Dull polish radiation grain manufacturing technology and shell of terminal equipment

A technology of manufacturing process and terminal equipment, applied in the direction of electrical equipment shell/cabinet/drawer, decorative art, special decorative structure, etc., can solve the problems of poor appearance and decorative effect, low user experience, etc., to achieve smooth hand feel and good visual effect. , The effect of improving the appearance decoration effect and the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

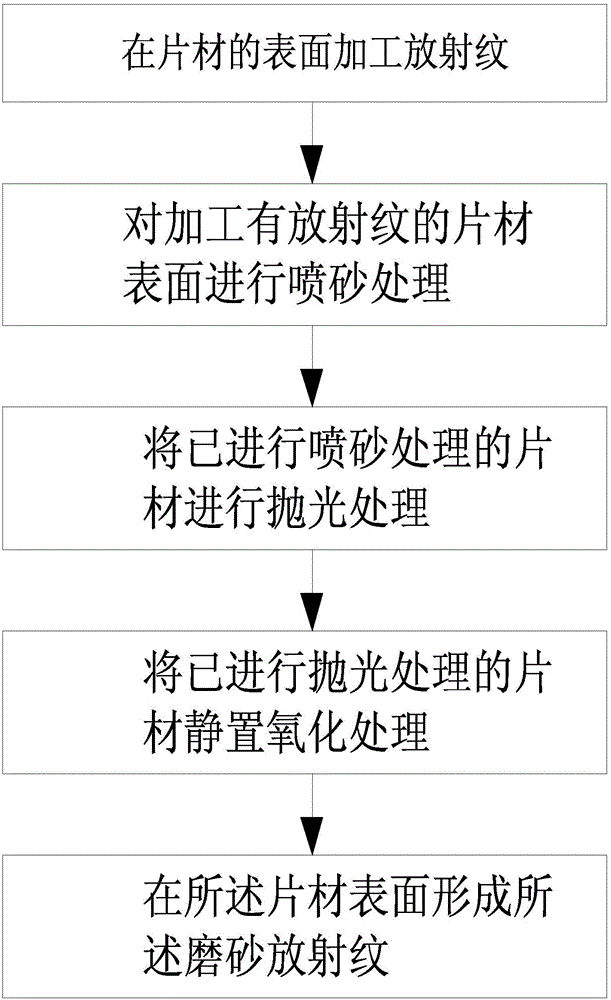

[0025] refer to figure 1 , Step 11: processing radial patterns on the surface of the sheet.

[0026] In this step, the sheet has a strong radiation effect by processing the radiation pattern on the surface of the sheet; and in the process of cutting, the tool will mechanically squeeze the surface of the sheet and form regular radiation patterns. The texture can effectively eliminate the material texture of the sheet itself, improve the appearance decoration effect and yield rate, and eliminate the steps of polishing or grinding before processing in the previous process, simplify the production process and improve production efficiency. Moreover, the texture has regularity, which can also improve the feel of the texture.

[0027] Step 12: In the sheet material processed with the radial pattern, sandblasting is performed on the surface processed with the radial pattern.

[0028] In this step, the total reflection in the radiation pattern can be changed to diffuse reflection by...

Embodiment 2

[0036] Step 21: Stamping and shaping the sheet.

[0037] In this embodiment, the sheet material can be selected from 2 series, 5 series, 6 series and other aluminum alloy materials suitable for stamping; through stamping, CNC (numerical control machine tool processing), wire cutting and other processing methods to process aluminum alloy sheets of appropriate size and shape material. In particular, the sheet can be a metal casing of a terminal such as a smart phone or a tablet computer.

[0038] This step specifically includes: stamping and correcting the sheet; wherein, the stamping pressure is 1450-1650N, and the stamping speed is 10-14 times / min. Among them, the stamping pressure is provided by a 155-165-ton stamping machine, and the stamping temperature can be normal temperature. Preferably, the above stamping pressure is 1568N, and the stamping speed is 12 times / min. Among them, the stamping pressure is provided by a 160-ton stamping machine, and the stamping temperatur...

Embodiment 3

[0067] An embodiment of the present invention also provides a casing of a terminal device, which uses the above-mentioned frosted radial pattern manufacturing process to form a frosted radial pattern on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com