A molybdenum diselenide/carbon nanotube array composite electrode, preparation method and application

A technology of carbon nanotube array and molybdenum diselenide, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low specific capacity, high current charge and discharge performance (poor rate performance, etc.) The effect of increasing surface area, enriching active sites, and slowing release volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

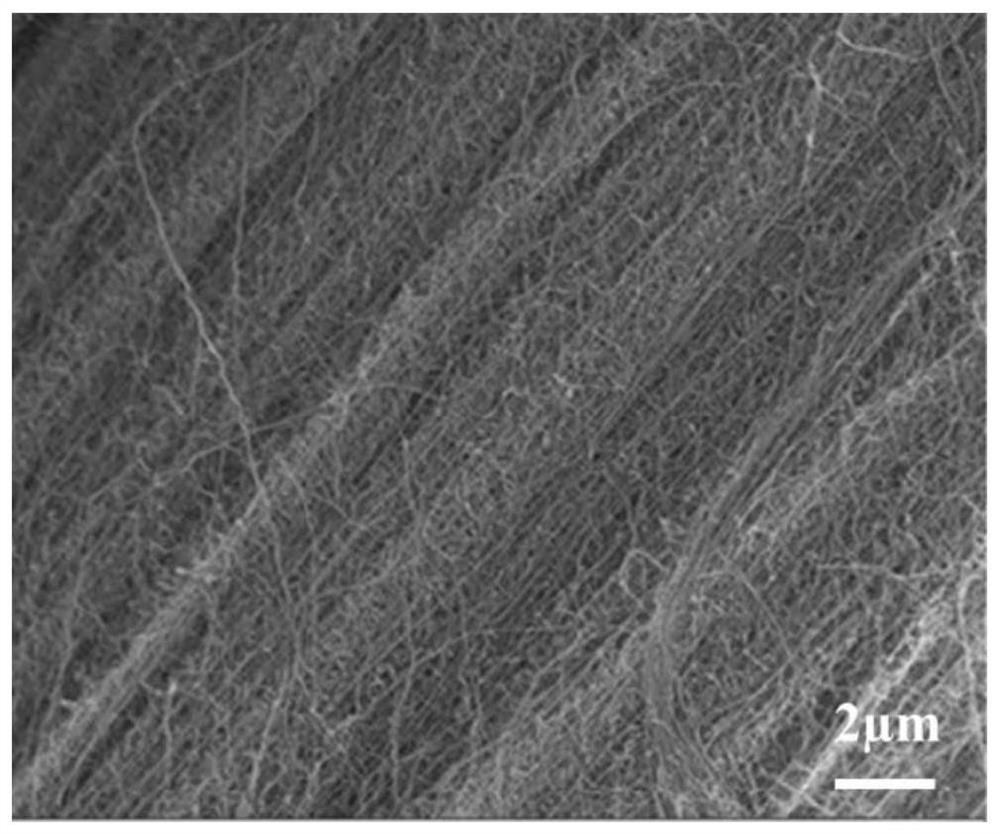

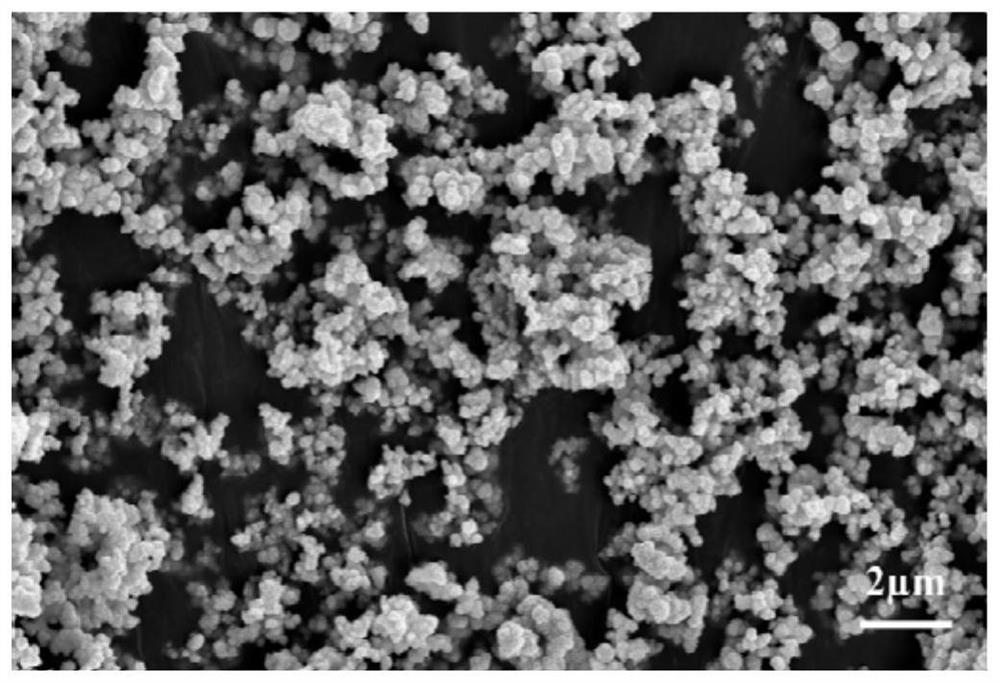

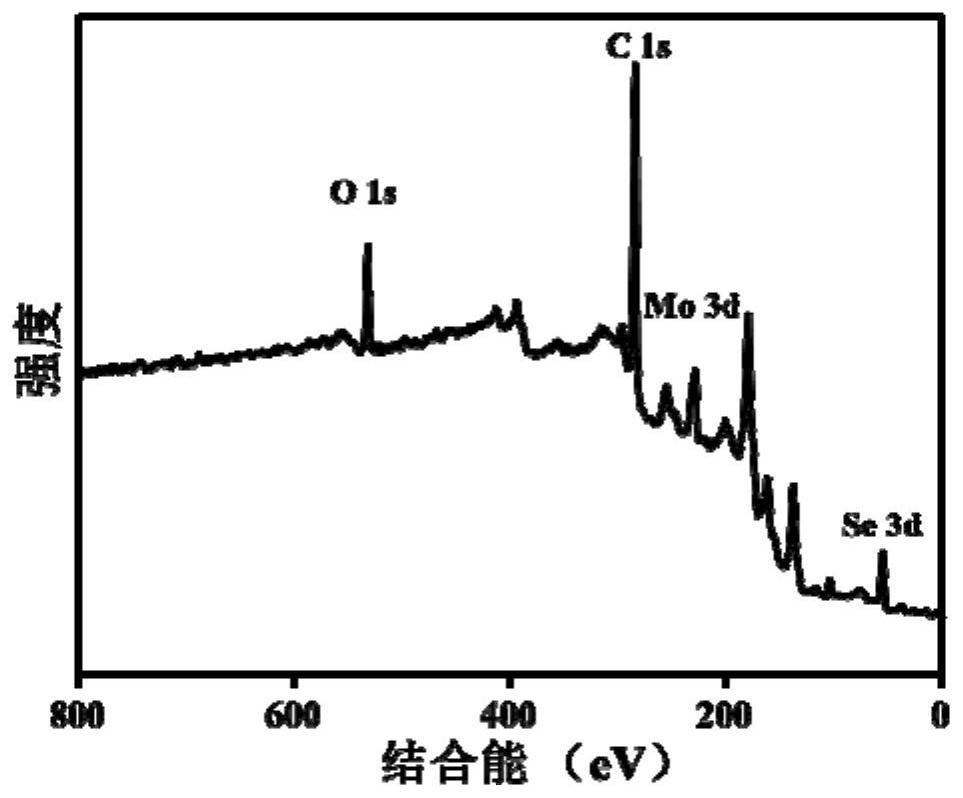

[0036] The invention uses a simple spray chemical deposition method to prepare a carbon nanotube array, and then grows molybdenum diselenide on the carbon nanotube array by a hydrothermal method to obtain a composite electrode material on which molybdenum diselenide is deposited on the surface of the carbon nanotube. In the following embodiments of the present invention, vertically aligned carbon nanotube arrays are prepared. The preparation method of molybdenum diselenide / carbon nanotube array composite electrode of the present invention specifically comprises the following steps:

[0037] Step 1: Preparation of carbon nanotube arrays:

[0038] Place the cleaned silicon wafer in the constant temperature zone of the tube furnace, exhaust it with argon, and then heat it to 700-750°C at a rate of 25°C per minute. When the temperature rises to 700-750°C, the argon and hydrogen At the same time, it is passed into the tube furnace, wherein the volume ratio of hydrogen is 10% to 20...

Embodiment 1

[0048] Step 1: Preparation of carbon nanotube arrays:

[0049] Clean the silicon wafer with anhydrous ethanol ultrasonically for 15 minutes, then ultrasonically clean it with deionized water for 15 minutes, and dry it naturally in a clean environment to remove surface impurities;

[0050] Place the cleaned silicon wafer (1cm*1cm) in the middle of the quartz boat, and place the quartz boat in the constant temperature zone of the tube furnace; use the protective gas argon with a flow rate of 0.5SLM to exhaust for 20min, and set it at a rate of 0.5SLM per minute. Heating at a rate of 25°C to 750°C, during which time the argon flow was maintained at 0.5 SLM. When the temperature rises to 750°C, the flows of argon and hydrogen are controlled to be 0.8SLM and 100SCCM (8:1) respectively, and they are simultaneously passed into the tube furnace for 8 minutes.

[0051] Acetylene with a flow rate of 40 SCCM was introduced as a carbon source, and at the same time, the catalyst of a mixe...

Embodiment 2

[0062] The difference between this example and example 1 is that the preparation temperature in step 2 is 180°C.

[0063] The properties of the molybdenum diselenide / carbon tube array composite electrode prepared in this example and its preparation as a supercapacitor electrode are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com