Method for preparing natural sliver paint

A technology of natural rock flake paint and rock flake paint, applied in the field of decorative paint, can solve the problems of inability to achieve the effect of natural rock, and achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

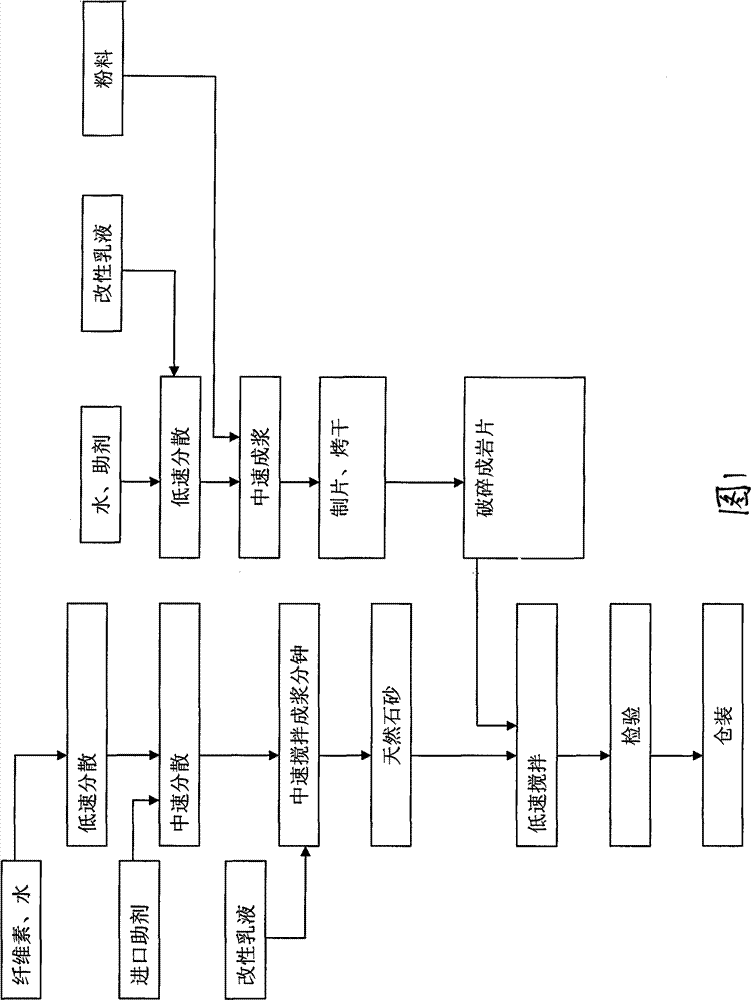

[0019] Such as figure 1 Shown, the preparation method of natural rock flake paint of the present invention comprises following specific steps: one), at first carry out the preparation of imitation marble rock flake paint semi-finished product:

[0020] Imitation marble flake paint belongs to a kind of synthetic resin emulsion sand wall architectural paint. First select the raw materials according to the traditional real stone paint (special styrene-acrylic emulsion for real stone paint, natural colored sand of various thicknesses and various additives and water) according to the existing production process of real stone paint to produce semi-finished products (see process flow chart) for mixing Ratio (percentage by weight): styrene-acrylic emulsion for real stone paint: 8-12%, natural sand of various colors: 70-80%, various additives 3-10%, tap water or deionized water: 5-10%, specific The process is to stir cellulose, water, additives, and emulsion into a slurry, and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com