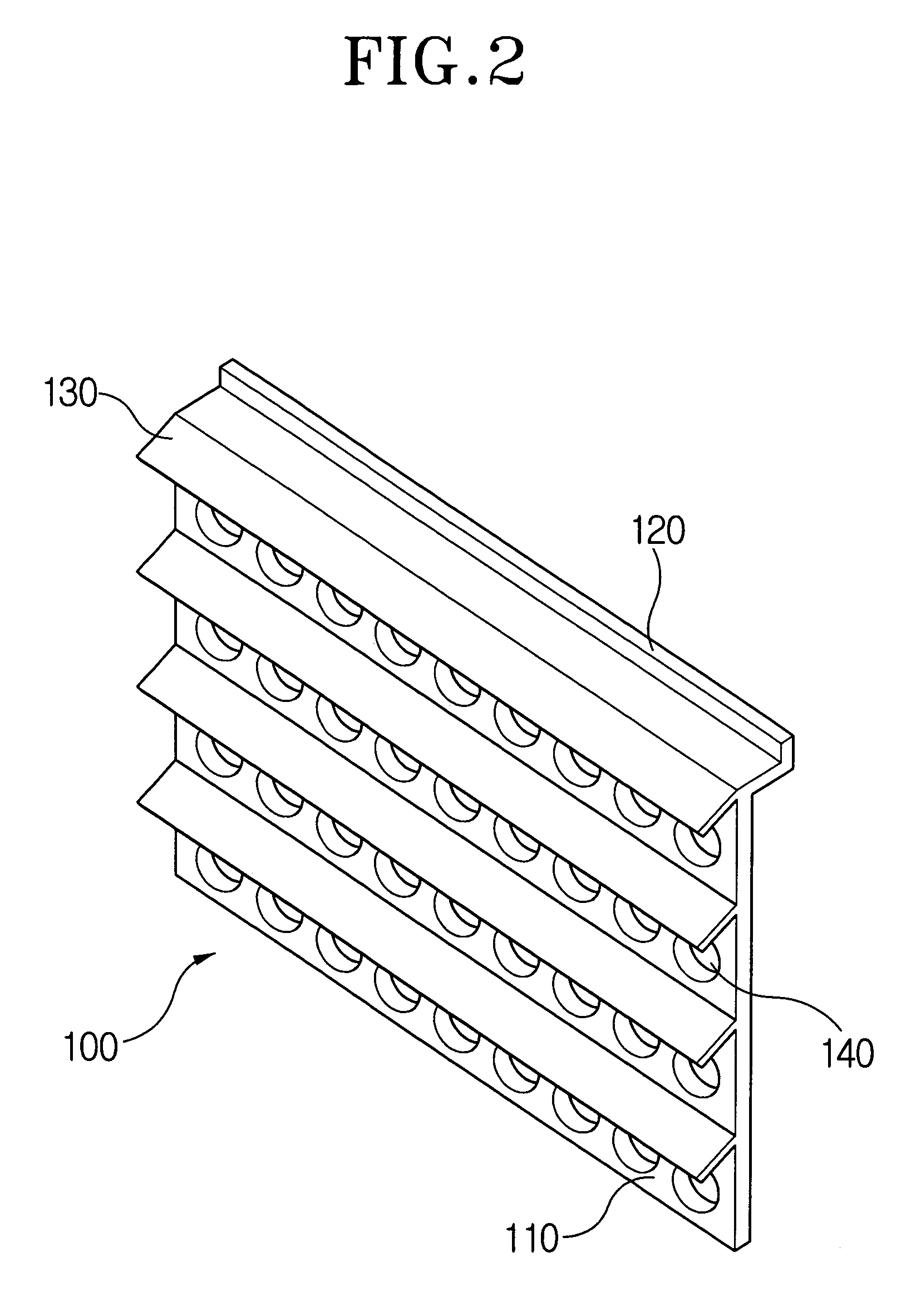

An LED fixing device of a pixel module for a sign board which is installed on the front side of an LED panel of a road sigh board and which facilitates the downward flow of the rainwater and prevents the rainwater from being introduced into a pixel module and a method for manufacturing the LED fixing device. The LED fixing plate comprises a fixing plate which is installed on the front side of a pixel module which comprises an LED driving circuit board into which an LED driving circuit is mounted and a plurality of LEDs which are arranged on the front side of the LED driving circuit board and flickered according to electrical signals and which has a plurality of LED through-holes to fix the LEDs, and at least one intercepting plate which is extended from the front side of the fixing plate to preventing the lowering of intensities of light of LEDs which is generated due to the interference of the sunlight. The method for manufacturing the LED fixing plate comprises the steps of extruding the fixing plate and the intercepting plate through a cavity of a mold integrally and continuously, cutting the integrally and continuously extruded fixing plate and intercepting plate at intervals of a predetermined distance, and punching the LED through-holes for fixing the LEDs in the fixing plate.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH +1

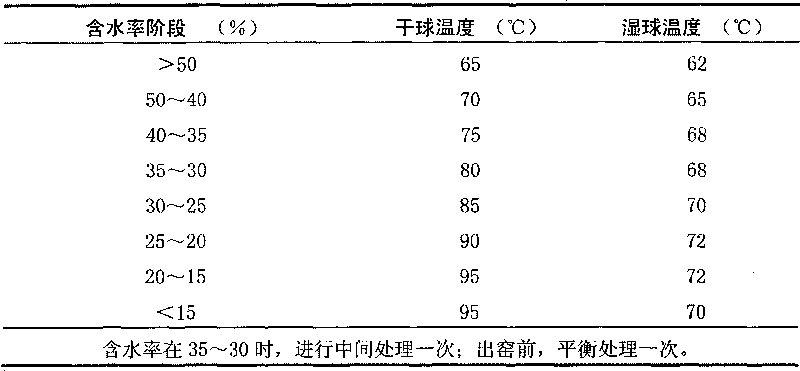

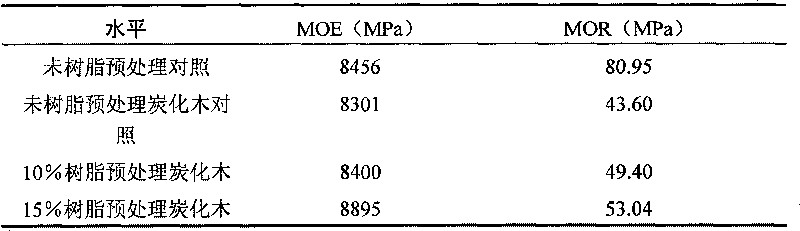

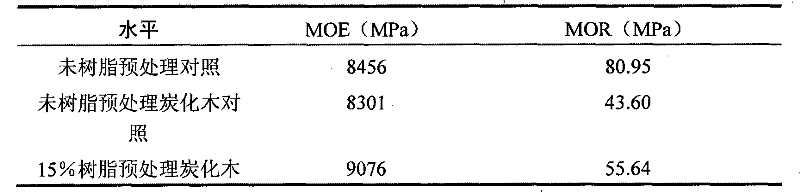

Method for producing rubber tree carbonized wood by resin pretreatment

ActiveCN101716790AHigh strengthIncrease added valuePressure impregnationWood impregnation detailsPulp and paper industryAdditional values

The invention belongs to the technical field of wood modification, in particular relating to a method for producing rubber tree carbonized wood by resin pretreatment. The method comprises the following steps: putting the rubber saw wood of which the water content is less than 15% in a vacuum treatment tank for impregnating; then, stacking and airing the wood, putting the wood in a kiln, routinely drying the wood in the kiln until the water content is less than 12%, and then, taking the wood out of the kiln; and putting the obtained wood in heat treatment equipment for high-temperature heat treatment, and taking the wood out of the kiln to obtain the rubber tree carbonized wood, wherein the water content of the wood is 4-6%. The invention has simple processes, high heating rate in the heat treatment process and high production efficiency, can increase the strength of the rubber tree carbonized wood by vacuum pressurization and impregnation of resin, and can effectively prevent the wood from deforming and cracking in the heat treatment process. The obtained rubber tree carbonized wood has the advantages of little loss of strength of the wood, elegant color, more excellent dimensional stability and durability and the like, and can be widely used for indoor and outdoor floors, landscapes, decorative materials and the like, thereby widening the application field of the rubber tree wood and increasing the additional value of the rubber tree wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

LED fixing device of a pixel module and method for manufacturing the same

InactiveUS7284881B2Reduce manufacturing costImprove productivityPlanar light sourcesLighting support devicesComputer moduleEngineering

An LED fixing device of a pixel module for a sign board is provided. The LED fixing device is installed on a front side of an LED panel of a road sign board, facilitates the downward flow of rainwater, and prevents the rainwater from being introduced into a pixel module. A method for manufacturing the LED fixing device is also provided. The method for manufacturing the LED fixing plate comprises the steps of extruding the fixing plate and the intercepting plate through a cavity of a mold integrally and continuously, cutting the integrally and continuously extruded fixing plate and intercepting plate at intervals of a predetermined distance, and punching the LED through-holes for fixing the LEDs in the fixing plate.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH +1

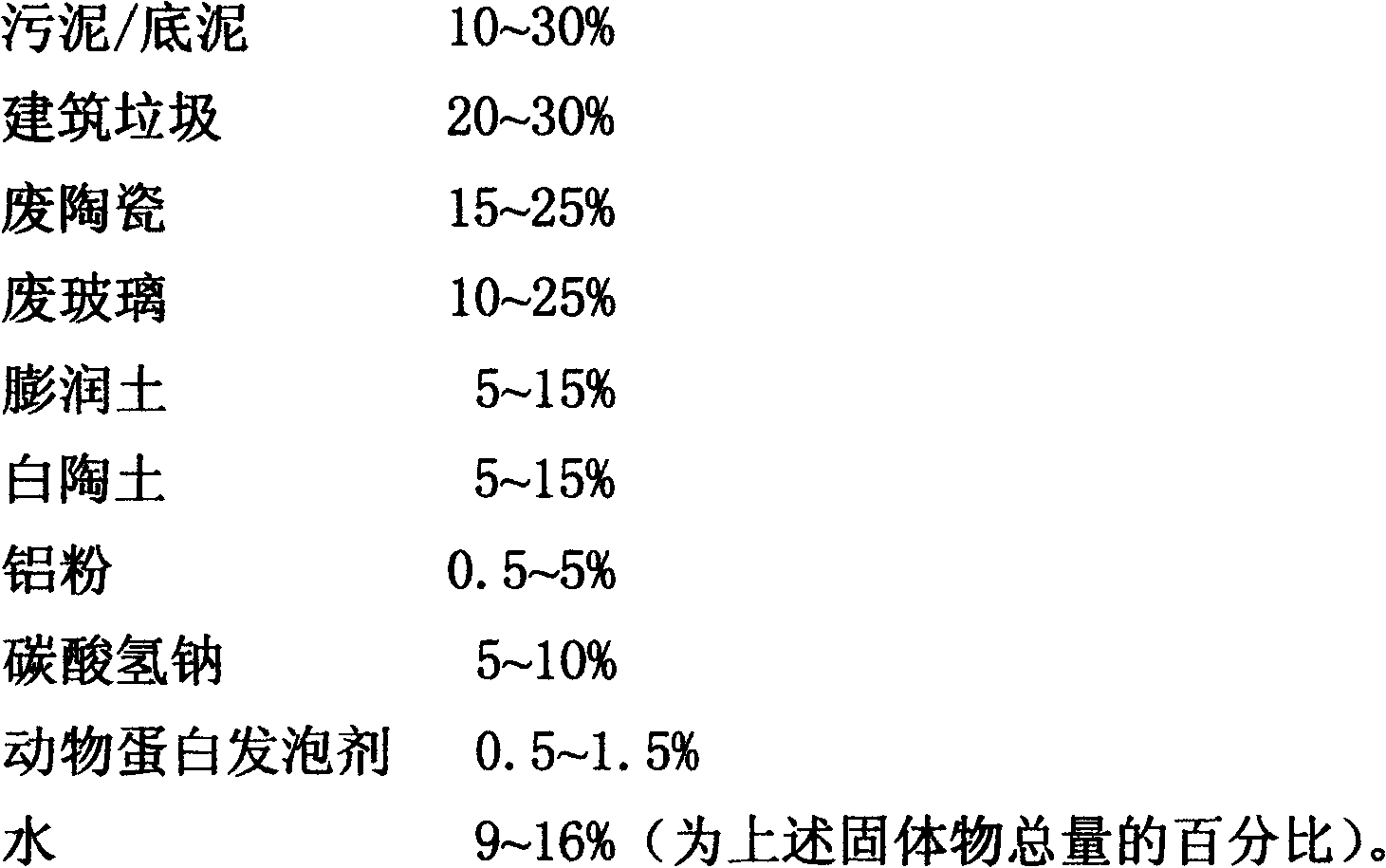

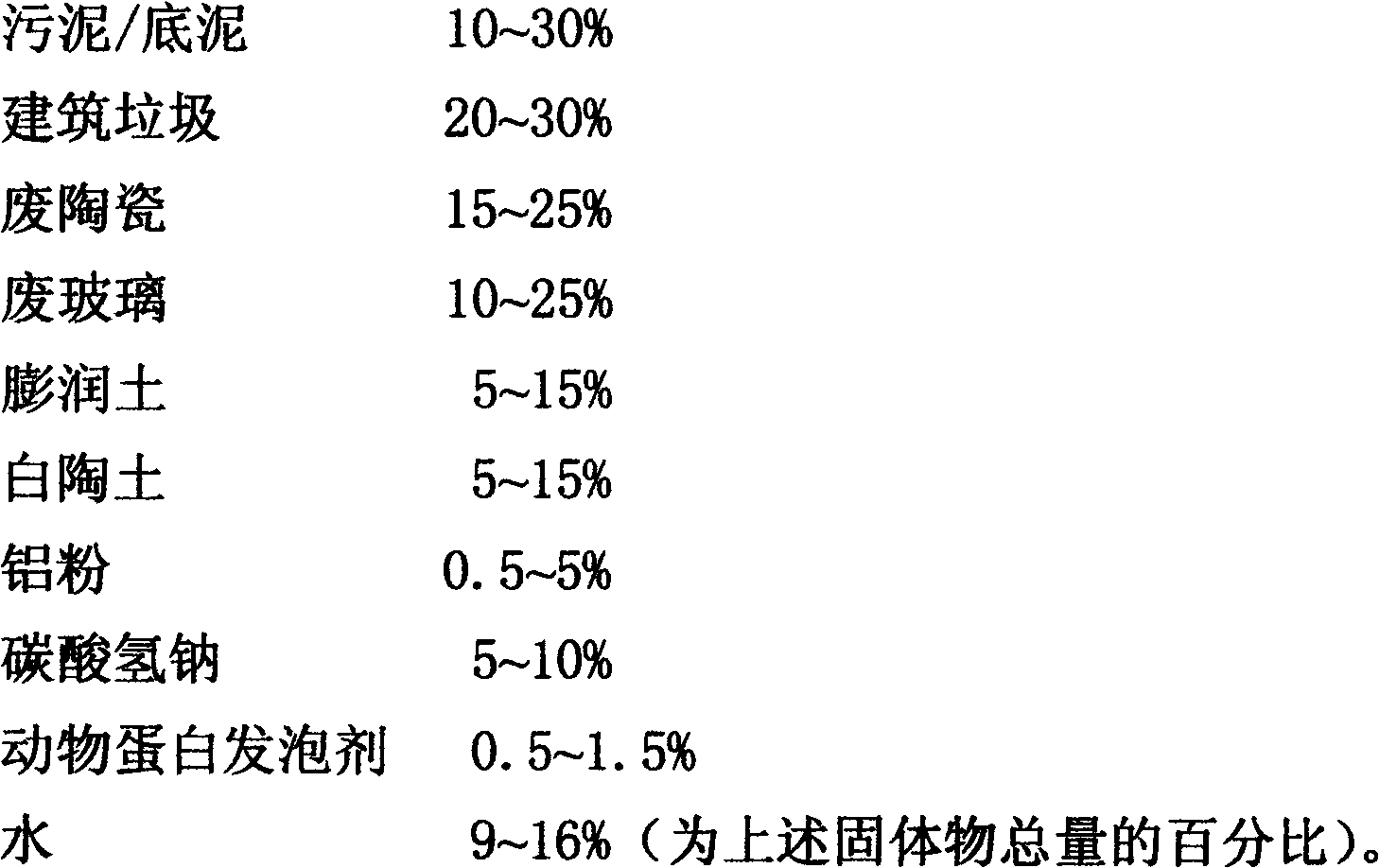

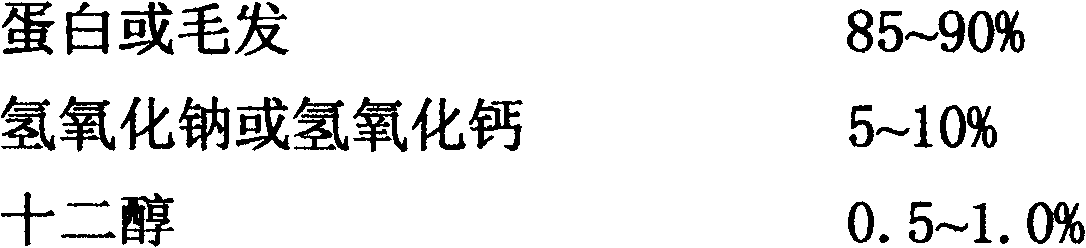

High-strength light foam ceramic plate and manufacturing method thereof

InactiveCN102627469AEasy accessLow priceConstruction waste recoverySolid waste disposalEnvironmental resistanceSodium bicarbonate

The invention discloses a high-strength light foam ceramic plate and a manufacturing method thereof, and belongs to the field of building material manufacturing. The ceramic plate comprises the following materials in percentage by weight: 10-30 percent of sludge / bottom mud, 20-30 percent of building waste, 15-25 percent of waste ceramic, 10-25 percent of waste glass, 5-15 percent of bentonite, 5-15 percent of kaolin, 0.5-5 percent of aluminum powder, 5-10 percent of sodium bicarbonate, 0.5-1.5 percent of animal albumen foaming agent and 9-16 percent (percentage of total amount of the solid matters) of water. The manufacturing method comprises the following steps of: mixing and crushing the main raw material; adding the animal albumen foaming agent and water; granulating; filling a granular material into a refractory combined mould; leveling; filling in a kiln; firing; and performing cold processing to produce a ceramic plate finished product. The high-strength light foam ceramic plate has the advantages of high product strength, small volume weight, fire proofing, excellent freeze proofing, long-term water proofing, readily available main raw material which basically comes from environmental solid waste, has a wide source and is low in cost and adoption of the animal albumen foaming agent of small using amount and wide source; the manufacturing process has the advantages of simplicity, high efficiency, energy conservation, environmental friendliness, no secondary pollution; and the high-strength light foam ceramic plate can be used as thermal insulation decorative materials, fire barriers and the like of exterior walls of buildings.

Owner:SICHUAN UNIV

Refrigerator deodorant and preparation method thereof

InactiveCN101879320AEffective chemical deodorizationEffective AntibacterialDeodrantsChemical industryRefrigerated temperature

The invention belongs to the field of the chemical industry, and discloses a refrigerator deodorant and a preparation method thereof. The refrigerator deodorant comprises pomelo peel essential oil, and the pomelo peel essential oil is prepared through the following method: pomelo peel is dried and smashed into pomelo peel powder; the pomelo peel powder is mixed with water according to the mass ratio of 1: 10 to 1: 15 and to be heated and extracted for 3 to 4 hours through refluxing to obtain the pomelo peel essential oil. The refrigerator deodorant also comprises gycol, polyvinyl alcohol, super absorbent resin, citric acid, sodium benzoate and carboxymethyl cellulose activator; or also comprises pomelo peel pectine, tartaric acid and ferrous sulfate; and also comprises beta-cyclodextrin. Chemical compositions of refrigerator deodorant can be reacted with bad-smelly gas. In the refrigerator, the essential oil also can inhibit the growth of bacteria so as to prevent the odor on the source; and at the same time, the refrigerator deodorant is safe and toxic-free, can be reacted at low temperature, and is applicable to the refrigerator environment.

Owner:SOUTH CHINA AGRI UNIV

Production process of flannel mould color burnt-out blanket

ActiveCN103385626AUse resource spaceLow costSucessive textile treatmentsBlanketEngineeringBurning out

The invention relates to a production process of a flannel mould color burnt-out blanket. The production process comprises the steps of raw material selection, weaving, printing pretreatment, printing and aftertreatment. The production process has the beneficial effects that the process is transferred to a circular screen printer to be operated, so that the resource space of a factory is greatly utilized, the cost is reduced, and the register is preciser; the traditional acidic burnt-out mode is broken through, alkaline burnt-out is adopted, so that the burnt-out variety is increased, and the diversity of the market is enriched; and the flannel burnt-out blanket integrates the characteristics of a burnt-out processing process and a foam printing process in unique styles of elegant and novel appearance, soft and smooth handfeel, graceful pendency and beautiful color, and forms cavities by a burnt-out process, and the phenomenon of sloughing or wadding loosing in the washing process can be prevented by the foam printing process after the cavities are formed.

Owner:ZHEJIANG TRUELOVE GROUP

Composite bamboo shoot fermenting agent and preparation method of fermented bamboo shoots

InactiveCN101999450AAppropriate proportionLow alcoholFruits/vegetable preservation using acidsFlavorAlcohol

The invention discloses a composite bamboo shoot fermenting agent and a preparation method of fermented bamboo shoots. The composite bamboo shoot fermenting agent contains monascus vinasse and liqueur koji. The preparation method of the fermented bamboo shoots comprises the following steps of: firstly, blanching bamboo shoots; and then, fermenting the bamboo shoots under the action of the composite bamboo shoot fermenting agent. Under the action of the composite bamboo shoot fermenting agent, aromatic substances, pigments, and the like in the vinasse are infiltrated in the bamboo shoot tissues. The prepared vinasse-processed bamboo shoots have the characteristics of unique fragrance and flavor, mellow and pleasant taste, elegant flavor, attractive color and rich nutrition. The preparation method can effectively prevent fresh bamboo shoots from aging, lessen the loss of nutrient contents, preserve the nutrient contents of the bamboo shoots and ensure the quality and the grade of the bamboo shoots. The fermented bamboo shoots prepared by using the method disclosed by the invention have appropriate proportions of liquor, sugar and acid, and have the advantages of low alcohol and sugar contents, stable resistance to acid and alkali, strong heat resistance and light resistance, stable resistance to oxidoreduction and favorable practical values and application prospects.

Owner:健盛食品股份有限公司

Scented tea of red-rooted salvia root

The invention relates to a scented tea of red-rooted salvia root made by adopting the whole red-rooted salvia flower. In the invention, red-rooted salvia buds picked in morning are taken as raw material, and are subject to airing in the shadow, enzyme killing, twisting, baking, sieving and other production procedures to produce a product; the product has the characteristics of light and elegant color of the tea soup, little bitter and sweet taste, pure and lofty and lasting scent, and cool, refreshing and tasty flavor. Body function of a drinker can be continuously adjusted in the process of drinking tea, thus achieving the effects of adjusting blood pressure, reducing blood fat and blood sugar, protecting blood vessels of heart and brain, eliminating fatigue, enhancing immunity, promoting appetite and sleep quality.

Owner:SHANGLUO CITY DANNONG BIOTECH DEV

Planting method for Afric lilium

InactiveCN101228825AElegant colorImprove cold resistanceCultivating equipmentsSoilless cultivationWarm waterLilium

The invention discloses a planting method for an African lily, which is characterized in that: the planting method is as follows: a. seed screening: the conditions for seed screening are that the seeds are full, of high maturity and of no impurities; b. immersion: immersing the screened seeds in a liquid of potassium permanganate of 0.03 percent to 0.07 percent for 20 to 40 minutes; c. cleaning: cleaning the seeds immersed in the liquid of potassium permanganate repetitively with clean water; d. immersing with warm water: immersing the cleaned seeds in warm water of 30 DEG C to 50 DEG C for 12 to 24 hours; e. media sowing: the media is mixed with soddy soil and perlite, and is then sown after spraying with enough water with shallow soil cover, which is followed up with soft flapping; the sewing temperature can be controlled between 18 to 21 DEG C; f. sprouting; g. seedling transplanting: transplanting the seedlings after the sprouts grow into seedling with a height of 4 to 6cm; h. field planting: when the seedling is as high as 13-18cm, field planting can be carried out; the invention has the characteristics of easy nursing and extensive managing.

Owner:薛麒麟

Color bamboo and timber processing method

InactiveCN102909766AHigh pigment contentImprove thermal stabilityWood treatment detailsStainingLacquer

A color bamboo and timber processing method comprises extraction of blueberry leaf dyeing liquid, mixing of staining liquids, dyeing of bamboo and timber, natural airing and the like. The color bamboo and timber processing method comprises the following steps: plant staining liquids extracted from blueberry leaves are non-toxic, have medicinal values, are natual and environmental-friendly staining liquids, are high in pigment content, are dark red or purplish red, and are light-resistant and high in heat stability; the bamboo and the timber deyed by the blueberry leaf dyeing liquid can permeate into the interior of a material, so that the material is consistent in internal appearnce and external appearnce, and natural in color; furniture made of the bamboo and the timber deyed according to the method is dark red or purple red, is more noble and elegant in color after being polished and varinished, can even achieve the effect of immitating padauk furniture, and meanwhile, can overcome the defect of paint fading, so that the paint surface is not faded when being touched, and remains consistent with the original paint surface after paint repair.

Owner:江西飞宇竹材股份有限公司

Natural organic green tea clean-production technology

ActiveCN103988921AImprove inner qualityAchieve refinementPre-extraction tea treatmentCooking & bakingBlood pressure

The invention relates to a natural organic green tea clean-production technology. The natural organic green tea clean-production technology utilizes green tea leaves as making raw materials and the used green tea leaves grow in an organic tea garden and are picked in the spring and summer. The natural organic green tea clean-production technology comprises fresh green tea selection, fresh tea grading tedding, de-enzyming, spreading cooling, winnowing, rolling, deblocking sieving, primary baking, tea strip tidying and shaping, re-baking, autoclaving fragrance-improvement, inspection classification and packaging. The natural organic green tea obtained by the technology has the characteristics of light and elegant tea soup color, sweet tea taste, fresh and lasting fragrance, abundant nutrition and good health care effects, can continuously adjust human body functions, adjust blood pressure, reduce blood fat, prevent cardiovascular diseases, protect heart and cerebral vessels, eliminate fatigue and improve immunity by being drunk by drinkers and is a good health beverage suitable for people of all ages.

Owner:柞水福青山茶文化有限公司

Electroplating method for flowers and tree leaves

InactiveCN1524978AGood conductive surface layerDoes not damage surface tissueElectrolytic organic material coatingChemical platingPalladium chloride

The invention provides a plating method for flowers and leaves comprising the steps of, cleaning with water to remove dirt in the gas cavity, immersing the pretreated flowers and leaves into solution containing tin chloride 8-12 g / l and chlorhydric acid 8-12 ml / l, for chemical plating, cleaning with water, immersing into water solution containing palladium chloride 0.15-0.25 g / l and chlorhydric acid 2-3 ml / l for surface activating treatment, then placing into solution containing nickel sulfate 25-0.25 g / l, sodium citrate 25-35 g / l, and ammonium chloride 45-55 / l, regulating pH to 10-11 of chemical nickel plating solution through ammonia for chemical plating of nickel, rhodium and other noble metal to obtain the final ornament.

Owner:夏红元

Method for dyeing modified cellulose fabrics by green walnut epicarp pigment

InactiveCN102644204ASimple dyeing processImprove dye uptakeDry-cleaning apparatus for textilesNatural dyesColour fastnessModified cellulose

A method for dyeing modified cellulose fabrics by green walnut epicarp pigment includes following steps of dyeing green walnut epicarp pigment dyeing extract liquor on the modified cellulose fabrics; and soaping, washing and drying after dyeing, washing and drying the modified cellulose fabrics by a direct dyeing process. The method is simple and easy in process, does not need mordant dyeing fixation and the like, is high in dyeing efficiency, fine in dyeing quality, free of toxin and pollution, low in cost and remarkable in economic and environment benefits, and has high friction resisting color fastness and washing resisting color fastness which are higher than four levels.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Low-concentration bamboo leaf health-care wine with wine flavor and preparation method thereof

The invention discloses a low-concentration bamboo leaf health-care wine with a wine flavor and a preparation method thereof. By using the extraction action of low-concentration ethanol in the wine, no large effect is generated when effective constituents of the bamboo leaves and the traditional Chinese medicinal materials are fully dissolved into the wine; abundant flavor and taste of the health-care wine are endowed by unique flavor substances of the wine and the bamboo leaves, so that the health-care wine disclosed by the invention not only has the effects of life cultivation and health preservation, and body building, but also is a drink which is pleasant to enter the mouth.

Owner:GUANGXI UNIV +1

Processing method for knitted garment having heather nostalgia style

ActiveCN102943362AEvenly distributedElegant colorFibre treatmentHeating/cooling textile fabricsProduct inspectionSize change

The present invention discloses a processing method for a knitted garment having a heather nostalgia style. The processing method is characterized in that a pure cotton heather knitted fabric is weaved, a setting machine stentering and pre-shrinking drying process is added in the traditional post-finishing process of the pure cotton heather knitted fabric, the fabric is sequentially subjected to processes of resin styling and garment dyeing, and the whole processing process sequentially comprises the following concrete steps: knitting, ??washing, ??dehydration, wet width opening, setting machine stentering, pre-shrinking drying, resin styling, fabric finished product inspection, garment manufacturing, ?garment dyeing, a soft finishing, dehydration and drying. The processing method has the following advantages that: the pure cotton knitted garment processed by the method has a small size change, the dyed garment has characteristics of stable quality, simple, elegant and soft fabric color and unique appearance, and has a heather nostalgia style, and the garment style is well enriched, such that consumers have more choices in leisure nostalgic clothing.

Owner:SHENGZHOU SHENGTAI KNITTING

Fancy glaze and method for manufacturing same

The invention discloses a fancy glaze and a preparation method thereof. The weight percentages of each component of the fancy glaze are 18 percent to 38 percent of potassium feldspar, 10 percent to 23 percent of calcite, 4 percent to 7 percent of talc, 3 percent to 7 percent of quartz, 4 percent to 10 percent of zirconium silicate, 2 percent to 5 percent of zinc oxide, 5 percent to 10 percent of alumina, 3 percent to 6 percent of barium carbonate, 6 percent to 10 percent of black mud, 0 percent to 0.3 percent of tripolyphosphate, 6 percent to 20 percent of water, 0 percent to 10 percent of squeegee oil and 0 percent to 10 percent of printing paste. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is 100 percent. The technical process of the method of manufacturing the fancy glaze is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature is 1195 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the glaze surface is smooth; the sintering temperature range is wide; the chromatic aberration can not be produced easily; the finished product rate is high; the cost can be reduced by about 40 percent.

Owner:清远市欧雅陶瓷有限公司

Pickles fermented in bamboo tube and preparation method thereof

InactiveCN104026521AEliminate bitternessElegant colorClimate change adaptationFood preparationFood flavorFermentation

The invention optimizes a preparation technology and a formula of pickles. A moso bamboo is used as a fermentation container of the pickles, in the fermentation process, the fermentation liquid of the pickles fully comes into contact with the bamboo tube, and the flavor substances of the moso bamboo is merged with the fermentation liquid of the pickles, so that bitter and astringent tastes of the pickles after fermentation are removed, the color and the luster of the pickles are simple and elegant, and the mouth feel of the pickles is rich, fragrant and pure; after the pickles are eaten, fragrance is remained in a mouth, and aftertastes are endless.

Owner:GUANGXI UNIV +1

Production method for carbonized wood finger-joint floor

InactiveCN103252817AIncrease profitImprove stabilityWood treatment detailsWood charring/burningFinger jointCarbonization

The invention relates to a production method for a carbonized wood finger-joint floor. Small-specification converted timbers are placed into a vacuum treating cylinder in a stacked mode, pressurization and impregnation are achieved to carry out insect prevention and termite prevention treatment, then the converted timbers are placed into carbonization equipment in a stacked mode, high-temperature drying and carbonization treatment are carried out, and the converted timbers are unloaded; then finger joint and width splicing are carried out on the converted timbers after life nourishing and moisture regaining, finger-joint floor blanks are obtained, mortise forming, painting, packaging are carried out on the finger-joint floor blanks, and then the finger-joint floor blanks are put into storage. According to the production method, a process of direct carbonization after the high-temperature drying is adopted, small-specification wood is converted into the floor blanks through the insect prevention, the carbonization and the finger joint, the drying and the carbonization are completed at a time, treating time is reduced, energy consumption is reduced, an obtained carbonization finger-joint floor combines two technologies, namely the carbonization and the finger joint, for improving stability of the wood, and meanwhile the appearance of tropic hard wood is given to fast growing wood; the floor has the advantages of being low in cost, good in stability of products, resistant to insects and termites and elegant in color, and has positive roles in improving the wood comprehensive utilization rate and popularizing wood carbonization techniques.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

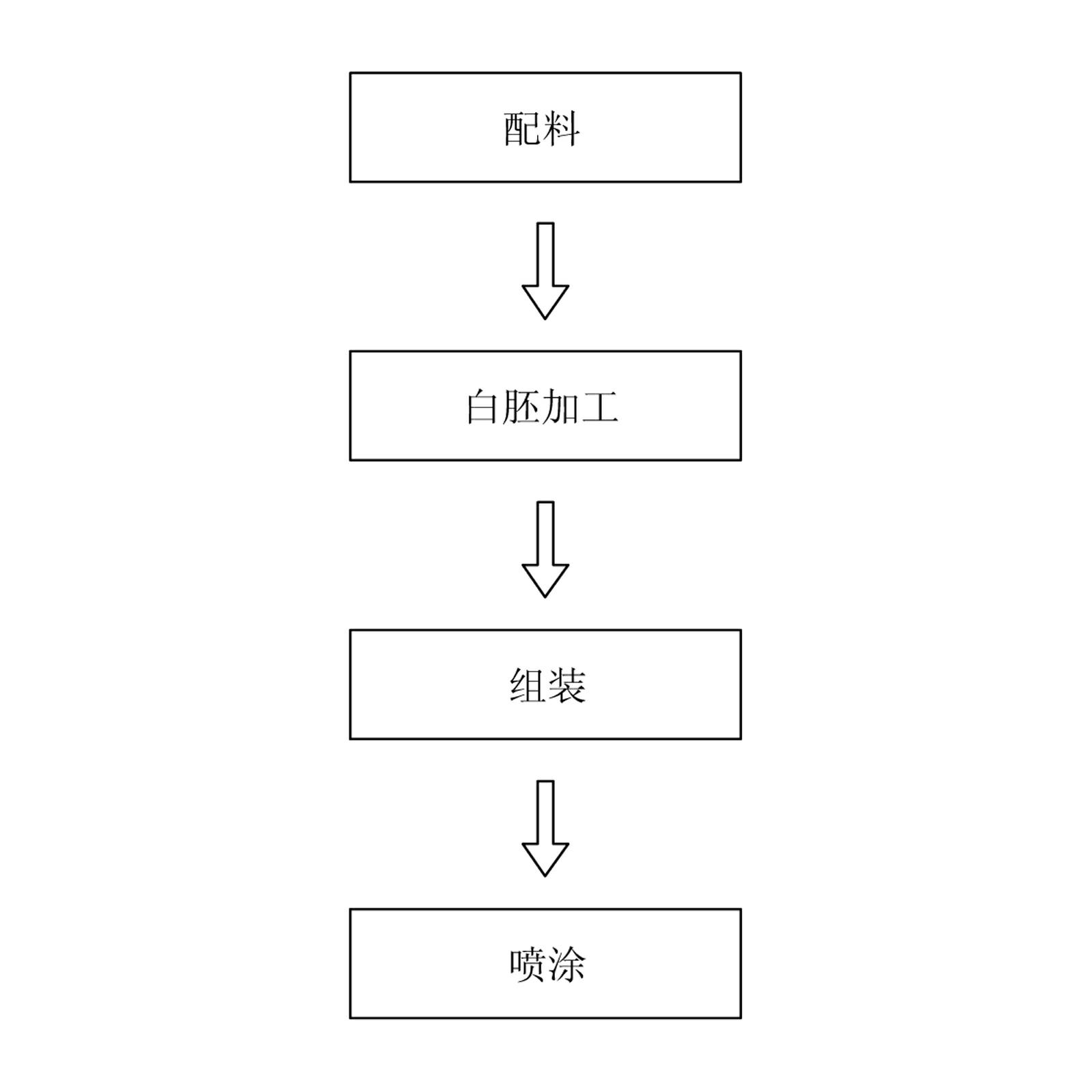

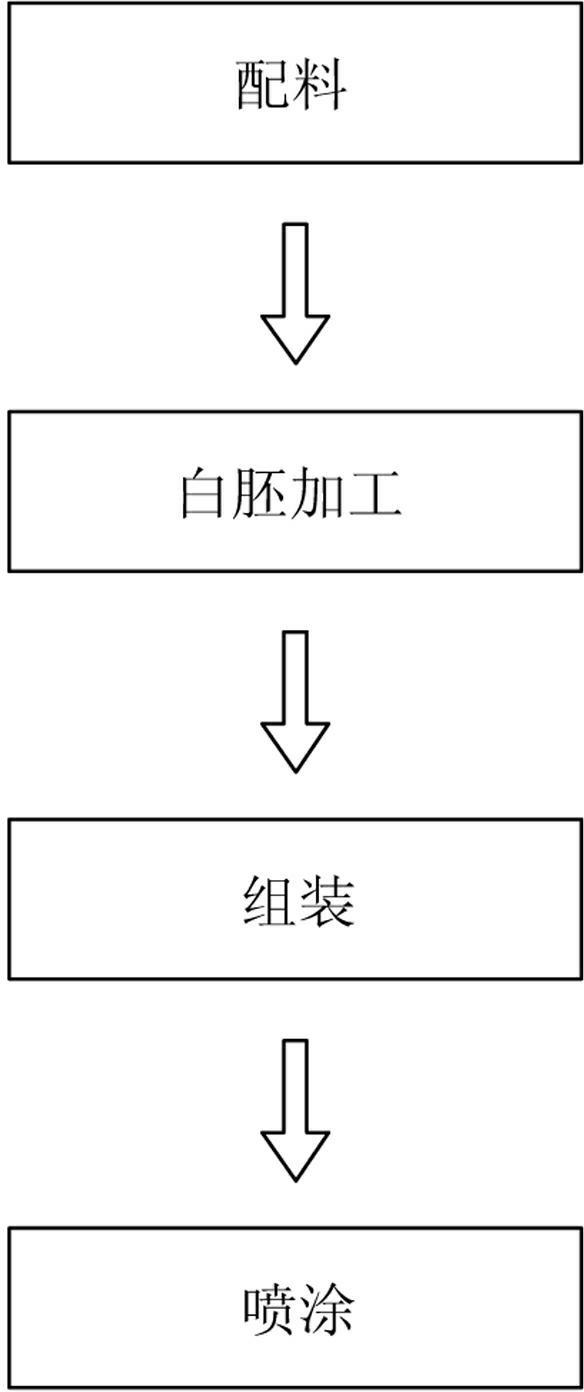

Method for producing and processing anti-pollution wooden door

InactiveCN102179852AHigh hardnessImprove scratch resistanceLiquid surface applicatorsWood working apparatusPositive pressureBlock effect

The invention discloses a method for producing and processing an anti-pollution wooden door. The method mainly comprises four steps of mixing, blank processing, assembly and spraying, wherein in the spraying step, the wooden door is sprayed by using a three-bottom-two-side positive pressure spraying process. By adoption of polyurethane (PU) finishing paint, the wooden door produced by the method has extremely high hardness, scratch resistance, chemical resistance, corrosion resistance, temperature stability, cleanability and blocking effects, so the wooden door is difficult to contaminate and easy to clean.

Owner:施雁鸣

Method for preparing persimmon leaf tea

InactiveCN101095446ACollection uniqueQuality improvementTea substituesFood preparationWater immersionCosmetic appearance

The invention relates to a method for preparing persimmon leaf tea, comprising persimmon leaf collecting, removing stalk, rolling and softening, frying and fumigating and drying. The persimmon leaf is picked from wild dwarf persimmon tree, and the picking time is from March to June, and the picked leaves should be not infected by disease, insects and pesticides, and should be fresh. The stalking elimination process is to remove stalk, burrs and harmful substance from persimmon leaves to ensure a bright outlook. The frying and fumigating is combined with inactivation and disinfection, which saves inactivation with hot water and cold water immersion processes, and prevents chlorophyl and vitamin from damage and loss. The invention is characterized by simple process, great amount of retained natural nutritional components, light color, fragrant and good taste.

Owner:何葵

Floor production process

InactiveCN101623890AFlame retardantMoisture-proofPolishing machinesLayered productsBiochemical engineeringRabbet

The invention provides a floor production process with low cost and simple working procedure, which comprises the following steps: by using a rabbet model, extruding a floor with rabbets at two sides by using an extruder; making rabbets at other two opposite sides of the extruded floor by using a double-head notching machine; printing patterns containing textures on the surface of the floor; and finally adhering an abrasion-resistant layer to the surface of the floor.

Owner:余弟昌

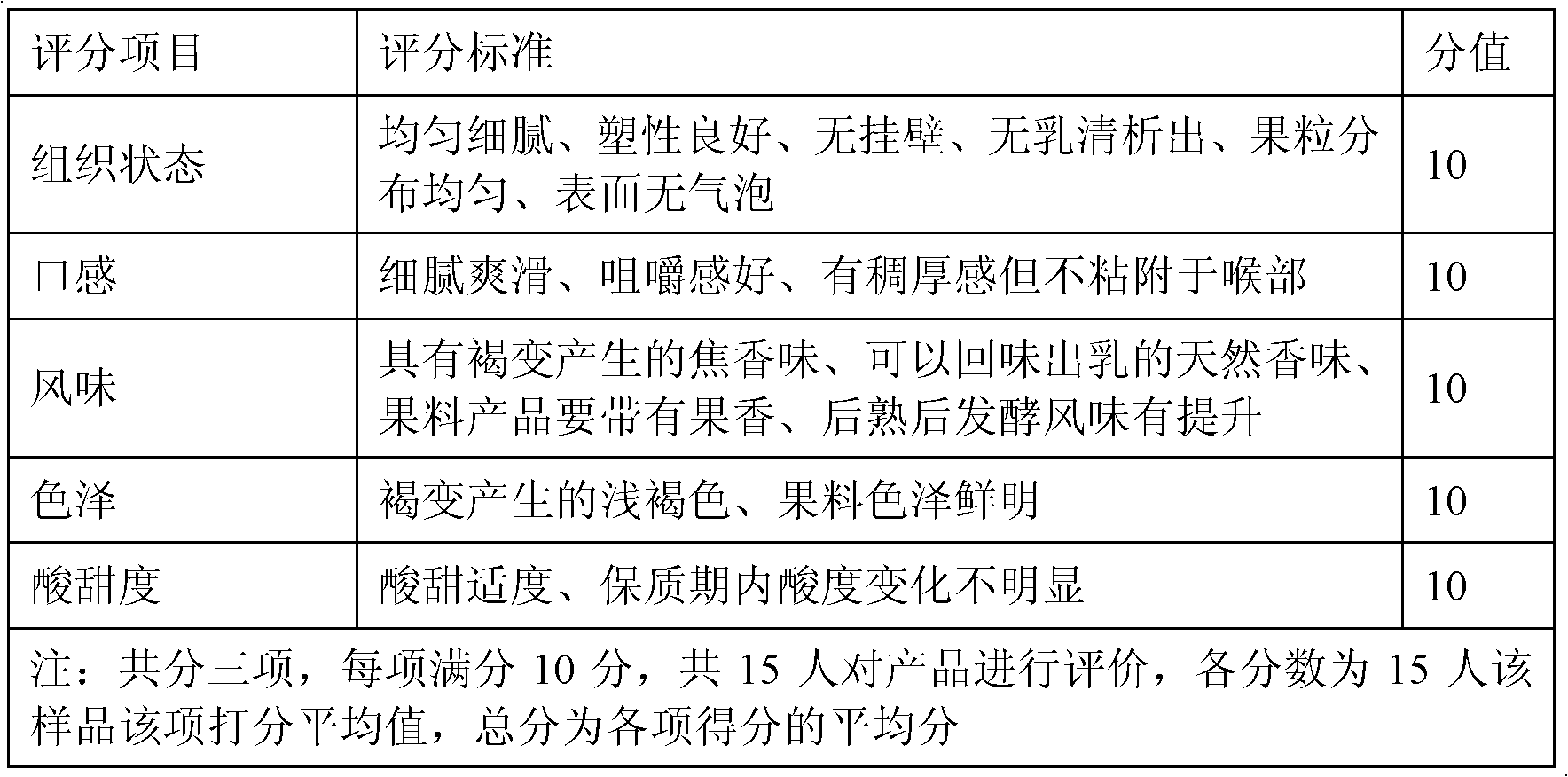

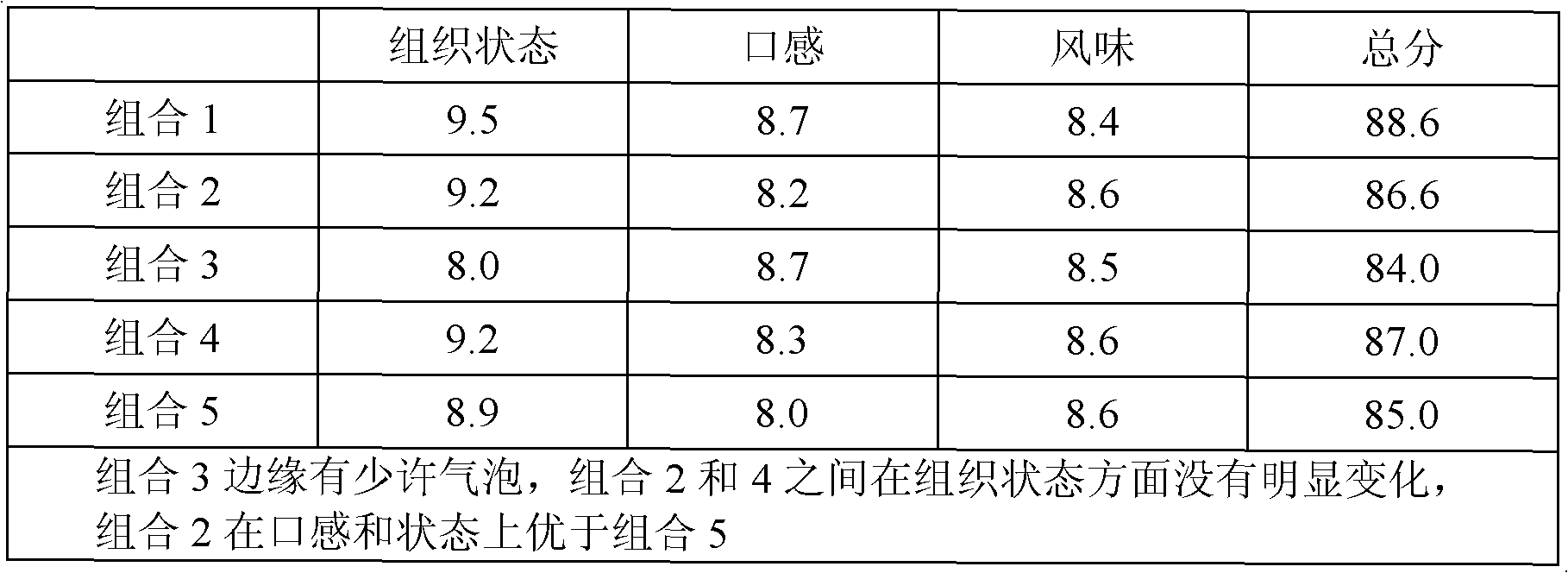

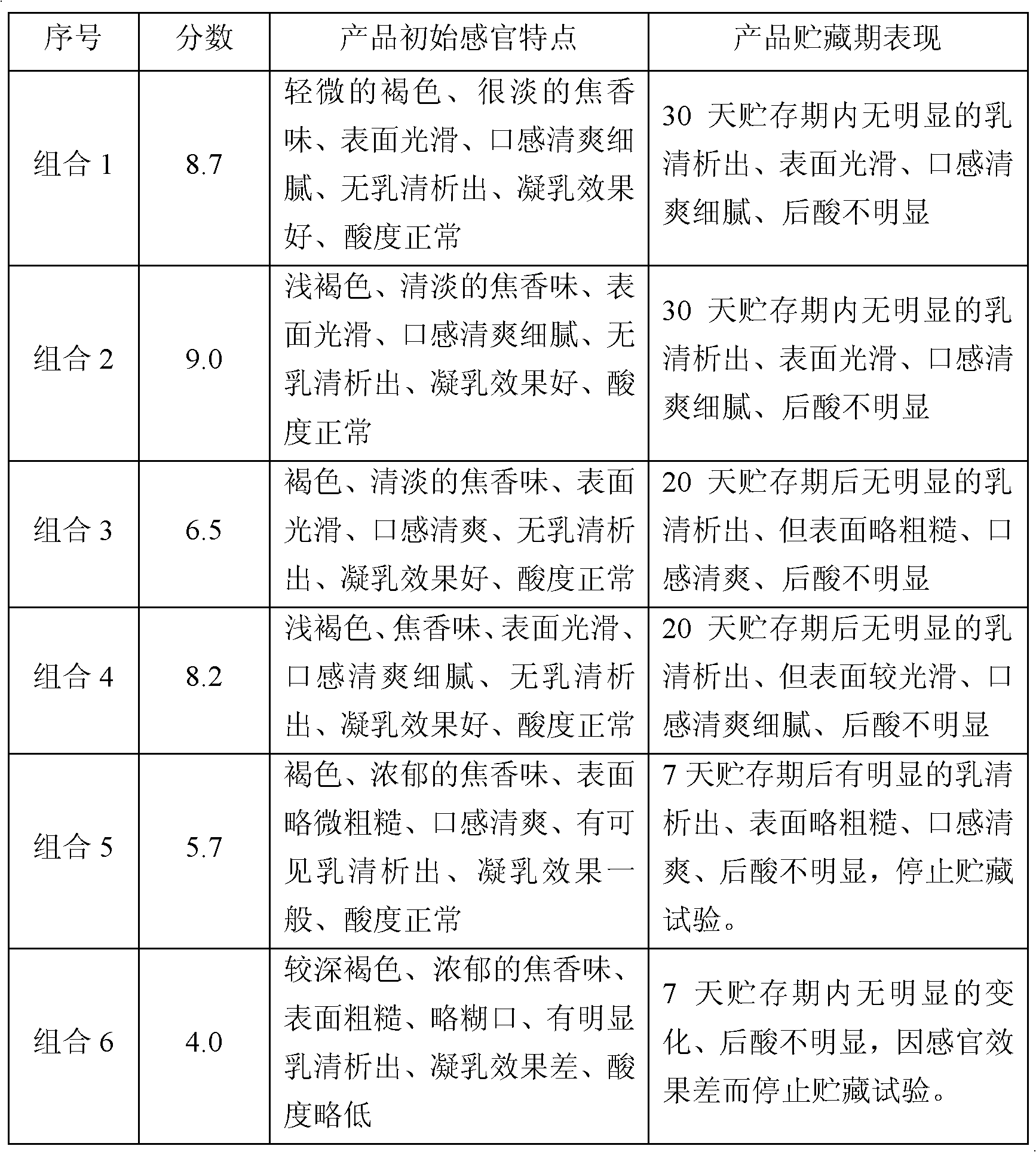

Partly skimmed cheese and preparation method thereof

The invention relates to partly skimmed cheese and a preparation method thereof. Each 100 parts of the partly skimmed cheese consists of the following raw materials by weight: 10 to 90 parts of whole milk powder, 750 to 860 parts of fresh milk, 20 to 50 parts of milk protein powder, 10 to 80 parts of inulin, 30 to 90 parts of sweetener, 5 to 15 parts of stabilizer and 10 to 15 parts of mixed lactobacillus starter. The invention also provides a preparation method of the partly skimmed cheese. The partly skimmed cheese is prepared by scientifically and effectively combining fresh cheese, nonenzymatic browning and the inulin, has the characteristics of soft and unique flavor, smooth mouthfeel, simple and elegant color, low cost and the like, and also has good nutritional and healthy functions and high market value.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

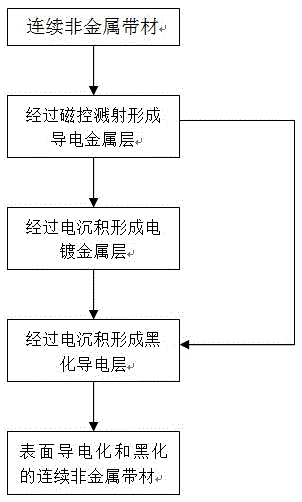

Conductive treatment and oxide treatment method for continuous non-metal strip

InactiveCN105648438AImprove conductivityImprove shielding effectMagnetic/electric field screeningFinal product manufactureMetal stripsElectromagnetic shielding

The invention discloses a conductive treatment and oxide treatment method for a continuous non-metal strip. Firstly, the surface of the continuous non-metal strip serving as a substrate is plated by metal, then an oxidized conductive layer is formed through electro-deposition, and the black continuous non-metal strip can be obtained. The strip has excellent conductivity, light absorption and extinction performance, heat absorption and cooling performance, friction resistance, corrosion resistance, electromagnetic shielding performance and wave-absorbing capacity, and has huge application value in the field of electromagnetic shielding and wave-absorbing materials.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

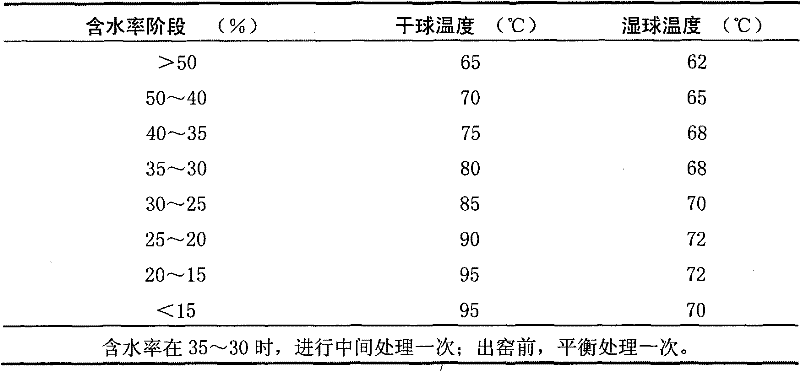

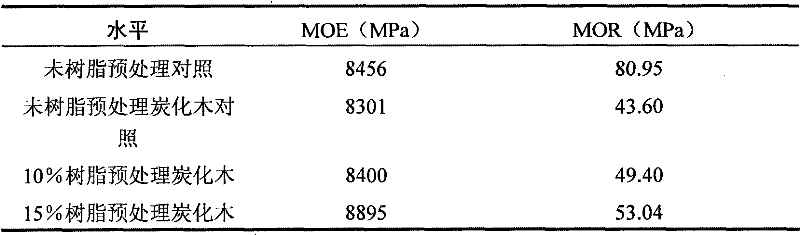

Method for producing rubber tree carbonized wood by resin pretreatment

ActiveCN101716790BHigh strengthIncrease added valuePressure impregnationWood impregnation detailsAdditional valuesUltimate tensile strength

The invention belongs to the technical field of wood modification, in particular relating to a method for producing rubber tree carbonized wood by resin pretreatment. The method comprises the following steps: putting the rubber saw wood of which the water content is less than 15% in a vacuum treatment tank for impregnating; then, stacking and airing the wood, putting the wood in a kiln, routinelydrying the wood in the kiln until the water content is less than 12%, and then, taking the wood out of the kiln; and putting the obtained wood in heat treatment equipment for high-temperature heat treatment, and taking the wood out of the kiln to obtain the rubber tree carbonized wood, wherein the water content of the wood is 4-6%. The invention has simple processes, high heating rate in the heattreatment process and high production efficiency, can increase the strength of the rubber tree carbonized wood by vacuum pressurization and impregnation of resin, and can effectively prevent the woodfrom deforming and cracking in the heat treatment process. The obtained rubber tree carbonized wood has the advantages of little loss of strength of the wood, elegant color, more excellent dimensional stability and durability and the like, and can be widely used for indoor and outdoor floors, landscapes, decorative materials and the like, thereby widening the application field of the rubber tree wood and increasing the additional value of the rubber tree wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Coating prepared by industrial waste of microsilica and preparation methods of coating

The invention relates to a coating prepared by an industrial waste of microsilica and preparation methods of the coating, belonging to the field of decorative materials. The coating comprises the following components in percentage by weight: 5-90 percent of substrate, 1-70 percent of microsilica, 0-10 percent of an adjuvant, 0-30 percent of pigment, 0-60 percent of a filler, 0-60 percent of a diluent and 0-40 percent of color paste. Moreover, the invention provides the two preparation methods. The industrial waste of microsilica is fully utilized and is changed into valuables, thus the environment pressure is reduced; and due to cheap raw materials, the coating has relatively good cost advantage, and the coating also has the advantages of compactness in structure, good gap-filling effect, firm attachment and delicate color.

Owner:贵州皓科新型材料有限公司

Water-containing lipstick and preparing method thereof

PendingCN108578274AIncrease moisture contentImprove stabilityCosmetic preparationsMake-upUltrasound deviceWater soluble

The invention provides a water-containing lipstick and a preparing method thereof. The water-containing lipstick is prepared from, by mass, 20-40% of emollient, 13-15% of hardening agent, 10-15% of brightening agent, 10-15% of polyglycero-2-triiso-stearate, 10-15% of polyglycero-2-diiso-stearate, 0.5-5% of pigment, 0.5-5% of lake and 10% of humectant. The water-containing lipstick is high in watercontent which can reach 10%, various water-soluble raw materials can be brought in, stability is high, the dropping point can reach 56-60 DEG C, the emulsifying effect is excellent, filling can be conducted through an ordinary filling device without defoaming through an ultrasonic device, and the obtained lipstick is diversified in color, capable of conducting tinting within one second and high in saturation degree.

Owner:GLOBAL COSMETICS HONG KONG CO LTD

Ecological ceramic tile and preparation method of the ecological ceramic tile

The invention discloses an ecological ceramic tile. Main raw materials of the ecological ceramic tile comprise 70 to 90 percent of gold tailings particles, 5 to 25 percent of bamboo carbon and 5 to 15 percent of purple gold clay. Aqueous solution of sodium silicate, with the weight of 2 to 4 percent of the total weight of the raw materials, is used as a bonder. A preparation method of the ecological ceramic tile comprises the following steps of: 1, placing the main raw materials into a mixer to mix the main raw materials for 5 to 15 minutes, then adding the aqueous solution of sodium silicateto mix for 60 to 120 minutes and carrying out ageing mixture for 10 to 14 hours to obtain a mixture; 2, carrying out pressure forming on the mixture under the pressure of 30 to 80MPa and then naturally drying the obtained product by 12 to 24 hours to obtain a dried formed product; and 3, sintering the dried formed product for 2 to 4 hours at the temperature of 1,000 to 1,250 DEG C to obtain the ecological ceramic tile. The ecological ceramic tile has functions of ammonia adsorption, far infrared emission and the like.

Owner:ZHEJIANG UNIV

New-form jade-like Ru porcelain

The invention discloses a new-form jade-like Ru porcelain which is characterized by comprising the following components in parts by weight: 15-41 parts of arkosic sandstone, 35-68 parts of kaolin, 15-21 parts of porcelain stone, 11-20 parts of gypsum powder, 25-40 parts of blue-and-white material, 15-21 parts of talcum, 11-15 parts of perlite, 5-11 parts of kieselguhr, 15-27 parts of medical stone, 3-9 parts of allophane, 3-7 parts of titanium dioxide, 1-4 parts of tin dioxide, 25-34 parts of peat, 1-4 parts of silicate and 10-32 parts of fluorite. The porcelain body has the translucent state of jade, and has elegant, simple and graceful color to generate brand-new visual impact and artistic effect, thereby implementing historic breakthrough in millennial Ru porcelain.

Owner:QINGDAO XIANGHAI ELECTRONICS

Old-imitation processing method of polyamide-ester fabric

ActiveCN105755723AElegant colorSoft colorFabric breaking/softeningFibre typesTextile printerPolymer science

The invention discloses an old-imitation processing method of polyamide-ester fabric. The whole processing process comprises the technological process as follows: fabric preparation, presetting, inkjet printing, baking, mechanical softening and finished product obtaining. Compared with a traditional old-imitation processing method of fabric, the method has the advantages that single-side coloring old-imitation finishing of the polyamide-ester fabric is realized, and meanwhile, the old-imitation effect of the fabric can be diversified and enriched through design of inkjet-printed patterns and pattern types. Besides, mechanical softening replaces traditional chemical softening, the old-imitation fabric is fluffy and thick in style, and a lot of chemical additives and energy are saved. The finally obtained old-imitation polyamide-ester fabric is gentle in color and rich and diversified in style, touches full and thick and has good visual and touch affinity.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Multi-component blending health-care yarn semi-worsted with tea fibers and preparation method as well as applications thereof

The invention discloses a multi-component blending health-care yarn semi-worsted with tea fibers. The multi-component blending health-care yarn comprises the tea fibers, antibacterial odor-resistant acrylic fibers, Jutecell fibers and cashmere fibers. The tea fibers are 20-35% by weight, the antibacterial odor-resistant acrylic fibers are 15-35% by weight, the Jutecell fibers are 15-30% by weight, and the cashmere fibers are 15-30% by weight. The performance indexes of the blending yarn are as follows: breaking strength of a single yarn is 12.9-18.1cN / tex, the variable coefficient Cv value of the breaking strength of the single yarn is 9.3-15.7%, and the variable coefficient Cv value of yarn evenness is 13.9-21.9%. Compared with the prior art, the multi-component blending health-care yarn semi-worsted with the tea fibers has health-care functions of antibiosis, bacteriostat, sterilization, deodorization, itching, skin protection, physical fitness, skin moisture and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com