Preparation method of MnFe2O4-TiO2-graphene aerogel

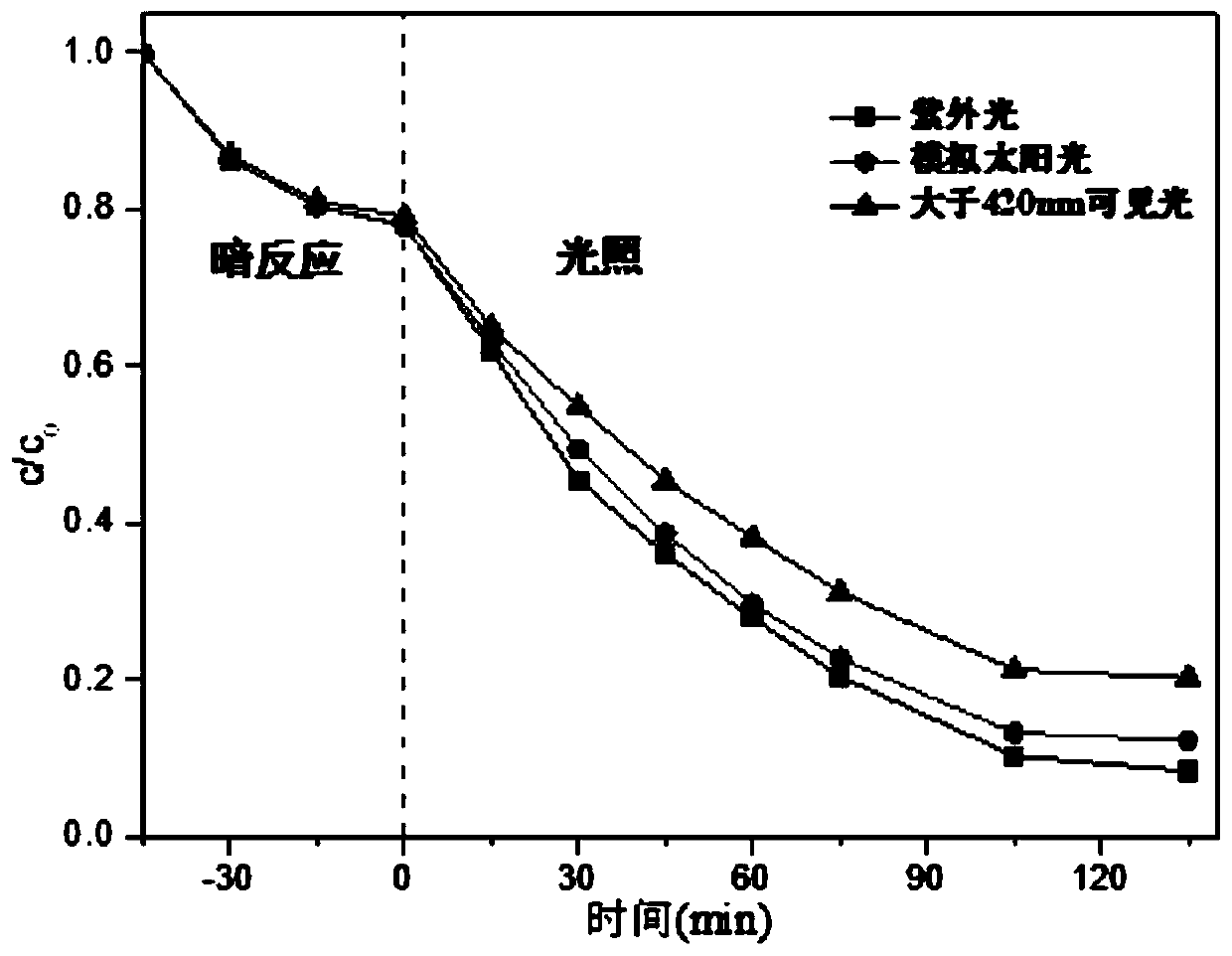

A mnfe2o4-tio2-, graphene aerogel technology, applied in aerogel preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as difficult recovery and reuse, Achieve the effect of improving the electron migration ability, large specific surface area, and convenient recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

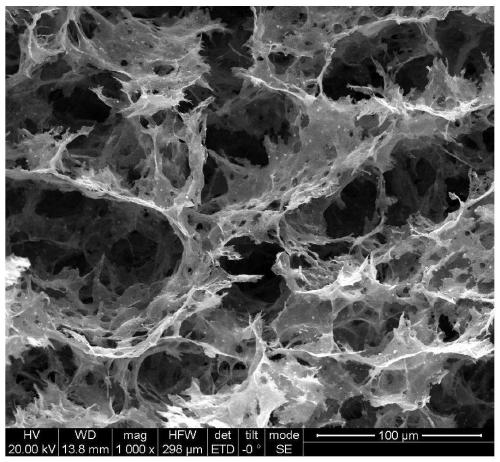

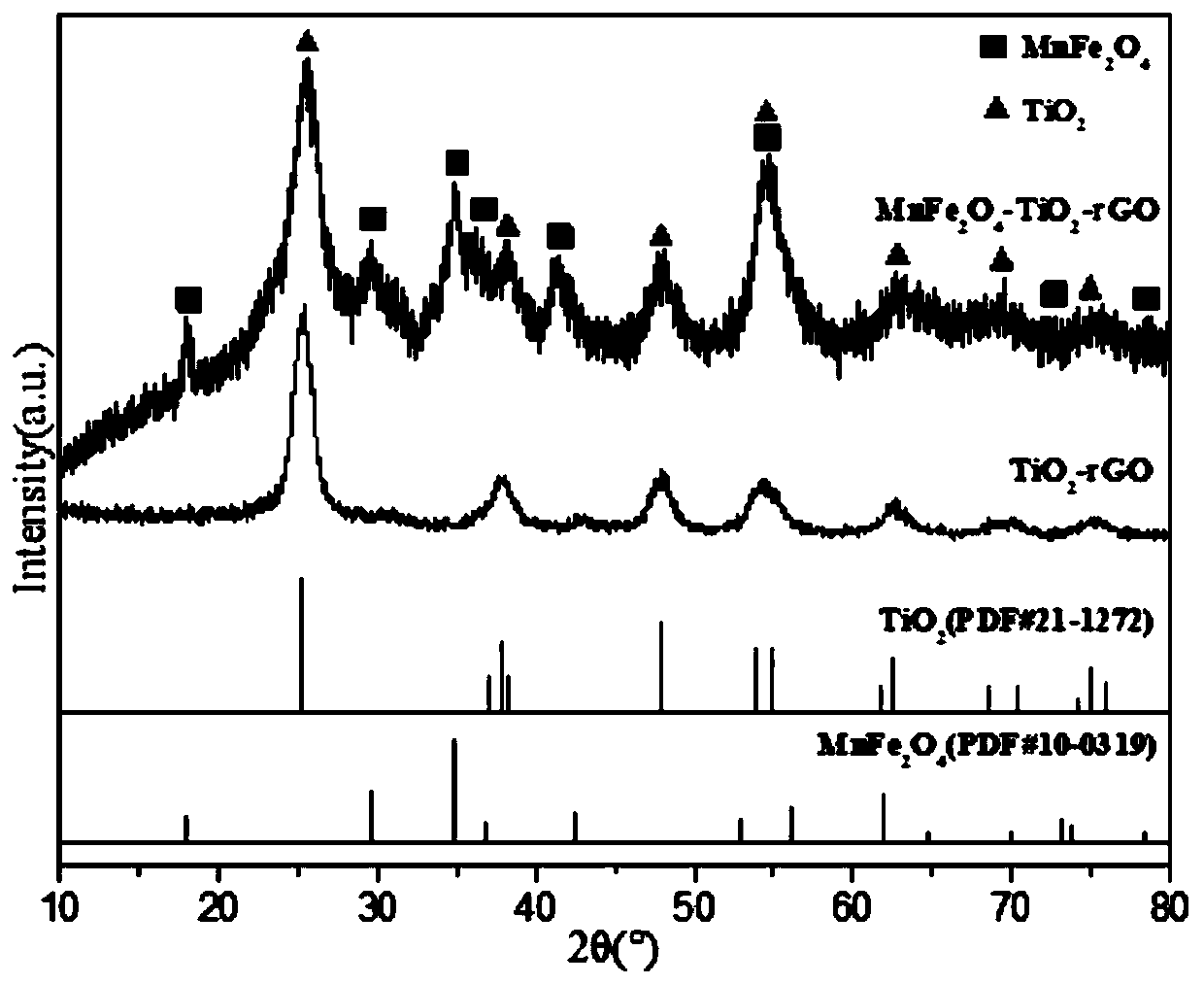

[0031] (1) Place 0.4g graphene oxide in 100mL ultrapure water, use an ultrasonic crusher at a power of 270W, crush for 2h, and prepare a 4mg / mL graphene oxide aqueous solution;

[0032] (2) Add 12.5mL (1) graphene oxide aqueous solution and 12.5mL absolute ethanol to the beaker for 30min, then dissolve 0.0913g ferric nitrate nonahydrate and 0.0285g manganese nitrate tetrahydrate in 5mL ultrapure water, pour Pour into a beaker and sonicate for 30 minutes to form solution A;

[0033] (3) Measure 1mL polyethyleneimine aqueous solution (40mg / mL) and add solution A to ultrasonic for 30min, pH to 10.5, then add 0.19mL tetrabutyl titanate to 5mL absolute ethanol, add to the above solution and ultrasonically for 30min , forming a good dispersion;

[0034] (4) Transfer the above dispersion to a 50mL high-temperature and high-pressure reactor, and react in an oven at 180°C for 24h;

[0035] (5) After the reaction is over, take out the sample after the reactor is cooled to room tempera...

Embodiment 2

[0041] (1) Place 0.4g graphene oxide in 100mL ultrapure water, use an ultrasonic crusher at a power of 270W, crush for 2h, and prepare a 4mg / mL graphene oxide aqueous solution;

[0042] (2) Add 12.5mL (1) graphene oxide aqueous solution and 12.5mL absolute ethanol to the beaker for 30min, then dissolve 0.0913g ferric nitrate nonahydrate and 0.0285g manganese nitrate tetrahydrate in 5mL ultrapure water, pour Pour into a beaker and sonicate for 30 minutes to form solution A;

[0043] (3) Measure 1mL polyethyleneimine aqueous solution (30mg / mL) and add solution A to ultrasonic for 30min, pH to 10, then add 0.125mL tetrabutyl titanate to 5mL absolute ethanol, add to the above solution and ultrasonicate for 30min , forming a good dispersion;

[0044] (4) Transfer the above dispersion to a 50mL high-temperature and high-pressure reactor, and react in an oven at 180°C for 24h;

[0045] (5) After the reaction is over, take out the sample after the reaction kettle is cooled to room t...

Embodiment 3

[0048] (1) Place 0.4g graphene oxide in 100mL ultrapure water, use an ultrasonic crusher at a power of 270W, crush for 2 hours, and prepare a 4mg / mL graphene oxide aqueous solution;

[0049] (2) Add 12.5mL (1) graphene oxide aqueous solution and 12.5mL absolute ethanol to the beaker for 20min, then dissolve 0.0913g ferric nitrate nonahydrate and 0.0285g manganese nitrate tetrahydrate in 5mL ultrapure water, pour Pour into a beaker and sonicate for 50 minutes to form solution A;

[0050] (3) Measure 1mL polyethyleneimine aqueous solution (30mg / mL) and add solution A to ultrasonic for 30min, pH to 10, then add 0.19mL tetrabutyl titanate to 5mL absolute ethanol, add to the above solution and ultrasonically for 30min , forming a good dispersion;

[0051] (4) Transfer the above dispersion to a 50mL high-temperature and high-pressure reactor, and react in an oven at 180°C for 24h;

[0052] (5) After the reaction is over, take out the sample after the reaction kettle is cooled to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com