Non-cracking soft-polishing glazed tile with wavellite effect on surface and preparation method thereof

A technology of silver star stone and glazed tiles, which is applied in the field of non-cracking soft-polished glazed tiles and its preparation, can solve the problems of expensive decorative materials and scarce content of silver star stone in nature, and achieve unique decoration, easy promotion, and unique artistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

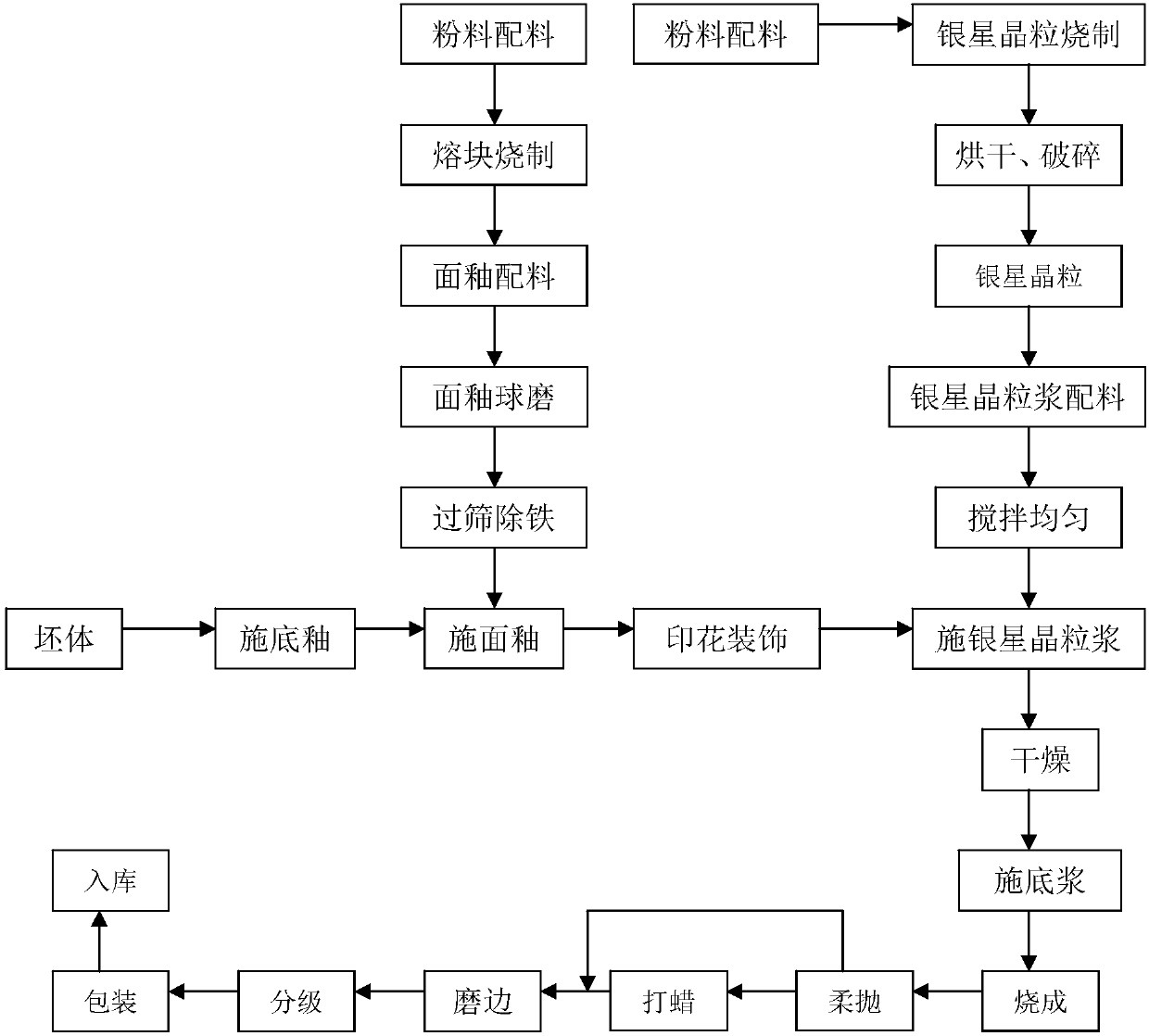

[0052] A method for preparing a non-cracking soft-polished glazed tile with a silver star effect on the surface, comprising the following steps:

[0053] A. Preparation of frit:

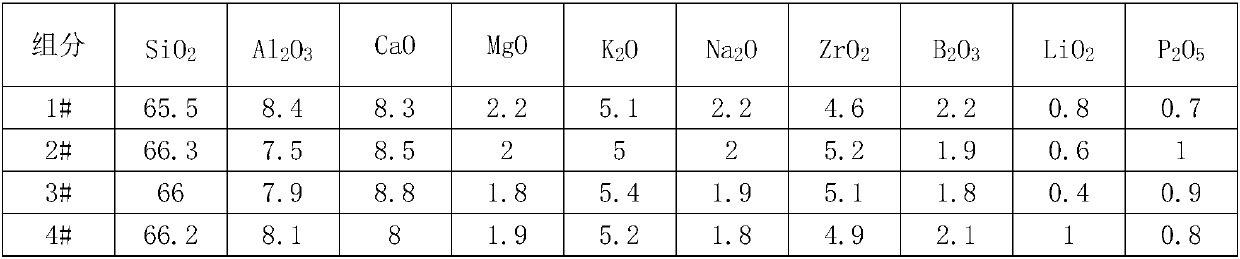

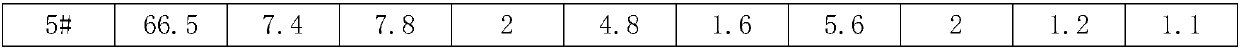

[0054] The chemical composition of the frit is shown in Table 1

[0055] Table 1, the chemical composition list of frit (weight percent, %)

[0056]

[0057]

[0058] Preparation of frit: select the corresponding proportion of quartz powder, feldspar powder, calcium carbonate, alumina powder, talcum powder, zircon powder, potassium carbonate, sodium carbonate, spodumene powder with a particle size of less than 150 mesh according to the chemical composition of the green body in Table 1 , apatite powder, boric acid raw materials, batching, mixing in a mixer, melting in a frit pool kiln, the melting temperature range is 1500 ° C ~ 1520 ° C, and then water quenched into frit particles, dried get frit;

[0059] B. Preparation of glaze:

[0060] The chemical composition of the surface glaze is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com