Method for performing surface treatment on golf head by aluminium -titanium nitride composite coating

A golf ball and composite coating technology, which is applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor intergranular corrosion resistance, poor surface finish, and large internal stress, etc. Achieve the effects of fast coating speed, unique decorative effect and low internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The invention provides a method for surface treatment of a golf head using an aluminum nitride-titanium composite coating, the method comprising the following steps:

[0055] (1) Equipment preparation:

[0056] The equipment includes the following parts:

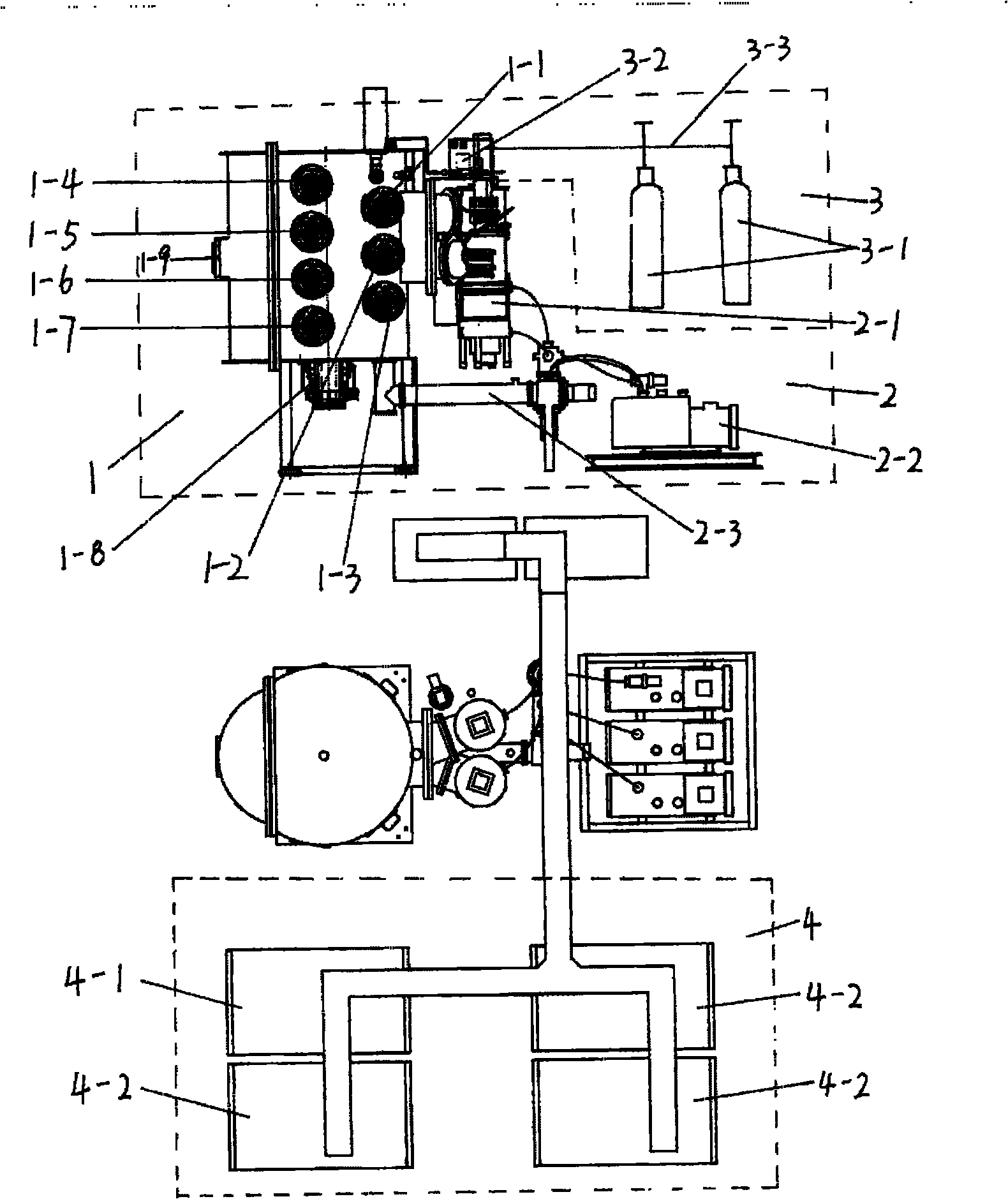

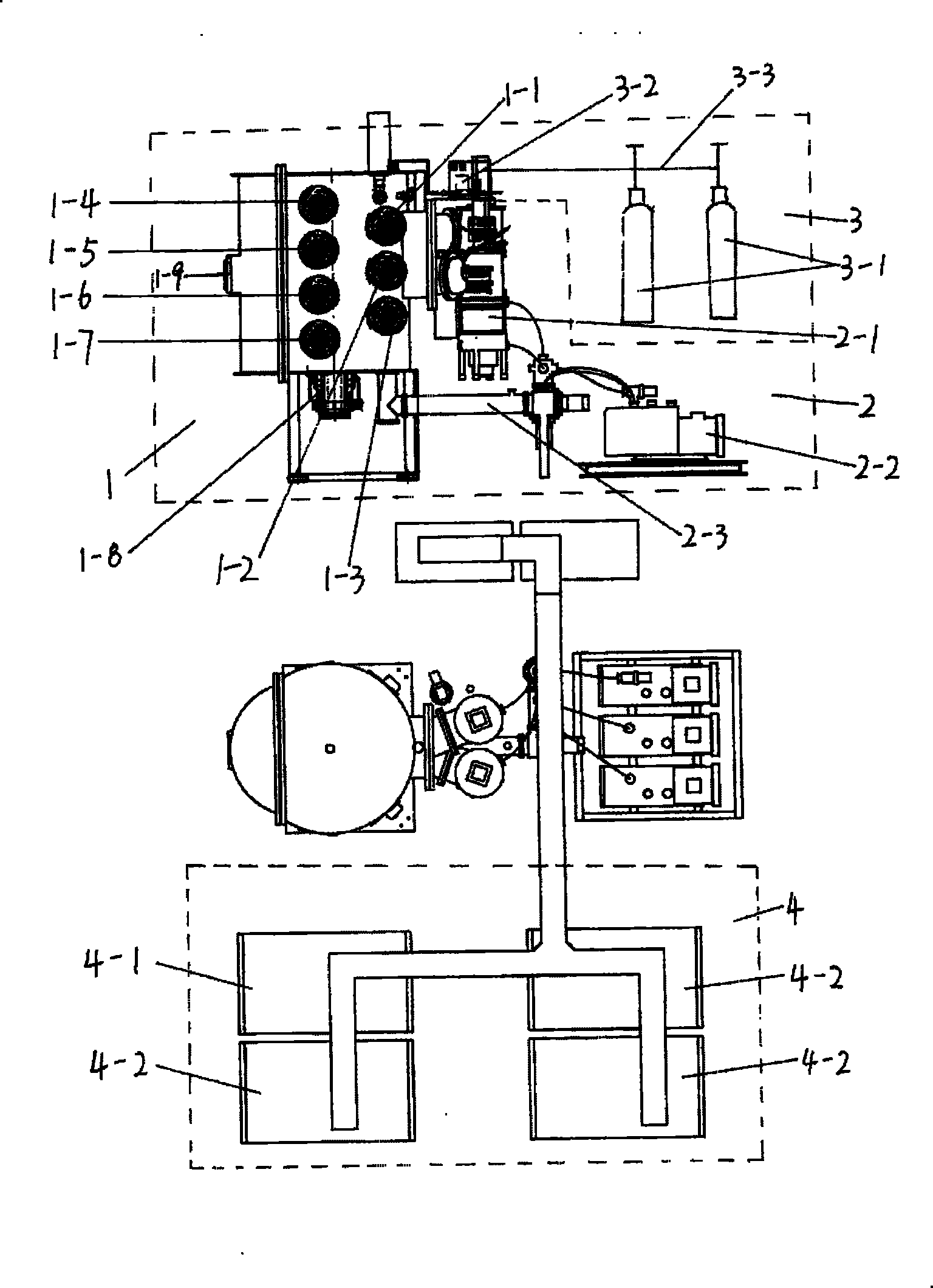

[0057] 1), vacuum chamber:

[0058] The vacuum chamber 1, also known as the furnace body, is a vacuum chamber welded with stainless steel plates. Centering on the furnace door 1-9, there are two rows of 14 arc evaporation sources in total on the left and right sides of the furnace door. To install aluminum-titanium targets; the arc evaporation sources on the left and right sides are arranged in the opposite way; the last column of the two arc evaporation sources on the right side of the furnace door is 3, and they are arranged in order as the first arc evaporation source 1-1, the second arc evaporation source The second arc evaporation source 1-2 and the third arc evaporation source 1-3; the previous column is 4, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com