Carbide band saw blade for woodworking

A technology of cemented carbide and cemented carbide knives is applied in the field of tools for sawing wood, which can solve the problems of water ripples on the sawing section, and achieve the effects of improving smoothness, eliminating lines and reducing cutting force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

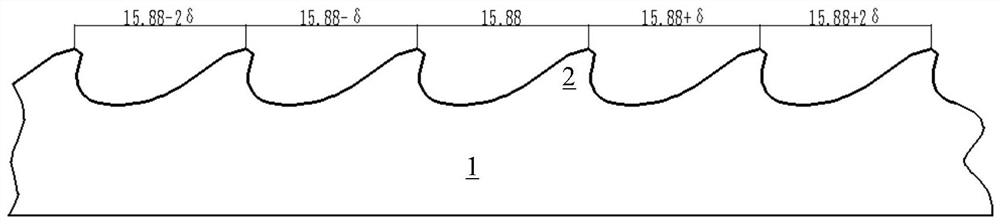

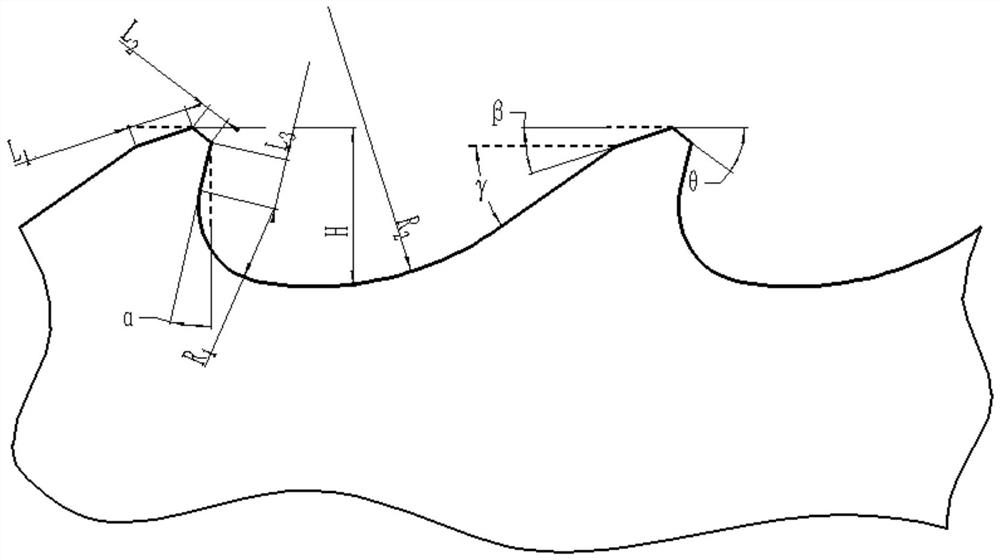

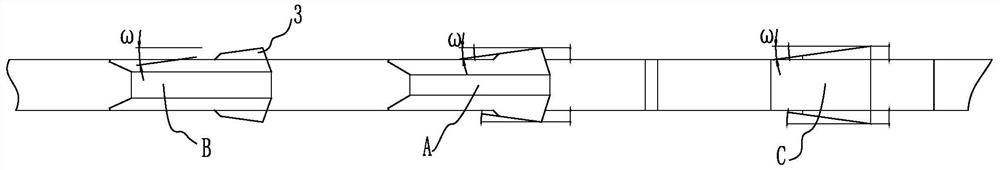

[0028] see Figure 1-5 , a cemented carbide band saw blade for woodworking, comprising a band saw back material 1 and a hard alloy cutter head 3, the band saw back material 1 includes a plurality of saw teeth 2 arranged at intervals, and the cemented carbide cutter head 3 is welded and fixed to the saw teeth 2 , the design of the band saw blade consists of two parts, one part is the design of the tooth profile, and the other part is the design of the grinding tooth form.

[0029] Design of tooth profile

[0030] See figure 1 As shown, the design of the 1.6Tpi tooth pitch: According to the tooth pitch calculation formula, the tooth pitch of 1.6 equal teeth is 15.88mm, but in the actual sawing process, water waves generally appear in wood processing, in order to better ensure the saw Cutting surface quality, eliminating the influence of water waves, changing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com