Method for producing rubber tree carbonized wood by resin pretreatment

A resin pretreatment, rubber tree technology, applied in the direction of impregnated wood, wood impregnation, wood processing appliances, etc., can solve the dimensional stability and corrosion resistance of treated wood and carbonized wood whose flexural strength and impact toughness decrease , low utilization rate of wood and other problems, to achieve the effect of elegant color, excellent dimensional stability and durability, and less loss of wood strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one: 10% urea-formaldehyde resin pretreatment produces rubber tree carbonized wood

[0020] 1. Resin pretreatment:

[0021] The rubberwood sawn timber with a moisture content of less than 15% is placed in a vacuum treatment tank, and the timber size is 1000mm×130mm×35mm (length×width×thick). First vacuumize the treatment tank, and keep it for 10 minutes after reaching a vacuum degree of -0.09MPa. Use the negative pressure in the tank to pump the impregnating resin with a concentration of 10% (average molecular weight 500, pH value 10) into the treatment tank. After the resin is filled, Apply a pressure of 1.5MPa and keep it for 40 minutes, then vacuum treatment for 10 minutes to discharge the residual resin in the wood cell cavity, open the tank door, and take out the wood.

[0022] 2. Resin curing and wood drying:

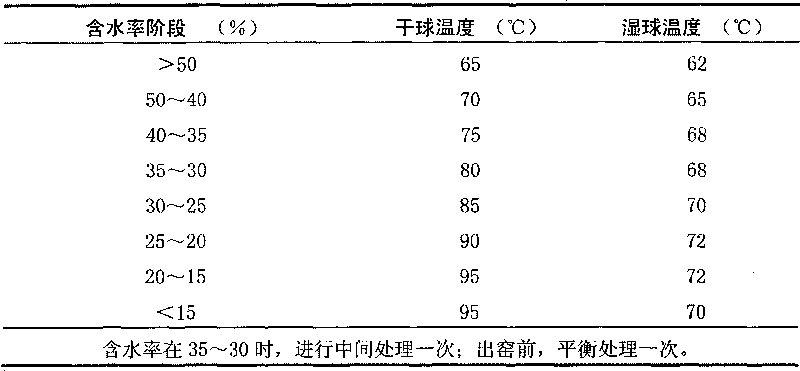

[0023] The resin-impregnated wood is stacked and air-dried for 3 days, and the moisture content is reduced to below 70%. The wood is stacked a...

Embodiment 2

[0030] Embodiment two: 15% urea-formaldehyde resin pretreatment produces rubber tree carbonized wood

[0031] 1, resin pretreatment: pretreatment resin concentration is 15%, and other treatment conditions are with embodiment one;

[0032] 2, resin solidification and wood drying are identical with embodiment one;

[0033] 3. The high-temperature heat treatment process is the same as in Embodiment 1.

Embodiment 3

[0034] Embodiment three: 15% phenolic resin pretreatment produces rubber tree carbonized wood

[0035] 1, resin pretreatment: pretreatment resin is phenolic resin, and concentration is 15%, and other treatment conditions are with embodiment one;

[0036] 2, resin solidification and wood drying are identical with embodiment one;

[0037] 3. The high-temperature heat treatment process is the same as in Embodiment 1.

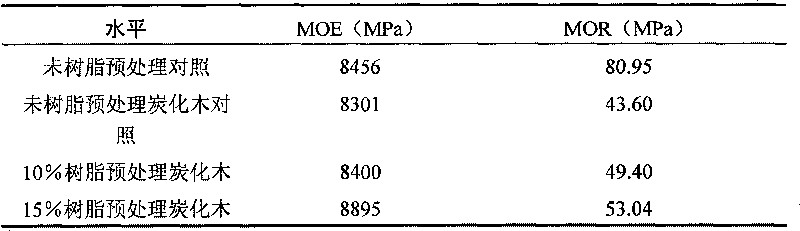

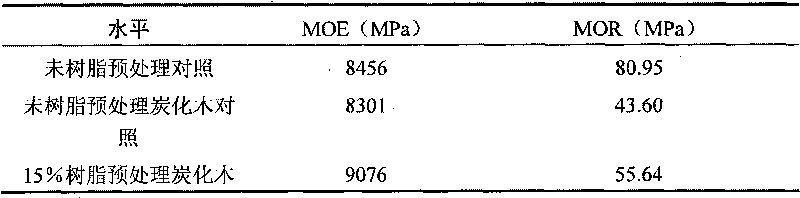

[0038] In accordance with the national standards "GB1936.1-91 Test method for flexural strength of wood" and "GB1936.2-91 Determination method for flexural modulus of wood", the mechanical properties of rubber tree carbonized wood obtained by treating urea-formaldehyde resin at 220°C for 3 hours were tested. As shown in Table 2, the flexural strength of rubber tree material control is 80.95MPa, its carbonized wood is 43.60MPa, 10% resin pretreated carbonized wood is 49.40MPa, and 15% resin pretreated carbonized wood has a flexural strength of 53.04MPa, compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com