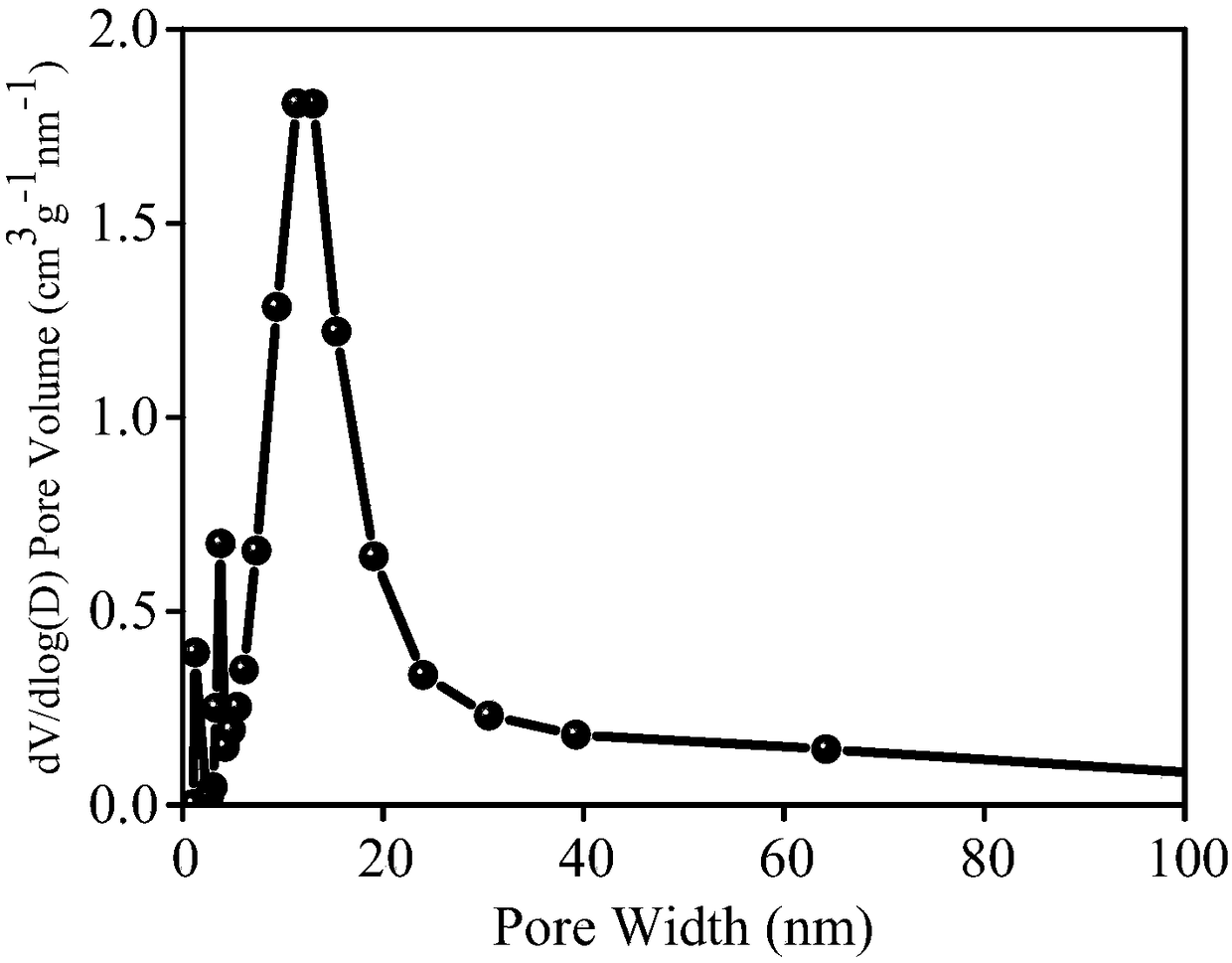

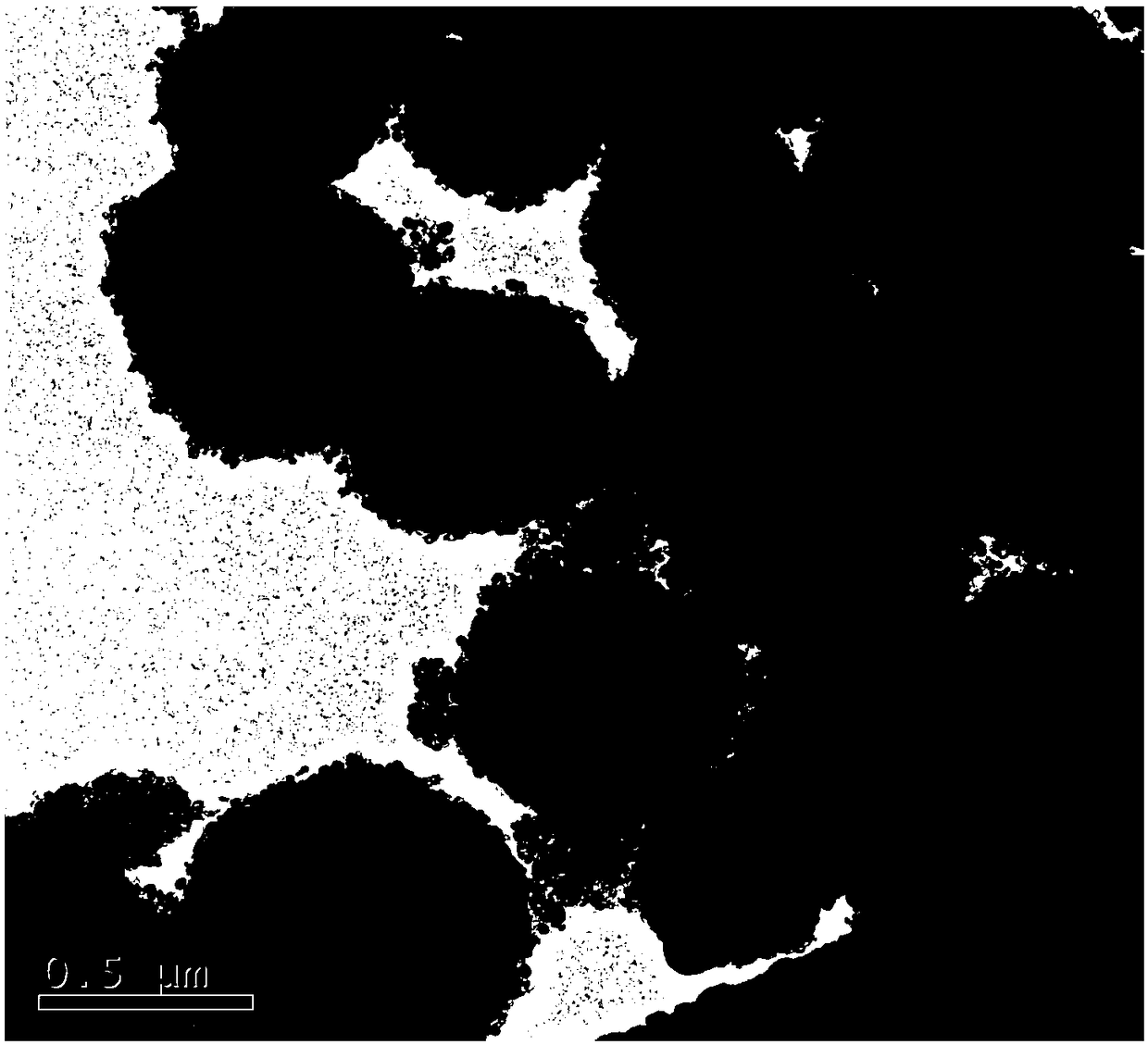

Thin-wall local graphitization porous carbon sphere material, preparation method thereof and application thereof in lithium sulfur battery

A technology of graphitization and porous carbon, which is applied in the preparation/purification of carbon, chemical instruments and methods, battery electrodes, etc., can solve the problems of low sulfur loading, poor cycle performance, and low energy density, and achieve high conductivity, The effect of low cost and high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add 5.4g of cellulose derivatives, 4.13g of sodium chloride, 2.72g of sodium dodecylsulfonate, and 4.1g of cobalt chloride into 20mL of deionized water, and stir at 50°C until the solution is clear to prepare a spray solution. Under an argon atmosphere, set the spray volume through the spray system to 5mL / min, and the atomization pressure to 10MPa, spray the spray solution at 160°C in the pyrolysis furnace, collect the crude product of spray pyrolysis; dry the obtained The crude pyrolysis product is sprayed and placed in a tube furnace in an inert atmosphere for further heat treatment at a temperature of 810°C. The resulting heat-treated product is further washed and dried to obtain a thin-walled localized graphitized porous carbon sphere material; the heat-treated product is decomposed After repeated washing with ion water and dilute acid, place it at 70°C and vacuum-dry for 12 hours. Repeated washing with deionized water and dilute acid can remove residual soluble sal...

Embodiment 2

[0048] Add 3.1g of modified polybutadiene resin, 4.13g of potassium chloride, 3.45g of polyvinylpyrrolidone, and 5.3g of ferric chloride into 20mL of deionized water, and stir at 50°C until the solution is clear to prepare a spray solution. Under an argon atmosphere, set the spray volume of the spray system to 2mL / min, and the atomization pressure to 20MPa, spray the spray solution at 180°C in the pyrolysis furnace, collect the crude product of spray pyrolysis; dry the obtained The crude pyrolysis product is sprayed and placed in a tube furnace in an inert atmosphere for further heat treatment at a temperature of 900°C. The heat-treated product is further washed and dried to obtain a thin-walled localized graphitized porous carbon sphere material; the heat-treated product is decomposed After repeated washing with ion water and dilute acid, place it at 70°C and vacuum-dry for 12 hours. Repeated washing with deionized water and dilute acid can remove residual soluble salts and i...

Embodiment 3

[0050] Add 3.1g of modified polybutadiene resin, 4.13g of potassium chloride, 3.45g of polyvinylpyrrolidone, and 5.3g of nickel trichloride into 20mL of deionized water, and stir at 50°C until the solution is clear to prepare a spray solution. Under an argon atmosphere, set the spray volume through the spray system to 2mL / min, and the atomization pressure to 15MPa, spray the spray solution at 200°C in the pyrolysis furnace, collect the crude product of spray pyrolysis; dry the obtained The crude pyrolysis product is sprayed and placed in a tube furnace in an inert atmosphere for further heat treatment at a temperature of 1000°C. The heat-treated product is further washed and dried to obtain a thin-walled localized graphitized porous carbon sphere material; the heat-treated product is decomposed After repeated washing with ion water and dilute acid, place it at 70°C and vacuum-dry for 12 hours. Repeated washing with deionized water and dilute acid can remove residual soluble sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com