Ferric oxide/attapulgite/three-dimensional graphene oxide heterogeneous catalyst and preparation method thereof

A heterogeneous catalyst, attapulgite technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the dissolution of Fe ions, broaden the pH range, and is not suitable for recycling and other problems, to achieve high adsorption capacity, improve catalytic performance, improve catalytic ability and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

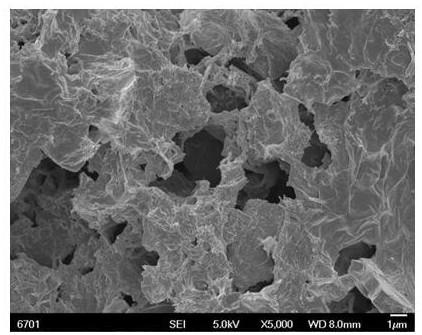

Image

Examples

Embodiment 1

[0019] (1) The attapulgite raw soil was soaked in 1:1 hydrochloric acid for 1.5 hours, washed, filtered, and dried. After purification, the attapulgite content was 70% to 90%. The purified attapulgite clay was baked in a muffle furnace at 600 °C for 2 hours.

[0020] (2) Take 60 mL of concentrated sulfuric acid in a flask, add 1 g of graphite powder and 1 g of sodium nitrate, stir vigorously in a low-temperature water bath at 0-5 °C, then slowly add 6 g of potassium permanganate, and stir for 3 h. The reaction mixture was transferred to a water bath at 35 °C and stirred for 3 h, then 140 mL of deionized water was added, and stirred at room temperature for 12 h. Continue to add 200 mL of deionized water to the mixture, and then slowly add 20 mL of hydrogen peroxide. After the product is left to settle, it is first washed with 5% dilute hydrochloric acid, and then washed with deionized water until it is neutral. Ultrasonic at 100 Hz for 2 hours, a three-dimensional Graphene oxi...

Embodiment 2

[0024](1) The attapulgite raw soil was soaked in 1:1.5 hydrochloric acid for 2 hours, washed, filtered, and dried. After purification, the attapulgite content was 70% to 90%. The purified attapulgite clay was put into a muffle furnace and fired at 500°C for 2.5 hours.

[0025] (2) Take 60 mL of concentrated sulfuric acid in a flask, add 1 g of graphite powder and 1 g of sodium nitrate, stir vigorously in a low-temperature water bath at 0-5 °C, then slowly add 6 g of potassium permanganate, and stir for 3 h. The reaction mixture was transferred to a water bath at 35 °C and stirred for 3 h, then 140 mL of deionized water was added, and stirred at room temperature for 12 h. Continue to add 200 mL of deionized water to the mixture, and then slowly add 20 mL of hydrogen peroxide. After the product is left to settle, it is first washed with 5% dilute hydrochloric acid, and then washed with deionized water until it is neutral. Ultrasonic at 100 Hz for 2 hours, a three-dimensional Gr...

Embodiment 3

[0029] (1) The original attapulgite soil was soaked in 1:5 hydrochloric acid for 2 hours, washed, filtered, and dried. After purification, the attapulgite content was 70% to 90%. The purified attapulgite clay was baked in a muffle furnace at 550 °C for 2 hours.

[0030] (2) Take 60 mL of concentrated sulfuric acid in a flask, add 1 g of graphite powder and 1 g of sodium nitrate, stir vigorously in a low-temperature water bath at 0-5 °C, then slowly add 6 g of potassium permanganate, and stir for 3 h. The reaction mixture was transferred to a water bath at 35 °C and stirred for 3 h, then 140 mL of deionized water was added, and stirred at room temperature for 12 h. Continue to add 200 mL of deionized water to the mixture, and then slowly add 20 mL of hydrogen peroxide. After the product is left to settle, it is first washed with 5% dilute hydrochloric acid, and then washed with deionized water until it is neutral. Ultrasonic at 100 Hz for 2 hours, a three-dimensional Graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com