Self-supporting layered bimetallic phosphide-graphdiyne composite catalyst as well as preparation method and application thereof

A composite catalyst, layered bimetallic technology, applied in the field of electrocatalysis, can solve the problems of low storage capacity, limited precious metal catalysts, high price, etc., to improve speed and stability, enrich active sites, and improve electronic interactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

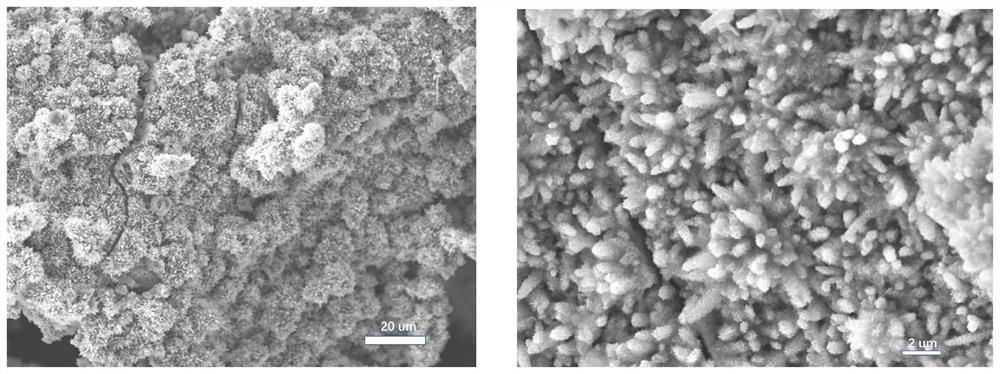

[0064] Step 1. Carrier pretreatment: before use, cut the nickel foam into small pieces with an area of (1cm×2cm), wash with hydrochloric acid, water, and acetone for 10 minutes each, and blow dry with Ar flow.

[0065] Step 2. Supporting double metal oxides: During the synthesis process, 2mmol Cu(NO 3 ) 2 ·3H 2 O with 2mmol NiCl 2 ·6H 2 O with 12mmol NH 4 Stir and mix F and 18mmol urea, immerse 2 pieces of nickel foam (about 160mg) into the solution, pour the mixture into a 100mL stainless steel reactor, seal the reactor, and heat at 180°C for 12 hours. After the reaction was naturally cooled to room temperature, the sample was washed with water and ethanol, and dried under vacuum at 60°C for 12 hours.

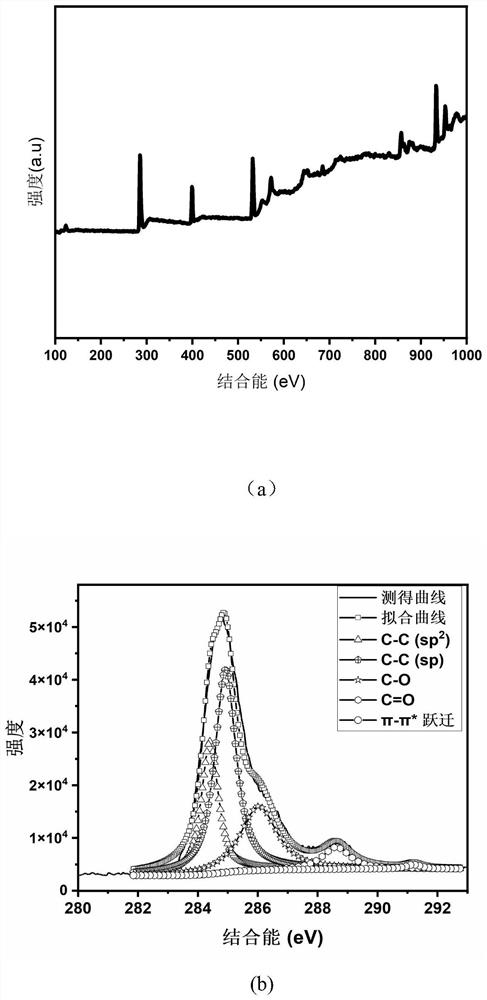

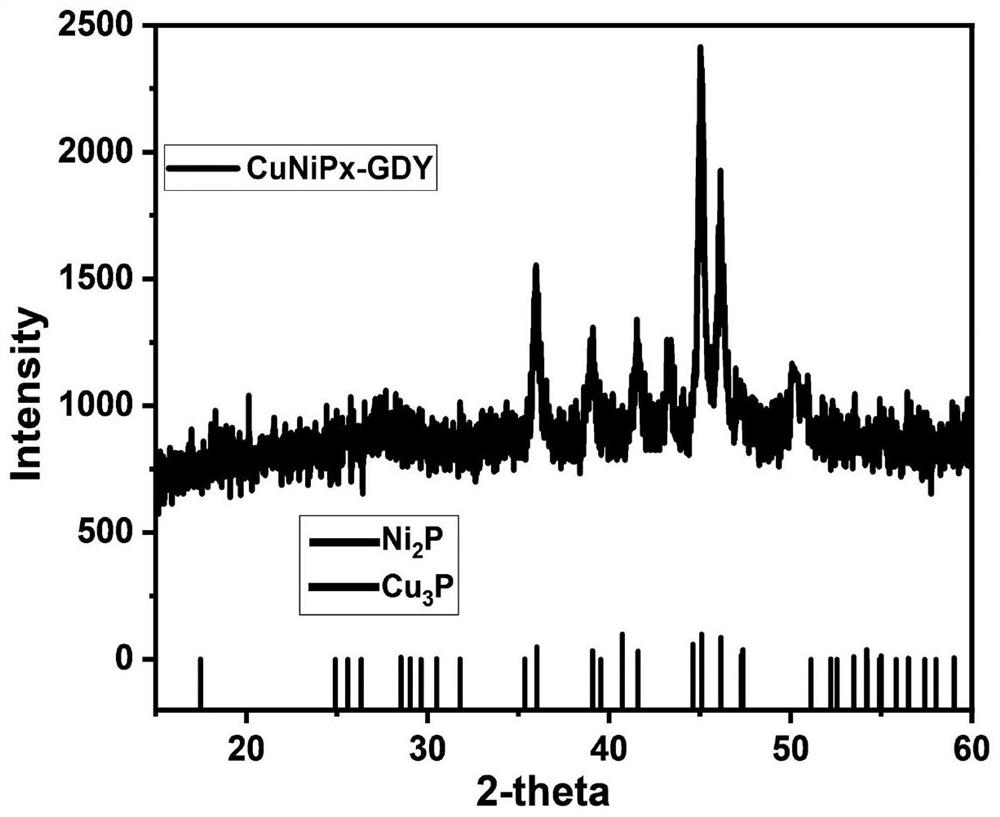

[0066] Step 3. Preparation of double metal oxide-graphyne composite material: then the mixed solution (THF:TMEDA=4:1) of step 2 product and tetrahydrofuran (THF) and tetramethylethylenediamine (TMEDA) is put into three necks Into the bottle, slowly add 8 mg of hexaethy...

Embodiment 2

[0069] Other steps are identical with embodiment 1, and difference is only in step 1 with 3mmol Cu (NO 3 ) 2 ·3H 2 O with 1mmol NiCl 2 ·6H 2 O with 12mmol NH 4 F and 18mmol urea were stirred and mixed to prepare a composite catalyst.

Embodiment 3

[0071] Other steps are identical with embodiment 1, difference is only in step 1 with 1mmol Cu(NO 3 ) 2 ·3H 2 O with 3mmol NiCl 2 ·6H 2 O with 12mmol NH 4 F and 18mmol urea were stirred and mixed to prepare a composite catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com