TS-1 zeolite material with multi-level pores and preparation method of TS-1 zeolite material

A technology of TS-1 and zeolite materials, applied in chemical instruments and methods, molecular sieve compounds, inorganic chemistry, etc., can solve the problems of limited application range, shorten the diffusion distance, simplify the operation process, reduce side reactions and carbon deposition the effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

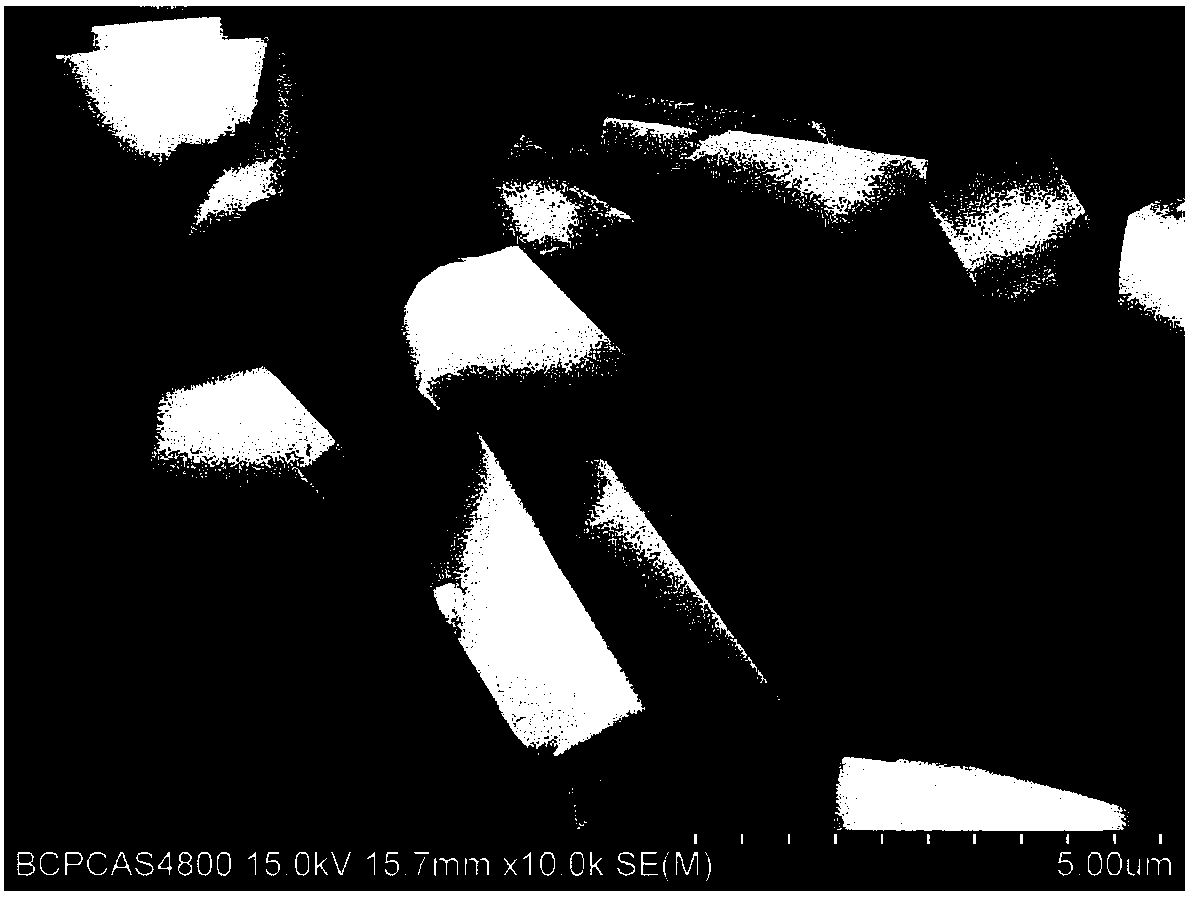

[0049] This example is carrier preparation.

[0050] Under the condition of stirring, add 9.6g of acetic acid to 29g of tetrapropyl titanate under ice bath, after stirring for 30min, add the mixture of 0.86g of polyethylene oxide, 5.42g of hydrochloric acid, and 3.8g of water, and stir evenly. A clear homogeneous solution was formed. Add 10.42g ethyl orthosilicate, and continue stirring for no less than 3h. Then 4.44 g of N-methylformamide was added, and after vigorous stirring for 5 min, the resulting mixture sol was transferred to a polytetrafluoroethylene test tube or a glass tube. The tube was sealed, aged at 60°C for 24 hours, and the wet gel was dried and calcined to obtain micron-sized through-hole TiO 2 -SiO 2 Overall material A1.

Embodiment 2

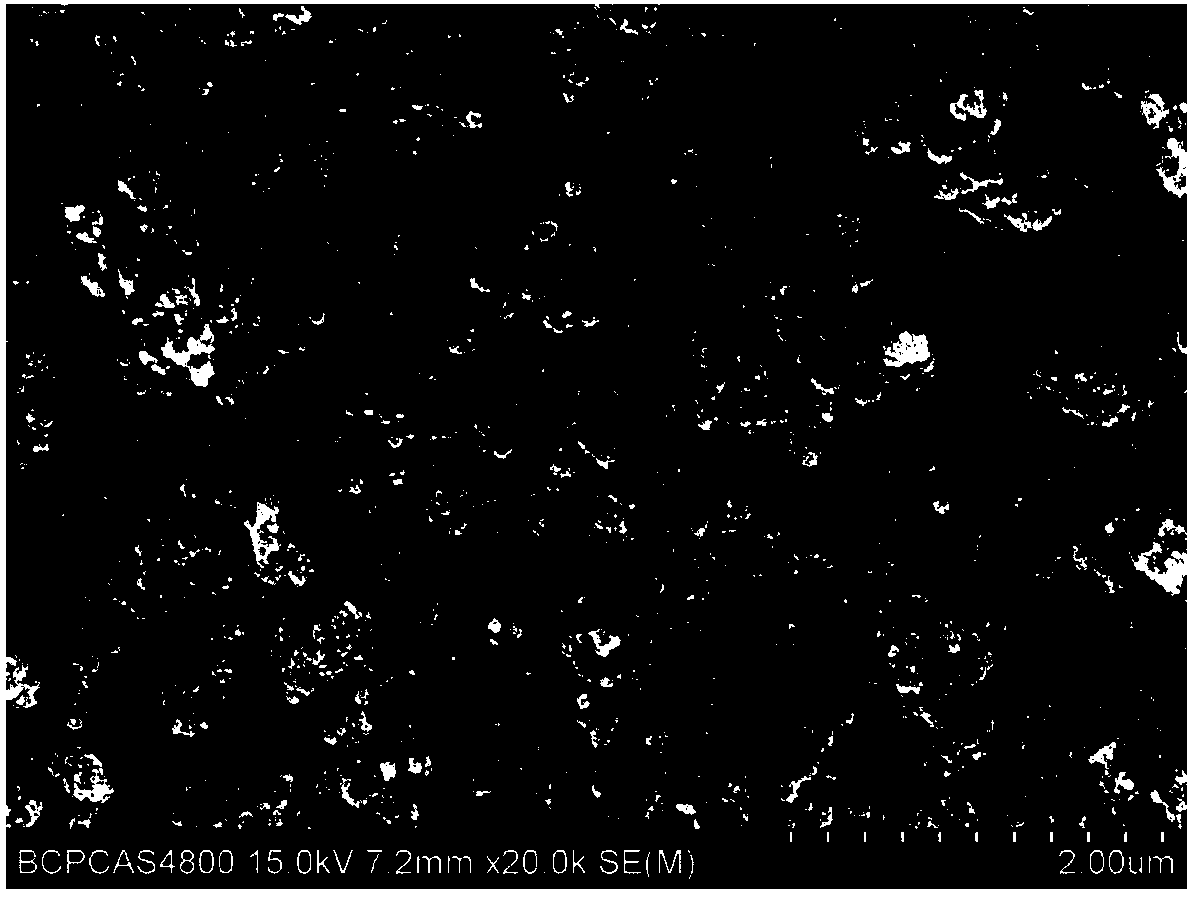

[0052] This example is carrier preparation.

[0053] Dissolve 0.4g of polyethylene oxide in a mixture of 3g of hydrochloric acid and 2g of water, and add this solution to a solution containing 18g of tetrabutyl titanate and 5.6g of acetic acid under stirring conditions. After stirring evenly, the Transparent homogeneous solution. Add 6.3g ethyl orthosilicate and continue stirring for 4h. Then 2.5 g of N-methylformamide was added, and after vigorous stirring for 4 min, the resulting mixture sol was transferred to a polytetrafluoroethylene test tube or a glass tube. The tube was sealed, aged at 70°C for 24 hours, and the wet gel was dried and calcined to obtain micron-sized through-hole TiO 2 -SiO 2 Overall material A2.

Embodiment 3

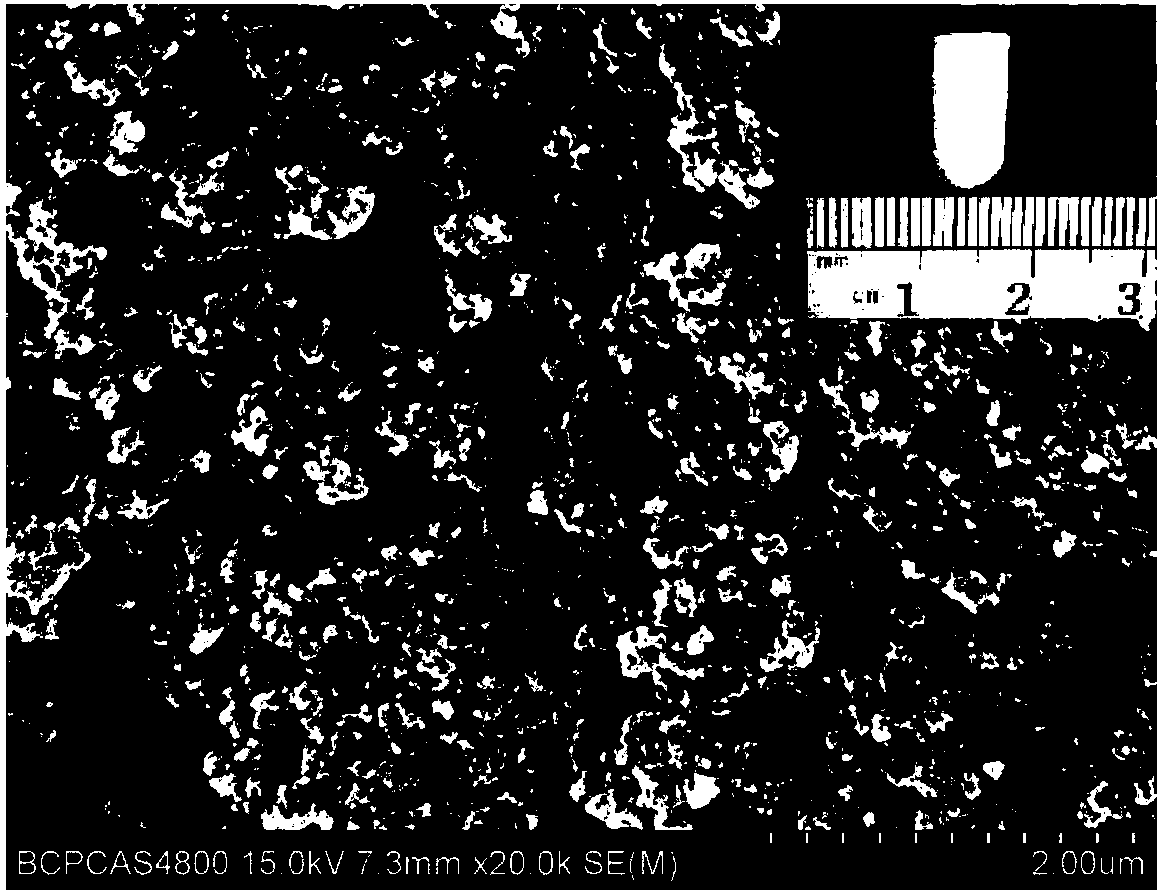

[0063] Dissolve 0.08g of sodium hydroxide in 12g of water, add 6.9g of tetrapropylammonium hydroxide, stir and mix evenly to obtain a precursor solution. Under ultrasound and / or negative pressure, micron-sized through-hole TiO 2 -SiO 2 Carrier A1 was immersed in the precursor solution for 30 min. The impregnated carrier was filtered and taken out, and placed on a support in the autoclave, the precursor filtrate was poured into the bottom of the autoclave, and water was added to make the solution at the bottom of the autoclave reach 10 g. The reaction kettle was sealed, and hydrothermal reaction was carried out at 175° C. for 2 d. The carrier was taken out and washed with water, dried at 110° C. for 12 hours, and calcined in an air atmosphere of 550° C. for 6 hours to obtain the hierarchically porous TS-1 zeolite material A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com