Monatomic Ir denitration catalyst based on TiO2 mesocrystals and preparation method thereof

A denitrification catalyst and catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve problems such as high operating temperature window and poisonous V-based catalysts , to achieve the effect of mild preparation method and good low-temperature denitrification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention also provides a TiO-based 2 Preparation method of mesogenic single-atom Ir denitration catalyst based on TiO 2 The preparation method of the mesogenic single-atom Ir denitration catalyst comprises the following steps;

[0021] S1: TiO 2 -Modification of MC: react with dopamine hydrochloride or levodopa solution (PH=8.5) with a concentration of 1-2 g / L for 24 hours to obtain functionalized PDA@TiO 2 ;

[0022] S2: The use of dopamine hydrochloride or levodopa on TiO 2 -MC carrier was modified to obtain PDA@TiO 2 -MC modified carrier, obtained PDA@TiO 2 -MC modified carrier was stirred in deionized water for 8h;

[0023] S3: add a certain concentration of chloroiridic acid aqueous solution into S2, stir and react for 8 hours, filter, wash with water, wash with alcohol and dry at 12°C;

[0024] S4: Utilize the redox reaction between the amino group on PDA and chloroiridic acid, the reaction temperature is 50-90°C;

[0025] S5: On PDA@TiO 2 In...

Embodiment 1

[0027] 1) TiO 2 Mesogen (TiO 2 -MC) modification, will quantify TiO 2 -MC dispersed in 1-2g / L dopamine hydrochloride solution (PH=8-10), stirred continuously at room temperature for 24h, filtered, washed with water, washed with alcohol to obtain PDA@TiO 2 -MC modified carrier.

[0028] 2) According to Ir / TiO 2 -MC = 0.02, will quantify PDA@TiO 2 -MC modified carrier and chloroiridic acid are dispersed in quantitative deionized water, heated to 60-90°C, stirred for 6 hours, filtered, washed with water, washed with alcohol, and dried at 110°C to obtain 0.02Ir / PDA@TiO 2 -MC single-atom denitration catalyst.

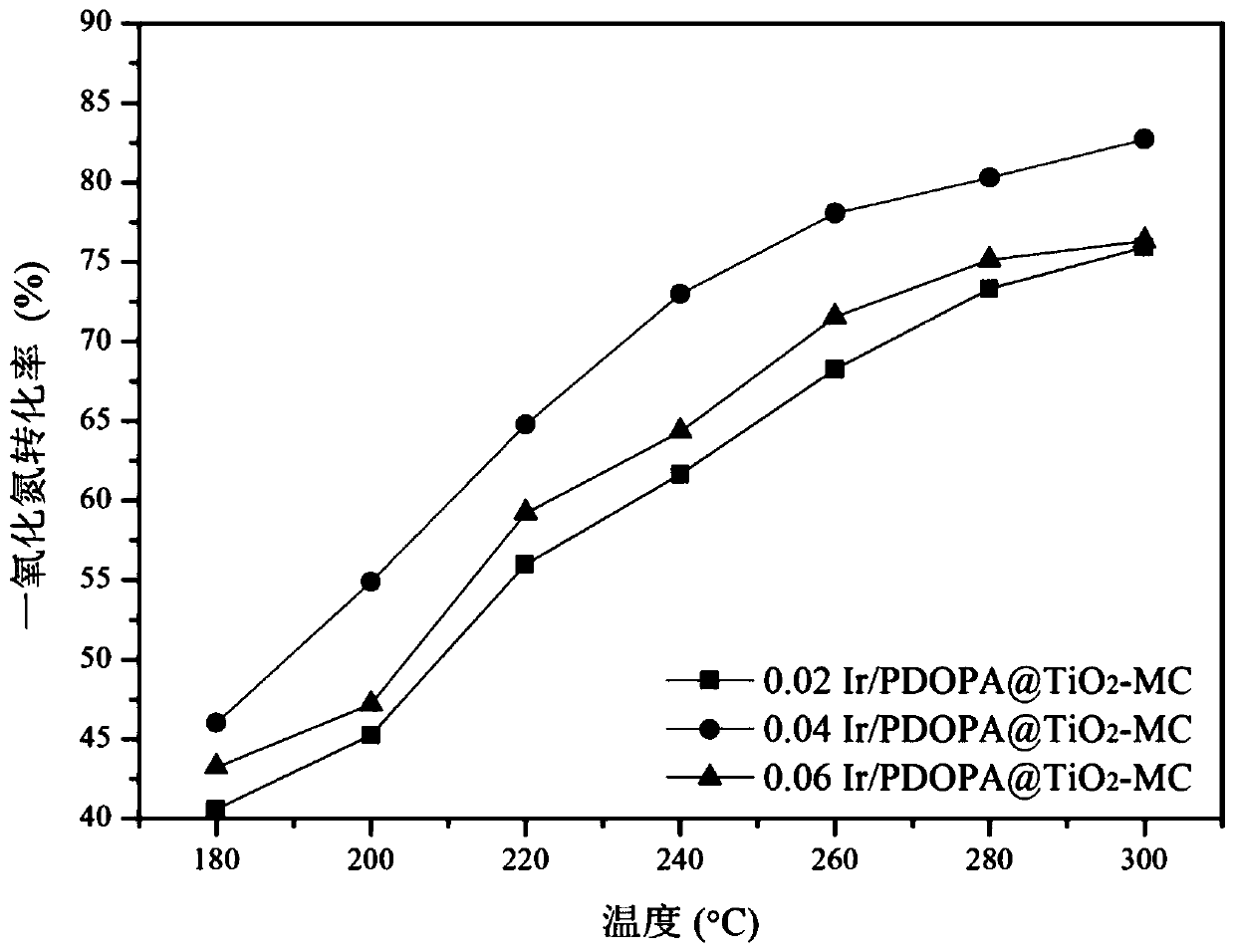

[0029] Denitrification activity test conditions: the total flow rate of simulated flue gas is 700mL / min, [NO]=[NH 3 ]=500ppm, [O 2 ] = 5%, N 2 As a balance gas, the space velocity is 28000mL·g -1 h -1 , measured 0.02Ir / PDA@TiO 2 The denitrification rate of -MC single-atom catalyst reaches 40.6%-75.9% at 180-300°C.

Embodiment 2

[0031] 1) TiO 2 Mesogen (TiO 2 -MC) modification, will quantify TiO 2 -MC dispersed in 1-2g / L dopamine hydrochloride solution (PH=8-10), stirred continuously at room temperature for 24 hours, filtered, washed with water, and washed with alcohol to obtain PDA@TiO 2 -MC modified carrier.

[0032] 2) According to Ir / TiO 2 -MC = 0.04, will quantify PDA@TiO 2 -MC modified carrier and chloroiridic acid were dispersed in quantitative deionized water, heated to 60-90°C, stirred for 6 hours, filtered, washed with water, washed with alcohol, and dried at 110°C to obtain 0.04Ir / PDA@TiO 2 -MC single-atom denitrification catalyst.

[0033] Denitrification activity test conditions: the total flow rate of simulated flue gas is 700mL / min, [NO]=[NH 3 ]=500ppm, [O 2 ] = 5%, N 2 As a balance gas, the space velocity is 28000mL·g -1 h -1 , measured 0.04Ir / PDA@TiO2 The denitrification rate of -MC single-atom catalyst reaches 46.0%-82.7% at 180-300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com