Method for manufacturing anti-slip glazed tile

A glazed tile and anti-slip technology, which is applied in the field of manufacturing anti-slip glazed tiles, can solve the problems of unsuitable ground paving, fuzzy anti-slip lines, non-slip glazed surface, etc., and achieve no effect on decorative effects, three-dimensional patterns, and good glaze quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

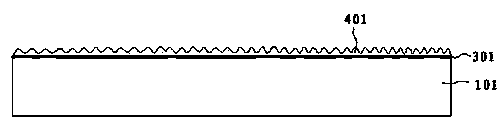

[0029] refer to figure 2 , in this embodiment, provide a kind of non-slip glazed tile, it comprises green body layer 101, printing layer 301, transparent surface glaze layer 401 from bottom to top, wherein transparent surface glaze layer 401 has a height of 0.1mm~0.6mm Anti-slip protrusions, the distance between the anti-slip protrusions is ≤2mm.

[0030] This kind of non-slip glazed tile can be prepared by the following methods:

[0031] Select the medium-temperature green body raw materials commonly used for glazed tiles (that is, the green body raw materials with a firing temperature between 1100 ° C and 1250 ° C, that is, plastic clay, feldspar, sand, additives (additives can include but not limited to plasticizers, water reducing materials, etc.) agent, etc.) and add water ball mill to make a slurry; then, after iron removal and stale processes, it is sent to a spray drying tower to be sprayed and dried to make a powder; In this embodiment, the specification of 600×600...

Embodiment 2

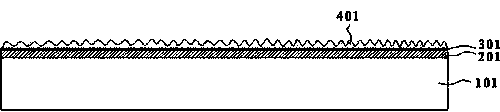

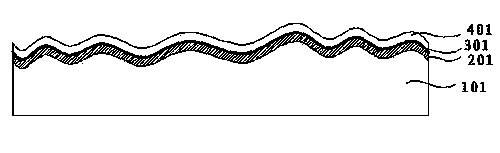

[0034] refer to image 3 , in the present embodiment, provide a kind of non-slip glazed tile, it comprises green body layer 101 from bottom to top, bottom glaze layer 201, printing layer 301, transparent surface glaze layer 401, wherein the transparent surface glaze layer 401 has a height of 0.1 mm~0.5mm anti-slip protrusions, the distance between the anti-slip protrusions is ≤2mm.

[0035] In this embodiment, the following process is used to prepare the above-mentioned non-slip glazed tiles.

[0036] Select the medium-temperature green body raw materials commonly used for glazed tiles (that is, the green body raw materials with a firing temperature between 1100 ° C and 1250 ° C, that is, plastic clay, feldspar, sand, additives (additives can include but not limited to plasticizers, water reducing materials, etc.) agent, etc.) and add water ball mill to make a slurry; then, after iron removal and stale processes, it is sent to a spray drying tower to be sprayed and dried to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com