Preparation method of La2Zr2O7 buffer layer film

A buffer layer and thin film technology, applied in the coating, metal material coating process, liquid chemical plating and other directions, can solve the problems of high cost of thin film preparation, difficult to obtain, etc., to reduce the coating cycle, reduce industrial costs, and facilitate implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add zirconyl nitrate and acetylacetone to propionic acid solvent (molar ratio zirconyl nitrate: acetylacetone: propionic acid = 1:4:4), reflux and stir at 50°C for 5 hours at a constant temperature, and then cool to room temperature to obtain Zr solution;

[0045] Add lanthanum nitrate to propionic acid solvent (molar ratio lanthanum nitrate:propionic acid=1:4), and stir at room temperature for 2 hours to obtain La solution;

[0046] Using methanol as a diluent, the above-mentioned La solution, Zr solution and methanol solvent were mixed in a molar ratio La: Zr: methanol = 1.3: 1: 20, and stirred at room temperature for 3 hours to obtain La 2 Zr 2 o 7 Precursor solution for buffer layer thin film; preparation of La 2 Zr 2 o 7 The gel film was subsequently dried at 90 °C for 10 min to obtain La 2 Zr 2 o 7 dry film;

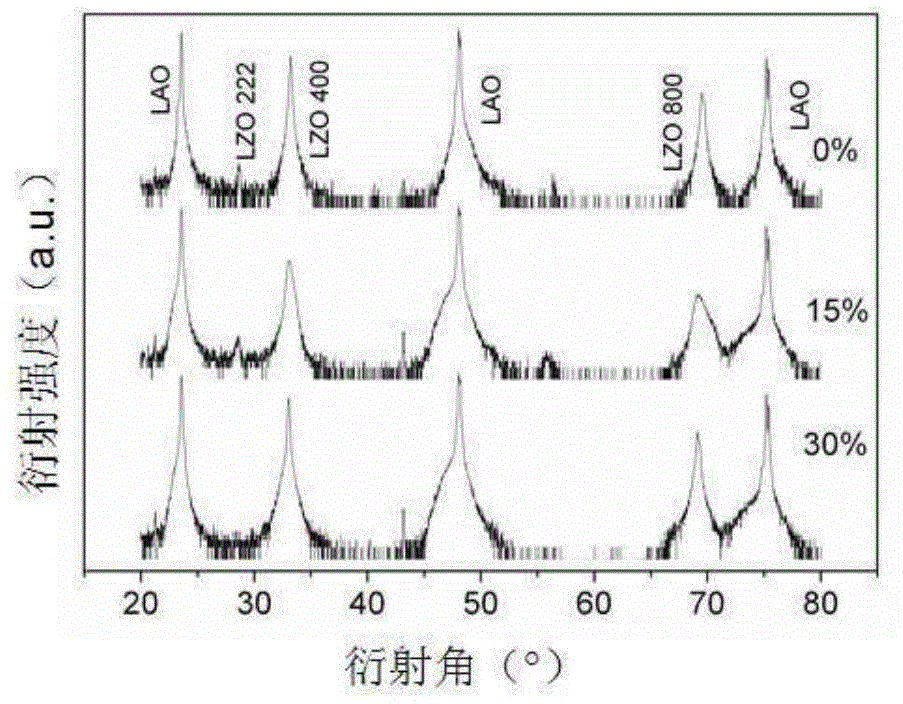

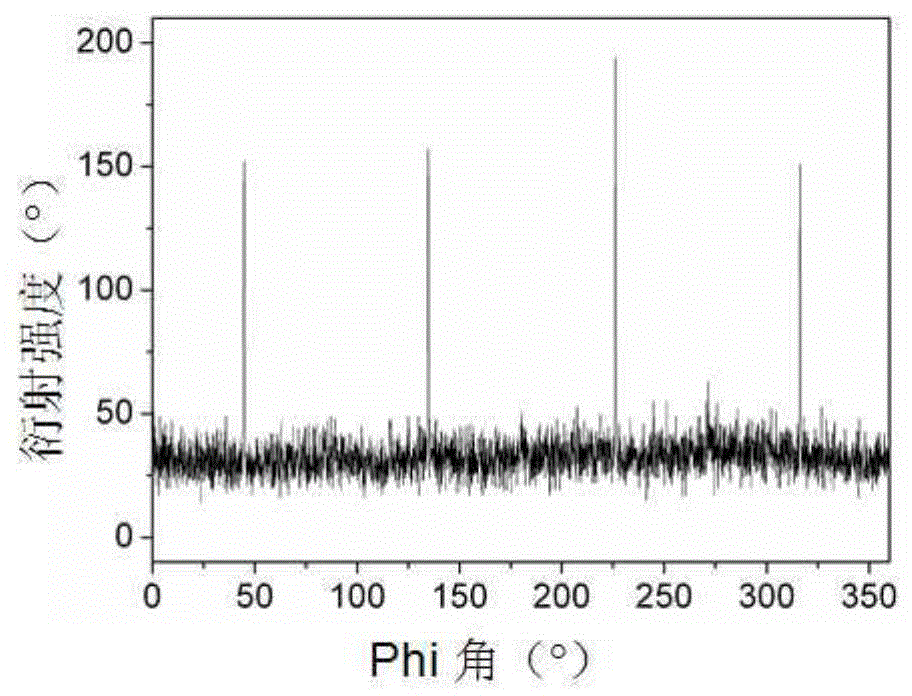

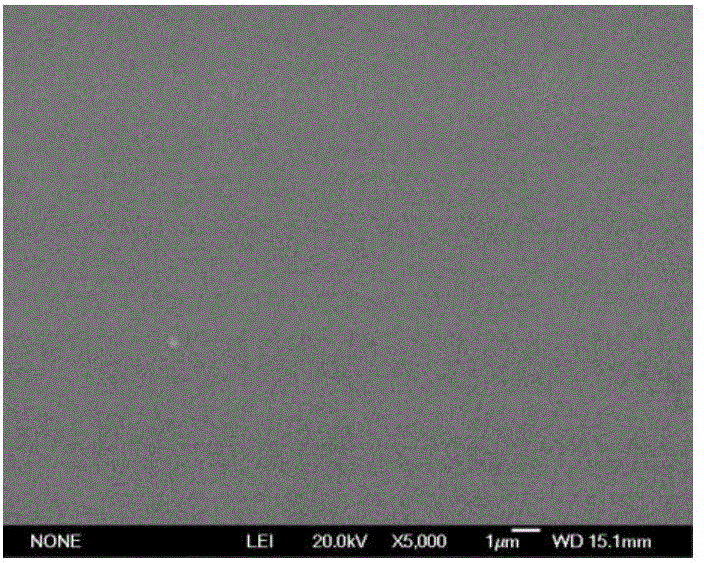

[0047] La 2 Zr 2 o 7 The dry film is put into a muffle furnace for heat treatment, and the temperature in the furnace is raised to 900°C at a ra...

Embodiment 2

[0050] Add zirconyl nitrate and acetylacetone to ethylene glycol monomethyl ether solvent (molar ratio zirconyl nitrate: acetylacetone: ethylene glycol monomethyl ether = 1:8:6), and stir under reflux at 80°C for 4 hours , and then cooled to room temperature to obtain a solution of Zr;

[0051] Add lanthanum nitrate to ethylene glycol monomethyl ether solvent (molar ratio of lanthanum nitrate: ethylene glycol monomethyl ether = 1:8), and stir at room temperature for 3 hours to obtain a La solution.

[0052] Using methanol as a diluent, the above-mentioned La solution, Zr solution and methanol solvent were mixed in a molar ratio La: Zr: methanol = 1.2: 1: 30, and stirred at room temperature for 3 hours to obtain La 2 Zr 2 o 7 Precursor solution for buffer layer thin film; La 2 Zr 2 o 7 The gel film was then dried at 80 °C for 20 min to obtain La 2 Zr 2 o 7 dry film;

[0053] La 2 Zr 2 o 7 The dry film was put into a quartz tube sintering furnace for heat treatment. ...

Embodiment 3

[0055] Add zirconium oxychloride and acetylacetone to propionic acid solvent (molar ratio zirconium oxychloride: acetylacetone: propionic acid = 1:4:10), reflux and stir at 40°C for 6 hours, then cool to room temperature , to obtain Zr solution;

[0056] Add lanthanum acetate to propionic acid solvent (molar ratio lanthanum acetate: propionic acid = 1:10), stir at room temperature for 4 hours to obtain La solution;

[0057] Using methanol as a diluent, the above-mentioned La solution, Zr solution and methanol were mixed in a molar ratio La: Zr: methanol = 1: 1: 90, and stirred at room temperature for 5 hours to obtain La 2 Zr 2 o 7 Buffer layer thin film precursor solution; using the dipping and pulling method to prepare La 2 Zr 2 o 7 The gel film was subsequently dried at 100 °C for 5 min to obtain La 2 Zr 2 o 7 dry film;

[0058] La 2 Zr 2 o 7 The dry film is put into a muffle furnace for heat treatment, and the temperature in the furnace is raised to 1050°C at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com