Asymmetric low-temperature catalytic filter material and preparation method thereof

A technology for low-temperature catalysis and filtering materials, which is applied in catalyst activation/preparation, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc. Optimal selection of catalytic reaction effect, high filtration precision, and effect of improving flue gas treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

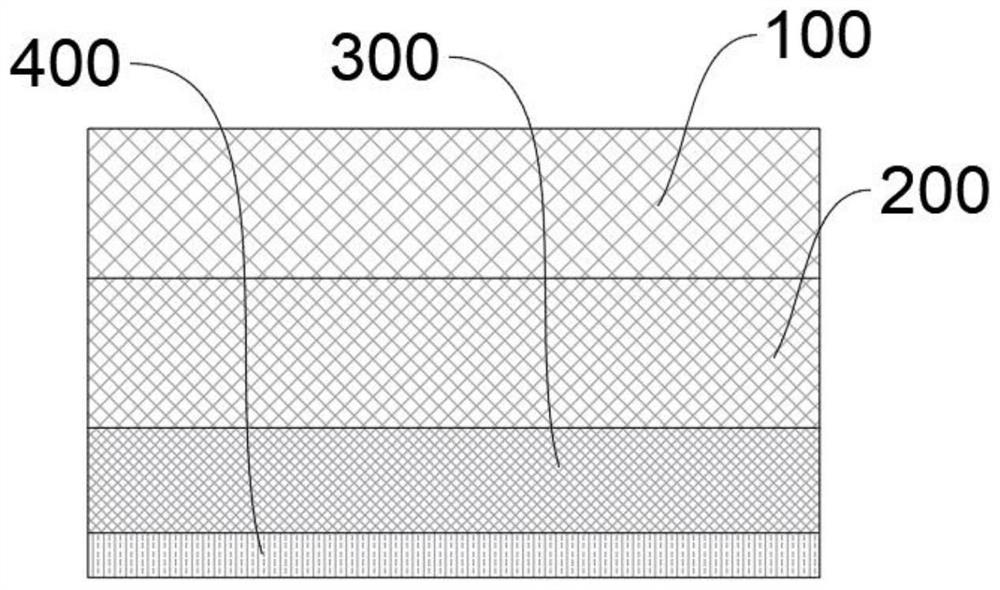

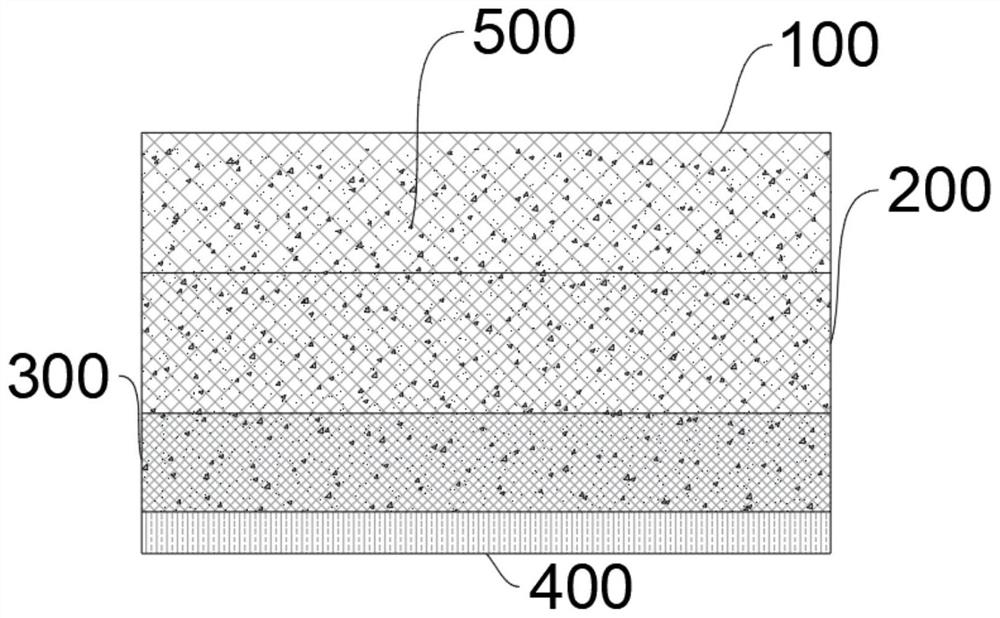

[0056] An asymmetric low-temperature catalytic filter material, which is a three-layer fiber mesh composite structure, is composed of three layers of metal fiber filter mesh, and the metal fiber used in the metal fiber filter mesh adopts formula 1, wherein the mesh number of the first layer of metal fiber filter mesh is 12 meshes, wire diameter 0.45mm, thickness 1.5mm; second metal fiber filter mesh 35 meshes, wire diameter 0.25mm, thickness 1.5mm; third layer metal fiber filter mesh 75 mesh, wire The diameter is 0.12mm and the thickness is 1.5mm. The above-mentioned metal fiber filter nets are stacked sequentially from top to bottom according to the mesh number of the filter nets from small to large, and are sintered at 1250°C for 2.5 hours under a pressure of 10 MPa to form a multi-layer fiber net composite structure. Further adopt the mode of modulation powder slurry to spray on the surface of the third layer of metal fiber filter screen with 360 order nickel-chromium-iron-...

Embodiment 2

[0058] Concrete operation is the same as embodiment 1, and different from embodiment 1 is:

[0059] The metal fiber filter mesh is stacked from top to bottom in order of mesh size from small to large, and sintered at 1300°C for 2 hours under a pressure of 10MPa to form a multi-layer fiber mesh composite structure. Then further use 500 mesh nickel-chromium-iron-iron-iron powder to spray on the surface of the third layer of metal fiber filter screen by modulating powder slurry. At the same time, PEG, PVB and PAA with a mass ratio of 1:1:1 are added as a binder, and the amount of the binder added is 10wt% of the nickel-chromium-iron-aluminium-iron powder, and the uniformly mixed powder slurry is sprayed on the wire The surface of the net is then dried at 100°C, and the spraying amount is 350g / m2 in terms of dry powder mass 2 , After sintering, a sintered metal powder filter layer is formed to form an asymmetric structure carrier.

Embodiment 3

[0061] Concrete operation is the same as embodiment 1, and different from embodiment 1 is:

[0062] The metal fiber filter mesh is stacked from top to bottom in the order of filter mesh size from small to large, and is sintered at 1250°C for 3 hours under the pressure of 10MPa to form a multi-layer fiber mesh composite structure. Subsequently, 300 mesh nickel-chromium-iron-iron-iron powder is sprayed on the surface of the third layer of metal fiber filter screen by modulating powder slurry. The liquid medium for adjusting the slurry is ethanol, and the amount of ethanol added is the mass of nickel-chromium-iron-iron-iron powder. At the same time, PVA is added as a binder. The amount of binder added is 5wt% of the nickel-chromium-iron-aluminium-iron powder. The uniformly mixed powder slurry is sprayed on the surface of the screen, and then dried at 80°C. The spraying amount 250g / m2 based on dry powder mass 2 , After sintering, a sintered metal powder filter layer is formed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com