Copper-iron molecular sieve based catalyst as well as preparation method and application thereof

A molecular sieve and catalyst technology, applied in the field of copper-iron molecular sieve-based catalyst and its preparation, can solve the problems of low hydrothermal stability, narrow activity temperature range, HC compound poisoning, etc., and achieve good low-temperature denitration activity, wide temperature window, Toxic reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

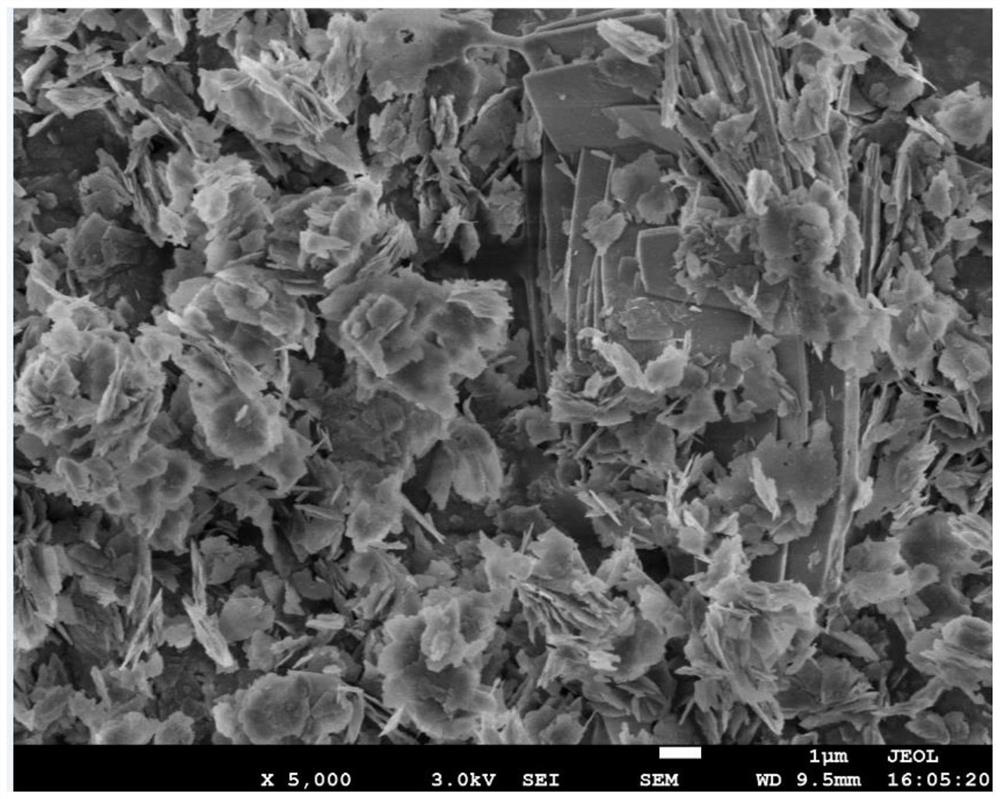

Image

Examples

Embodiment 1

[0024] Embodiment 1 prepares MCM-22 molecular sieve matrix;

[0025] Take distilled water, NaOH, sodium metaaluminate, silica sol (JN-40), and hexamethyleneimine (HMI) according to the mass ratio of 65g: 1.5g: 0.6g: 23.7g: 10g, mix well, stir for at least 1h, and age After 2 hours, crystallize at 170°C for 7 days to obtain a solid-liquid mixed precursor, then filter and wash until the filtrate is neutral, and dry the filter residue overnight at 110°C, and then bake it in air at 550°C 6h, the obtained solid was stirred and exchanged twice with 1mol / L ammonium nitrate solution at 80°C, each time for 2h, after suction filtration and washing until the filtrate was neutral, the obtained filter residue was directly dried in an environment of 110°C, and then in Calcined in air at 550°C for 6h to obtain MCM-22 molecular sieve.

Embodiment 2

[0026] Embodiment 2 prepares ZSM-5 molecular sieve matrix;

[0027] Take distilled water, NaOH, sodium metaaluminate, silica sol (JN-40), and tetrapropylammonium hydroxide (TPAOH) according to the mass ratio of 45g: 1.6g: 0.9g: 20.1g: 9.5g and mix them evenly, and stir for at least 1 hour. After aging for 2 hours, crystallize at 170°C for 3 days to obtain a solid-liquid mixed precursor, then filter and wash until the filtrate is neutral, dry the filter residue at 110°C overnight, and then roast it in air at 550°C for 6 hours to obtain Stir and exchange the solid with 1mol / L ammonium nitrate solution at 80°C for 2 times, each time for 2h, after suction filtration and washing until the filtrate is neutral, dry the obtained filter residue at 110°C, and then roast it in air at 550°C for 6h , to obtain ZSM-5 molecular sieve.

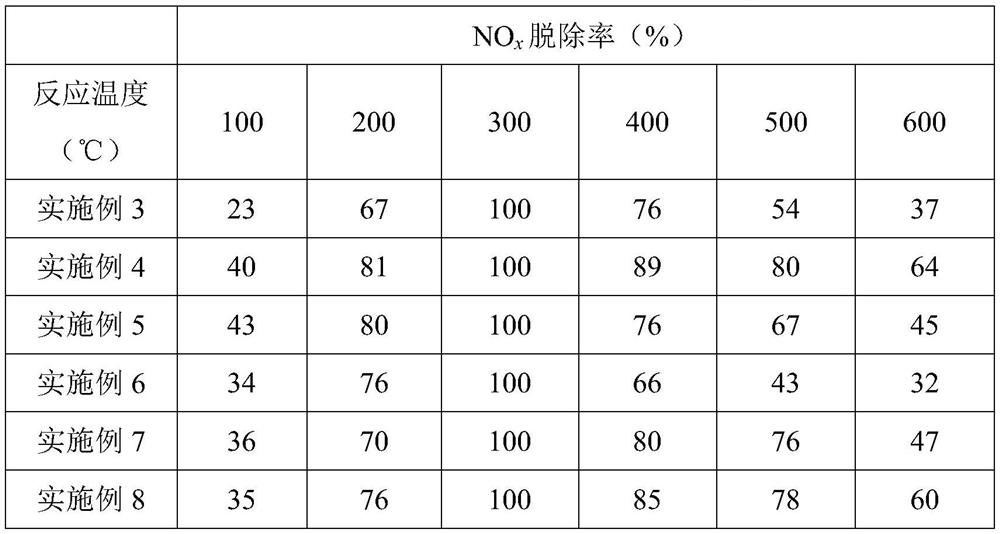

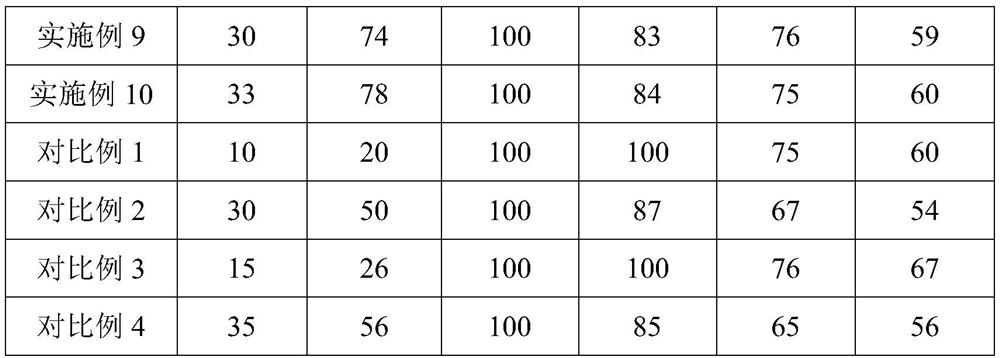

Embodiment 3~10

[0028] Embodiment 3~10 prepares copper-iron molecular sieve-based catalyst;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com