High-strength light foam ceramic plate and manufacturing method thereof

A foamed ceramic plate and the technology of the production method are applied in the field of decorative insulation materials for exterior walls and building materials production, which can solve the problems of limited source of raw materials, complicated production process, large energy consumption, etc., and achieve low raw material prices and simple firing process , The effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

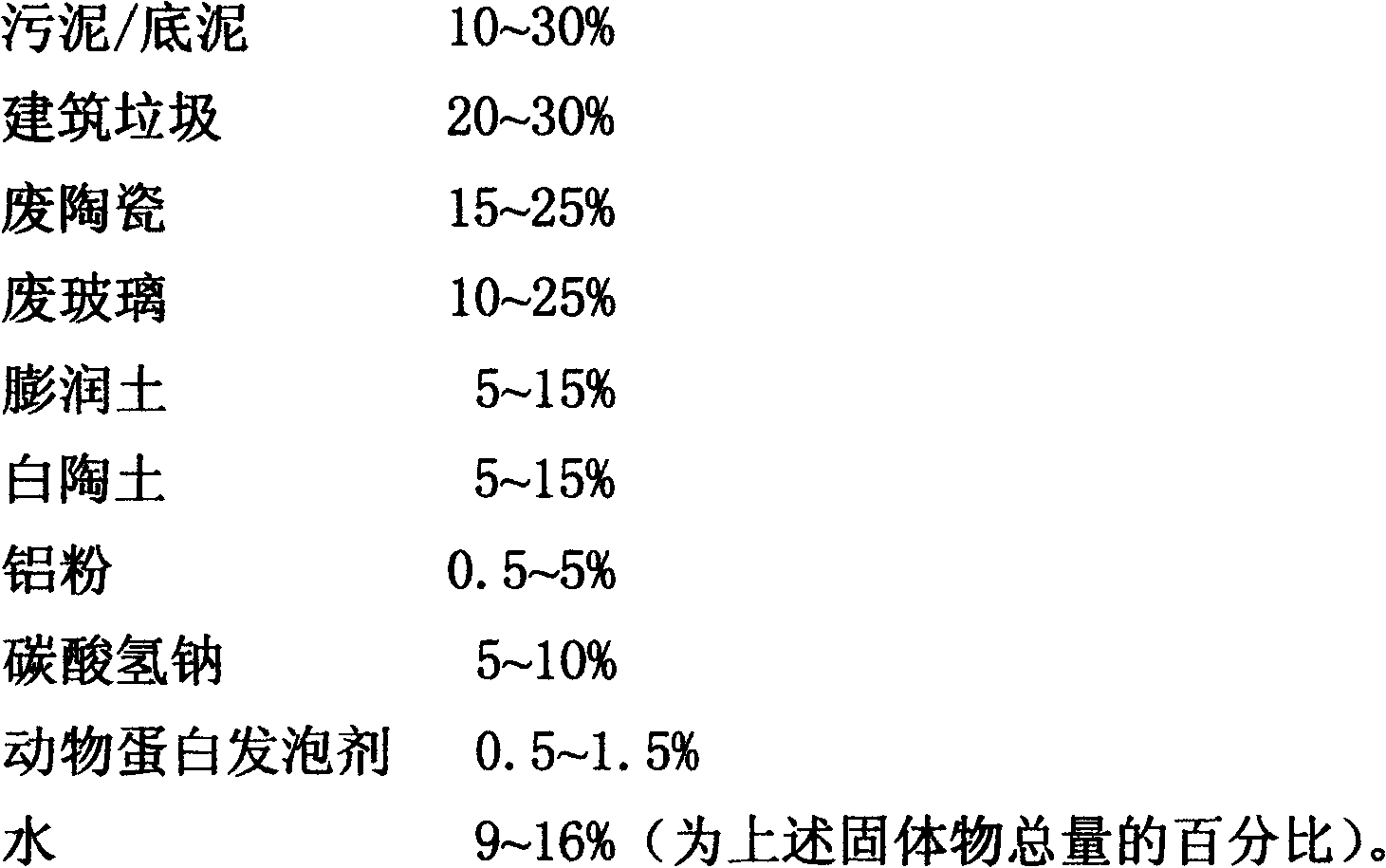

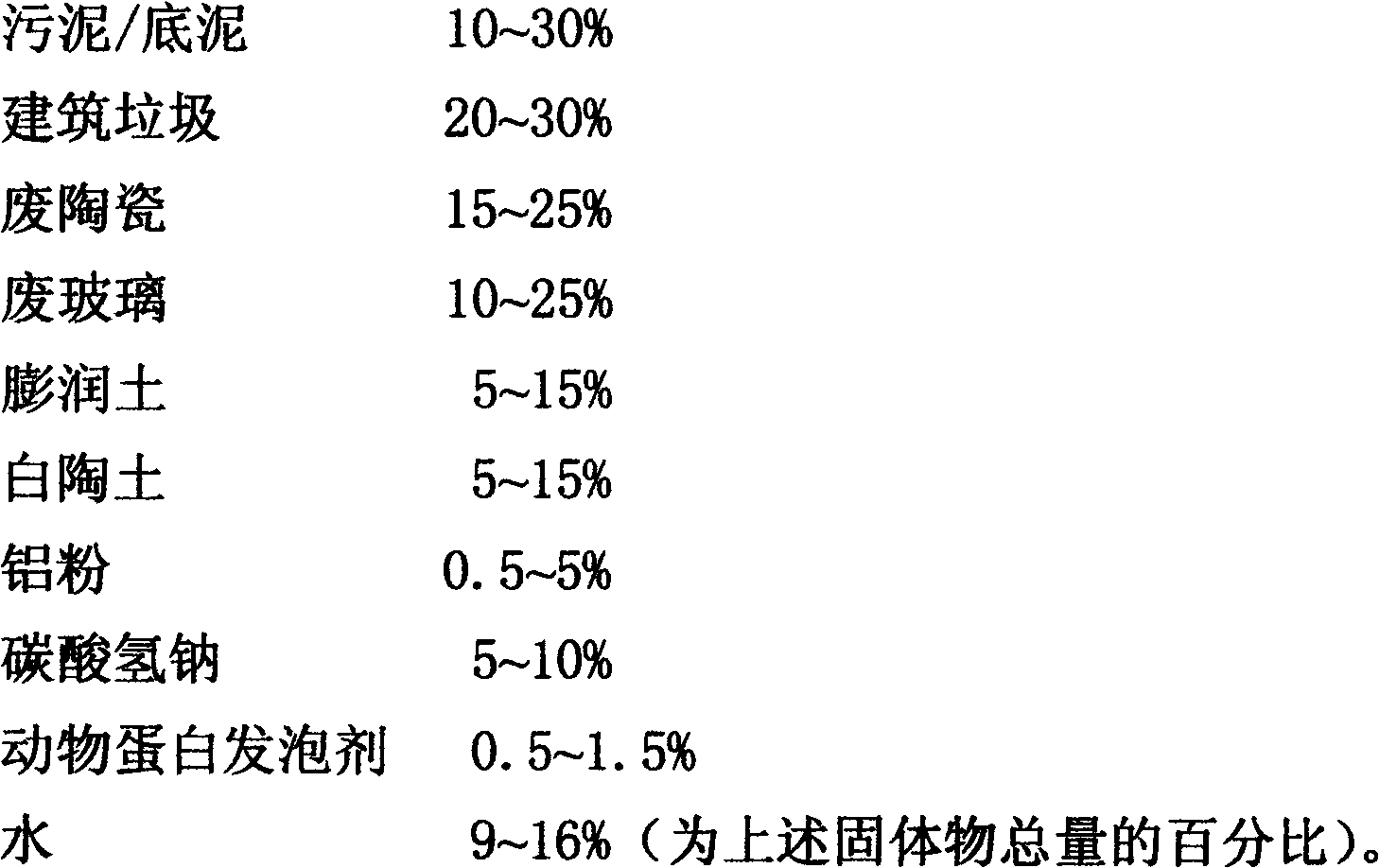

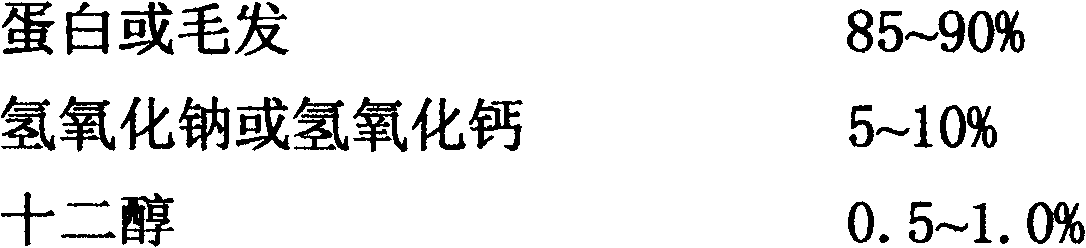

Embodiment approach 1

[0025] Select 20% of sludge, 20% of construction waste, 10% of waste ceramic sheets, 5% of bentonite, 20% of waste glass, 18% of pottery clay, 1% of aluminum powder, and 5% of sodium bicarbonate. Stir evenly, pulverize to 80 mesh, add Animal protein whipping agent 1% and appropriate amount of water (being 12% of above-mentioned solid matter total amount), after crossing 20 mesh sieves and granulating, pack into the self-made corundum quality refractory combined mould, gently press and scrape off, the mold backing plate, mold The surface of the frame is sprayed with AL 2 o 3 , and then loaded into a resistance furnace and fired in three stages of 300°C, 700°C, and 1200°C, each fired for 30 minutes, and can be made into a bulk density of 0.5g / cm 3 Lightweight foam ceramic plate.

[0026] The lightweight foamed ceramic plate has a bulk density of 0.5g / cm 3 , the flexural strength is 20Mpa, the thermal conductivity is less than 0.1W / (m.k), the water resistance is good, it is im...

Embodiment approach 2

[0028] Select 20% of river and lake bottom mud, 20% of construction waste, 10% of waste ceramic chips, 10% of bentonite, 20% of waste glass, 14% of pottery clay, 0.5% of aluminum powder, 5% of sodium bicarbonate, stir evenly, and crush to 80 mesh , add 0.5% of animal protein foaming agent and appropriate amount of water (12% of the total amount of the above solids), pass through a 20-mesh sieve and granulate, then put it into a self-made corundum quality refractory mold and lightly press and scrape it flat. , The surface of the mold frame is sprayed with AL 2 o 3 , and then loaded into a roller kiln and fired in three stages of 250°C, 600°C, and 1190°C, fired for 30min, 40min, and 30min respectively, and can be made into a bulk density of 0.6g / cm 3 , Lightweight foamed ceramic plates with a compressive strength at room temperature of 20Mpa.

Embodiment approach 3

[0030] Select 15% of river and lake bottom mud, 21% of construction waste, 10% of waste ceramic chips, 13% of bentonite, 20% of waste glass, 10% of pottery clay, 5% of aluminum powder, and 5% of sodium bicarbonate. Stir evenly and crush to 80 mesh , add 1% of animal protein foaming agent and appropriate amount of water (10% of the total amount of the above solids), pass through a 20-mesh sieve for granulation, and then put it into a self-made corundum refractory mold with light pressure and scrape it flat. , The surface of the mold frame is sprayed with AL 2 o 3 , and then loaded into a porous pusher kiln and fired in three stages of 300°C, 600°C, and 1200°C, each fired for 30 minutes, and can be made into a bulk density of 0.6g / cm 3 The lightweight foamed ceramic board can float on the water for a long time, impervious to water for a long time, and has good frost resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com