Patents

Literature

30results about How to "Good low temperature denitrification activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare-earth doped low-temperature denitration catalyst and preparation method thereof

ActiveCN103055848ALow running costLow retrofit costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthSlurry

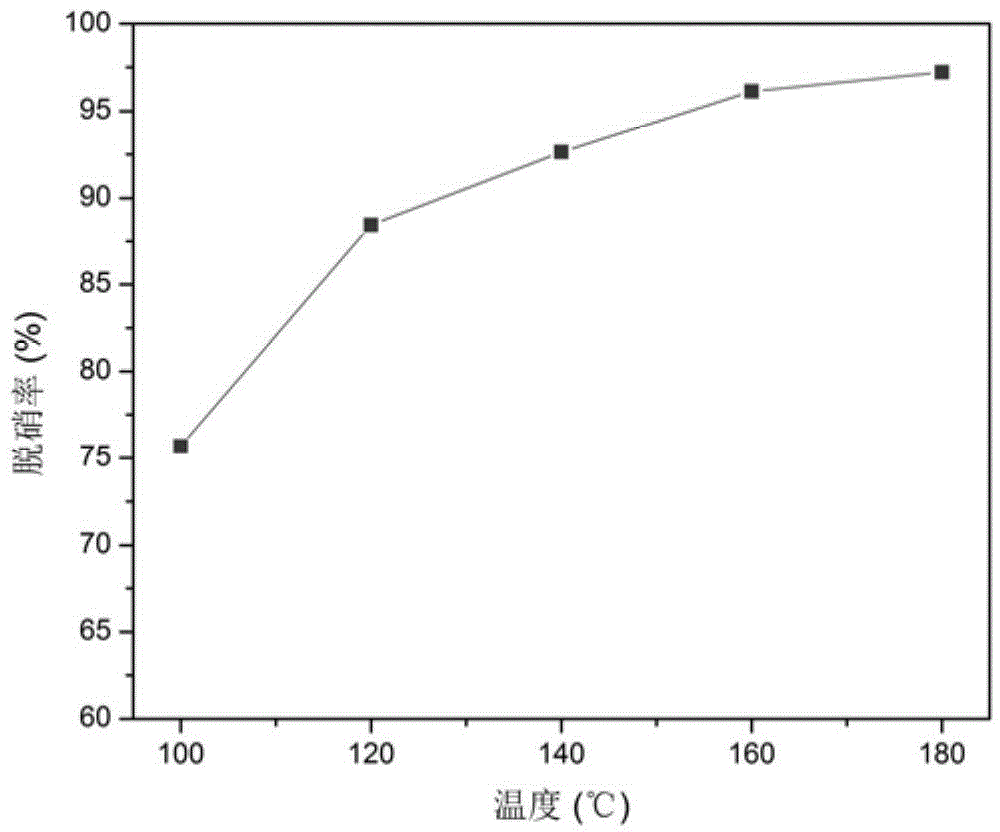

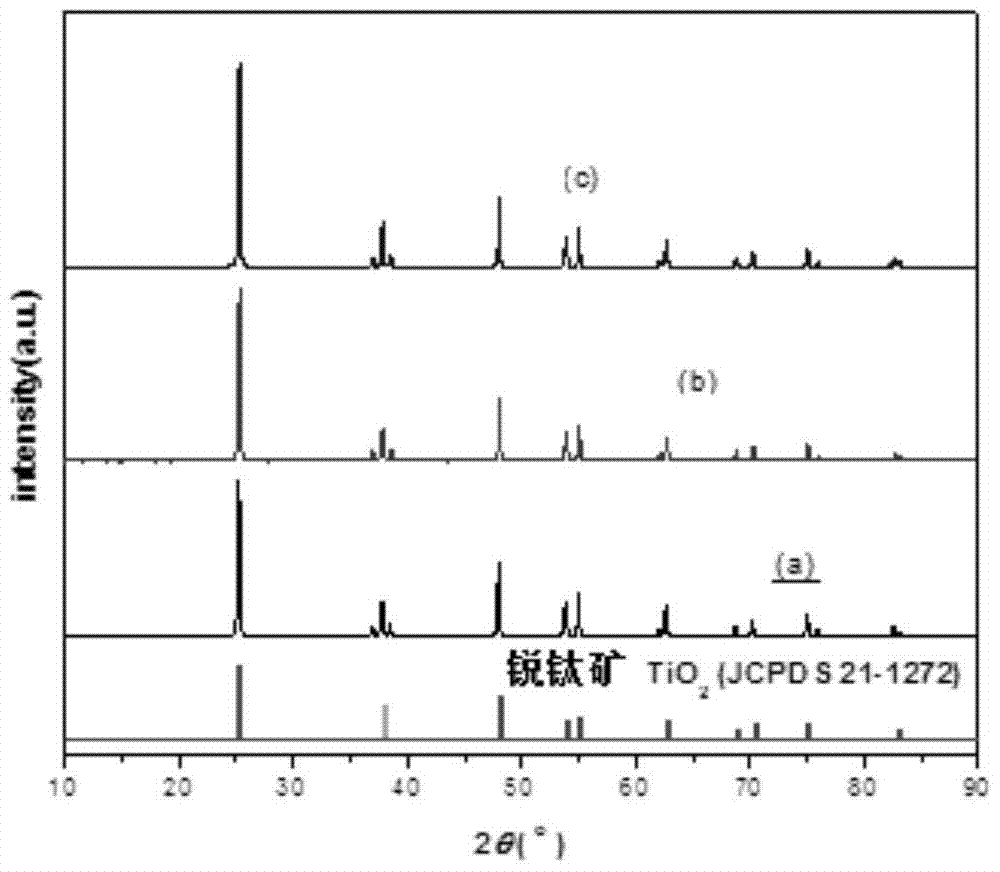

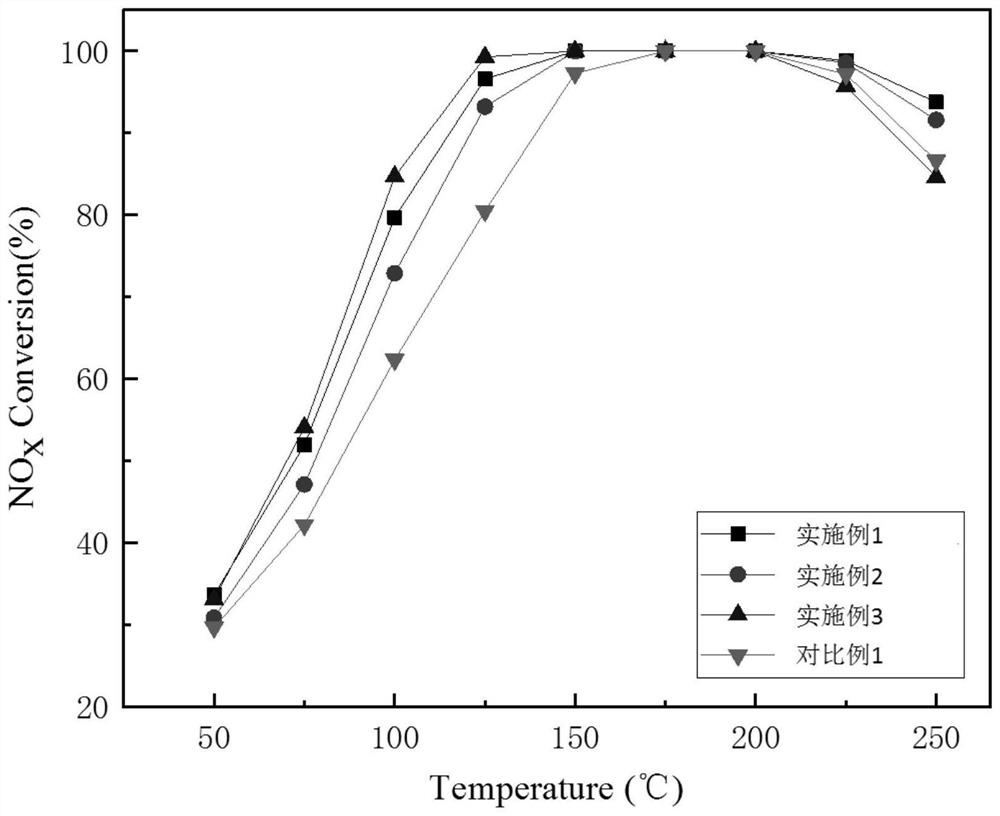

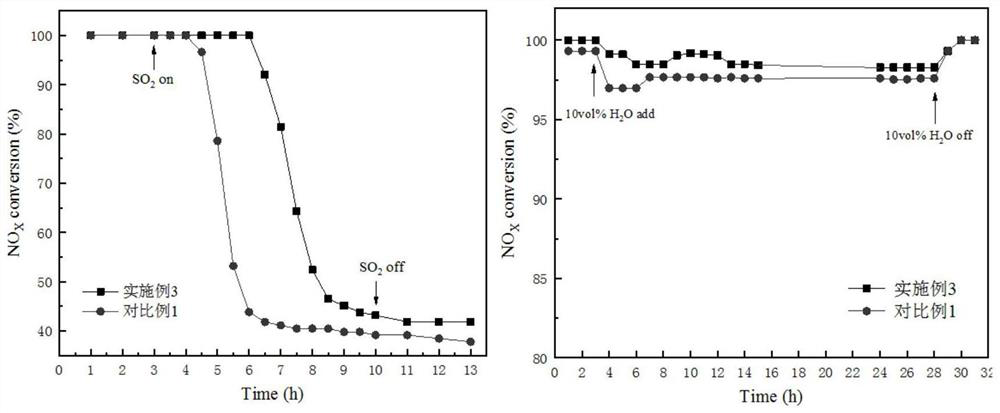

The present invention relates to a rare-earth doped low-temperature denitration catalyst and a preparation method thereof. The main active component of the catalyst is manganese oxide, the carrier is titanium oxide, and cerium oxide and iron oxide are used as cocatalysts. The preparation method includes the following steps: adding solutions of various metal nitrates into a metatitanic acid slurry, then adjusting the pH of the mixture to obtain complete precipitation by using concentrated ammonia, stirring for a while, and performing centrifugal filtration to the resulting suspension, and drying and calcining at a temperature to obtain the rare-earth doped low-temperature denitration catalyst; wherein the molar ratio of each element is as follows: Mn: Fe: Ce: Ti = 5: (0 ~ 2): 4:20. In the temperature range of 140-180 DEG C, the denitration activity of the metal oxide low temperature catalyst of the present invention can reach 80-98%, and the catalyst has a relatively excellent water and sulfur resistance performance.

Owner:ZHEJIANG HAILIANG ENVIRONMENTAL MATERIALS

Honeycomb wire mesh catalyst for stationary source tail gas denitration and preparation thereof

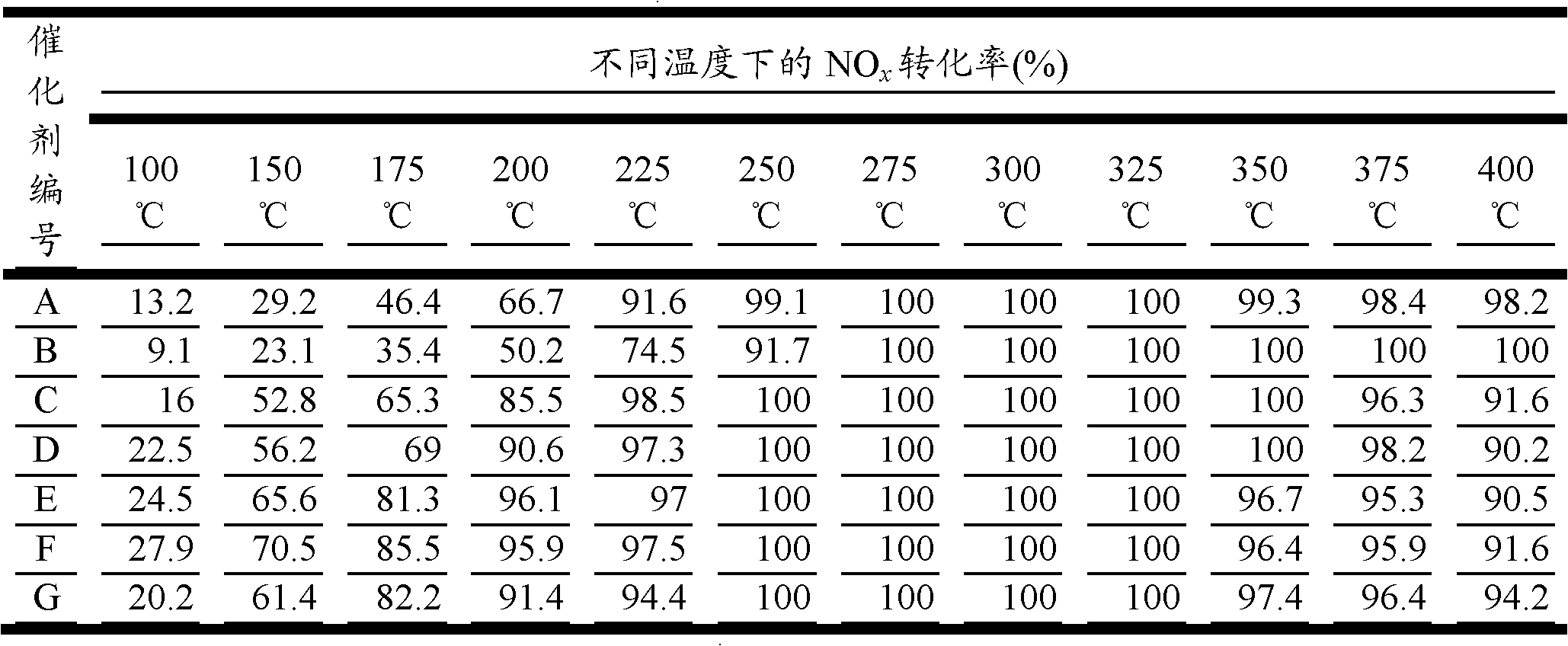

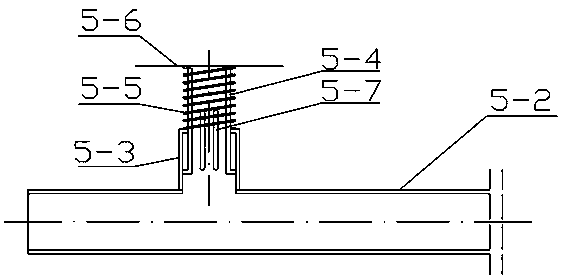

ActiveCN102166515AGood low temperature denitrification activityGood anti-sulfur at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMoistureSmoke

The invention belongs to the field of the preparation of catalysts for stationary source tail gas denitration, and relates to the preparation of a catalyst by using a honeycomb metal carrier. Tabular and corrugated wire meshes attached with aluminum oxide coatings are stacked alternately and fixedly molded to form a catalyst carrier; a passage inside the carrier has a three-dimensional transparent structure. The preparation is characterized in that: the catalyst is prepared by loading the active components V2O5, WO3 and TiO2 on the surface of the catalyst carrier by a stepwise loading method; the mass sum of the V2O5, the WO3 and the TiO2 is 10-70 percent of the total weight of the aluminum oxide coatings and the V2O5, the WO3 and the TiO2; and the mass of V elements is 0.2-5.6 percent of the mass sum of the V2O5, the WO3 and the TiO2. The catalyst of the invention has low-temperature denitration activity and low-temperature sulfur and water resistant performance; and when the smoke temperature is 250 DEG C, the SO2 concentration is 600 ppm and the moisture content is 10%, the denitration efficiency of the catalyst is above 90%.

Owner:DALIAN UNIV OF TECH

Supported iron-based composite oxide catalyst and preparation method thereof

InactiveCN102658161AWide denitrification temperature windowGood low temperature denitrification activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumTitanium oxide

The invention relates to supported iron-based composite oxide catalyst and a preparation method thereof. The catalyst is made of titanium oxide or aluminum oxide serving as a carrier, iron and cerium serving as a host, and optional one or a plurality of transition metals such as tungsten, molybdenum, titanium and zirconium serving as axillaries. The mole ratio of the iron to the cerium is 1.0-10.0:1. The mole ratio of the host to the auxiliaries is 1.0-5.0:1. The mole ratio of the total of the host and auxiliaries to the carrier is 0.1-0.5:1. The preparation method includes: preparing the auxiliaries and the host into solution, soaking the carrier in the solution, dropwise adding precipitant for precipitation, filtering, drying and calcining. The catalyst has wide denitration temperature window and fine low-temperature denitration activity.

Owner:SHANDONG UNIV

Preparation method of supported type denitration catalyst

ActiveCN102658155AReduce manufacturing costReduce energy consumptionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMicrowaveActive component

The invention relates to a preparation method of a supported type denitration catalyst. The preparation method comprises the following steps of: adopting soluble iron salt and cerate as active components, adding water for dissolving and mixing to prepare mixed solution; adding corresponding carriers into the mixed solution, dipping, dripping an alkaline precipitating agent till the pH is equal to 9-10, precipitating completely, then filtering, and cleaning to obtain a filter cake; putting the filter cake into a microwave experiment table for microwave treatment, then drying, finally calcining, and activating to prepare the catalyst. The catalyst prepared by the invention has the advantages that a denitration temperature window is wide, the low-temperature denitration activity is good, the energy consumption of the preparation method is low, and the preparation of the denitration catalyst is reduced.

Owner:SHANDONG UNIV

Mn/Co-based low-temperature SCO catalyst and preparation method thereof

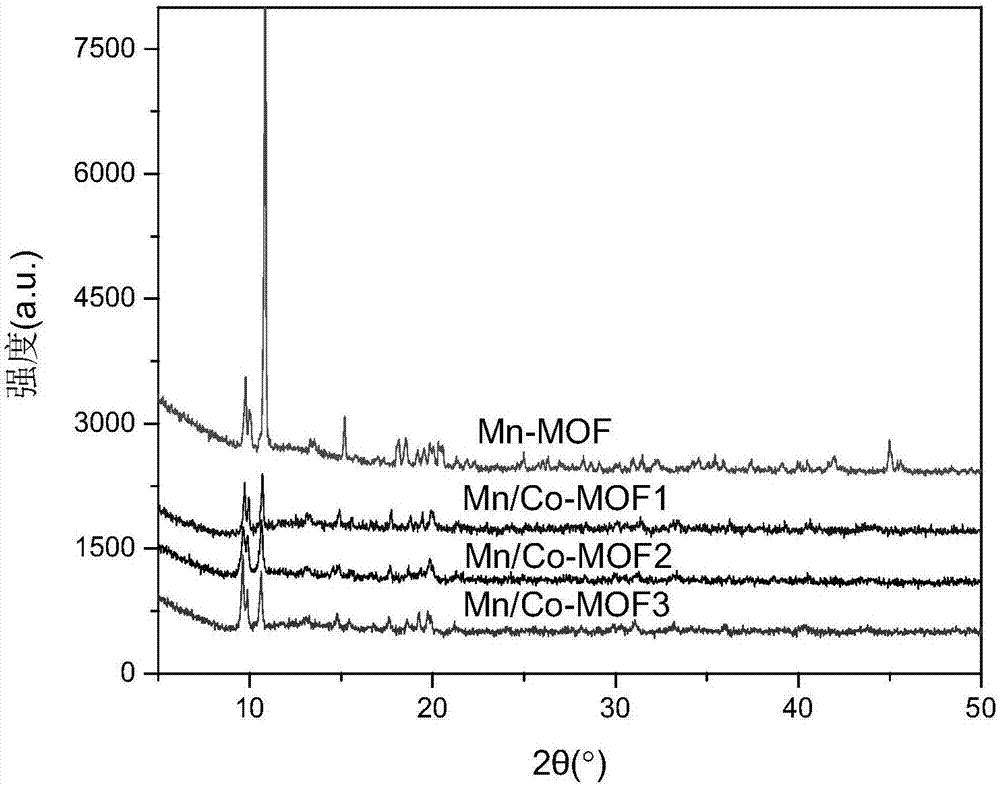

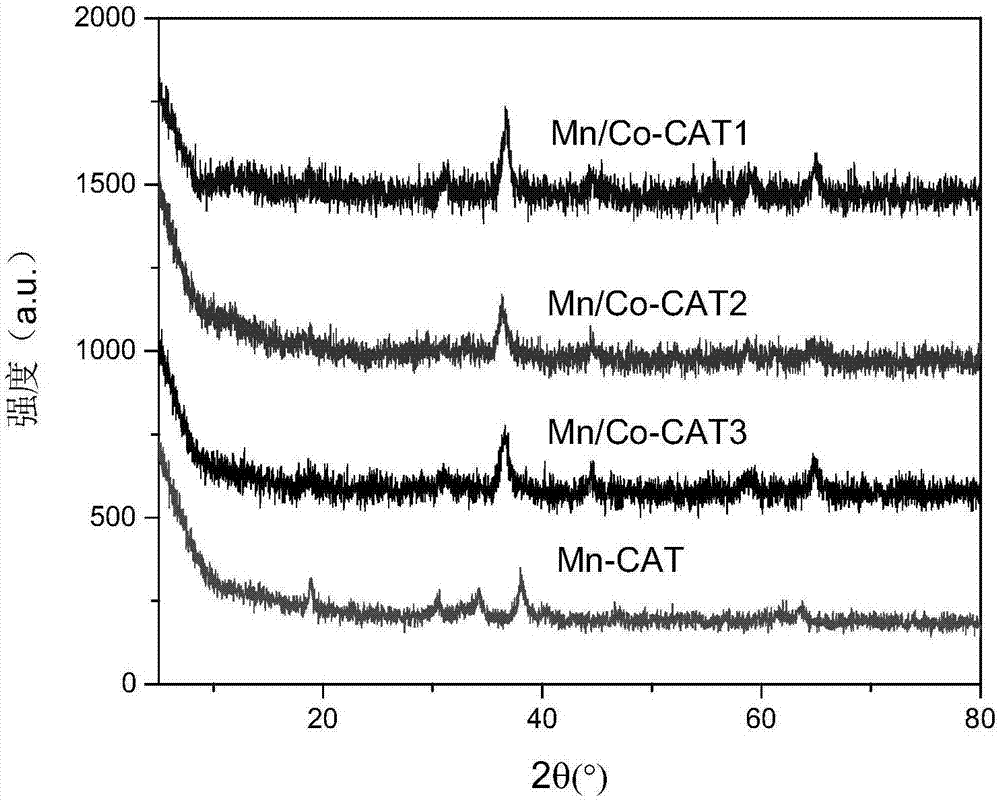

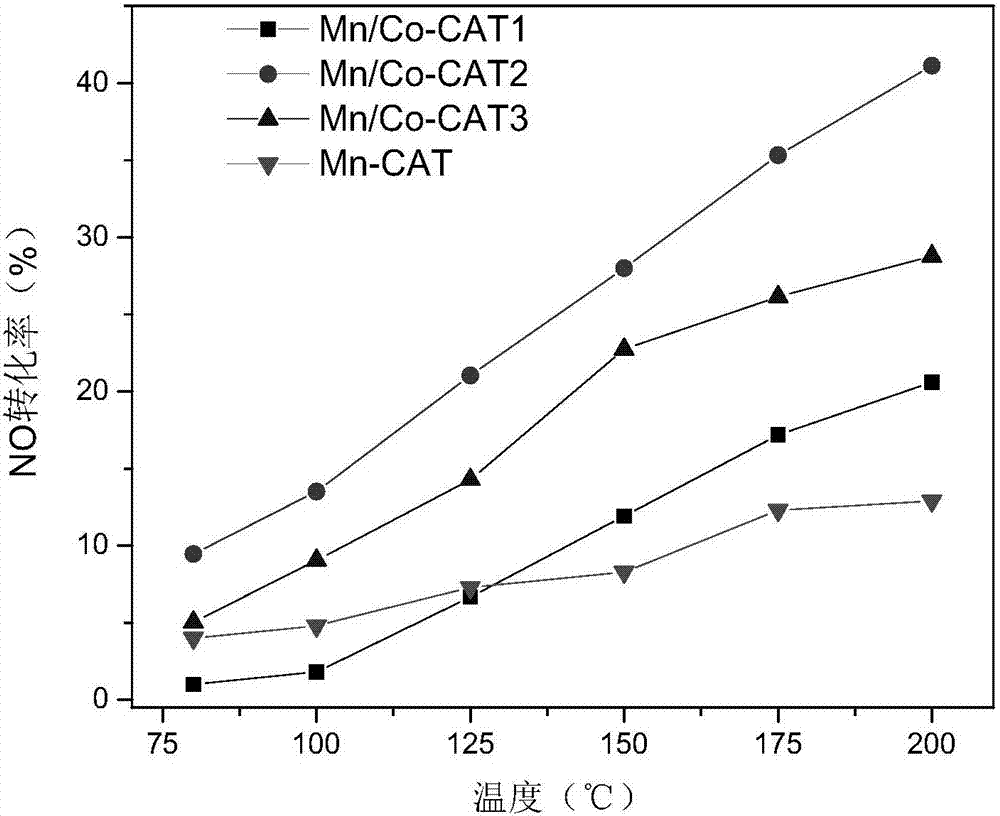

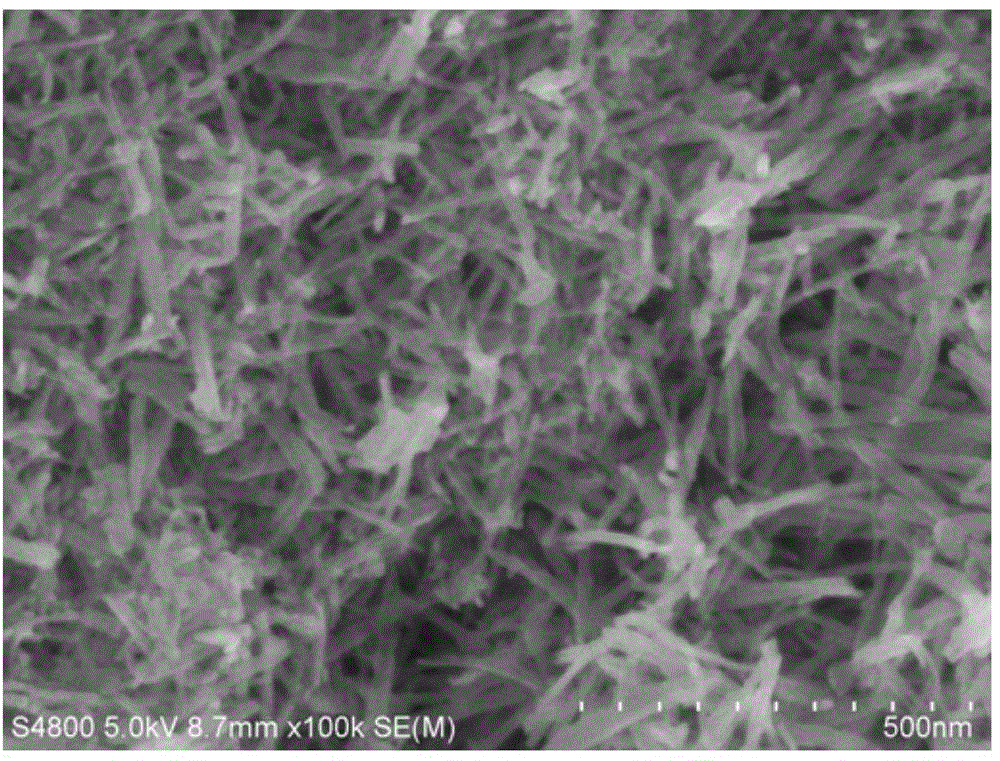

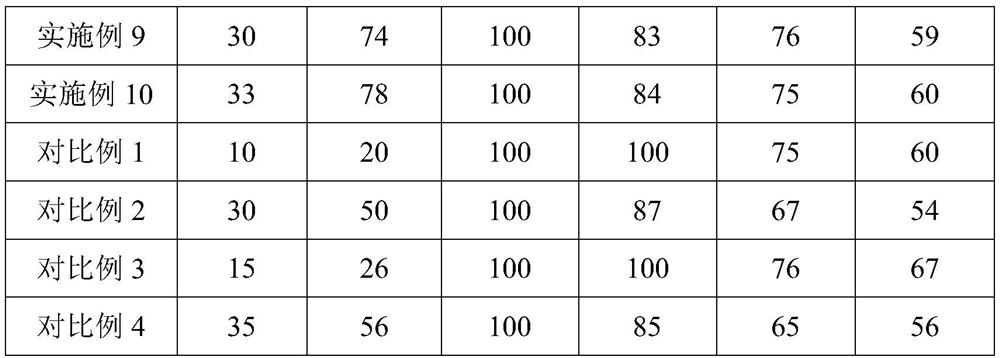

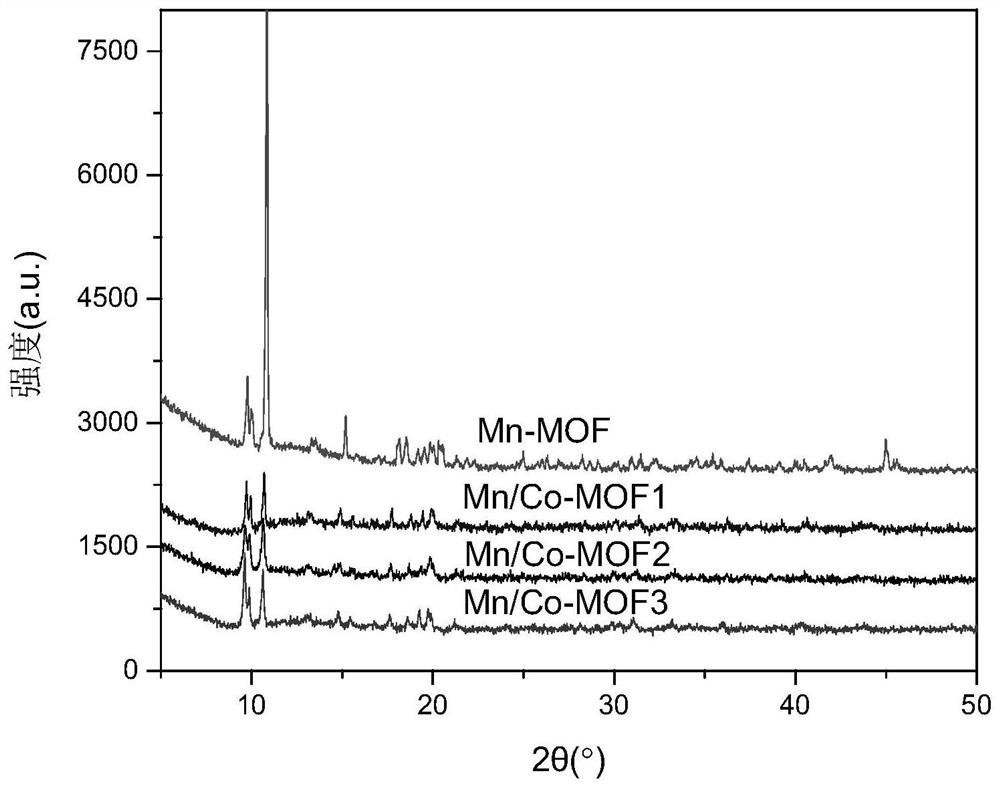

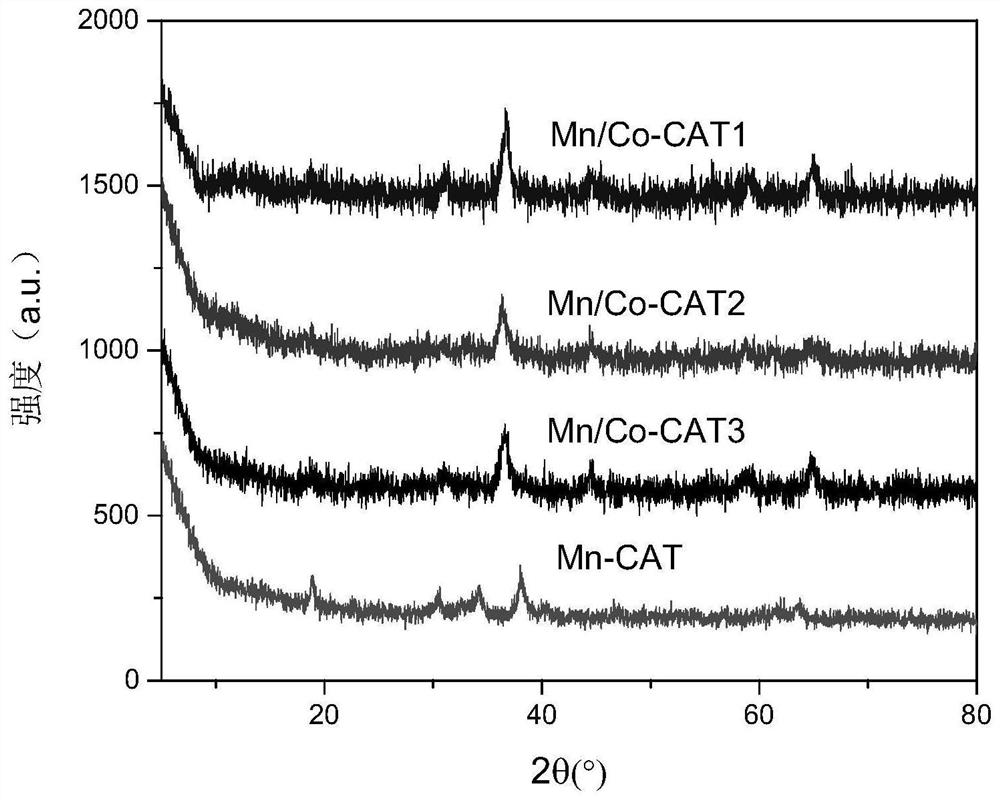

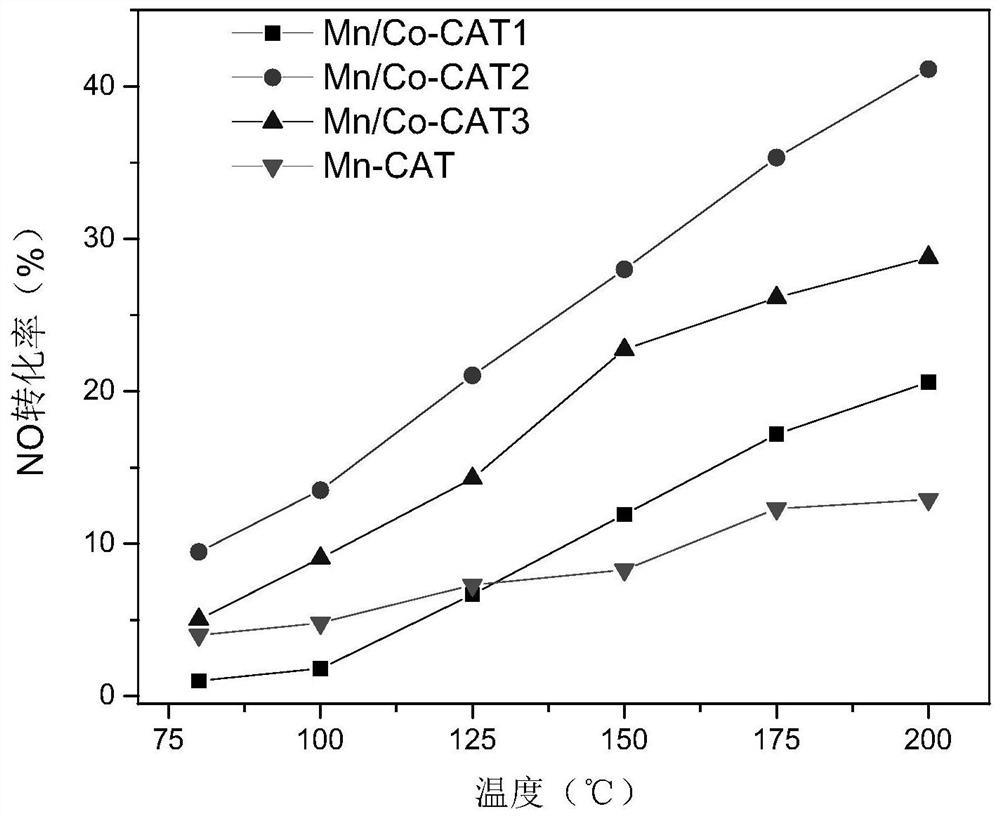

ActiveCN107362807AHigh porosityStable structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseMetal-organic framework

The invention discloses a Mn / Co-based low-temperature SOC catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving manganese-containing metal salt and cobalt-containing metal salt in dimethylformamide, adding an organic ligand and water, and magnetically stirring and uniformly mixing the components to obtain a mixed solution; and (2) carrying out hydrothermal reaction on the obtained mixed solution in a reactor, reacting to obtain Mn / Co double-metal organic framework crystal, soaking the Mn / Co double-metal organic framework crystal in the dimethylformamide and activating the Mn / Co double-metal organic framework crystal, and then purifying, filtering and roasting the activated crystal to obtain the Mn / Co-based low-temperature SCO catalyst. The Mn / Co-based low-temperature SCO catalyst has good low-temperature denitration activity. Compared with an existing low-temperature denitration catalyst, the Mn / Co-based low-temperature SOC catalyst has the advantages that the conversion rate of catalyzed NO is greatly increased, at the low temperature of 150-200 DEG C, the catalyzed conversion rate of NO can reach 50% or above, and existing industrial requirements can be met.

Owner:SOUTH CHINA UNIV OF TECH

Flue gas denitration catalyst applied at a low temperature and preparation method thereof

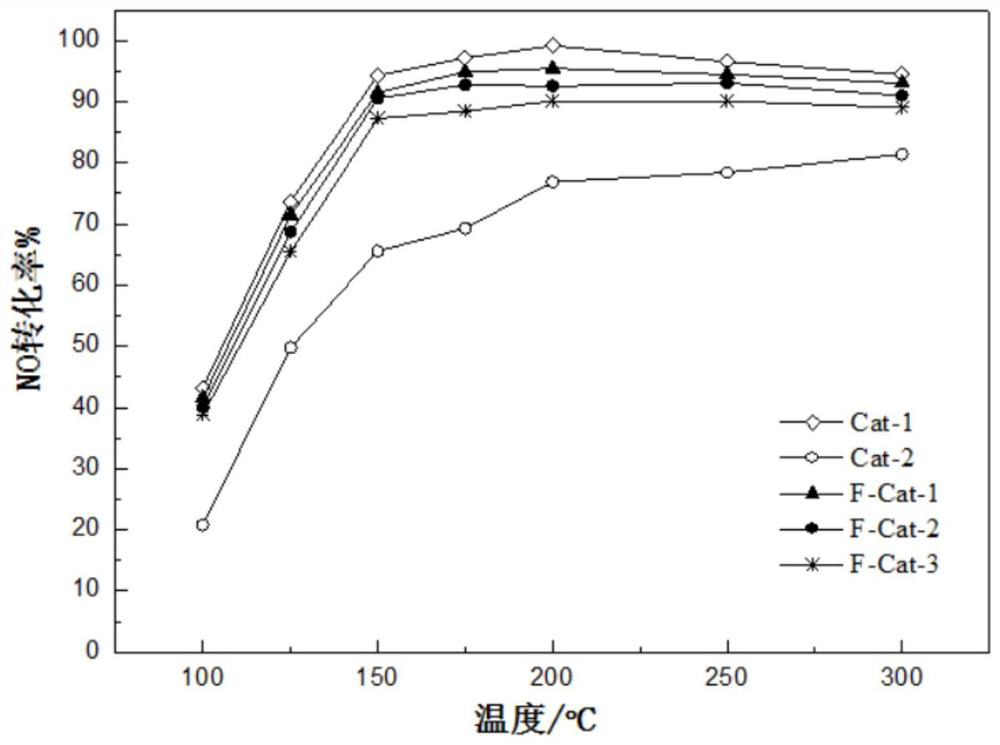

InactiveCN105148904AGood low temperature denitrification activityStrong resistance to sulfur and water poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNiobiumCerium

The invention relates to a catalyst and a preparation method thereof, in particular to a flue gas denitration catalyst applied at a low temperature and a preparation method thereof. TiO2 doped with one or multiple of Al2O3, SiO2 or ZrO2 is taken as a carrier, glass fiber is taken as a skeleton, and vanadium compounded with one or multiple of tungsten, molybdenum, cerium, manganese, niobium or phosphorus is taken as an active component. The flue gas denitration catalyst comprises the carrier, active precursor aqueous solution, glass fiber, stearic acid, lactic acid, wood pulp, monoethanolamine, polyoxyethylene, methylcellulose, ammonia water and water. The catalyst has good low-temperature denitration activity; and within the temperature of 150-300 DEG C, denitration efficiency of the catalyst is up to 85% or above. The catalyst has high sulfur-poisoning resistance and water-poisoning resistance capacity, and long-term use of the catalyst at a low temperature is guaranteed. Further, the catalyst can be applied to fields such as glass production, coking, cement, industrial kilns, waste incineration and chemical engineering widely. The invention further provides a preparation method of the catalyst, which is reasonable in processing.

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

Selective catalytic reduction low-temperature denitration catalyst and preparation method thereof

InactiveCN104815671AGood low temperature denitrification activityImprove denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationStrong acids

The invention relates to a catalyst capable of performing catalytic oxidation on nitric oxides in industrial smoke gas under a low-temperature condition and a preparation process thereof. The preparation method comprises the following steps: (1) dissolving strong acid into water to prepare a strong acid solution; (2) pouring potassium permanganate or soluble salt of iron or cerium into the strong acid solution, stirring to sufficiently mix and dissolve the potassium permanganate or a soluble salt of iron or cerium; (3) performing hydrothermal reaction on the solution; (4) after the hydrothermal reaction, performing suction filtration to obtain oxide precipitates, and washing the oxide precipitates with the acid solution and distilled water respectively; (5) drying the obtained sample; and (6) grinding the dried sample to obtain the required selective catalytic reduction low-temperature denitration catalyst. According to the method, the preparation process is simple, and the selective catalytic reduction low-temperature denitration catalyst with good performance can be prepared by simply weighing, mixing, reacting, filtering and drying, the synthesis temperature is relatively low, roasting is not required, requirements of high-temperature reaction to instruments and equipment are lowered, risks to body safety are avoided, and the advantages are remarkable.

Owner:WUHAN UNIV OF TECH

Supported iron-based composite oxide catalyst and preparation method thereof

InactiveCN102658161BWide denitrification temperature windowGood low temperature denitrification activityMetal/metal-oxides/metal-hydroxide catalystsCeriumTitanium oxide

The invention relates to supported iron-based composite oxide catalyst and a preparation method thereof. The catalyst is made of titanium oxide or aluminum oxide serving as a carrier, iron and cerium serving as a host, and optional one or a plurality of transition metals such as tungsten, molybdenum, titanium and zirconium serving as axillaries. The mole ratio of the iron to the cerium is 1.0-10.0:1. The mole ratio of the host to the auxiliaries is 1.0-5.0:1. The mole ratio of the total of the host and auxiliaries to the carrier is 0.1-0.5:1. The preparation method includes: preparing the auxiliaries and the host into solution, soaking the carrier in the solution, dropwise adding precipitant for precipitation, filtering, drying and calcining. The catalyst has wide denitration temperature window and fine low-temperature denitration activity.

Owner:SHANDONG UNIV

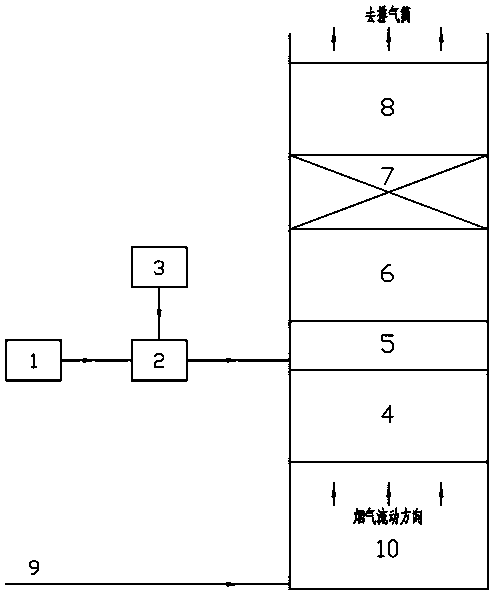

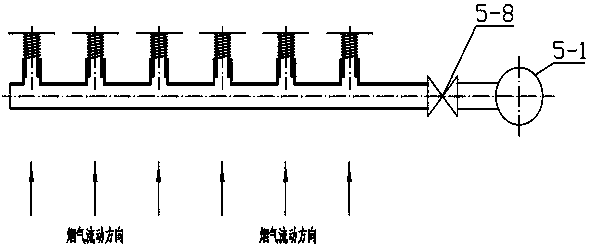

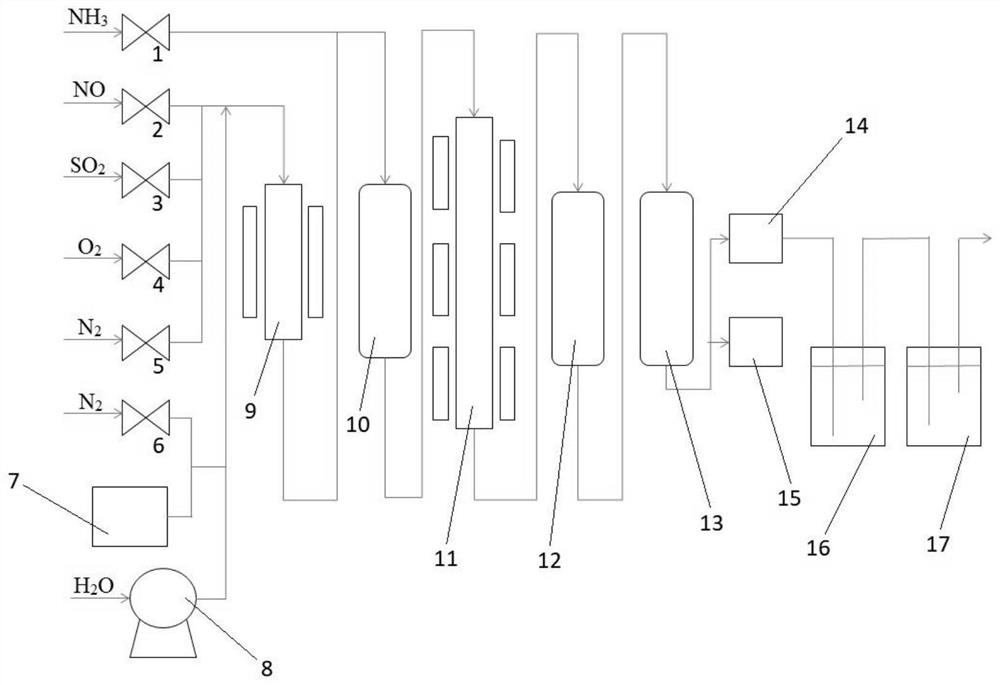

Denitration treatment method of flue gas discharged by ethylene cracking furnace

ActiveCN109482065AImprove denitrification activityExcellent water vapor resistanceGas treatmentMolecular sieve catalystsCerium nitrateCerium nitrate hexahydrate

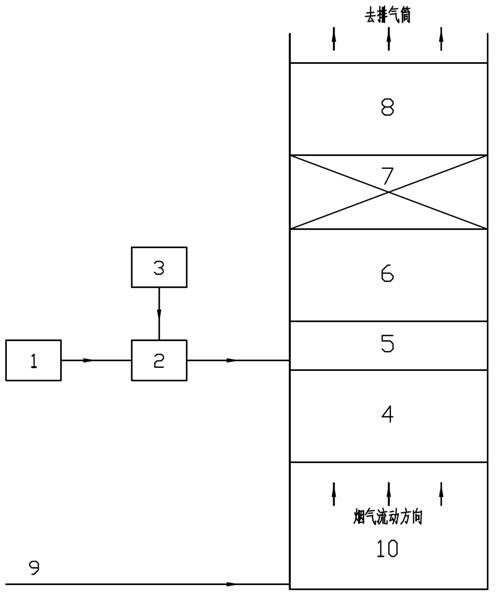

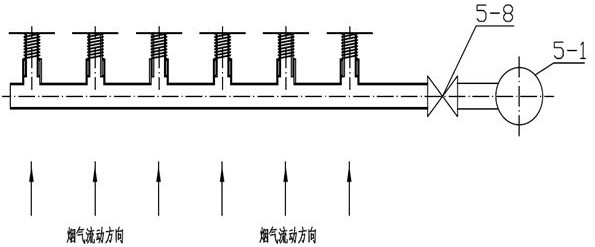

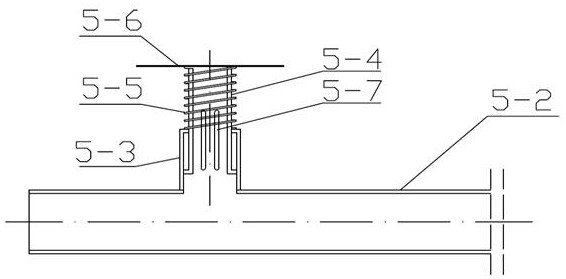

The invention relates to a denitration treatment method of flue gas discharged by an ethylene cracking furnace. The flue gas sequentially flows a radiation section, a convection heat exchange sectionA, an ammonia injection grid, a convection heat exchange section B, an SCR denitration reaction section and a convection heat exchange section C, and the SCR denitration reaction section is filled with a catalyst. A preparation method of the catalyst includes the steps: (1) adding carbon black powder and cerium nitrate into silicon-containing ethanol solution, uniformly mixing materials under thecondition of ultrasonic dispersion, separating solid and liquid, and drying a solid phase to obtain silicon and cerium modified carbon black powder; (2) adding the modified carbon black powder in titanium-containing ethanol solution, adding dilute nitric acid solution to form sol-gel, treating the sol-gel at high temperature in anaerobic atmosphere, and calcining the treated sol-gel in oxygen containing atmosphere to obtain a silicon-cerium-containing macro-porous titanium dioxide carrier; (3) mixing the titanium dioxide carrier, a molecular sieve and an active component precursor to form a honeycomb denitration catalyst. The method is good in denitration activity and high in water-vapor-resistant capability, and the catalyst cannot be easily cracked and long in service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

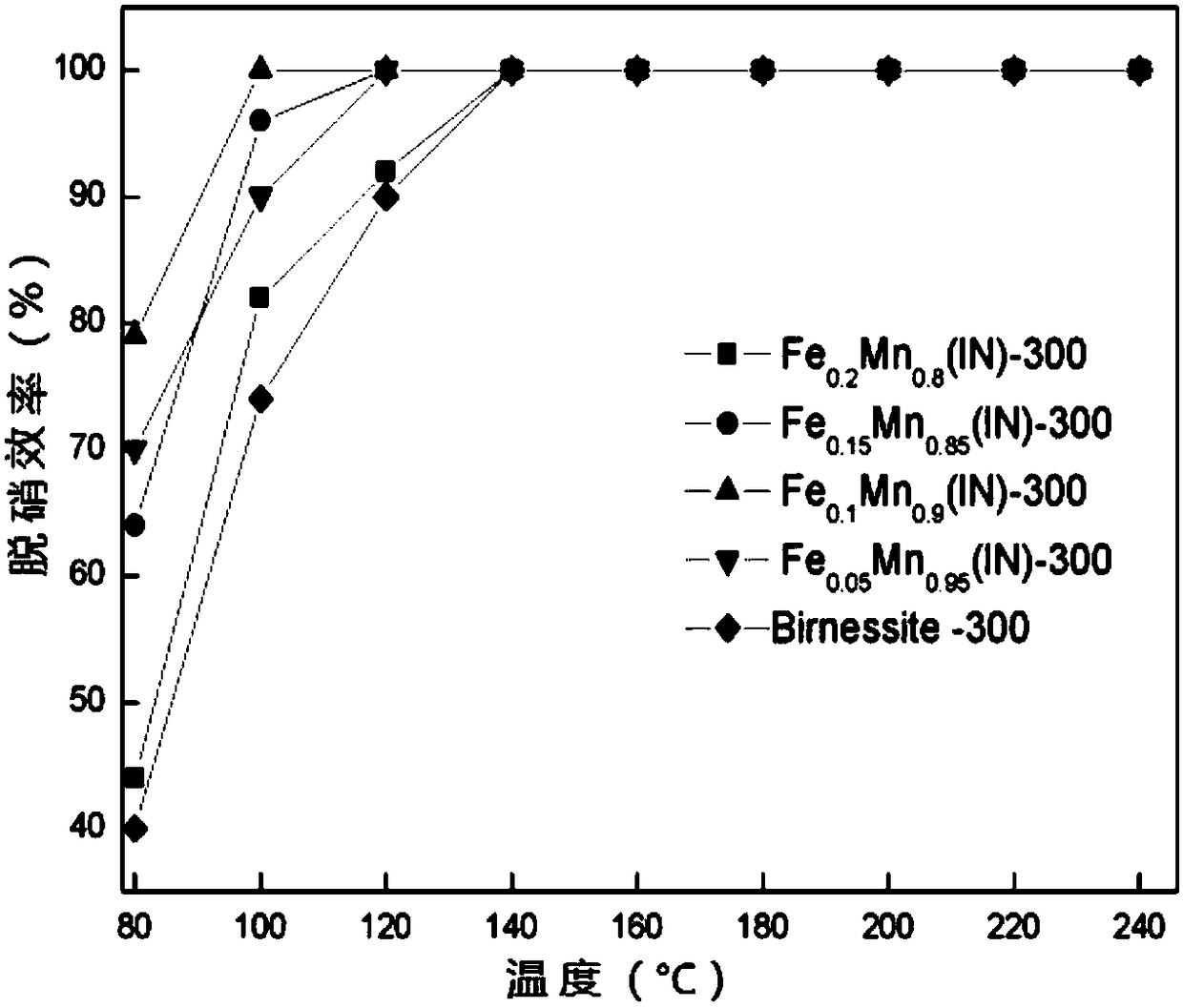

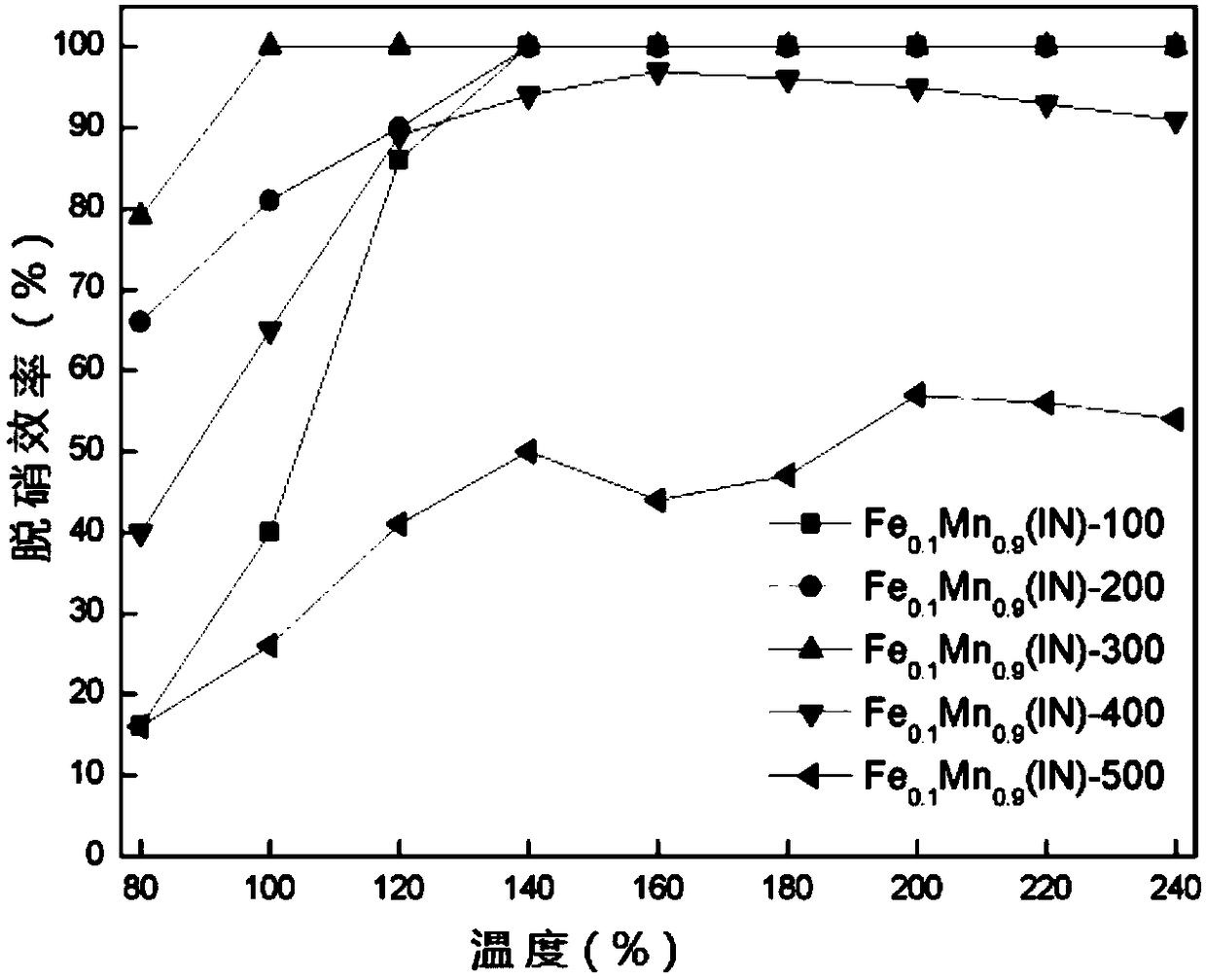

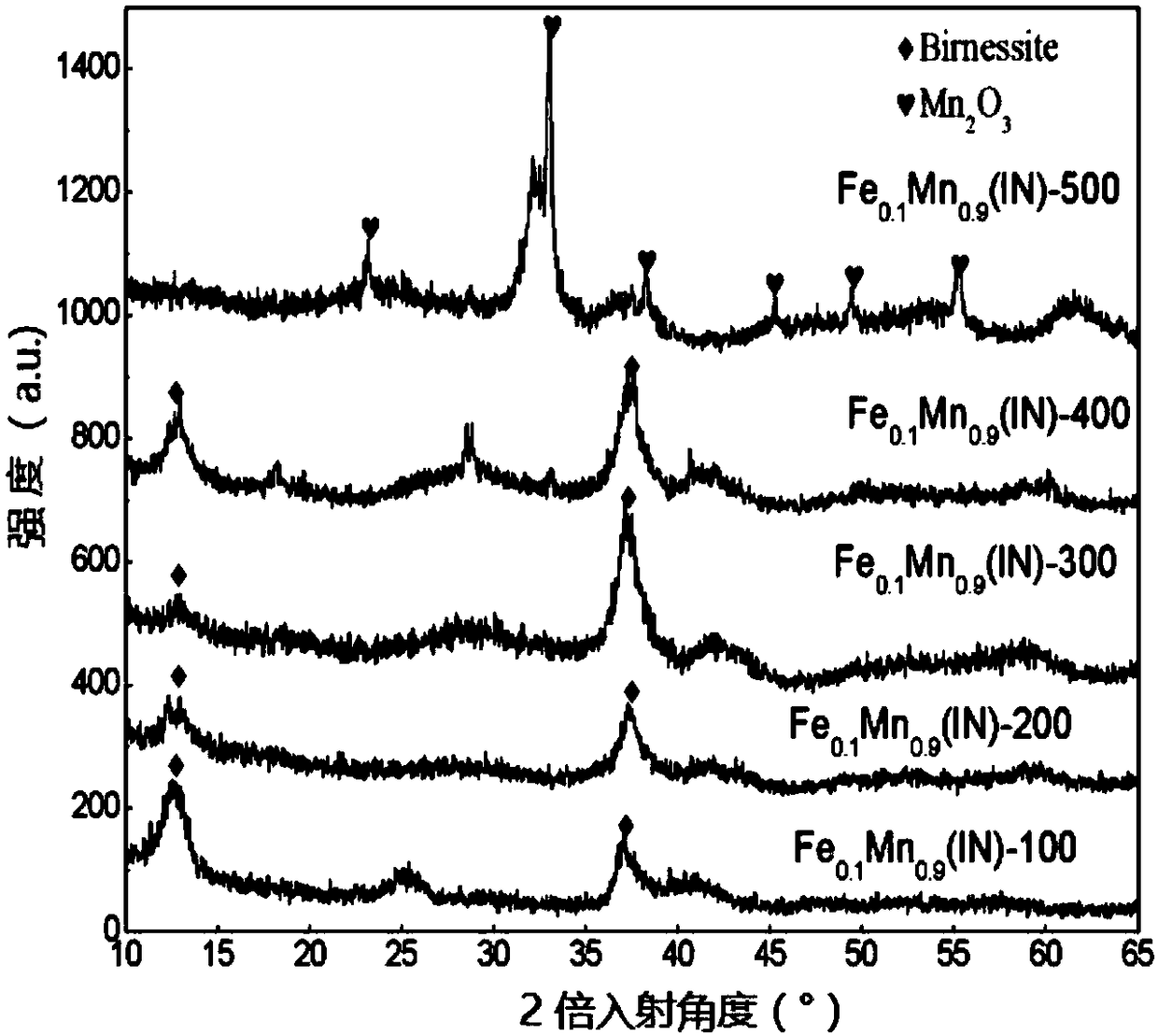

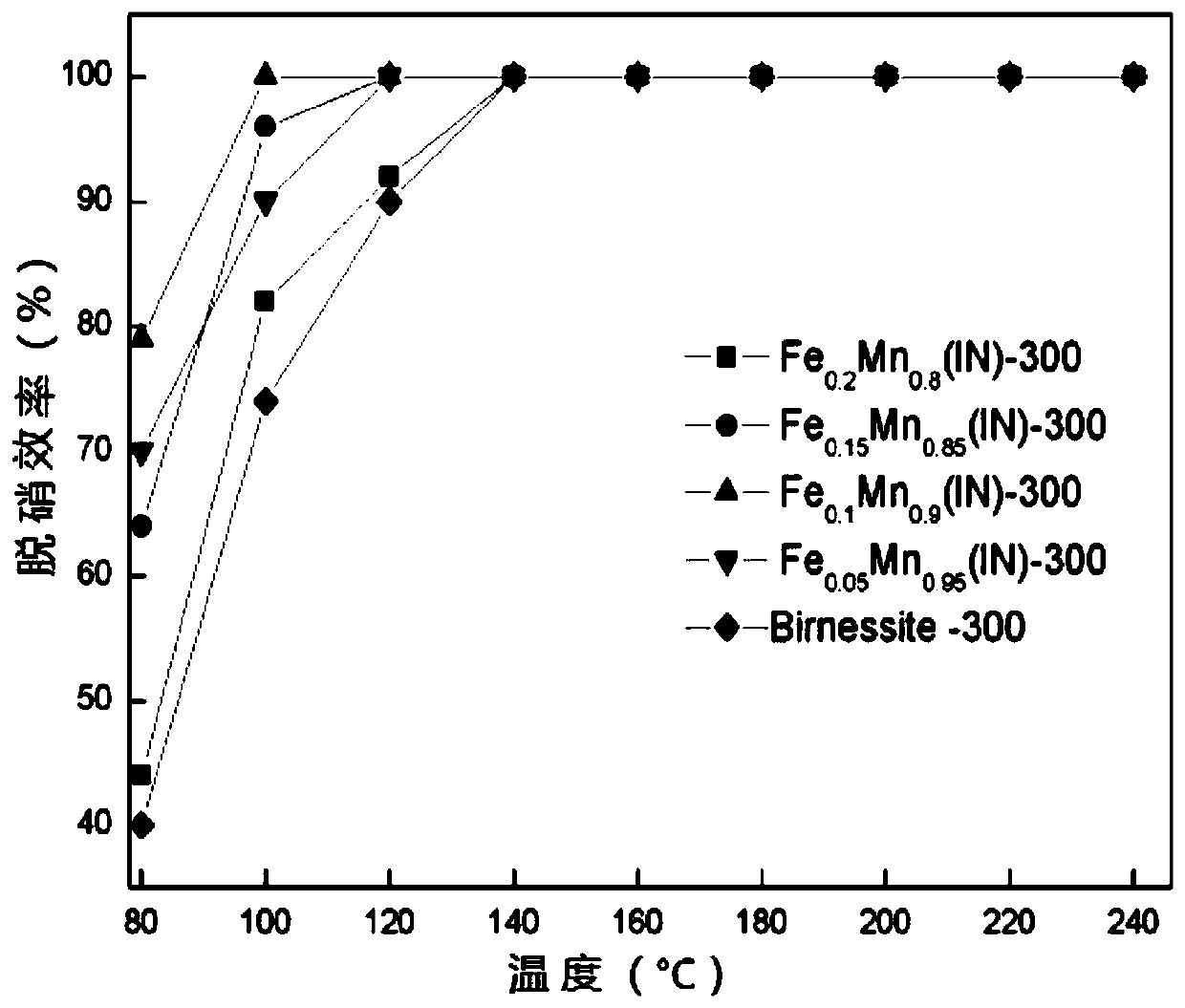

Preparation method of iron or copper oxide pillared layered manganese oxide low-temperature denitration catalyst

ActiveCN108067247AGood low temperature denitrification activityImprove sulfur resistanceGas treatmentDispersed particle separationFiltrationCopper oxide

The invention provides a preparation method of an iron or copper oxide pillared layered manganese oxide low-temperature denitration catalyst. The method mainly uses a shared precursor method. Throughhydroxide preparation, hydroxide oxidization, suction filtration and washing, drying and roasting preparation, the iron or copper oxide pillared layered manganese oxide low-temperature denitration catalyst is obtained. The low-temperature denitration catalyst has the advantages that the active temperature window is low; the denitration efficiency is high; the method is applicable to the SCR (selective catalytic reduction) method low-temperature denitration technology.

Owner:海南中盛旭鑫低碳科技有限公司

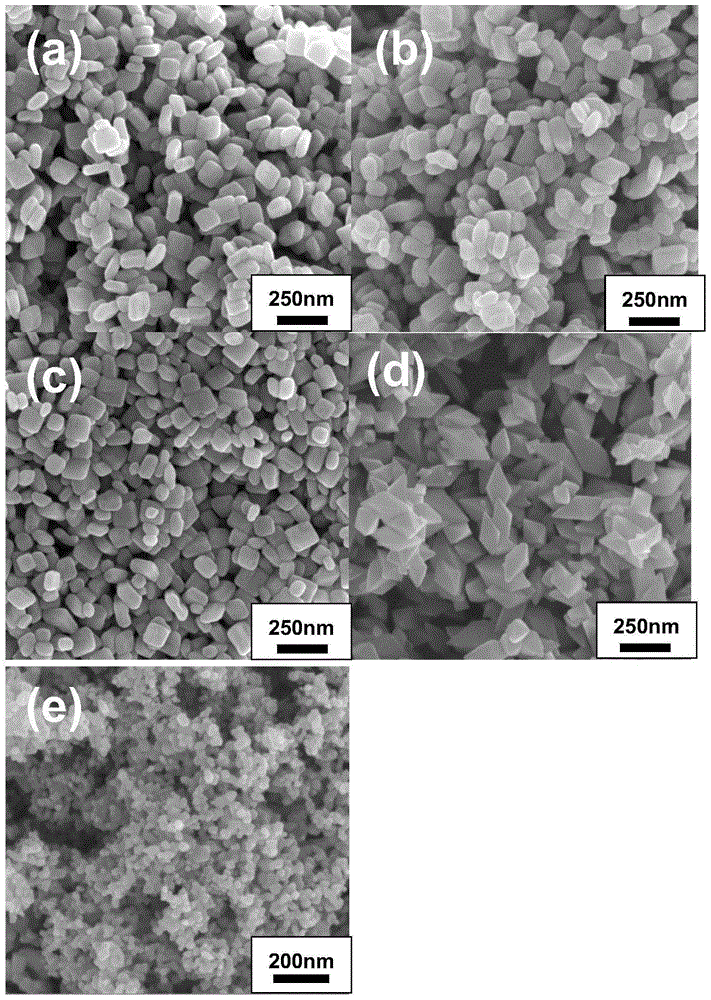

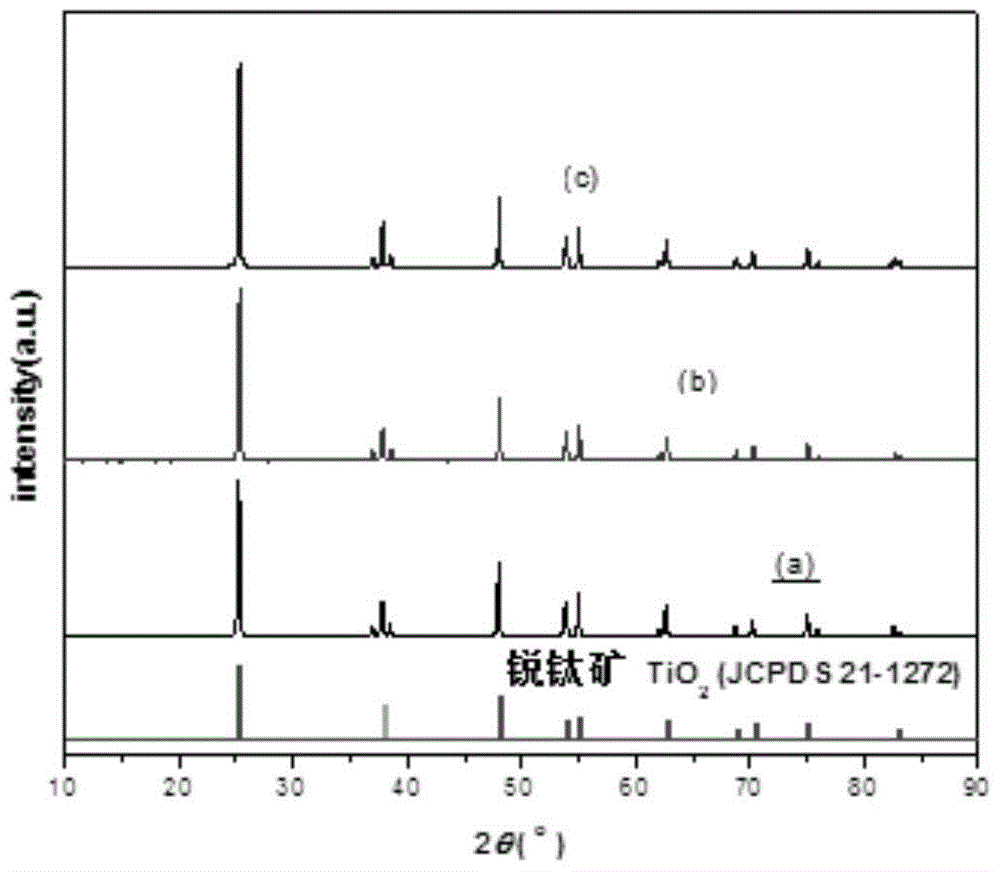

Preparation of low-temperature NH3-SCR catalyst with slice-shaped V2O5/TiO2 as carrier and application of catalyst in denitration

ActiveCN105032398ARegular shapeUniform sizeDispersed particle separationPerfluorocarbons/hydrofluorocarbons capturePtru catalystPhysical chemistry

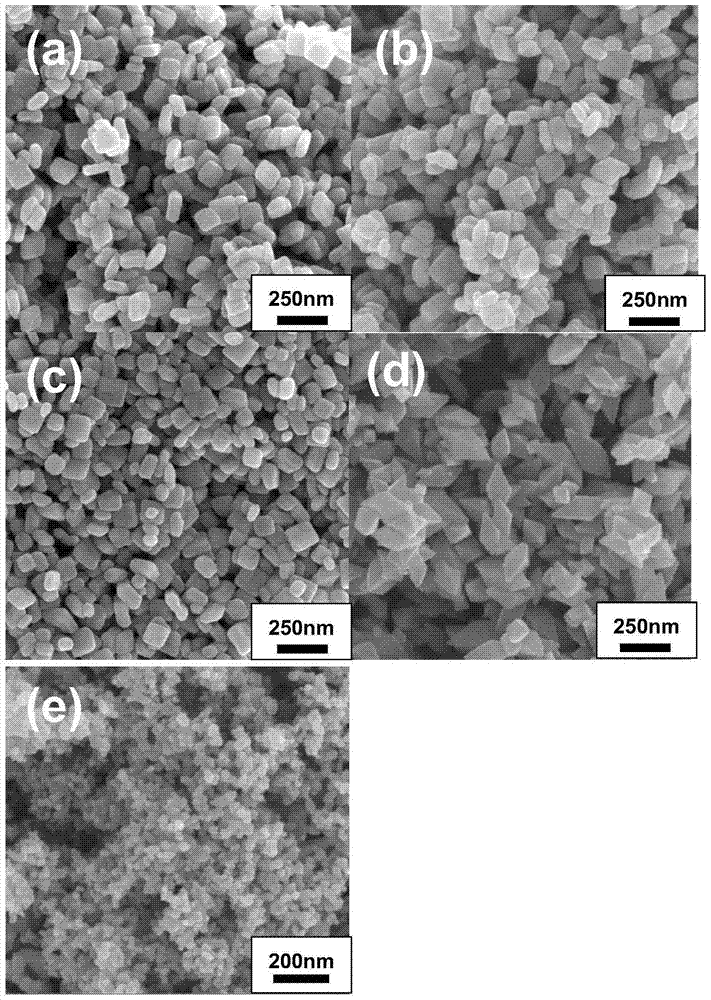

The invention discloses a preparation of a low-temperature NH3-SCR catalyst with slice-shaped V2O5 / TiO2 as a carrier and application of the catalyst in denitration and belongs to the field of environment protecting and environment catalyzing. The catalyst is prepared in the manner that the slice-shaped TiO2 serves as the carrier, and V2O5 active components are loaded through an impregnation method, wherein the content of V2O5 is 3wt%, and the content of TiO2 is 97 wt%. The slice-shaped TiO2 serves as the carrier, and compared with commercial TiO2P25, the slice-shaped TiO2 has regular features and better crystallinity. The slice-shaped TiO2 preferentially exposes a high-energy crystal face [001], mutual action between the carrier and the active components is improved through the high surface energy, higher reducibility is achieved, and the NH3-SCR denitration activity of the catalyst is enhanced. NH3 serves as a reducing agent, and compared with a vanadium-titanium catalyst prepared through a commercial P25 carrier and an octahedral carrier, the slice-shaped vanadium-titanium catalyst has better low-temperature denitration activity, and at the temperature of 250 DEG C, the denitration activity can reach 98 percent and is higher than that of other catalyst by 20 percent or more.

Owner:BEIJING UNIV OF TECH

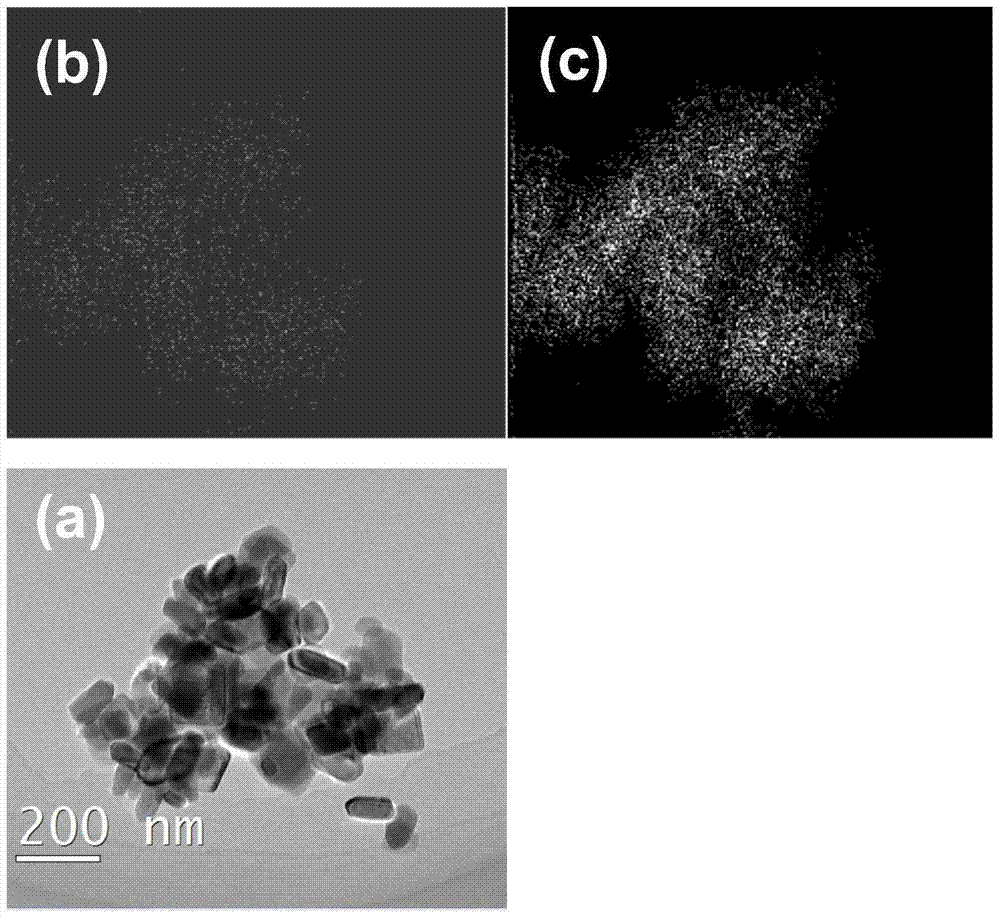

Novel core-shell structure catalyst for synergistic denitration and demercuration and preparation method ofnovel core-shell structure catalyst

InactiveCN112221488AStrong oxidation abilityApplicable to denitrification and mercury removal treatment requirementsHeterogenous catalyst chemical elementsDispersed particle separationManganese sulphatePtru catalyst

The invention discloses a novel core-shell structure catalyst for synergistic denitration and demercuration and a preparation method of a novel core-shell structure catalyst and belongs to the technical field of chemical environment-friendly catalysts. According to the core-shell structure catalyst disclosed by the invention, nanoscale TiO2 is used as a catalyst shell, and an alpha-MnO2 nanorod loaded with CeO2 is used as an inner core. The preparation method comprises the following steps of: by taking potassium permanganate and manganese sulfate as raw materials, preparing alpha-MnO2 nanorodparticles by adopting a hydrothermal method; loading CeO2 on the alpha-MnO2 nanorod particles by adopting an excessive impregnation method, so as to prepare CeO2-MnO2 particles; and wrapping the CeO2-MnO2 particles with the nanoscale TiO2 by adopting a hydrothermal method, so as to prepare the catalyst. The novel core-shell type catalyst for simultaneous denitration and demercuration still has relatively strong capability of catalyzing mercury oxidation under the condition that HCl does not exist in flue gas, and also has good low-temperature denitration activity.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

A sheet-like morphology is the carrier v 2 o 5 /tio 2 low temperature nh 3 Preparation of ‑scr catalyst and its application in denitrification

ActiveCN105032398BRegular shapeUniform sizeDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureOctahedronHigh energy

The invention discloses a preparation of a low-temperature NH3-SCR catalyst with slice-shaped V2O5 / TiO2 as a carrier and application of the catalyst in denitration and belongs to the field of environment protecting and environment catalyzing. The catalyst is prepared in the manner that the slice-shaped TiO2 serves as the carrier, and V2O5 active components are loaded through an impregnation method, wherein the content of V2O5 is 3wt%, and the content of TiO2 is 97 wt%. The slice-shaped TiO2 serves as the carrier, and compared with commercial TiO2P25, the slice-shaped TiO2 has regular features and better crystallinity. The slice-shaped TiO2 preferentially exposes a high-energy crystal face [001], mutual action between the carrier and the active components is improved through the high surface energy, higher reducibility is achieved, and the NH3-SCR denitration activity of the catalyst is enhanced. NH3 serves as a reducing agent, and compared with a vanadium-titanium catalyst prepared through a commercial P25 carrier and an octahedral carrier, the slice-shaped vanadium-titanium catalyst has better low-temperature denitration activity, and at the temperature of 250 DEG C, the denitration activity can reach 98 percent and is higher than that of other catalyst by 20 percent or more.

Owner:BEIJING UNIV OF TECH

Rare-earth doped low-temperature denitration catalyst and preparation method thereof

ActiveCN103055848BLow running costLow retrofit costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthSlurry

The present invention relates to a rare-earth doped low-temperature denitration catalyst and a preparation method thereof. The main active component of the catalyst is manganese oxide, the carrier is titanium oxide, and cerium oxide and iron oxide are used as cocatalysts. The preparation method includes the following steps: adding solutions of various metal nitrates into a metatitanic acid slurry, then adjusting the pH of the mixture to obtain complete precipitation by using concentrated ammonia, stirring for a while, and performing centrifugal filtration to the resulting suspension, and drying and calcining at a temperature to obtain the rare-earth doped low-temperature denitration catalyst; wherein the molar ratio of each element is as follows: Mn: Fe: Ce: Ti = 5: (0 ~ 2): 4:20. In the temperature range of 140-180 DEG C, the denitration activity of the metal oxide low temperature catalyst of the present invention can reach 80-98%, and the catalyst has a relatively excellent water and sulfur resistance performance.

Owner:ZHEJIANG HAILIANG ENVIRONMENTAL MATERIALS

Low-temperature denitration catalyst and preparation method and application thereof

PendingCN112473655AGood low temperature denitrification activityWide reaction temperature windowGas treatmentHeterogenous catalyst chemical elementsCombustion chamberTitanium oxide

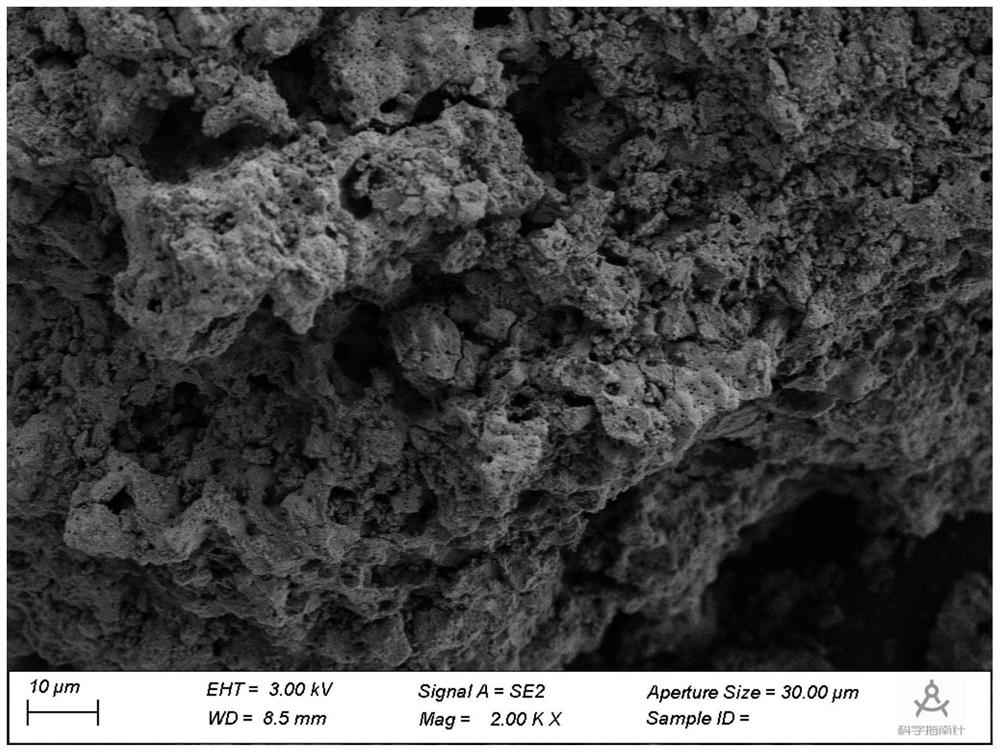

The invention relates to a low-temperature denitration catalyst and a preparation method and application thereof, and the method comprises the following steps: (1) dissolving manganese nitrate, ceriumnitrate and fuel in deionized water to obtain a mixed solution; (2) adding titanium dioxide into the mixed solution, and uniformly stirring to obtain a product; and (3) placing the obtained product in a pre-preheated combustion chamber for rapid combustion, then continuously roasting for a certain time, and finally grinding to obtain the Mn-Ce-Ox / TiO2 low-temperature denitration catalyst which isused for NH3-SCR reaction. Compared with the prior art, the preparation method has the advantages that the operation is simple, the prepared catalyst is porous and fluffy, the low-temperature denitration activity is better, the reaction temperature window is wider, the water resistance and sulfur resistance are better, and the like.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

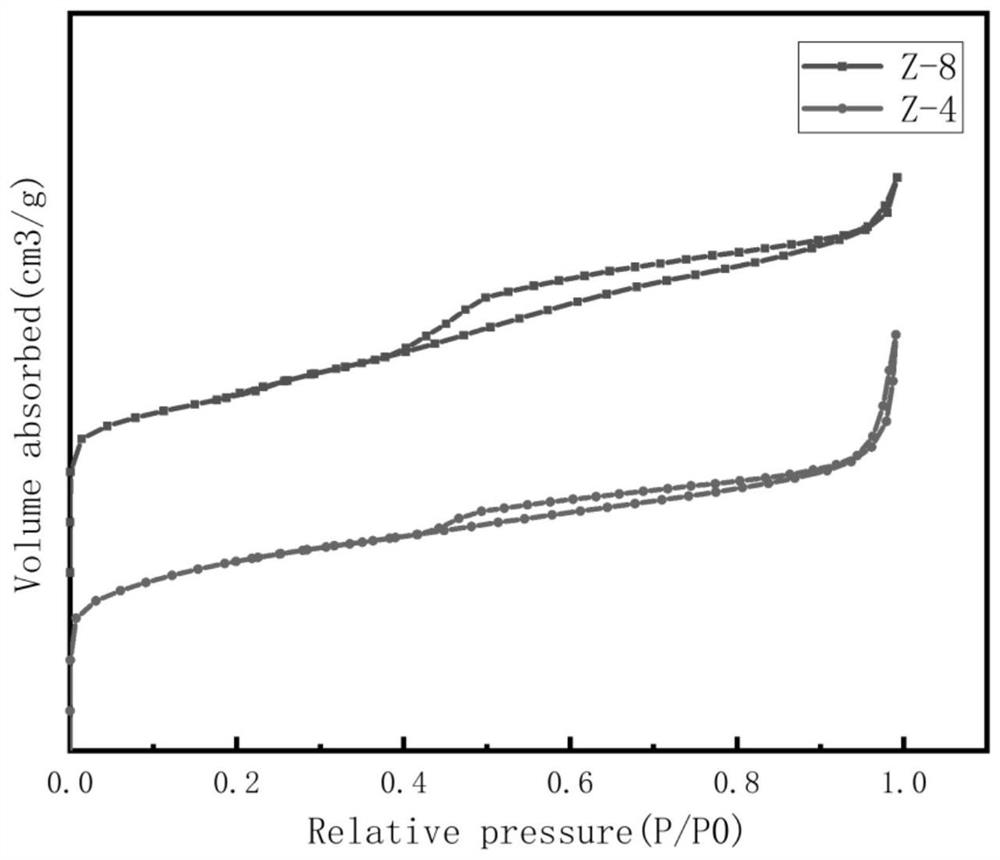

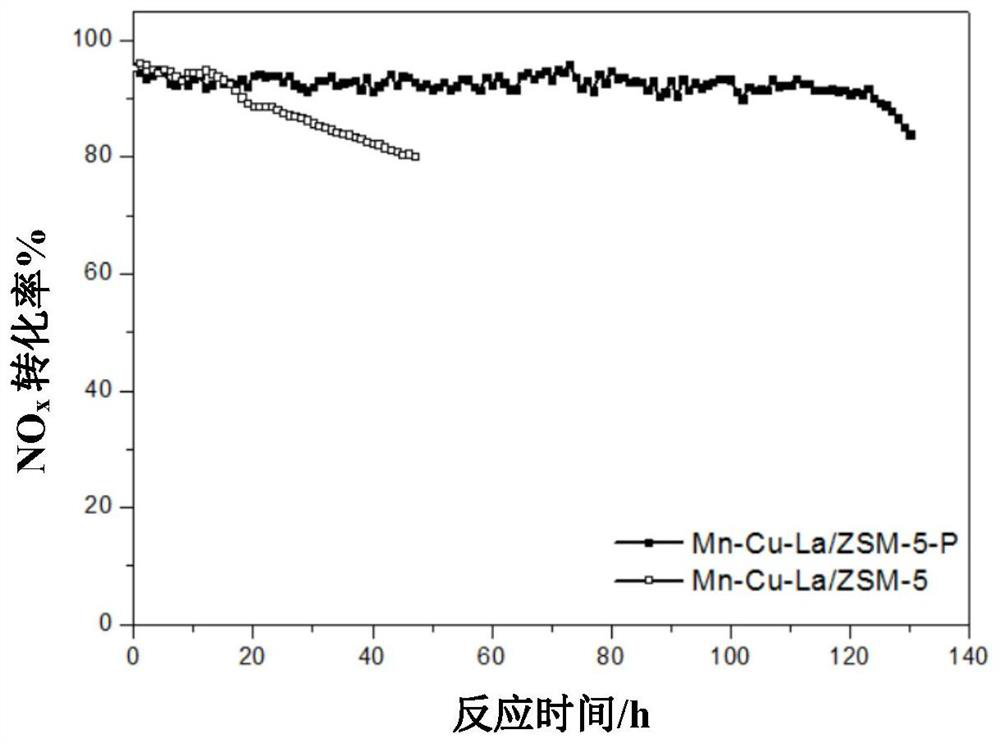

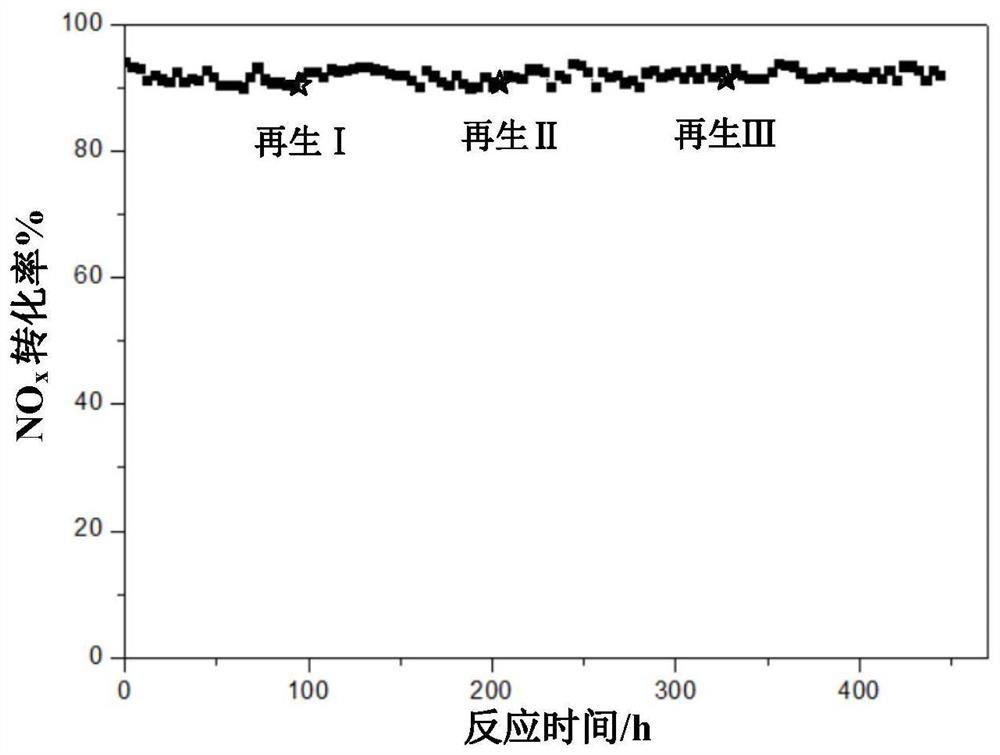

Preparation of Mn-Ce-Sb/hierarchical porous ZSM-5 catalyst and low-temperature denitration application thereof

InactiveCN113769777AImprove efficiencyImprove sulfur resistanceMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention discloses preparation and low-temperature denitration application of a Mn-Ce-Sb / hierarchical porous ZSM-5 catalyst, wherein a hierarchical porous ZSM-5 molecular sieve is prepared by a soft template method, and Mn, Ce and Sb are loaded by an impregnation method to synthesize the Mn-Ce-Sb / hierarchical porous ZSM-5 catalyst so as to improve the low-temperature denitration performance and the sulfur resistance of the Mn-Ce-Sb / hierarchical porous ZSM-5 catalyst. The hierarchical porous ZSM-5 molecular sieve has a developed porous structure, combines adjustable acidity and good hydrothermal stability of a microporous molecular sieve and excellent mass transfer and diffusion performance of a mesoporous material, is simple to prepare and has good repeatability. The hierarchical porous ZSM-5 molecular sieve catalyst prepared by the method shows good low-temperature denitration performance and sulfur resistance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

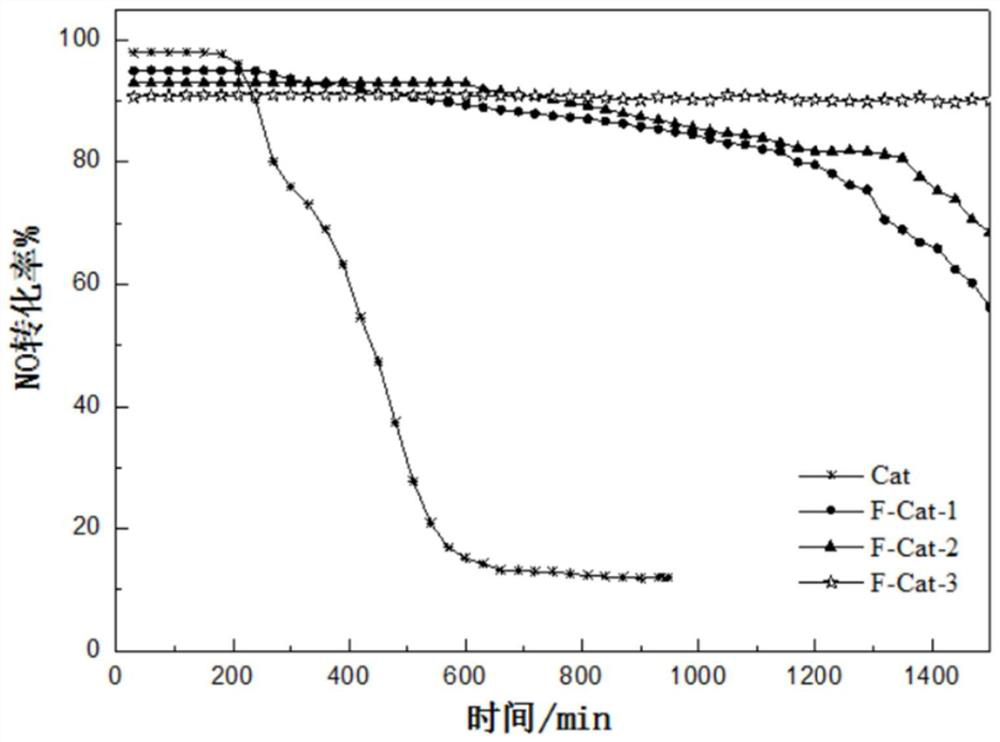

Sweet dumpling type formed sulfur-resistant low-temperature denitration catalyst as well as preparation method and application thereof

PendingCN112138714AHas anti-sulfur poisoning propertiesPromote circulationCatalyst protectionMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a sweet dumpling forming sulfur-resistant low-temperature denitration catalyst as well as a preparation method and application thereof. The denitration catalyst comprises a molecular sieve and a protective shell, the molecular sieve is wrapped by the protective shell; the molecular sieve is loaded with an active component; the protective shell contains titanium oxide; and the protective shell has a porous structure. The protective shell can be flexibly adjusted according to the content of sulfur and water under different working conditions. The denitration catalyst hasthe characteristics of sulfur resistance and water resistance, has a pore structure, reduces pressure drop, enables reaction gas to be more easily close to a catalytic center, is used for denitrationof fixed source flue gas, has the advantages of excellent low-temperature activity and sulfur poisoning resistance, and can be repeatedly used through regeneration.

Owner:DALIAN UNIV OF TECH

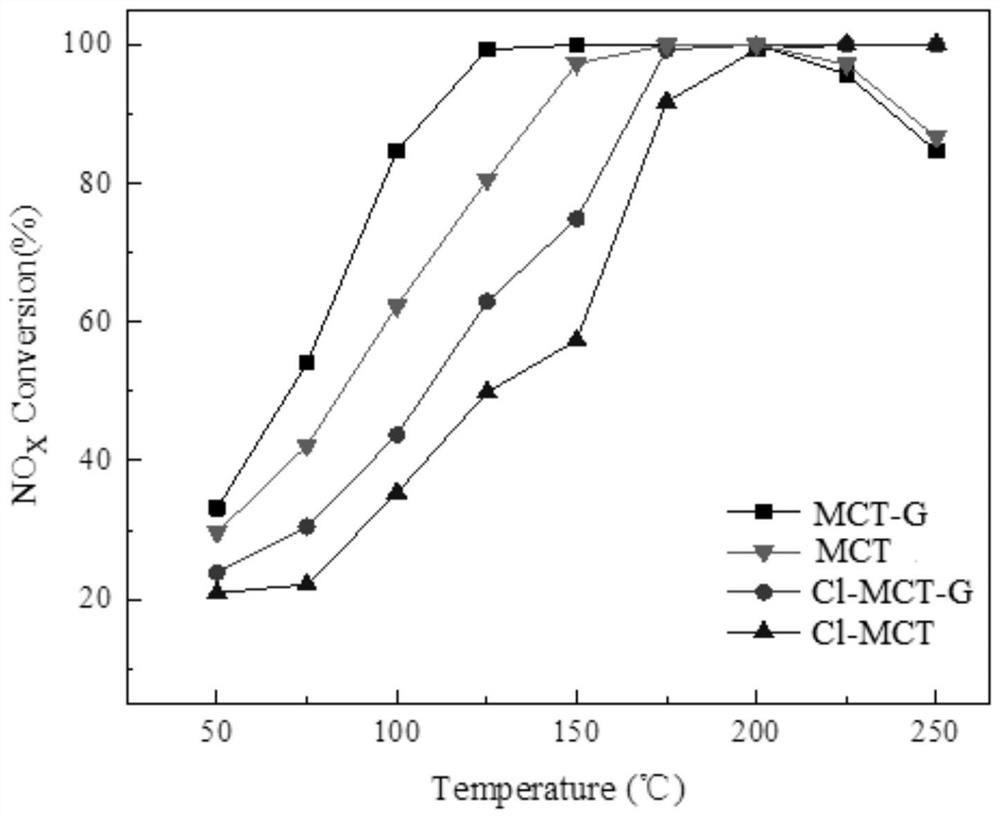

Low-temperature denitration catalyst capable of resisting halogen element Cl poisoning and preparation method and application of low-temperature denitration catalyst

PendingCN113457670AGood low temperature denitrification activityWide reaction temperature windowHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystCombustion chamber

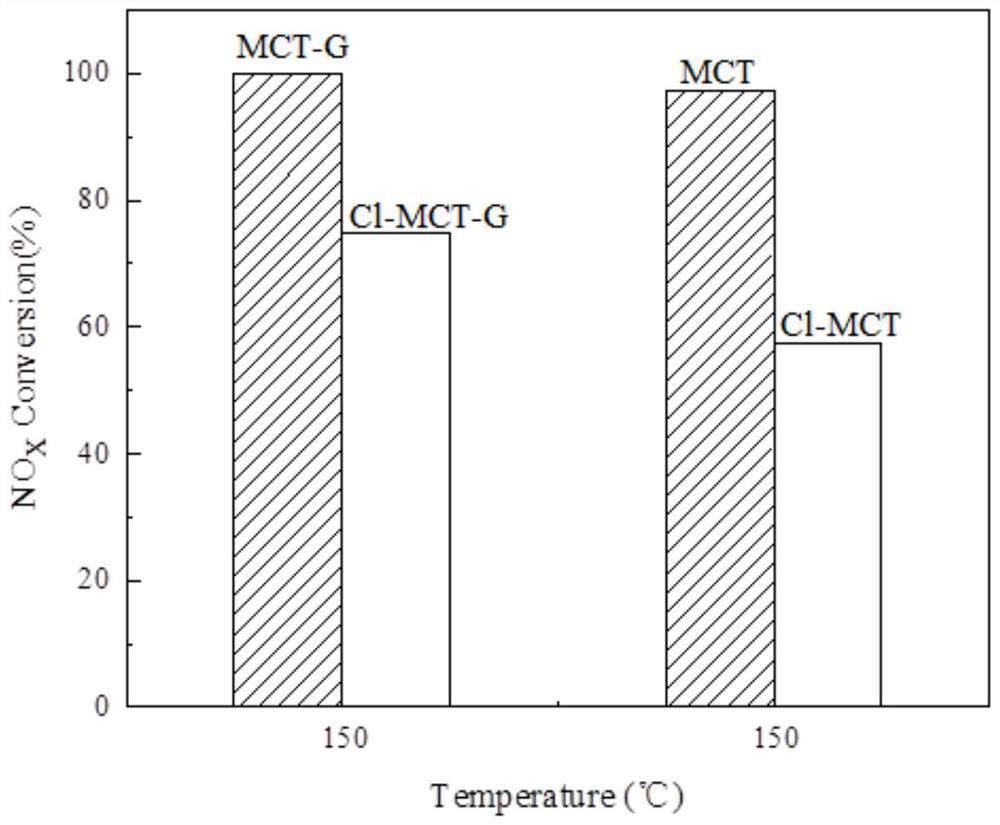

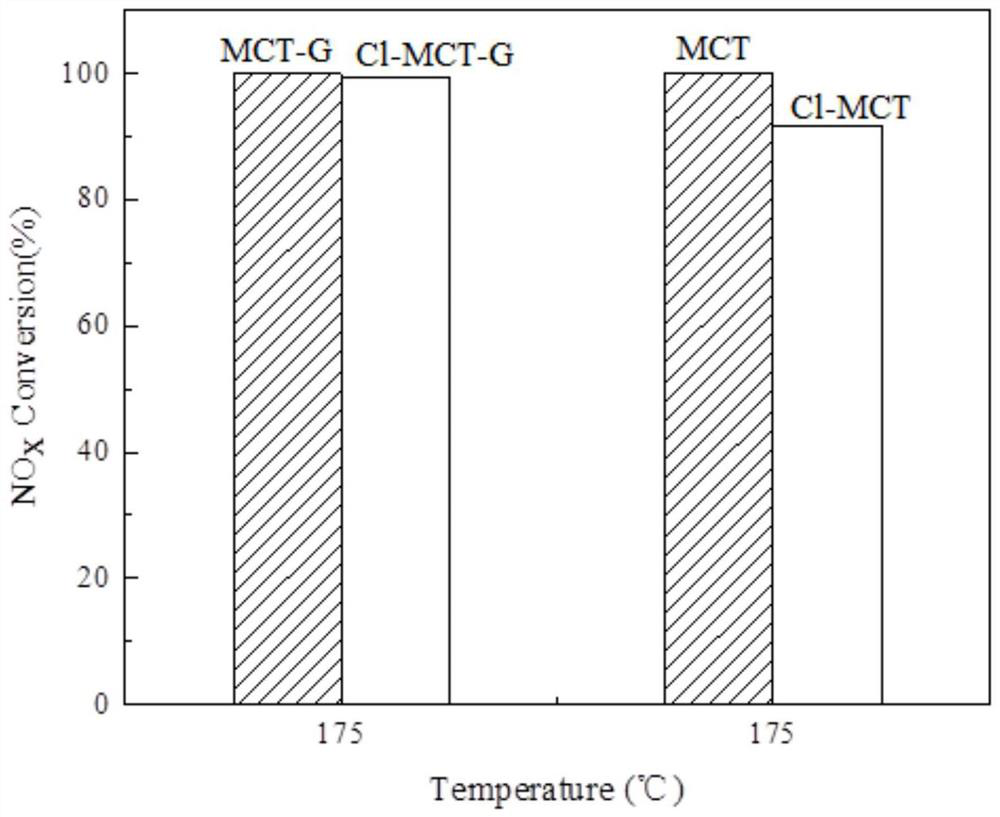

The invention relates to a low-temperature denitration catalyst capable of resisting halogen element Cl poisoning and a preparation method and application thereof. The catalyst is prepared through a surface impregnation combustion method, and the preparation method comprises the following steps: (1) dissolving manganous nitrate, cerous nitrate and fuel in deionized water to obtain a mixed solution; (2) adding titanium dioxide into the mixed solution, and uniformly stirring to obtain a precursor product; and (3) burning the precursor product in a combustion chamber, continuously roasting, and grinding the obtained solid reaction product to obtain the target product. The catalyst is used for NH3-SCR reaction. Compared with a catalyst prepared by a traditional impregnation method, the Mn-Ce-Ox / TiO2 low-temperature denitration catalyst prepared by the preparation method disclosed by the invention has relatively good low-temperature denitration activity and halogen element Cl poisoning resistance, and the reduction amplitude of the NOx conversion rate of the catalyst is relatively small in a temperature range of 100-200 DEG C; equipment required in the preparation process is simple, the cost of raw materials is low, the combustion reaction is mild, and the method is a simple, safe and reliable new method.

Owner:SHANGHAI INST OF TECH

Cerium-iron molecular sieve based catalyst with wide temperature range and preparation method thereof

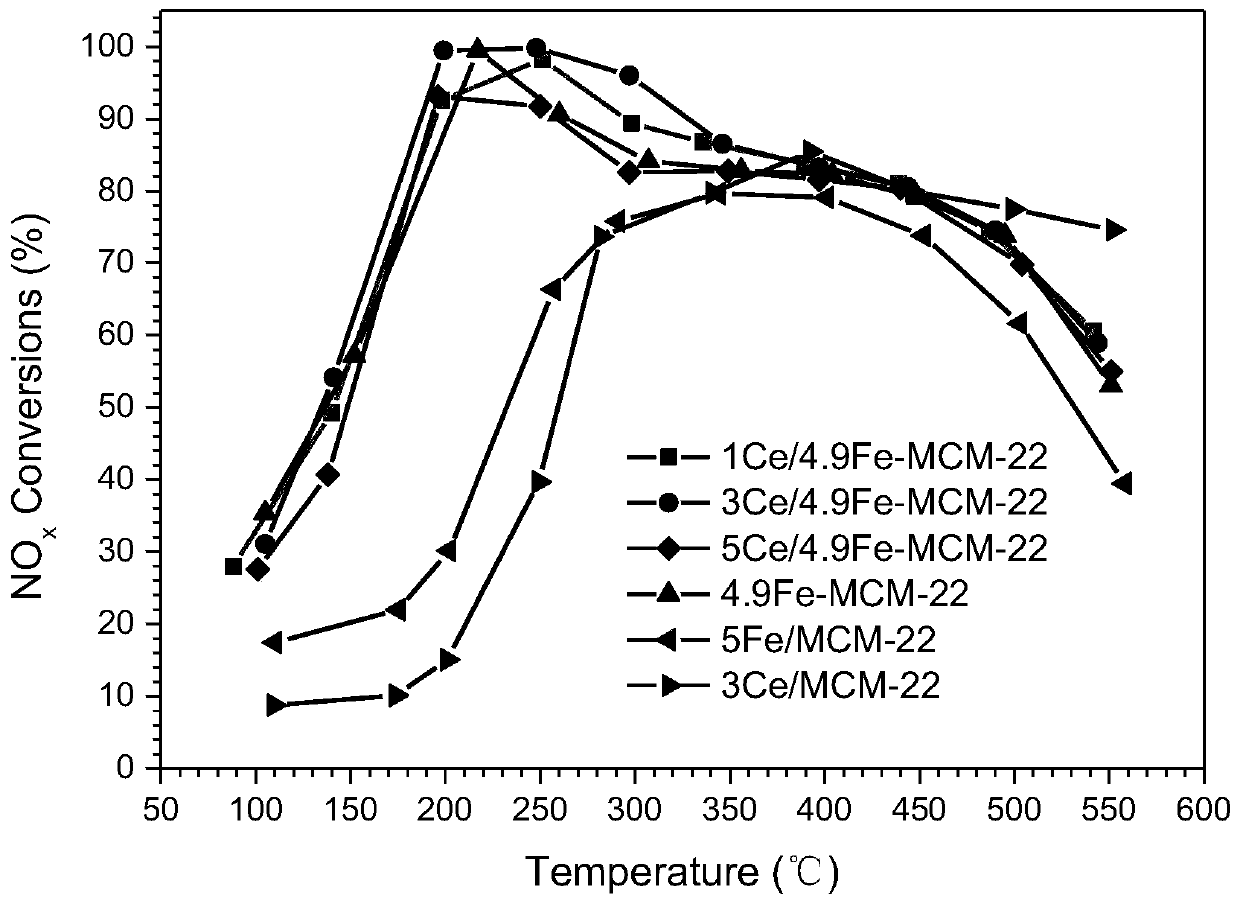

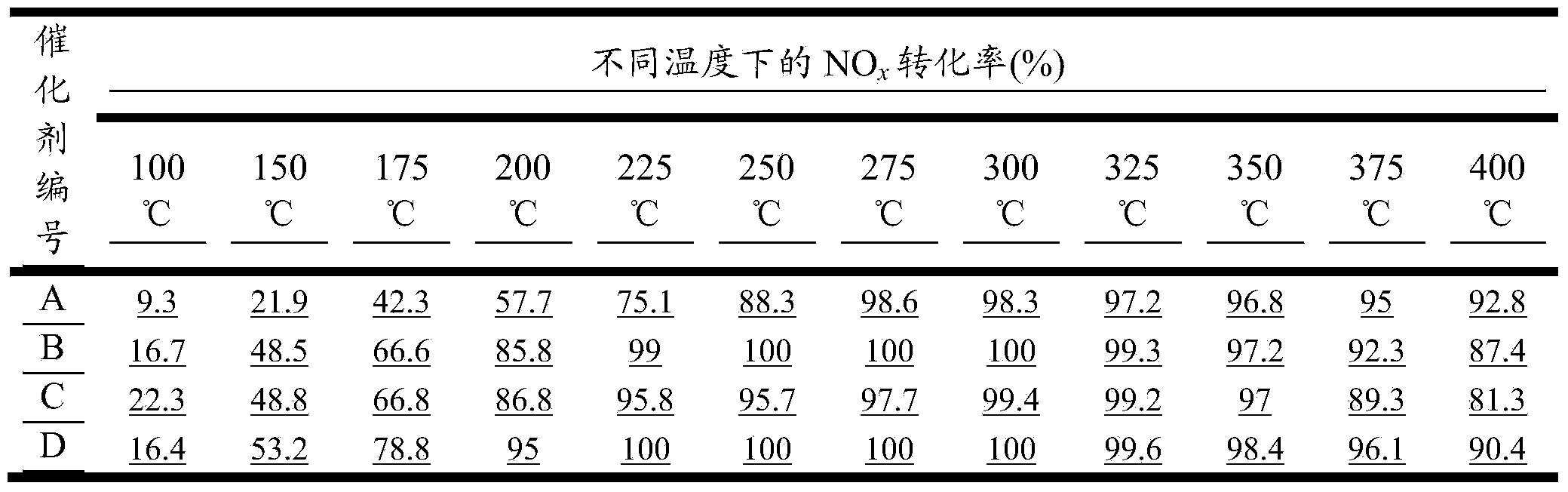

ActiveCN111437875ASimple manufacturing processLow activity temperature rangeGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a cerium-iron molecular sieve based catalyst with a wide temperature range and a preparation method thereof. A novel MCM-22 molecular sieve is used as a catalyst, the synthesischaracteristics of the molecular sieve are utilized, Fe is introduced in situ in the hydrothermal synthesis process to serve as an active site of an NH3-SCR reaction, an Fe-MCM-22 catalyst is obtained, then an active component Ce is introduced through an isopyknic impregnation method, and the bimetal supported Ce / Fe-MCM-22 catalyst is prepared and used for removing nitrogen oxide through NH3-SCR.The Fe-MCM-22 catalyst prepared by the method has the advantages that the active Fe component is uniformly dispersed, the low-temperature catalytic activity of the catalyst is obviously improved, andthe temperature window is widened; the catalyst has good dispersibility and redox property and is high in activity and is a Ce / Fe-MCM-22 catalyst which is high in activity and wide in active temperature interval.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of supported type denitration catalyst

ActiveCN102658155BReduce manufacturing costReduce energy consumptionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMicrowaveActive component

The invention relates to a preparation method of a supported type denitration catalyst. The preparation method comprises the following steps of: adopting soluble iron salt and cerate as active components, adding water for dissolving and mixing to prepare mixed solution; adding corresponding carriers into the mixed solution, dipping, dripping an alkaline precipitating agent till the pH is equal to 9-10, precipitating completely, then filtering, and cleaning to obtain a filter cake; putting the filter cake into a microwave experiment table for microwave treatment, then drying, finally calcining, and activating to prepare the catalyst. The catalyst prepared by the invention has the advantages that a denitration temperature window is wide, the low-temperature denitration activity is good, the energy consumption of the preparation method is low, and the preparation of the denitration catalyst is reduced.

Owner:SHANDONG UNIV

High-strength manganese oxide granular catalyst and preparation process thereof

PendingCN112808265AAchieve recyclingGood low temperature denitrification activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberGlass fiber

The invention discloses a high-strength manganese oxide granular catalyst, which is characterized by comprising the following raw material components by weight: 50-70% of manganese carbonate, 10-30% of clay, 10-20% of an inorganic binder, 1-5% of an organic binder and 3-10% of inorganic fiber. The invention also discloses a preparation process of the high-strength manganese oxide particle catalyst. The process comprises the following steps: selecting a manganese carbonate precursor with special composition requirements, mixing the manganese carbonate precursor with high-surface-area clay, an inorganic binder and water to form a mixture, adding glass fiber and an organic binder into a kneading machine, and carrying out strong kneading to obtain corresponding manganese carbonate pug; and in a two-stage vacuum extruder, carrying out vacuum extrusion and cutting to obtain green body pug particles, and drying and roasting to obtain manganese oxide catalyst particles. The catalyst provided by the invention has excellent denitration efficiency.

Owner:NANJING WEIHENG EXPERIMENTAL EQUIP CO LTD

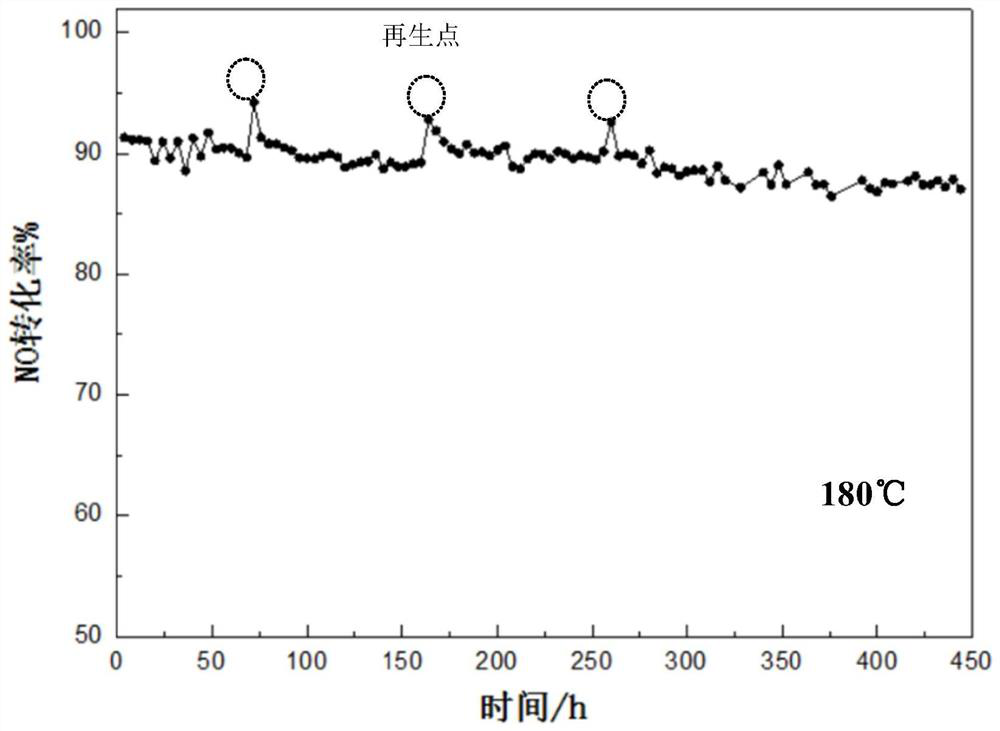

Denitration catalyst as well as preparation method and application thereof

ActiveCN114308114AExcellent low temperature NH

<sub>3</sub>

-SCR catalytic activityExcellent low temperature NH <sub>3<</sub> Catalyst protectionMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a denitration catalyst. The denitration catalyst comprises a molecular sieve and a protective layer, the protective layer is coated on the surface of the molecular sieve; the molecular sieve is loaded with an active component; and the protective layer contains a SiOx-TiOx crystal substance. The invention further discloses a preparation method of the denitration catalyst and application of the denitration catalyst in denitration of waste gas containing water and / or sulfur. The denitration catalyst has good low-temperature denitration activity (lt; and the Ti content of the SiOx-TiOx crystal substance protective layer is increased in a gradient manner, so that the water resistance and sulfur resistance of the denitration catalyst are greatly improved, and the denitration catalyst can be reused through regeneration.

Owner:DALIAN UNIV OF TECH

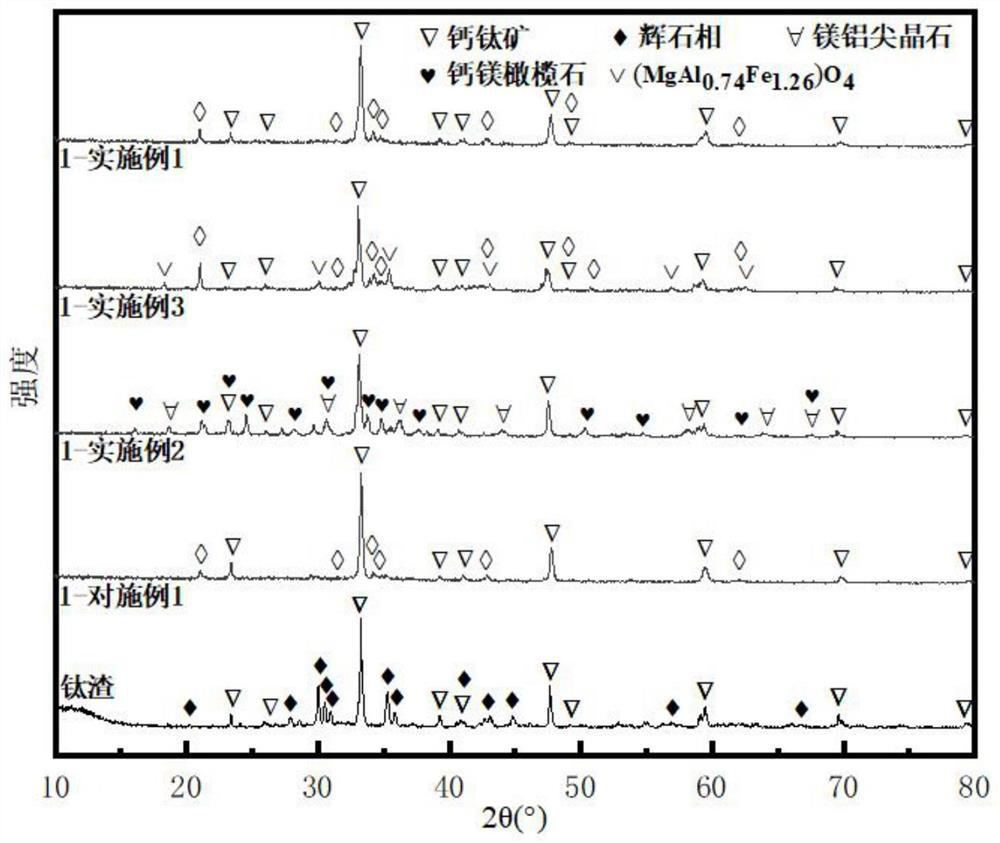

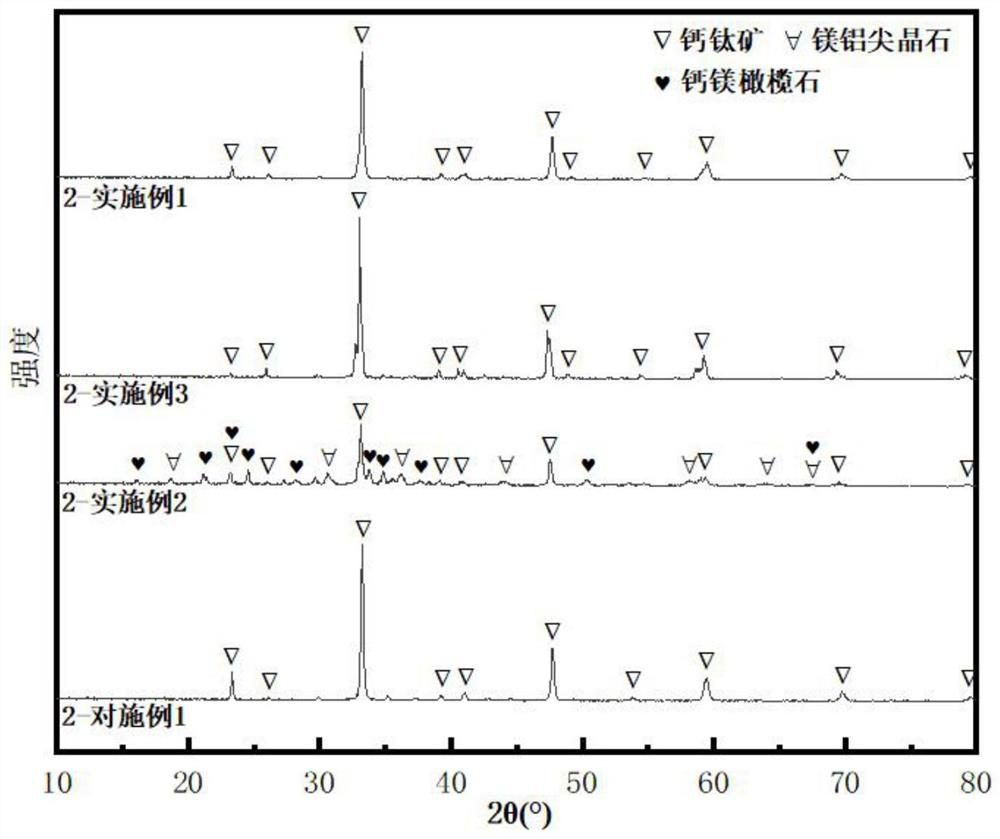

Efficient response optical coupling denitration catalyst and preparation method thereof

PendingCN112675868ARealize high value-added applicationsFacilitating Light-Coupled Low-Temperature Denitrification PerformanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementIndustrial waste

The invention discloses an efficient response optical coupling denitration catalyst and a preparation method thereof, and belongs to the technical field of blast furnace slag application. The preparation method of the product comprises the following steps: uniformly mixing the titanium-containing blast furnace slag with the rare earth element oxide, the transition metal oxide and a certain amount of sodium hydroxide, heating to melt, reconfiguring a silicate phase while solid-dissolving transition group elements into a perovskite phase, and stripping the silicate phase through acid leaching treatment, thereby finally obtaining the perovskite-based functional material. The obtained product is the optical coupling low-temperature denitration catalyst with efficient response activity. According to the catalyst prepared by the method disclosed by the invention, the removal rate of NOx can reach 100% and the N2 selectivity can reach 92% under a low-temperature condition (140 DEG C) in a manner of adding a light source, so that the denitration catalyst capable of efficiently responding under the low-temperature condition is prepared at low cost in a short process; and the method disclosed by the invention has great significance in high-added-value application of the titanium-containing blast furnace slag and continuous and efficient removal of NOx in industrial waste gas.

Owner:安徽工业大学科技园有限公司

A denitrification treatment method for exhaust gas from an ethylene cracking furnace

ActiveCN109482065BImprove denitrification activityExcellent water vapor resistanceGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a denitrification treatment method for flue gas discharged from an ethylene cracking furnace. The flue gas flows sequentially through a radiation section, a convective heat exchange section A, an ammonia injection grid, a convective heat exchange section B, an SCR denitrification reaction section and a convective heat exchange section. C, the preparation method of the catalyst filled in the SCR denitration reaction section is as follows: (1) Add carbon black powder and cerium nitrate to the ethanol solution containing silicon source, mix under ultrasonic dispersion conditions, separate solid-liquid, and carry out solid phase Dry to obtain silicon and cerium modified carbon black powder; (2) Add modified carbon black powder to ethanol solution containing titanium source, add dilute nitric acid solution to form sol-gel, and then treat at high temperature in an oxygen-free atmosphere , roasted in an oxygen-containing atmosphere to obtain a macroporous titania carrier containing silicon and cerium; (3) After mixing the titania carrier, molecular sieve and active component precursor, molding it to obtain a honeycomb denitration catalyst. The method of the invention has good denitrification activity, strong ability to resist water vapor, the catalyst is not easy to crack, and the service life is long.

Owner:CHINA PETROLEUM & CHEM CORP +1

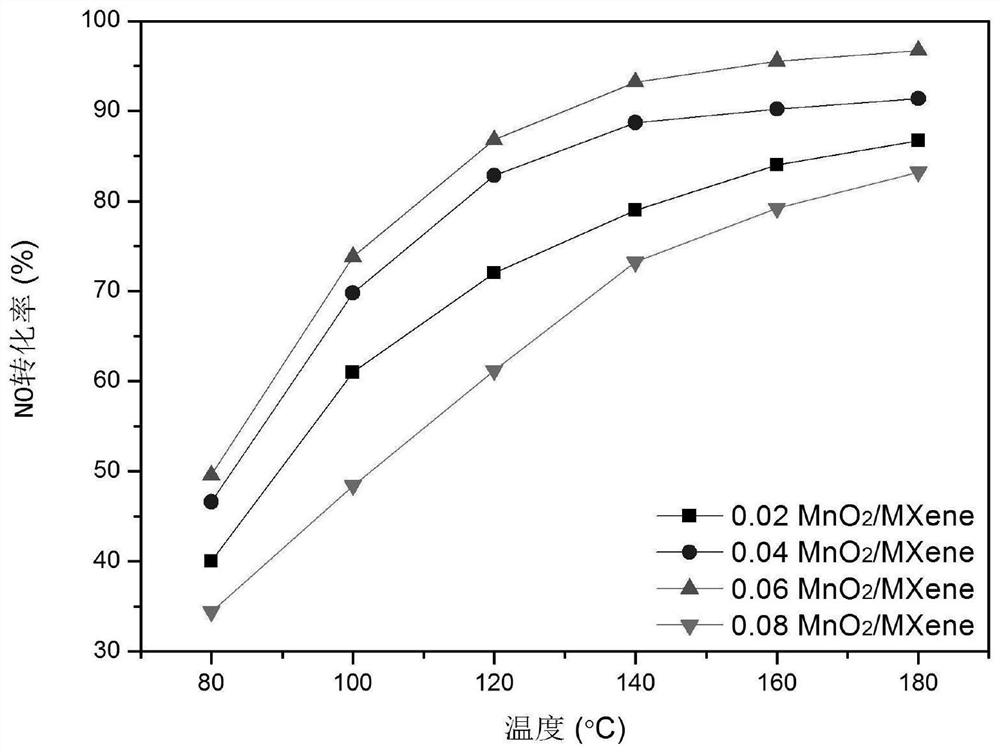

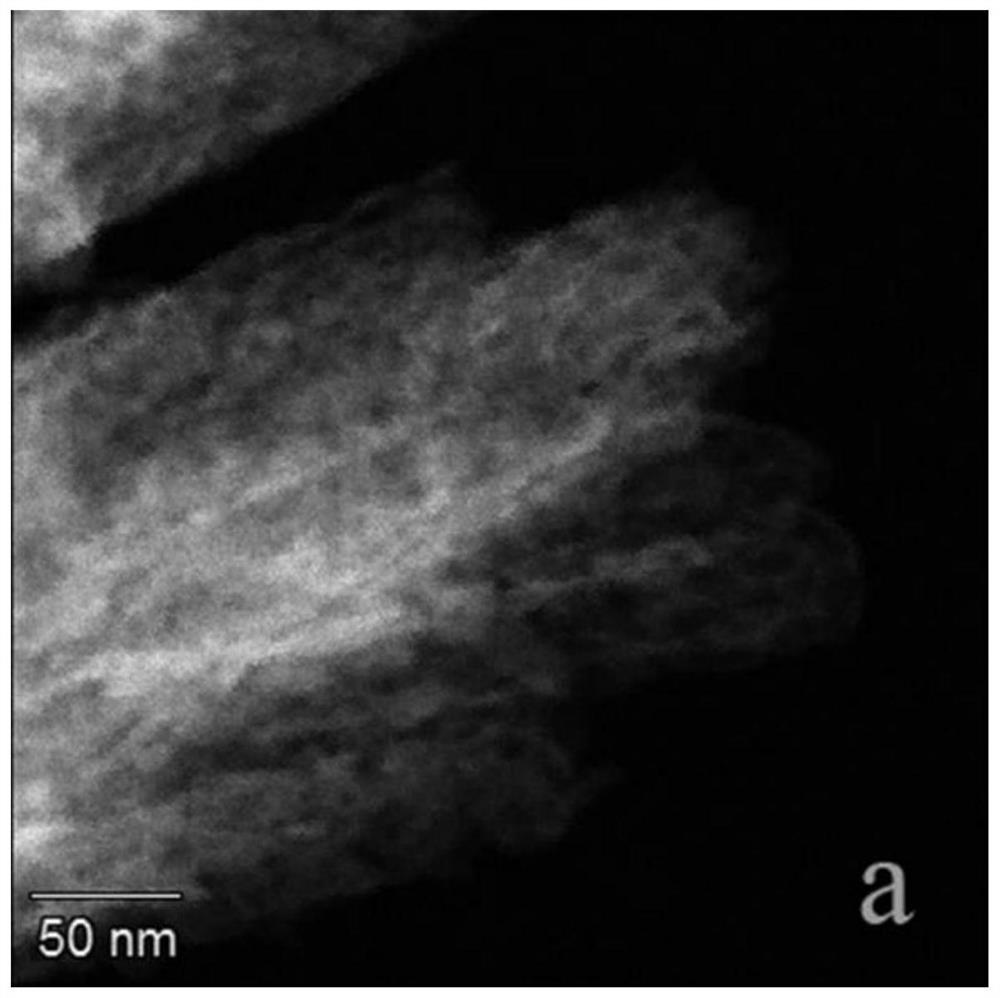

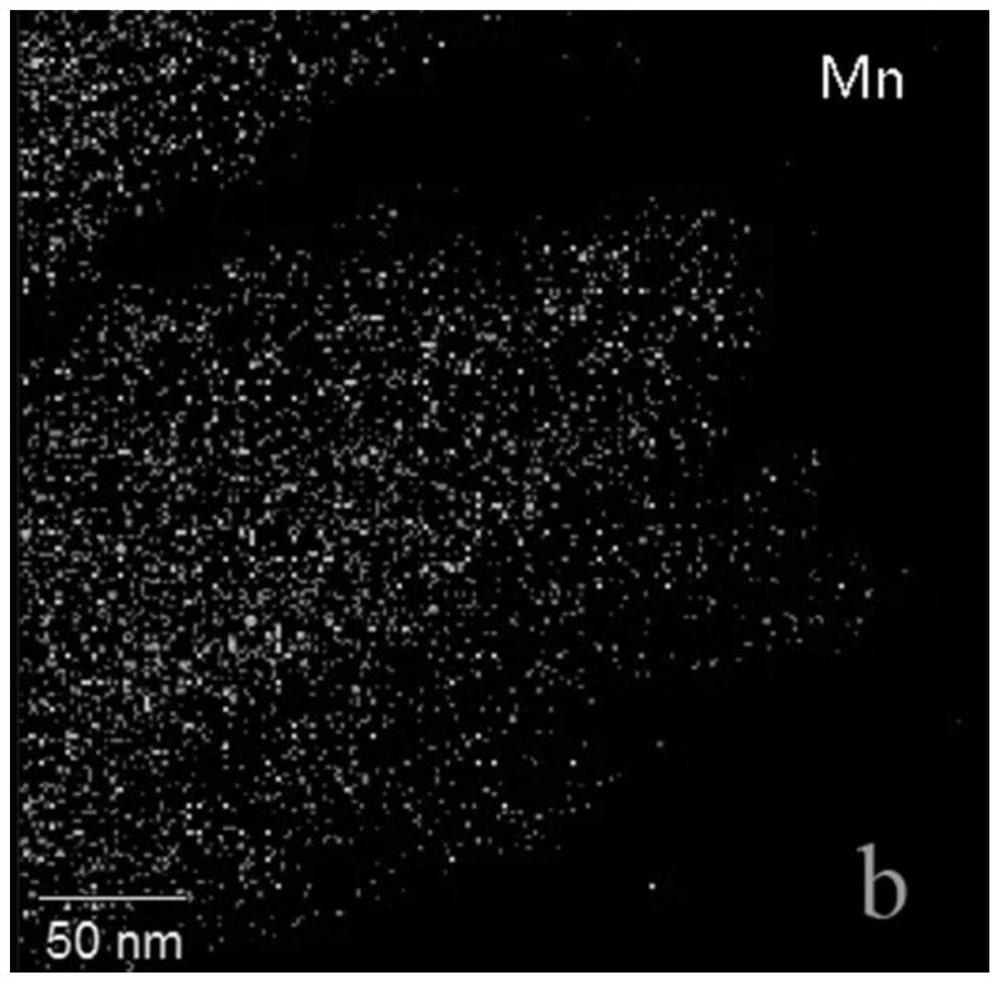

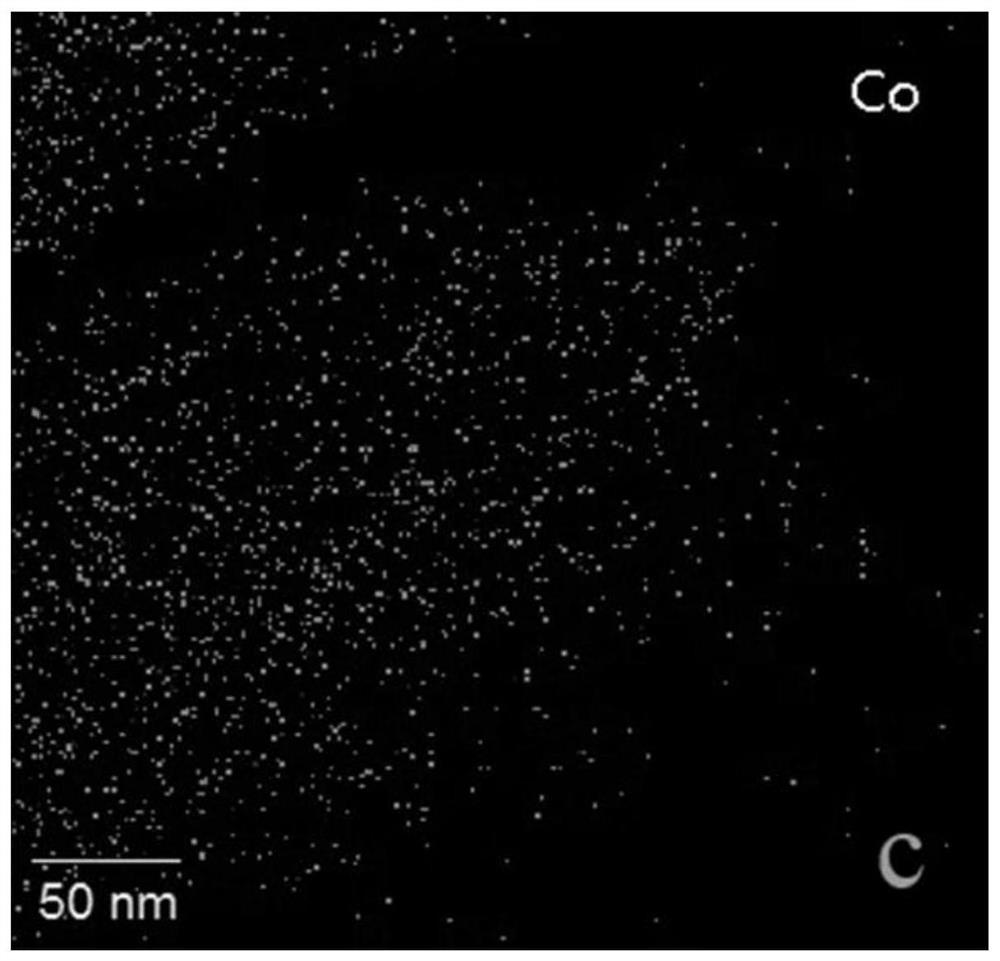

MnO2 low-temperature denitration catalyst based on MXene carrier, and preparation method thereof

PendingCN111672538AGood low temperature denitrification activityMild preparation methodGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPolypyrrole

The invention discloses a MnO2 low-temperature denitration catalyst based on an MXene carrier, and a preparation method thereof, and belongs to the technical field of catalyst preparation. A carrier of the catalyst is MXene, an active component of the catalyst is MnO2 metal oxide, the molar ratio of MnO2 to MXene is 0.01 to 0.1, and the MXene carrier is prepared based on related literature. The MXene is used as the carrier, the modification effect of polypyrrole or poly(3,4-ethylenedioxythiophene) is utilized, a redox reaction between polypyrrole or poly(3,4-ethylenedioxythiophene) and KMnO4 is combined, the MnO2 / MXene low-temperature denitration catalyst is obtained through in-situ generation of the MnO2 active component on the surface of the MXene, the catalyst shows good low-temperaturedenitration activity at the temperature of 80-180 DEG C, and the preparation method of the catalyst is mild and safe.

Owner:HENAN UNIV OF URBAN CONSTR

A modified low-temperature SCO denitration catalyst and its preparation method

ActiveCN108262049BImprove stabilityHigh catalytic oxidation activityHeterogenous catalyst chemical elementsDispersed particle separationCerium nitratePtru catalyst

The invention discloses a modified low-temperature SCO denitration catalyst and a preparation method thereof. The preparation method comprises: (1) dissolving manganese nitrate, cobalt nitrate and cerium nitrate in dimethylformamide, adding an organic ligand, and ultrasonicating until the solution is evenly mixed; (2) heating the mixed solution obtained in step (1), Hydrothermal reaction to obtain Mn / Co / Ce mixed multi-metal organic framework crystal material; the prepared crystal material is washed, filtered, dried and roasted in sequence to obtain low-temperature SCO denitration catalyst; (3) Ultrasonic impregnation of low-temperature SCO with modified solution The denitration catalyst is taken out and dried to obtain the modified low-temperature SCO denitration catalyst. The modified low-temperature SCO denitrification catalyst of the present invention has a NO conversion rate of 62.41% at 100°C. Compared with the SCO denitrification catalyst before modification, the activity has increased by 40.05%, which can better meet the current industrial requirements. The field of low-temperature denitrification has great potential application prospects.

Owner:SOUTH CHINA UNIV OF TECH

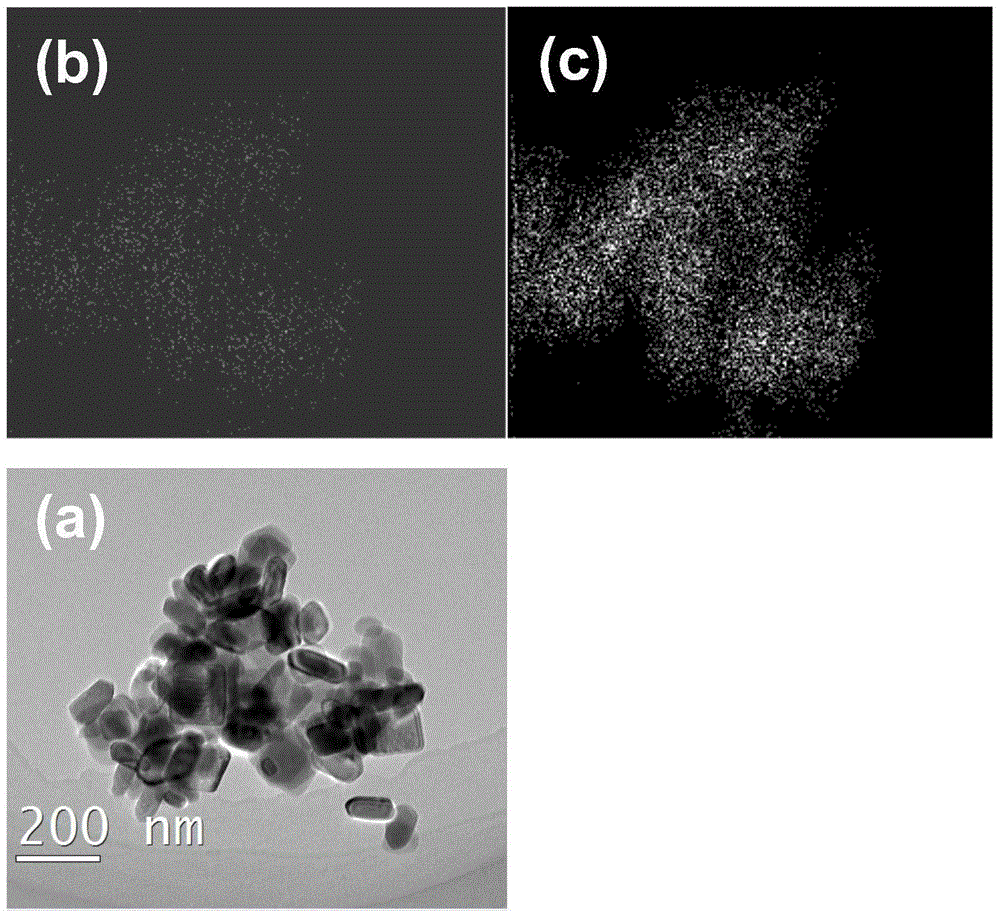

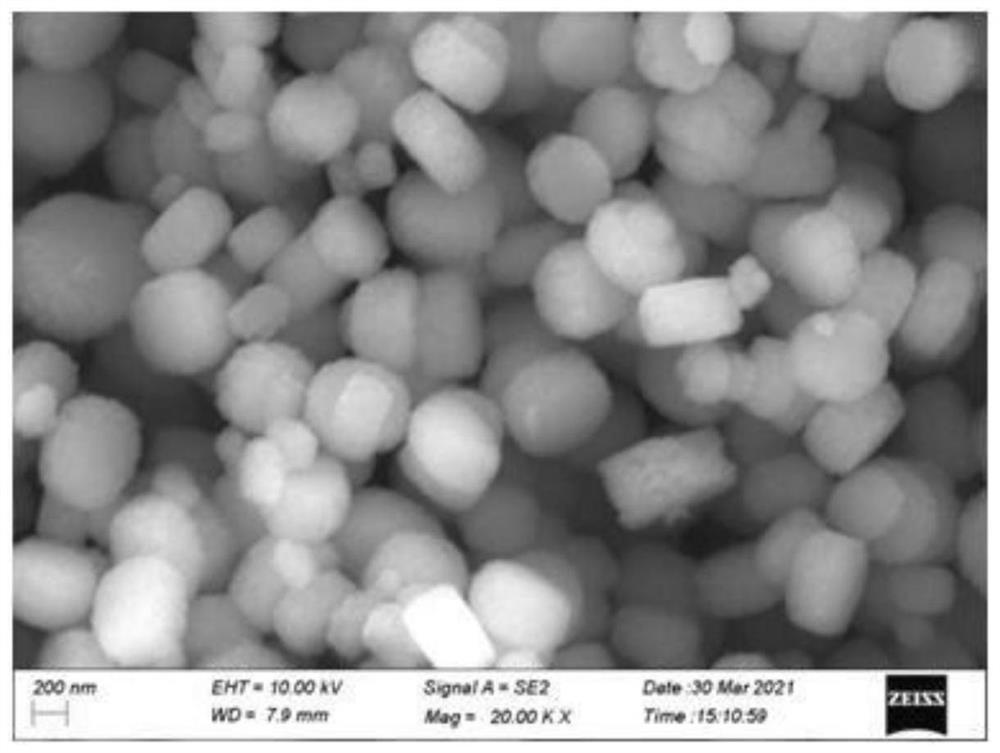

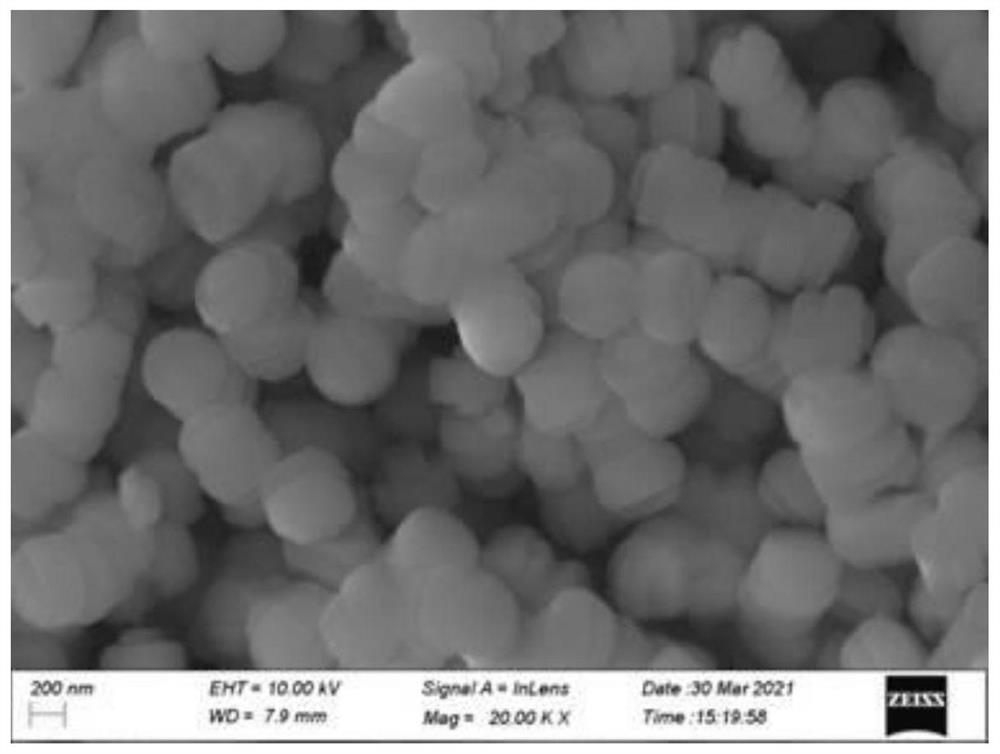

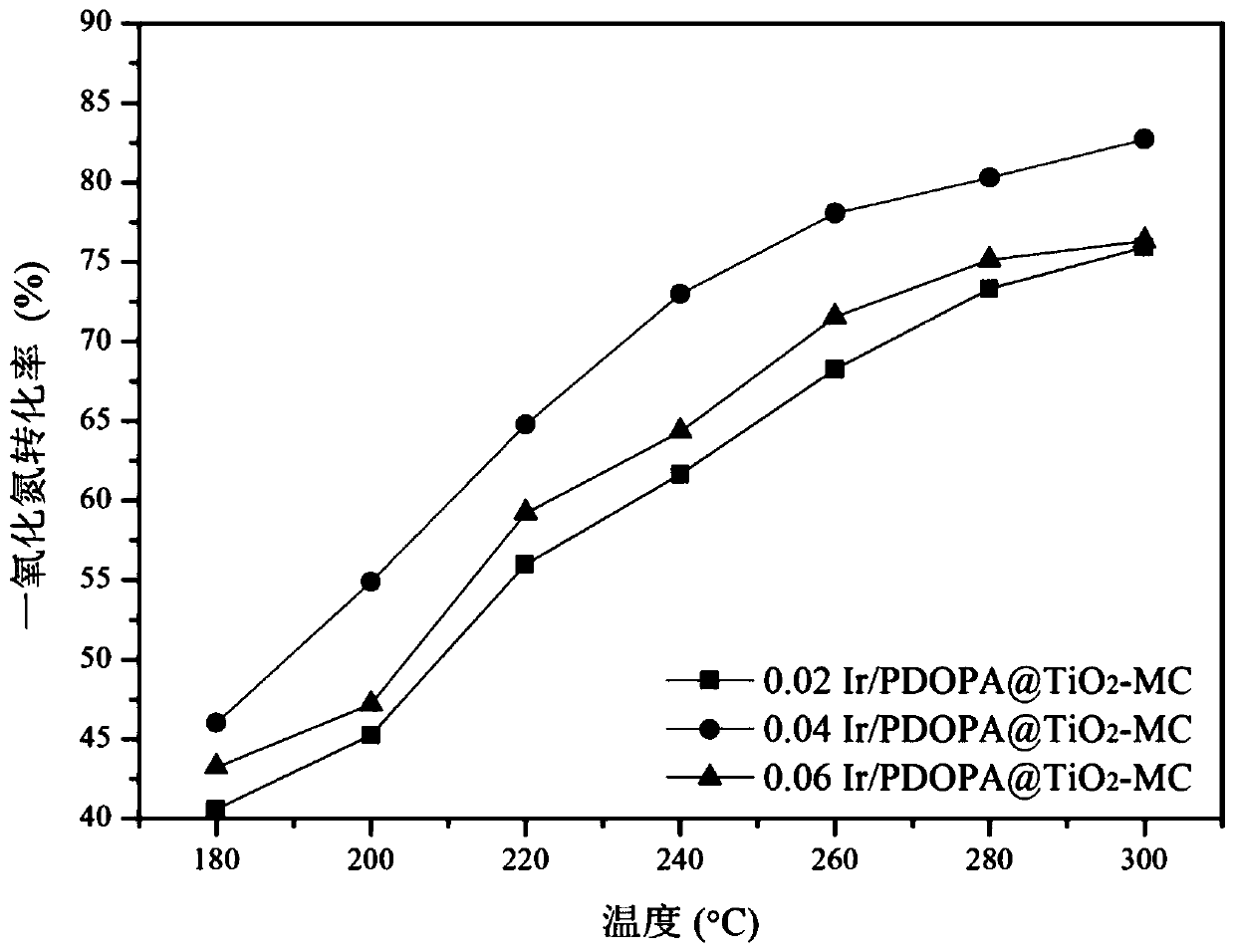

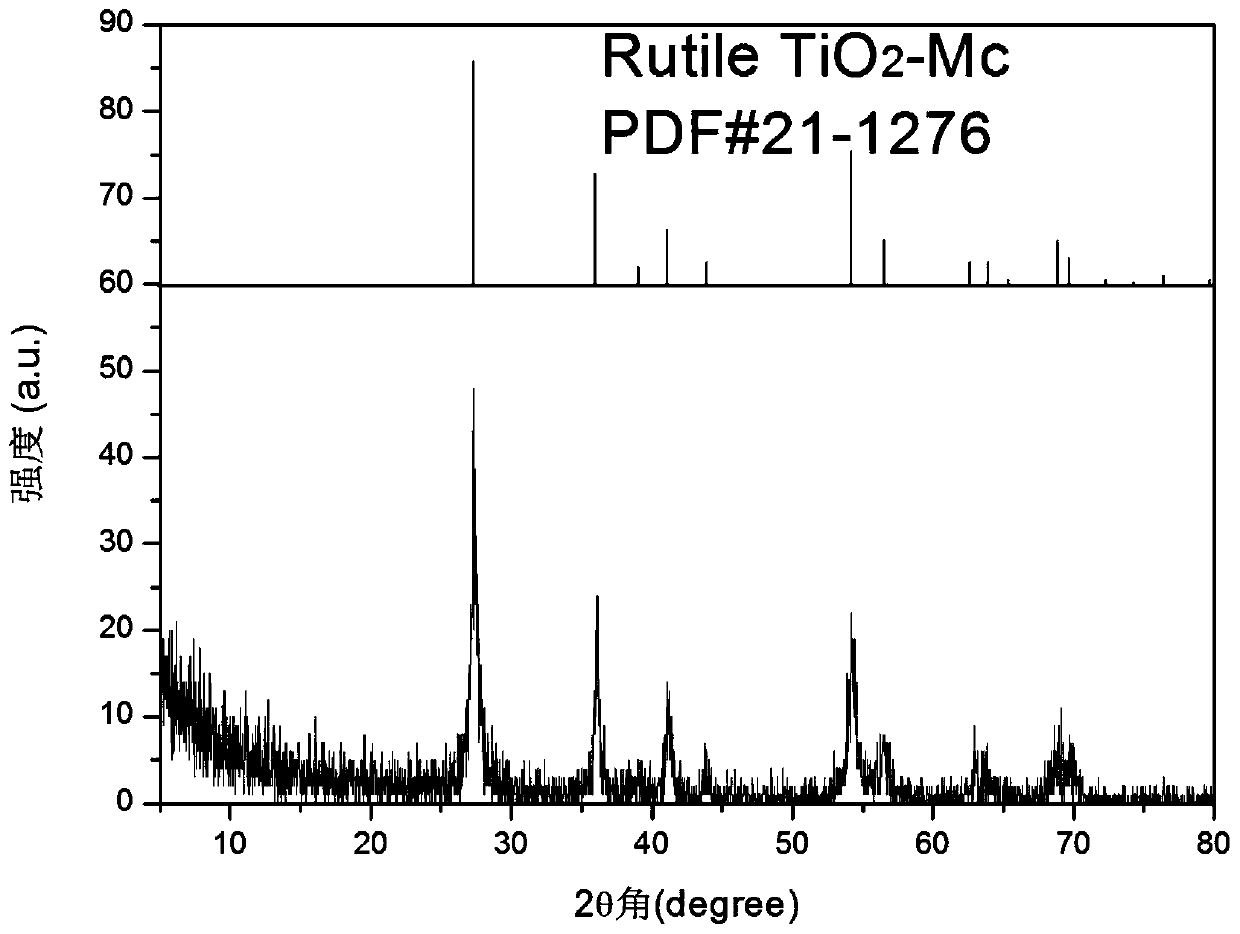

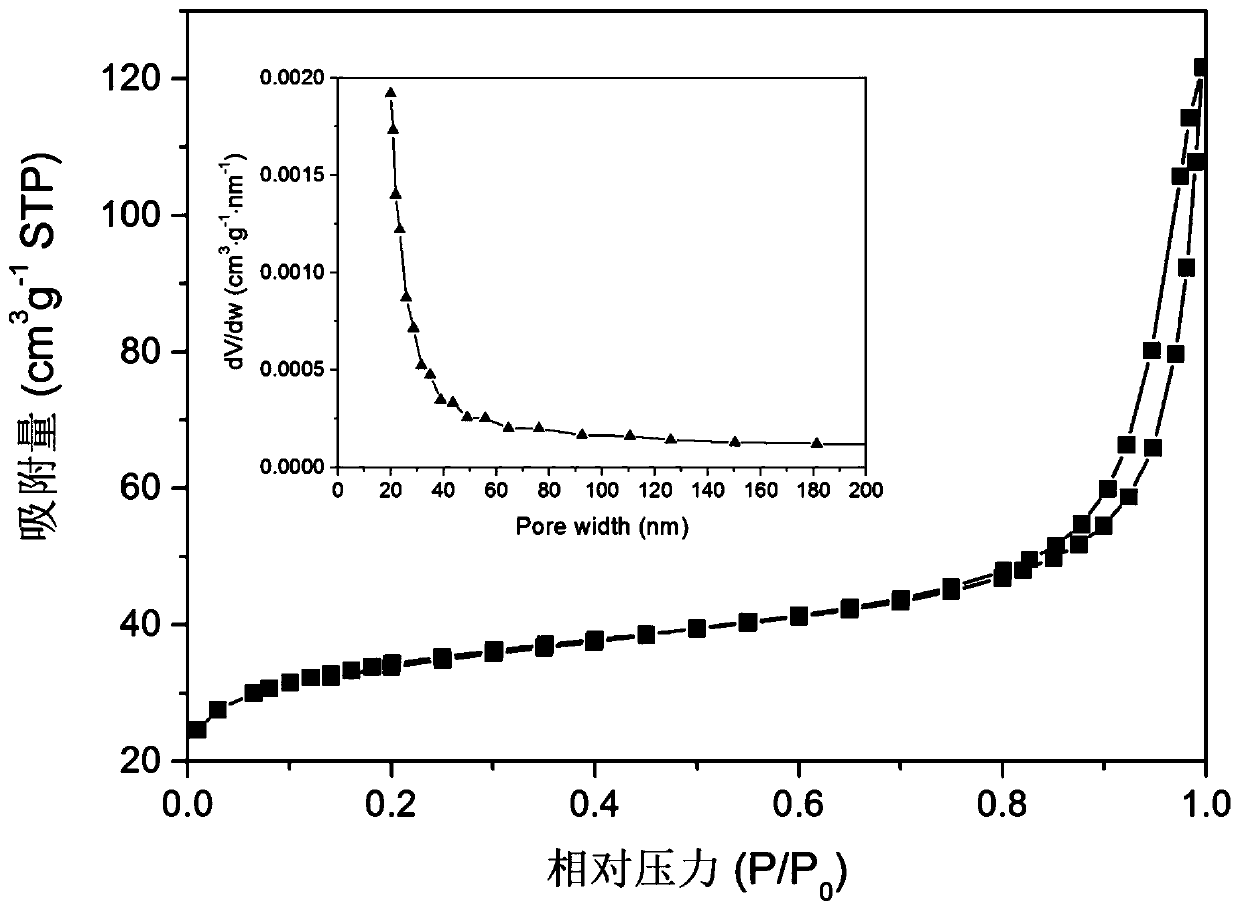

Monatomic Ir denitration catalyst based on TiO2 mesocrystals and preparation method thereof

ActiveCN111450878AGood low temperature denitrification activityMild preparation methodOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationMesocrystalPhotochemistry

The invention discloses a monatomic Ir denitration catalyst based on TiO2 mesocrystals in the technical field of denitration catalyst preparation. A carrier of the catalyst is mesocrystal TiO2-MC, theactive component is a single-atom Ir metal, and the molar ratio of Ir / TiO2 to MC is 0.02 to 0.08. TiO2-MC is used as a carrier, the modification effect of dopamine hydrochloride or levodopa is utilized, and a redox reaction between Ir<4+> and NH2<-> is combined. According to the TiO2 mesocrystal-based monatomic Ir denitration catalyst and a preparation method thereof, TiO2-MC is used as a carrier, the modification effect of dopamine hydrochloride or levodopa is utilized, the redox reaction between Ir<4+> and NH2<-> is combined, a secondary functionalized platform is obtained on the TiO2 mesocrystal, and by combining the redox effect of Ir<4+> and NH2<-> groups on chloroiridic acid, the catalyst provides good low temperature denitration activity at a temperature of 180-300 DEG C, and the preparation method is mild, safe and environmentally friendly.

Owner:HENAN UNIV OF URBAN CONSTR

Preparation method of iron oxide pillared layered manganese oxide low temperature denitrification catalyst

ActiveCN108067247BGood low temperature denitrification activityImprove sulfur resistanceGas treatmentDispersed particle separationPtru catalystPhysical chemistry

Owner:海南中盛旭鑫低碳科技有限公司

Copper-iron molecular sieve based catalyst as well as preparation method and application thereof

ActiveCN113058641AGood low temperature denitrification activityWide temperature windowInternal combustion piston enginesMolecular sieve catalystsMolecular sieveMaterials science

The invention discloses a copper-iron molecular sieve based catalyst as well as a preparation method and application thereof, and belongs to the technical field of denitration catalysis in environmental protection. According to the catalyst, MCM-22 and ZSM-5 are used as carriers, and loaded metals Cu and Fe are used as active components, the content of Cu accounts for 1.5-5.0% of the total weight of the copper-iron molecular sieve-based catalyst, the content of Fe accounts for 1.5-5.0% of the total weight of the copper-iron molecular sieve-based catalyst, the general formula of the copper-iron molecular sieve-based catalyst is xCu / yFe-MCM-22 / ZSM-5, wherein x is the mass percentage content of the metal Cu in the catalyst and is 2.0-4.5%, y is the mass percent content of metal Fe in the catalyst, and the value is 2.0-4.5%. The catalyst solves the problems that traditional copper-based and iron-based molecular sieve catalysts are narrow in temperature window and low in denitration activity, under the standard SCR reaction atmosphere condition, the denitration efficiency of the catalyst within the temperature range of 200-500 DEG C can reach 80% or above, and the catalyst has good low-temperature denitration activity and a wide temperature window.

Owner:武汉钢铁有限公司

A kind of MN/CO-based low-temperature SCO catalyst and preparation method thereof

ActiveCN107362807BHigh porosityStable structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic transformationPtru catalyst

The invention discloses a Mn / Co-based low-temperature SOC catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving manganese-containing metal salt and cobalt-containing metal salt in dimethylformamide, adding an organic ligand and water, and magnetically stirring and uniformly mixing the components to obtain a mixed solution; and (2) carrying out hydrothermal reaction on the obtained mixed solution in a reactor, reacting to obtain Mn / Co double-metal organic framework crystal, soaking the Mn / Co double-metal organic framework crystal in the dimethylformamide and activating the Mn / Co double-metal organic framework crystal, and then purifying, filtering and roasting the activated crystal to obtain the Mn / Co-based low-temperature SCO catalyst. The Mn / Co-based low-temperature SCO catalyst has good low-temperature denitration activity. Compared with an existing low-temperature denitration catalyst, the Mn / Co-based low-temperature SOC catalyst has the advantages that the conversion rate of catalyzed NO is greatly increased, at the low temperature of 150-200 DEG C, the catalyzed conversion rate of NO can reach 50% or above, and existing industrial requirements can be met.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com