Preparation method of carbon fiber composite material coating and carbon fiber composite device

A composite material and carbon fiber technology, used in coatings, devices for coating liquids on surfaces, etc., can solve the problems of cumbersome processing procedures, complex coating structures, and high processing costs, reducing production costs, optimizing technological processes, and improving The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

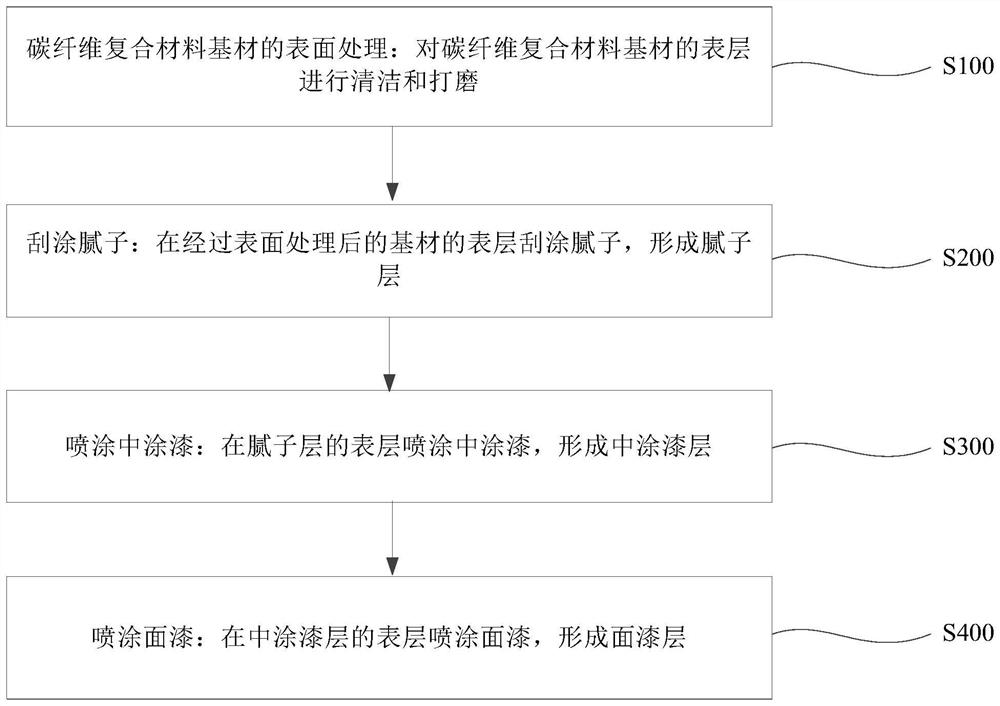

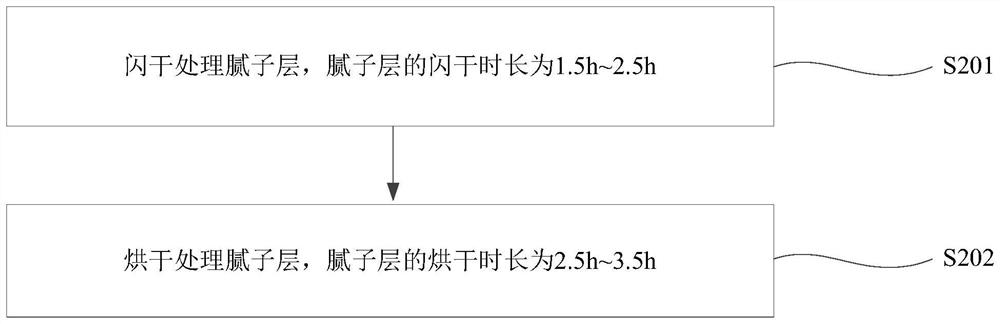

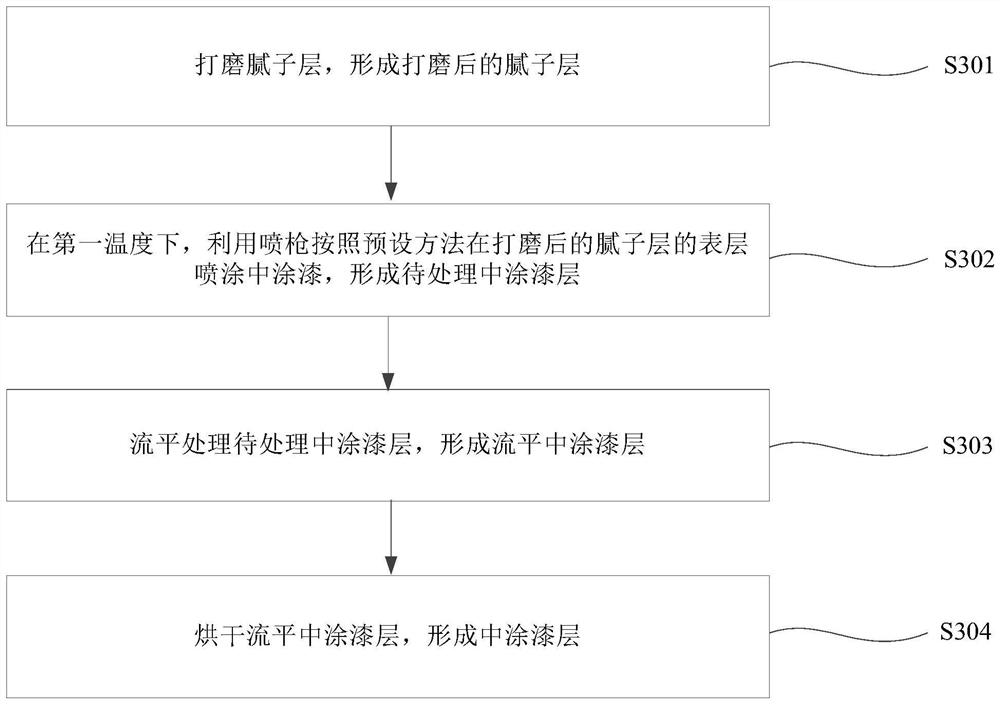

[0048] In the current coating preparation method for the surface of the material, firstly, the surface of the substrate needs to be treated to remove grease and pollutants on the surface of the substrate, to improve the surface cleanliness and roughness of the material, and then to spray the primer on the surface of the substrate , and then scrape putty on the surface of the material that has been sprayed with primer, spray the middle paint, and finally spray the topcoat. Such a prepared coating structure is successively provided with a primer, a putty layer, an intermediate paint layer and a top coat layer on the surface of the substrate. However, such a coating preparation method has many steps, complicated process, long manufacturing cycle and high manufacturing cost. In addition, repeated high-temperature baking is required in the preparation process, which will reduce the performance of the matrix such as resin in the carbon fiber composite material, and then affect the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com