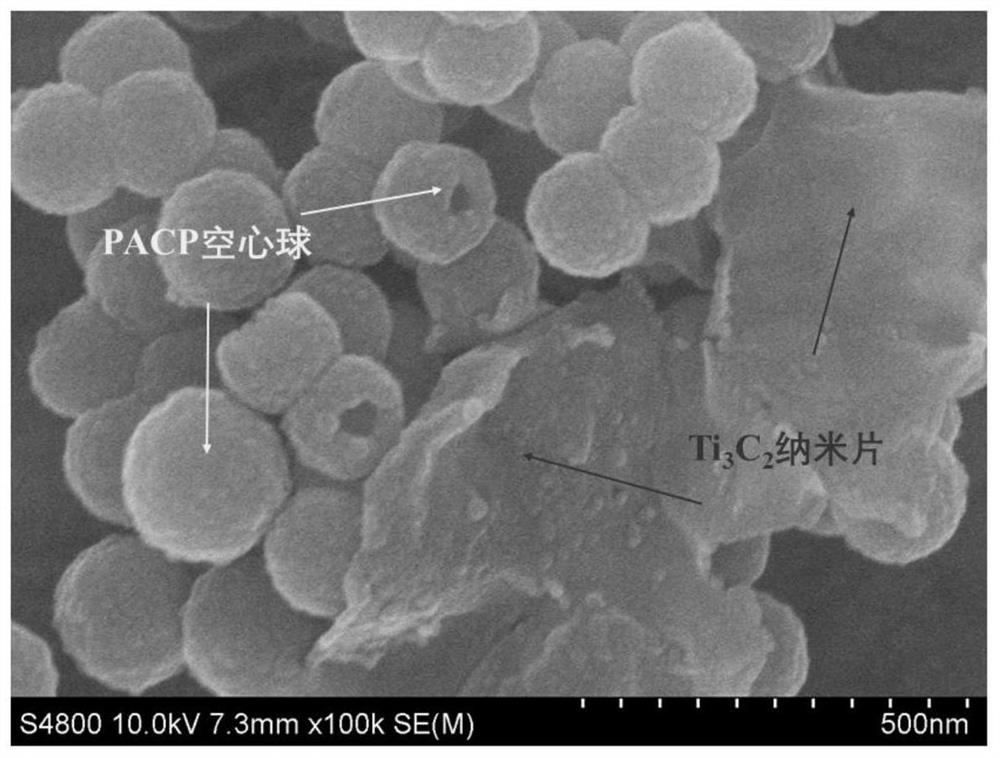

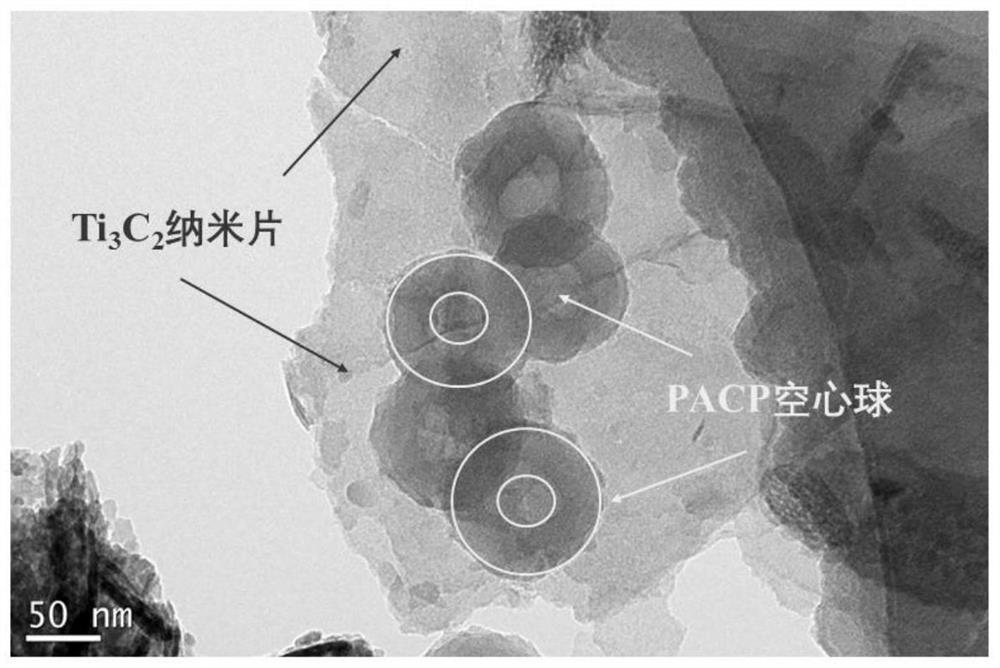

Conductive polymer hollow sphere PACP@ titanium carbide composite material and preparation method thereof

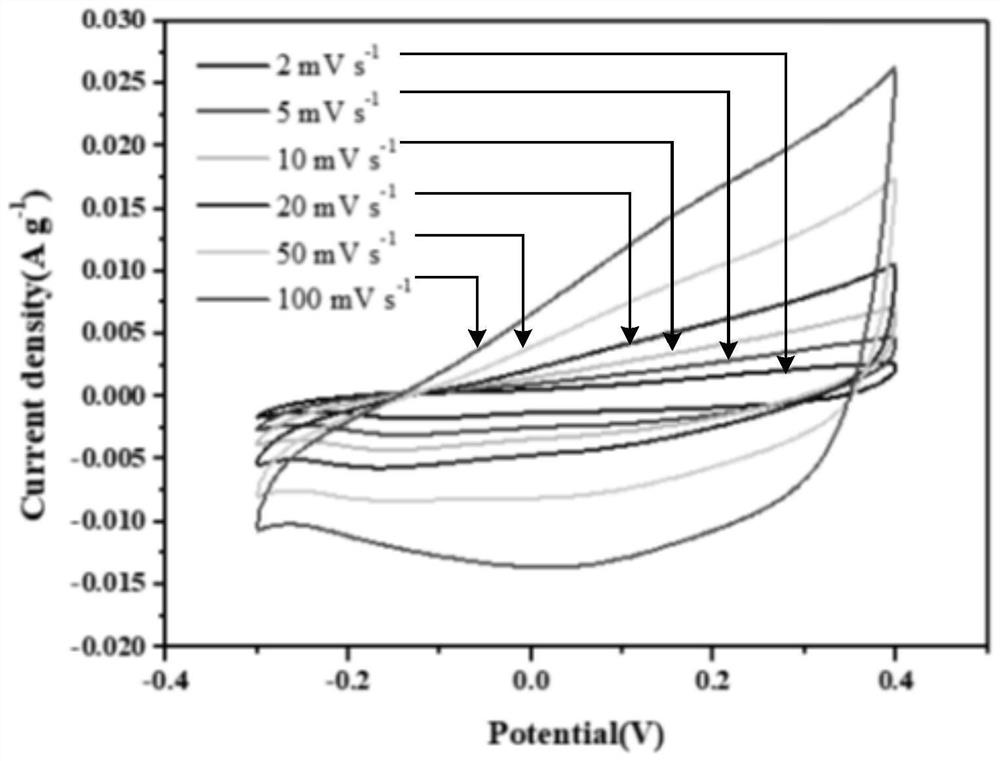

A technology of conductive polymers and composite materials, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors. Effects of Particle Transport and Diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1, Lamellar Ti 3 C 2 preparation of

[0038] Weigh 2g of LiF and 20mL of 9M HCl (specifically, 15mL of concentrated HCl+5mL of water with a mass concentration of 36% and 15mL of concentrated HCl+5mL of water) into a 50mL polytetrafluoroethylene beaker and stir for 10min to make the LiF disperse into hydrochloric acid solution, slowly add 2g of Ti 3 AlC 2 , magnetically stirred for 24 h to obtain reaction solution A. Wash the reaction solution A with ionic water until the pH>6, then centrifuge, dissolve the centrifuged precipitate in 300mL ultrapure water to obtain the dispersion B, carry out the vacuum deoxygenation of the dispersion B for 2 hours, and then ultrasonically treat it for 1 hour , centrifuged for 1 h, and the supernatant after centrifugation was freeze-dried to obtain sheet Ti 3 C 2 Powder.

[0039] Step 2, prepare PACP mixture

[0040] Weigh 0.38mL of aniline and 0.29mL of pyrrole and mix them in a beaker, add 60mL of deionized water and 0.06g...

Embodiment 2

[0046] Step 1, Lamellar Ti 3 C 2 preparation of

[0047] Weigh 2g of LiF and 20mL of 9M HCl (specifically, 15mL of concentrated HCl+5mL of water with a mass concentration of 36% and 15mL of concentrated HCl+5mL of water) into a 50mL polytetrafluoroethylene beaker and stir for 10min to make the LiF disperse into hydrochloric acid solution, slowly add 2g of Ti 3 AlC 2 , magnetically stirred for 24 h to obtain reaction solution A. Wash the reaction solution A with ionic water until the pH>6, then centrifuge, dissolve the centrifuged precipitate in 300mL of ultrapure water to obtain the dispersion B, carry out the vacuum deoxygenation of the dispersion B for 2 hours, and then ultrasonically treat it for 1 hour , centrifuged for 1 h, and the supernatant after centrifugation was freeze-dried to obtain sheet Ti 3 C 2 Powder.

[0048] Step 2, prepare PACP mixture

[0049] Weigh 0.38mL of aniline and 0.29mL of pyrrole and mix them in a beaker, add 60mL of deionized water and 0....

Embodiment 3

[0053] Step 1, Lamellar Ti 3 C 2 preparation of

[0054] Weigh 2g of LiF and 20mL of 9M HCl (specifically, 15mL of concentrated HCl+5mL of water with a mass concentration of 36% and 15mL of concentrated HCl+5mL of water) into a 50mL polytetrafluoroethylene beaker, and stir for 10min to make LiF evenly disperse into hydrochloric acid solution, slowly add 2g of Ti 3 AlC 2 , magnetically stirred for 24 h to obtain reaction solution A. Wash the reaction solution A with ionic water until the pH>6, then centrifuge, dissolve the centrifuged precipitate in 300mL ultrapure water to obtain the dispersion B, carry out the vacuum deoxygenation of the dispersion B for 2 hours, and then ultrasonically treat it for 1 hour , centrifuged for 1 h, and the supernatant after centrifugation was freeze-dried to obtain sheet Ti 3 C 2 Powder.

[0055] Step 2, prepare PACP mixture

[0056] Weigh 0.38mL of aniline and 0.29mL of pyrrole and mix them in a beaker, add 60mL of deionized water and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com