Preparation method of ozone catalytic decomposition catalyst using expandable graphite as carrier

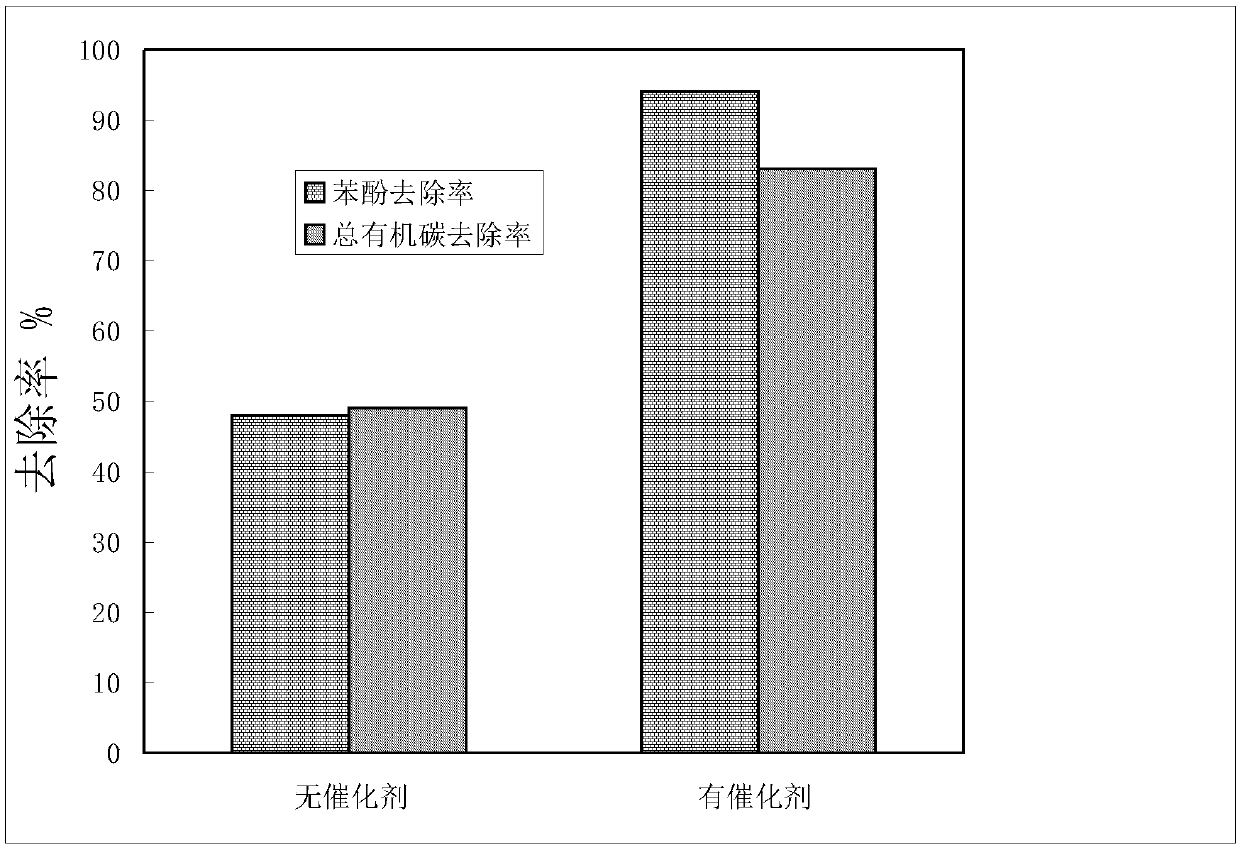

A technology of expanded graphite and catalytic decomposition, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., which can solve the problem of catalyst performance carrier being greatly affected and environmental hazards in the preparation process large, unstable catalyst activity, etc., to achieve the effect of abundant active sites, excellent adsorption performance, and improved disposal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of expanded graphite carrier loaded with cerium active components:

[0037] First, the ozone pre-oxidation treatment of flake graphite: 150g deionized water is added into a beaker with a volume of 500mL, and the beaker filled with deionized water is placed on a multifunctional stirrer, and then 100g of flakes with a particle size of 80 mesh Add graphite into the beaker and turn on the stirring control switch of the stirrer; then insert the gas generating tube of the ozone generator into the bottom of the beaker, turn on the power switch of the ozone generator, the gas source used by the ozone generator is pure oxygen, and the gas generating tube is passed into the solution The amount of ozone is 5mg / L, and the flake graphite is subjected to ozonation at room temperature for 20min; Flake graphite was dried at 80°C for 8 hours;

[0038] Carry out chemical oxidation intercalation treatment to flake graphite next: first 25g mass concentration is that 70% pe...

Embodiment 2

[0051] (1) Preparation of expanded graphite carrier loaded with cerium active components:

[0052] First, the ozone pre-oxidation treatment of flake graphite: first add 150g of deionized water into a beaker with a volume of 500mL, and place the beaker containing deionized water on a multifunctional stirrer, and then put 100g of deionized water with a particle size of 80 mesh Add flake graphite into the beaker and turn on the stirring control switch of the agitator; then insert the gas generating tube of the ozone generator into the bottom of the beaker and turn on the power switch of the ozone generator. The gas source used by the ozone generator is pure oxygen, which is passed into the The amount of ozone in the solution was 5 mg / L, and the flake graphite was subjected to ozonation at room temperature for 24 minutes; after the ozone oxidation was completed, the solution was filtered to collect the flake graphite powder, and then the flake graphite was washed with deionized wat...

Embodiment 3

[0065] (1) Preparation of expanded graphite carrier loaded with cerium active components:

[0066] First, the ozone pre-oxidation treatment of flake graphite: first add 150g of deionized water into a beaker with a volume of 500mL, and place the beaker containing deionized water on a multifunctional stirrer, and then put 100g of deionized water with a particle size of 80 mesh Add flake graphite into the beaker and turn on the stirring control switch of the agitator; then insert the gas generating tube of the ozone generator into the bottom of the beaker and turn on the power switch of the ozone generator. The gas source used by the ozone generator is pure oxygen, which is passed into the The amount of ozone in the solution was 5 mg / L, and the flake graphite was subjected to ozonation at room temperature for 27 minutes; after the ozone oxidation was completed, the solution was filtered to collect the flake graphite powder, and then the flake graphite was washed with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com