Copper and bismuth co-doped nano titanium dioxide photocatalyst and preparation and application thereof

A nano-titanium dioxide and photocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbon production from carbon oxides, etc., can solve the problems affecting the effective utilization of sunlight and solar energy utilization. It can solve the problems of low and high carrier recombination rate, and achieve the effect of effective utilization and resource utilization, large application potential, and high photon efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

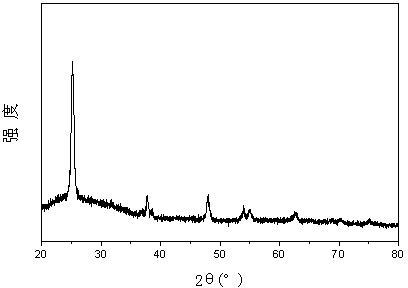

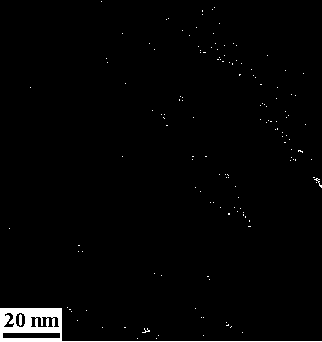

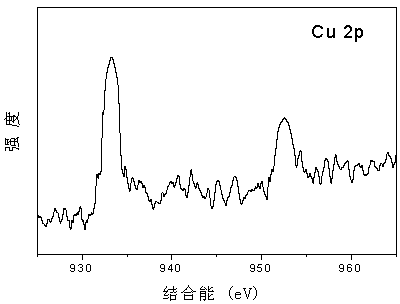

Embodiment 1

[0030] 2.0g nano-TiO 2 The powder was placed in 75 mL of 10mol / L KOH solution, and 0.05 g CuCl was added to it 2 with 0.2 g Bi(NO 3 ) 3 , stirred at room temperature for 20 min to obtain a mixed suspension, transferred the obtained mixed suspension to a 100 mL stainless steel reactor, placed the reactor in a microwave digestion apparatus, and reacted at a constant temperature of 120 °C for 6 h, cooled, poured off the supernatant, and used Wash with ionic water to neutrality, then wash with 0.1 mol / L nitric acid solution and deionized water, centrifuge filter and dry the obtained precipitate at 90 °C for 8 h to obtain a powder sample; calcinate the obtained powder sample at 400 °C for 2 h to obtain copper , bismuth co-doped nano-TiO 2 Photocatalyst, in terms of mole fraction, the doping amount of copper is 1.1%, the doping amount of bismuth is 2.4%, the crystal form is anatase type, the shape is nanotube, the length is about 200 nm, and the diameter is 8 nm.

[0031] Visibl...

Embodiment 2

[0033] 3.0g nano-TiO 2 The powder was placed in 80 mL of 12mol / L NaOH solution, and 0.02 g Cu(NO 3 ) 2 with 0.12 g Bi(Ac) 3 , stirred at room temperature for 30 min to obtain a mixed suspension, which was transferred to a 100 mL stainless steel reactor, and the reactor was placed in a microwave digestion apparatus at a constant temperature of 130 °C for 8 h. Wash with water until neutral, then wash with 0.05 mol / L hydrochloric acid solution and deionized water, centrifuge and dry at 80 °C for 10 h to obtain a powder sample; calcinate the obtained powder sample at 500 °C for 1 h to obtain copper and bismuth co-doped Nano TiO 2 Photocatalyst, in mole fraction, wherein the doping amount of copper is 0.3%, the doping amount of bismuth is 0.8%, the crystal form is anatase type, the shape is nanobelt, the length is about 500 nm, and the diameter is 6 nm.

[0034] Add 100 mL of 0.01 mol / L Na to the reactor 2 CO 3 solution and 0.1 g of the copper-bismuth co-doped nano-TiO prepar...

Embodiment 3

[0036] 5.0gTiO 2 The colloid was placed in 100 mL of 15mol / L KOH solution, and 0.08 g CuSO 4 with 0.66 g BiCl 3 , stirred at room temperature for 15 min to obtain a mixed suspension, which was transferred to a 150 mL stainless steel reactor, and the reactor was placed in a microwave digestion apparatus at a constant temperature of 150 °C for 5 h. Wash with water until neutral, then wash with 0.2 mol / L nitric acid solution and deionized water, centrifuge and dry at 95 °C for 7 h to obtain a powder sample; calcinate the obtained powder sample at 450 °C for 1.5 h to obtain copper and bismuth co-doped Nano TiO 2 Photocatalyst, in mole fraction, wherein the doping amount of copper is 0.5%, the doping amount of bismuth is 3.4%, the crystal form is anatase type, the shape is nanowire, the length is about 1.0 μm, and the diameter is 5 nm.

[0037] Add 100 mL of 0.01 mol / L Na to the reactor 2 CO 3 solution and 0.1 g of the copper-bismuth co-doped nano-TiO prepared above 2 Photoca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com