Selective catalytic reduction low-temperature denitration catalyst and preparation method thereof

A low-temperature denitration and selective technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of expensive raw materials, low purity, harmful to human health, etc. problems, to avoid the requirements of equipment and threats to personal safety, the preparation process is simple, and the advantages are obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The molar ratio is potassium permanganate: water: sulfuric acid: ferrous sulfate = 1:40:0.4:2.5, and the raw materials are weighed, wherein the water is distilled water, and the medicines are of analytical grade. Add the weighed potassium permanganate and ferrous sulfate into the acid solution made by mixing sulfuric acid and water, stir for 20 minutes, then pour it into the reaction container, and react with water at 90°C for 24 hours. The sample was washed 5 times with sulfuric acid solution and then washed 3 times with distilled water, then dried at 110°C for 6 hours, cooled and ground to a certain particle size to obtain a catalyst sample.

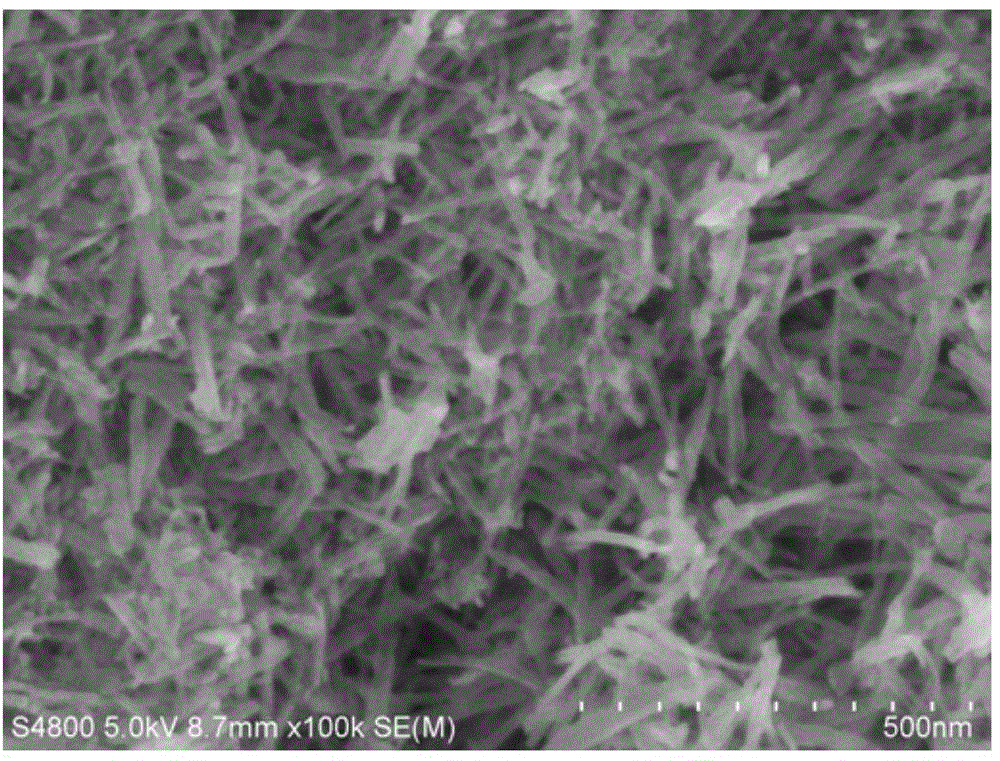

[0029] figure 1 The morphology of the catalyst under a scanning electron microscope. It can be seen from the image that the catalyst particles are fibrous and arranged irregularly. The intricate arrangement of the catalyst particles makes it have a very rich pore structure and a large specific surface area, which is helpful for...

Embodiment 2

[0032] The molar ratio is potassium permanganate: water: sulfuric acid: ferrous sulfate = 1:25:0.4:1.8 Weigh the raw materials, wherein the water is distilled water, and the medicines are of analytical grade. Add the weighed potassium permanganate and ferrous sulfate into the acid solution made by mixing sulfuric acid and water, stir for 10 minutes, then pour it into the reaction container, and react with water at 70°C for 36 hours. The sample was washed with sulfuric acid solution for 3 times and then with distilled water once, then dried at 100°C for 10 hours, cooled and ground to a certain particle size to obtain the catalyst sample.

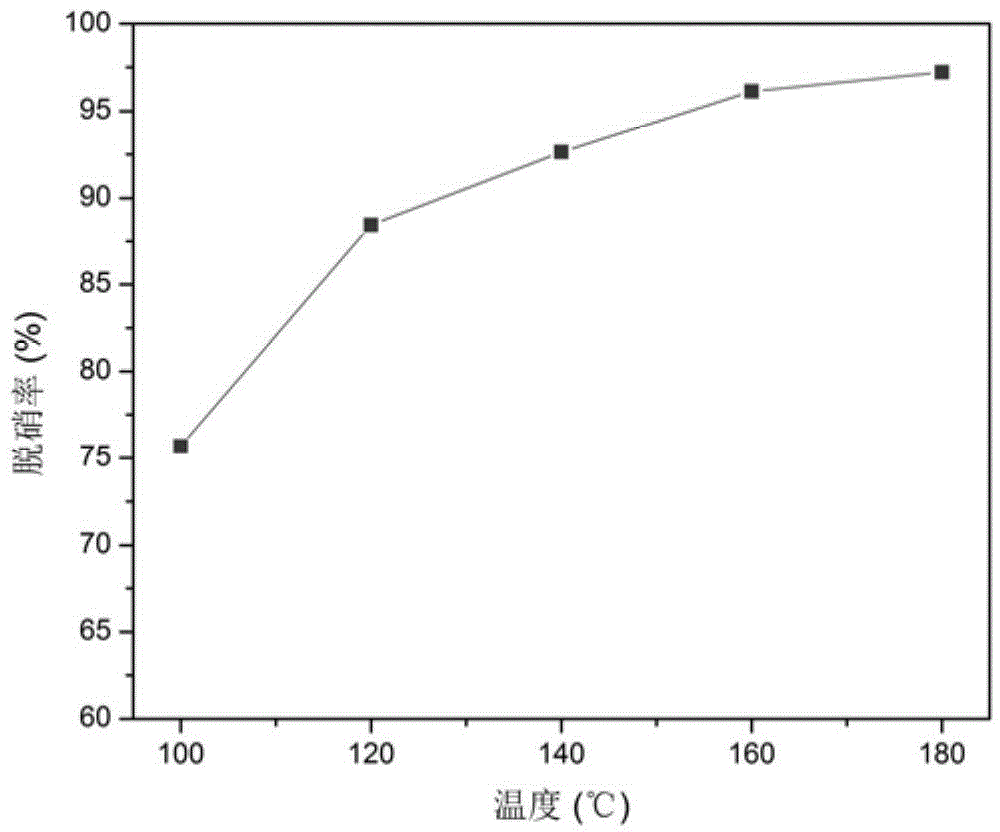

[0033] The catalyst samples were pressed into discs and placed in a fixed-bed quartz tube reactor for selectivity and denitration performance tests. Under the conditions of a reaction temperature of 100-180°C and a space velocity of 33600ml / (g·h), the average The denitrification efficiency is above 90%, and the NO removal rate can reach 70% a...

Embodiment 3

[0035] The molar ratio is potassium permanganate: water: sulfuric acid: cerium nitrate = 1:5:0.05:0.3, wherein the water is distilled water, and the medicines are of analytical grade. Add the weighed potassium permanganate and cerium nitrate into the acid solution made by mixing sulfuric acid and water, stir for 5 minutes, then pour it into the reaction container, and conduct a hydrothermal reaction at 110°C for 10 hours. The sample was washed twice with sulfuric acid solution and then washed twice with distilled water, then dried at 80°C for 16 hours, cooled and ground to a certain particle size to obtain a catalyst sample.

[0036] The catalyst samples were pressed into discs and placed in a fixed-bed quartz tube reactor for selectivity and denitration performance tests. Under the conditions of a reaction temperature of 100-180°C and a space velocity of 33600ml / (g·h), the average The denitrification efficiency is above 95%, and the NO removal rate can reach 88% at 100°C. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com