MnO2 low-temperature denitration catalyst based on MXene carrier, and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the toxicity of V-based catalysts , high operating temperature window, etc., to achieve good low-temperature denitrification activity and mild preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An MXene-supported MnO 2 Low temperature denitration catalyst, the carrier of the catalyst is MXene, and the active component is MnO 2 Metal oxides, of which MnO 2 The loading amount of / MXene catalyst was 0.02-0.08, and the preparation of MXene support was referred to the relevant literature.

[0019] A kind of MnO based on MXene carrier as claimed in claim 1 2 Preparation method of low temperature denitration catalyst, the MnO based on MXene carrier 2 The preparation method of the low-temperature denitration catalyst comprises the following steps: preparing MnO with polypyrrole-modified MXene 2 / MXene catalyst as an example, the method for preparing the catalyst with poly(3,4-ethylenedioxythiophene) modified MXene support is similar:

[0020] S1: Modification of MXene: The MXene carrier is placed in 0.01-0.3 mol / L pyrrole acetone, immersed in pyrrole acetone for 3-5 hours, filtered, and dissolved in acetone at room temperature to obtain MXene with pyrrole monomer ...

Embodiment 2

[0023] In this example, MnO was prepared from polypyrrole-modified MXene 2 / MXene catalyst as an example, the method of poly(3,4-ethylenedioxythiophene)-modified MXene support to prepare catalyst is similar).

[0024] (1) Modification treatment of MXene: The MXene carrier was immersed in 0.04mol / L pyrrole acetone for 3-5 hours, filtered, and dissolved in acetone at room temperature to obtain MXene with pyrrole monomer adsorbed on the surface;

[0025] (2) The MXene obtained in step (1) is placed in a KMnO4 solution with a concentration of 0.04mol / L, stirred and reacted at room temperature for 1-3h, suction filtered, washed with water, washed with alcohol, and dried at 100°C to prepare MnO in situ 2 / Ppy / MXene low temperature denitration catalyst;

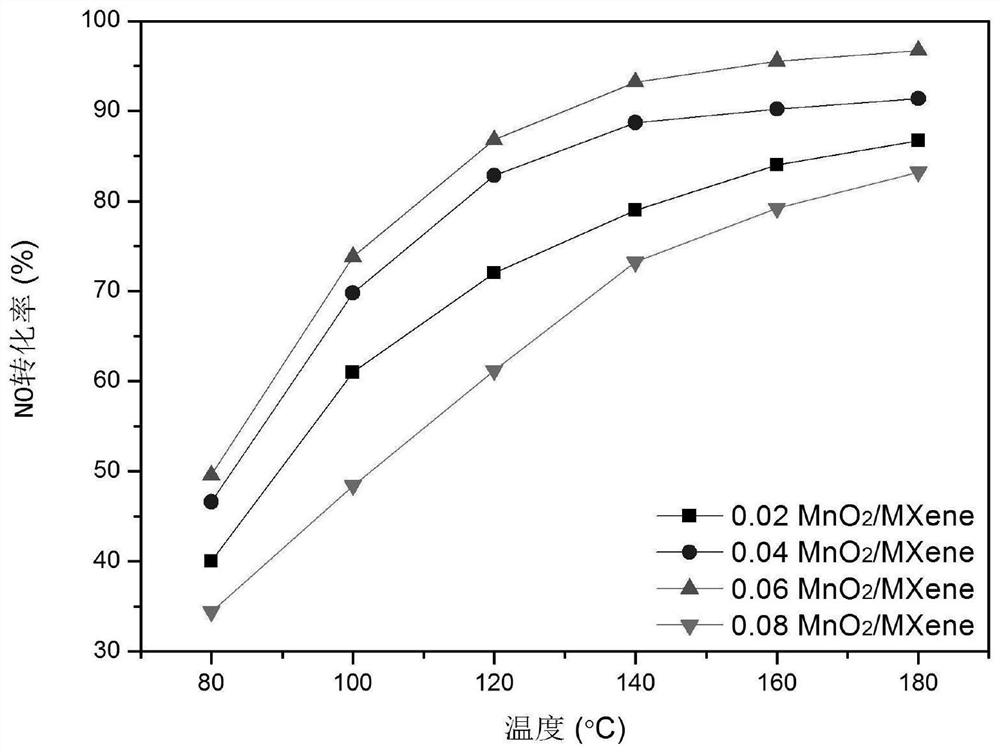

[0026] Test conditions for denitration activity: the total flow rate of simulated flue gas is 600mL / min, [NO]=[NH 3 ]=500ppm, [O 2 ]=5%, N 2 As the balance gas, the space velocity is 60000mL·g -1 ·h -1 , measured as 0.02MnO 2...

Embodiment 3

[0028] In this example, MnO was prepared from polypyrrole-modified MXene 2 / MXene catalyst as an example, the method of poly(3,4-ethylenedioxythiophene)-modified MXene support to prepare catalyst is similar).

[0029] (1) Modification treatment of MXene: The MXene carrier was immersed in 0.04mol / L pyrrole acetone for 3-5 hours, filtered, and dissolved in acetone at room temperature to obtain MXene with pyrrole monomer adsorbed on the surface;

[0030] (2) The MXene obtained in step (1) was placed in a KMnO4 solution with a concentration of 0.06 mol / L, stirred and reacted at room temperature for 1 to 3 h, suction filtered, washed with water, washed with alcohol, and dried at 100 °C to prepare MnO in situ. 2 / Ppy / MXene low temperature denitration catalyst;

[0031] Test conditions for denitration activity: the total flow rate of simulated flue gas is 600mL / min, [NO]=[NH 3 ]=500ppm, [O 2 ]=5%, N 2 As the balance gas, the space velocity is 18000mL·g -1 ·h -1 , measured as 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com