Cerium-iron molecular sieve based catalyst with wide temperature range and preparation method thereof

A molecular sieve and catalyst technology, which is applied in the field of cerium-iron molecular sieve-based catalysts with a wide temperature range and its preparation, can solve the problems of dispersion and the influence of catalyst SCR performance in the existing state, and achieve good low-temperature denitrification activity, good application prospects, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

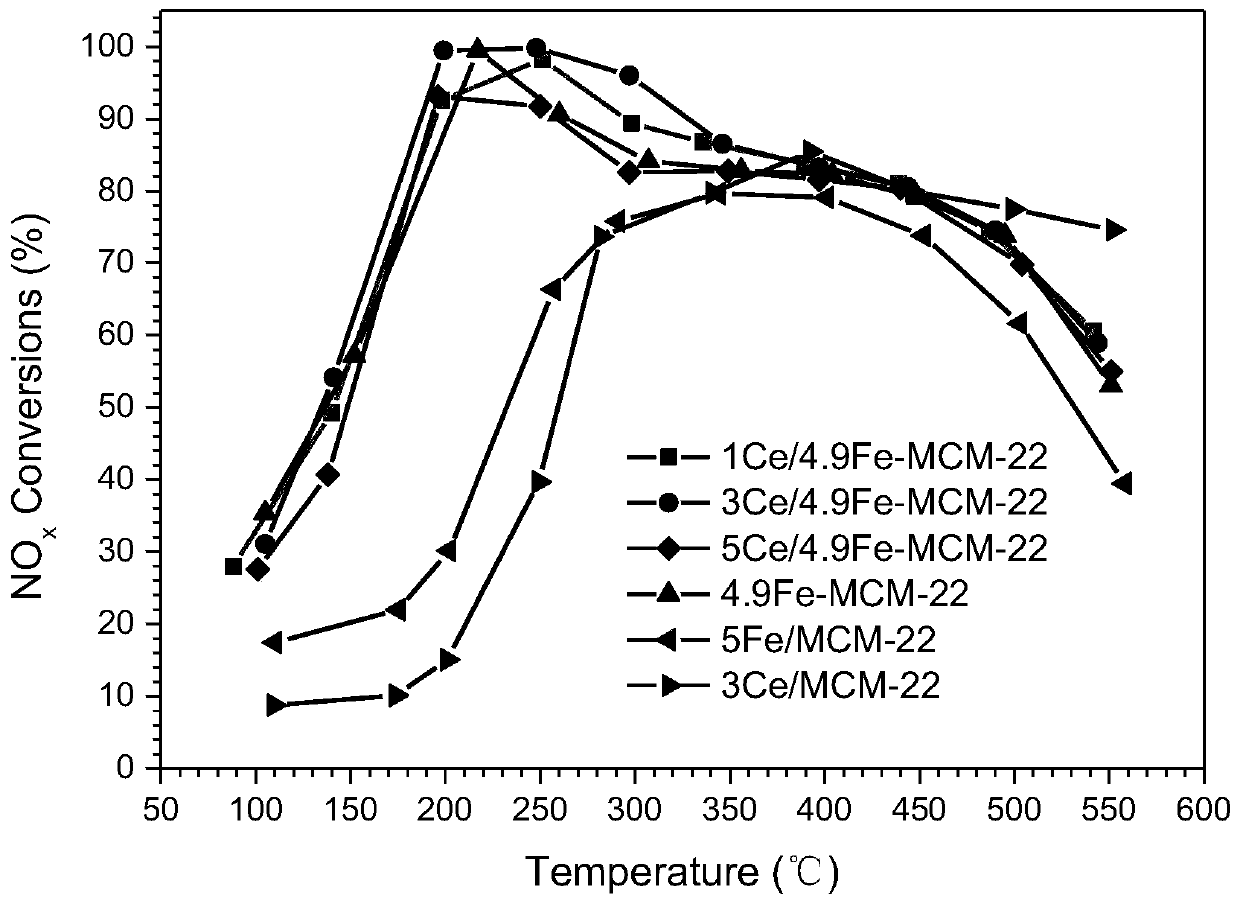

Embodiment 1

[0032] Take 65g of pure water, add 1.5g of NaOH, 0.6g of sodium metaaluminate, and 23.7g of silica sol, stir and mix evenly to obtain solution A, take 50g of pure water, add 3.2g of ferric nitrate, and stir to obtain solution B, slowly dissolve B solution Add solution A, stir and mix for 1 hour with magnetic force, then add hexamethyleneimine and continue to stir and age for 2 hours. Rotate and crystallize for 7 days. The crystallized product was suction filtered, washed, dried, ground, and roasted to obtain an iron-doped Na-type MCM-22 sample. Under the condition of water bath at 80°C, Na-type MCM-22 was ion-exchanged with 1mol / L ammonium nitrate solution, and after suction filtration, washing, drying, grinding, and roasting, Fe-MCM-22 with an iron content of 4.9% was obtained. Sample designation: 4.9Fe-Al-MCM-22.

Embodiment 2

[0034] Take 0.06g of cerium nitrate hexahydrate, dissolve it in 8g of water, take 2g of 4.9Fe-MCM-22 sample, disperse in the above solution, stir at room temperature for 24h, dry and grind to obtain 1Ce / 4.9Fe with a Ce loading of 1%. - MCM-22 catalyst.

Embodiment 3

[0036] Take 0.18g of cerium nitrate hexahydrate, dissolve it in 8g of water, take 2g of 4.9Fe-MCM-22 sample, disperse in the above solution, stir at room temperature for 24h, dry and grind to obtain 3Ce / 4.9Fe with a Ce loading of 3%. - MCM-22 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com