Supported iron-based composite oxide catalyst and preparation method thereof

A composite oxide and catalyst technology, applied in the field of denitration catalysts, can solve the problems of poor low temperature activity and narrow denitration activity temperature window, and achieve the effects of reducing poisoning, widening the denitration temperature window, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

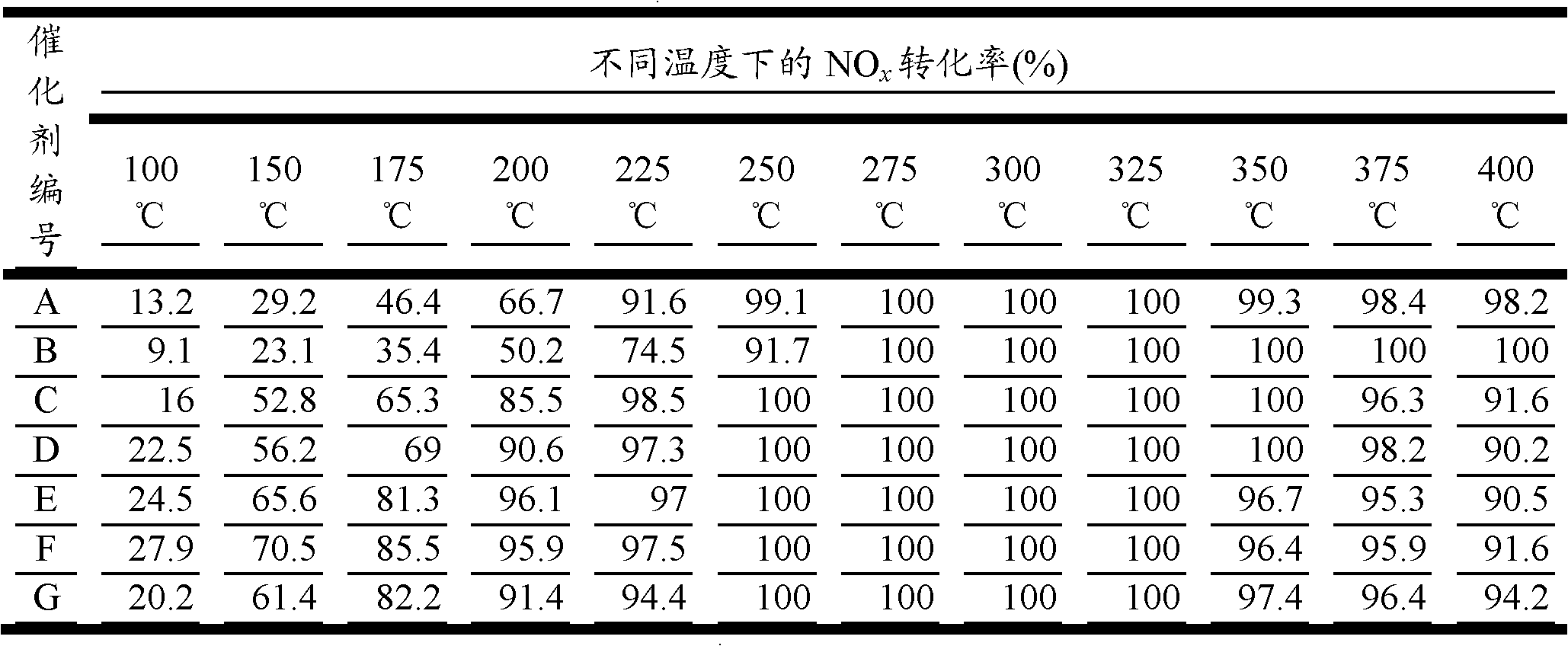

Examples

Embodiment 1

[0019] Dissolve the ammonium tungstate solution in the oxalic acid solution (the mass ratio of ammonium tungstate to oxalic acid is 1:2), and add a certain amount of ferric nitrate and cerium nitrate solution to the solution, stir the solution evenly by magnetic stirring, and add to the solution Add a certain amount of titania carrier to control Fe: Ce: W: TiO 2 The molar ratio of the mixture is 17.5:2.5:5:95. Firstly, the magnetic stirring is continued for 1 hour at room temperature for impregnation, and then an excessive amount of ammonia water is slowly added dropwise to the mixed solution for deposition until the pH value of the mixed solution is 9-10. After complete filtration and washing, the filter cake is put into a drying box and dried at 105°C, and the catalyst is obtained by calcining and activating in a muffle furnace at 400°C in air for 5 hours at most. Grind and sieve the prepared catalyst, take 40-60 mesh for later use, and become catalyst A.

Embodiment 2

[0021] The steps are as in Example 1, and ammonium molybdate is used instead of ammonium tungstate to prepare catalyst B.

Embodiment 3

[0023] Dissolve ferric nitrate, cerium nitrate and zirconium oxychloride in a certain amount of distilled water to obtain a mixed solution, stir the solution uniformly with magnetic force, add a certain amount of titanium dioxide carrier to the solution, and control Fe: Ce: Zr: TiO 2 The molar ratio of the mixture is 17.5:2.5:5:95. Firstly, the magnetic stirring is continued for 1 hour at room temperature for impregnation, and then an excessive amount of ammonia water is slowly added dropwise to the mixed solution for deposition until the pH value of the mixed solution is 9-10. After complete filtration and washing, the filter cake is put into a drying box and dried at 105°C, and the catalyst is obtained by calcining and activating in a muffle furnace at a maximum of 500°C in air for 5 hours. Grind and sieve the prepared catalyst, and take 40-60 mesh for later use. become catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com