Rare-earth doped low-temperature denitration catalyst and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effects of reducing erosion, obvious low-temperature denitrification activity, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

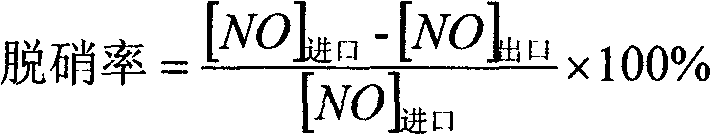

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Preparation of a low-temperature denitration catalyst with the molar ratio of each element being Mn:Ce:Ti=5:4:20.

[0014] (1), 90g metatitanic acid is added in water and is mixed with the slurry of concentration 500g / L;

[0015] (2), 434g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) be mixed with the solution of 5mol / L; The solubility of manganese nitrate solution is 50%.

[0016] (3), take by weighing 44.75g manganese nitrate solution and pipette the cerium nitrate solution of 20ml, join both solutions in the metatitanic acid slurry simultaneously, stir 30min;

[0017] (4), after the stirring is finished, adjust the pH to 10.2 with 28% ammonia water at a speed of 8ml / min, and stir for 2h; obtain a suspension, and then centrifugally filter the suspension at 3200r / min;

[0018] (6) Finally, the filtered product was dried at 90°C for 24 hours, and then calcined at 450°C at a heating rate of 5°C / min for 2 hours to obtain a low-temperature denitration catalyst.

[...

Embodiment 2

[0022] Example 2: Preparation of a low-temperature denitration catalyst with the molar ratio of each element being Mn:Ce:Fe:Ti=5:4:1:20.

[0023] (1), 90g metatitanic acid is added in water and is mixed with the slurry of concentration 500g / L;

[0024] (2), 434g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) and 404g iron nitrate (Fe(NO 3 ) 3 9H 2 O) be mixed with the solution of 5mol / L; The solubility of manganese nitrate solution is 50%.

[0025] (3), take by weighing 44.75g manganese nitrate solution, pipette the cerium nitrate solution of 20ml and the ferric nitrate solution of 5ml, join the three solutions in the metatitanic acid slurry simultaneously, stir 30min;

[0026] (4), after the stirring is finished, adjust the pH to 10.2 with 28% ammonia water at a speed of 8ml / min, and stir for 2h; obtain a suspension, and then centrifugally filter the suspension at 3200r / min;

[0027] (6) Finally, the filtered product was dried at 90°C for 24 hours, and then calcined at 450°C at ...

Embodiment 3

[0029] Example 3: Preparation of a low-temperature denitration catalyst with the molar ratio of each element being Mn:Ce:Fe:Ti=5:4:2:20.

[0030] (1), 90g metatitanic acid is added in water and is mixed with the slurry of concentration 500g / L;

[0031] (2), 434g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) and 404g iron nitrate (Fe(NO 3 ) 3 9H 2 O) be mixed with the solution of 5mol / L; The solubility of manganese nitrate solution is 50%.

[0032] (3), take by weighing 44.75g manganese nitrate solution, pipette the cerium nitrate solution of 20ml and the ferric nitrate solution of 10ml, join the three solutions in the metatitanic acid slurry simultaneously, stir 30min;

[0033] (4), after the stirring is finished, adjust the pH to 10.2 with 28% ammonia water at a speed of 8ml / min, and stir for 2h; obtain a suspension, and then centrifugally filter the suspension at 3200r / min;

[0034] (6) Finally, the filtered product was dried at 90°C for 24 hours, and then calcined at 450°C at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com