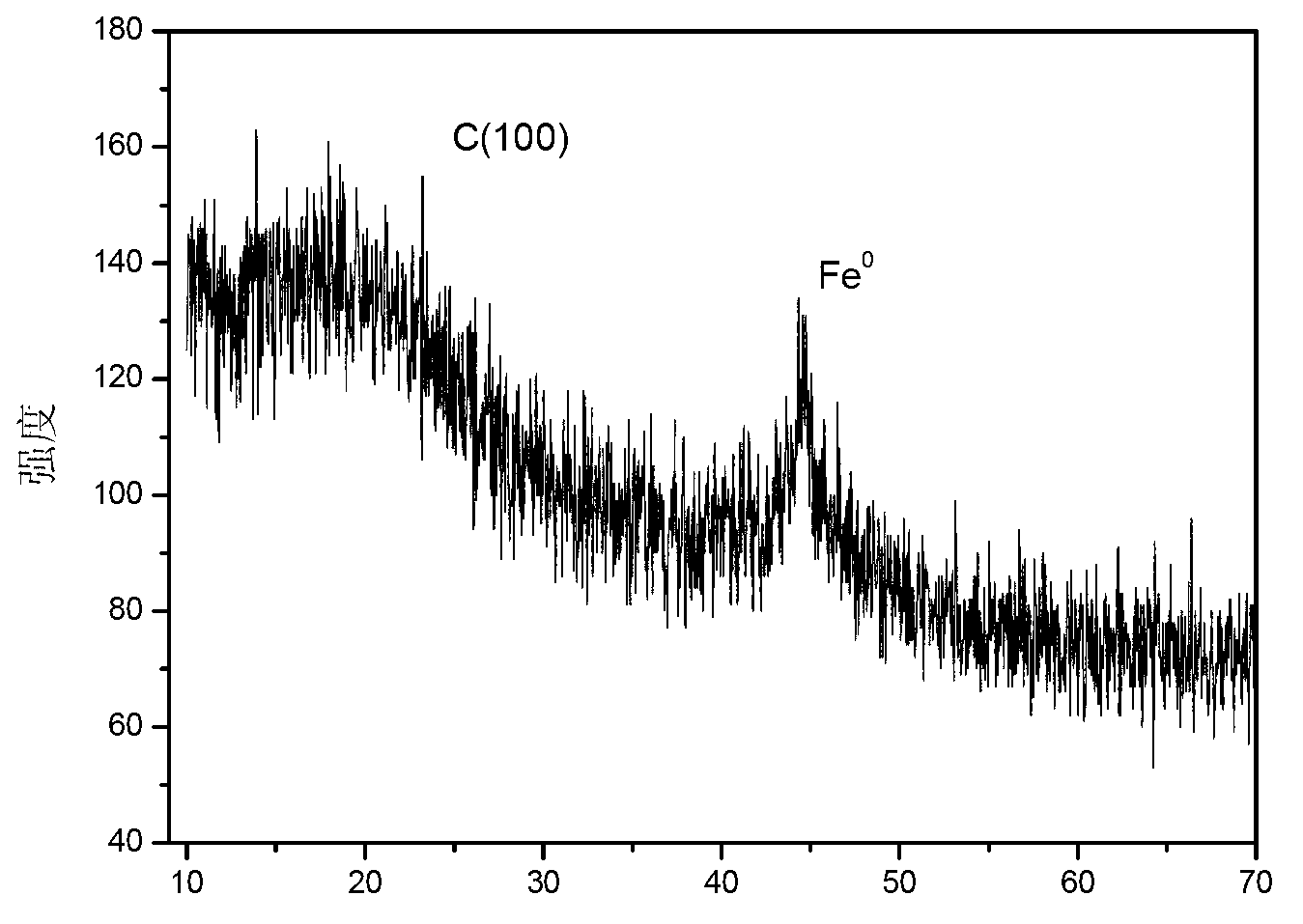

Method for preparing ordered mesoporous carbon loaded nano zero-valent iron composite material

A nano-zero-valent iron and composite material technology, applied in the field of mesoporous material preparation, can solve the problems of reduced material reactivity, channel collapse, limited nano-zero-valent iron particles, etc., to reduce storage and transportation costs, improve stability, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example uses FeCl 2 4H 2 O, NaBH 4 and polyethylene glycol 4000 to prepare ordered mesoporous carbon-supported nano-zero-valent iron composites with a loading rate of 20%.

[0024] (1) 1.2791g FeCl 2 4H 2 O and 1.7997g of ordered mesoporous carbon (that is, the mass ratio of Fe to C is 1:5) were dissolved in 90mL of 80% ethanol aqueous solution and stirred for 30 minutes;

[0025] (2) Add 0.3g PEG-4000 to the above mixture, and adjust the pH of the mixture to 6.5 with 0.1mol / L NaOH solution;

[0026] (3) Add 1.7354g KBH 4 Dissolve in 64.3mL deionized water (to make KBH with a concentration of 0.5mol / L 4 solution), added to the mixture at a rate of 1 drop / second, the added KBH 4 The molar amount of the iron ion is 5 times that of the iron ion. After the addition, the stirring reaction is continued for 60 minutes, and the ordered mesoporous carbon-loaded nano-zero-valent iron composite material can be generated;

[0027] (4) Separation of ordered mesoporous c...

Embodiment 2

[0031] In this example, Fe 2 (SO 4 ) 3 , NaBH 4 and polyethylene glycol 6000 to prepare ordered mesoporous carbon-supported nano-zero-valent iron composites with a loading rate of 10%.

[0032] (1) 1.2871g Fe 2 (SO 4 ) 3 Dissolve 3.6040g of ordered mesoporous carbon (that is, the mass ratio of Fe to C is 1:10) in 90mL of 80% ethanol aqueous solution, and stir for 30 minutes;

[0033] (2) Add 0.3g of polyethylene glycol 4000 (PEG-6000) to the above mixture, and adjust the pH of the mixture to 6.0 with 0.1mol / L NaOH solution;

[0034] (3) Add 1.2177g NaBH 4 Dissolve in 64.3mL deionized water (to make NaBH with a concentration of 0.5mol / L 4 solution), added to the mixture at a rate of 1 drop / second, the added NaBH 4 The molar amount of the iron ion is 6 times that of the iron ion. After the addition, the stirring reaction is continued for 30 minutes, and the ordered mesoporous carbon-loaded nano-zero-valent iron composite material can be generated;

[0035] (4) Separation...

Embodiment 3

[0038] This embodiment adopts Fe(NO 3 ) 3 9H 2 O and polyvinylpyrrolidone-K30 to prepare ordered mesoporous carbon-supported nano-zero-valent iron composites with a loading rate of 30%.

[0039] (1) 2.6000g Fe(NO 3 ) 3 9H 2 O and 1.2013g of ordered mesoporous carbon (i.e. the mass ratio of Fe to C is 3:10) were dissolved in 90mL of 80% ethanol aqueous solution and stirred for 30 minutes;

[0040] (2) Add 0.3g polyvinylpyrrolidone-K30 (PVP-K30) to the above mixture, and adjust the pH of the mixture to 6.8 with 0.1mol / L NaOH solution;

[0041] (3) Add 1.7354g KBH 4 Dissolve in 64.3mL deionized water (to make KBH with a concentration of 0.5mol / L 4 solution), added to the mixture at a rate of 2 drops / second, the added KBH 4 The molar amount of the iron ion is 4 times that of the iron ion. After the addition, the stirring reaction is continued for 90 minutes, and the ordered mesoporous carbon-loaded nano-zero-valent iron composite material can be generated;

[0042] (4) Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com