Efficient response optical coupling denitration catalyst and preparation method thereof

A denitrification catalyst and optical coupling technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as large energy consumption, complex process, and poor photoactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

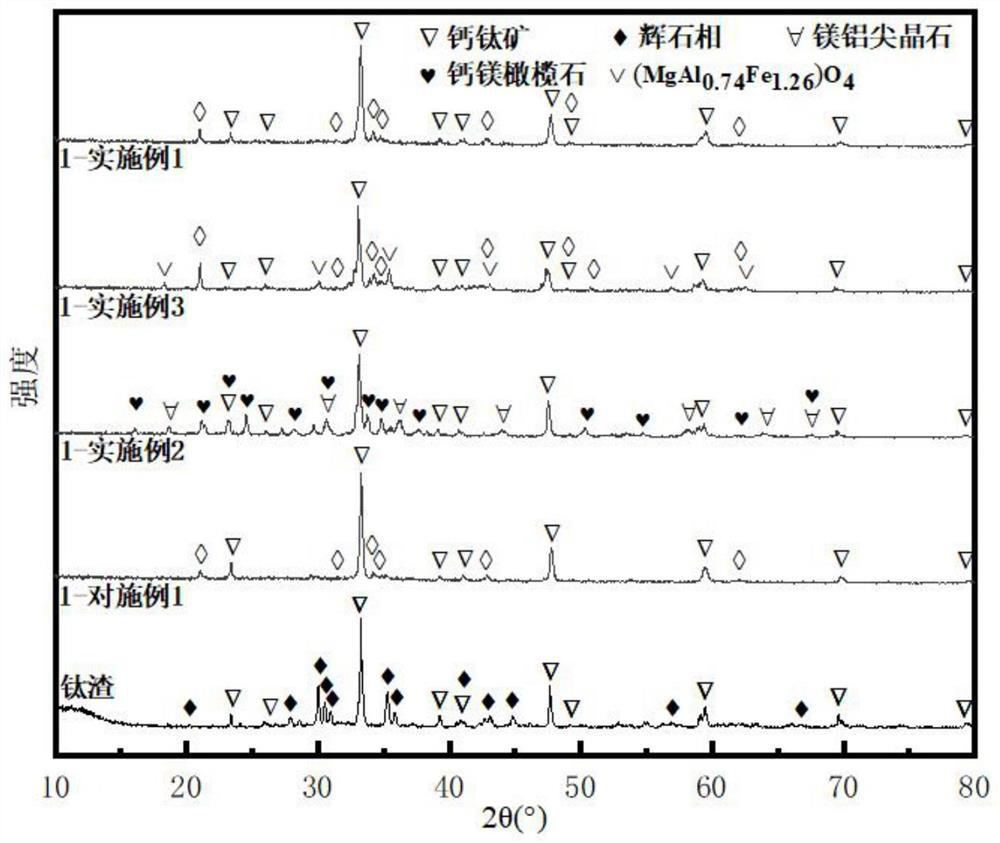

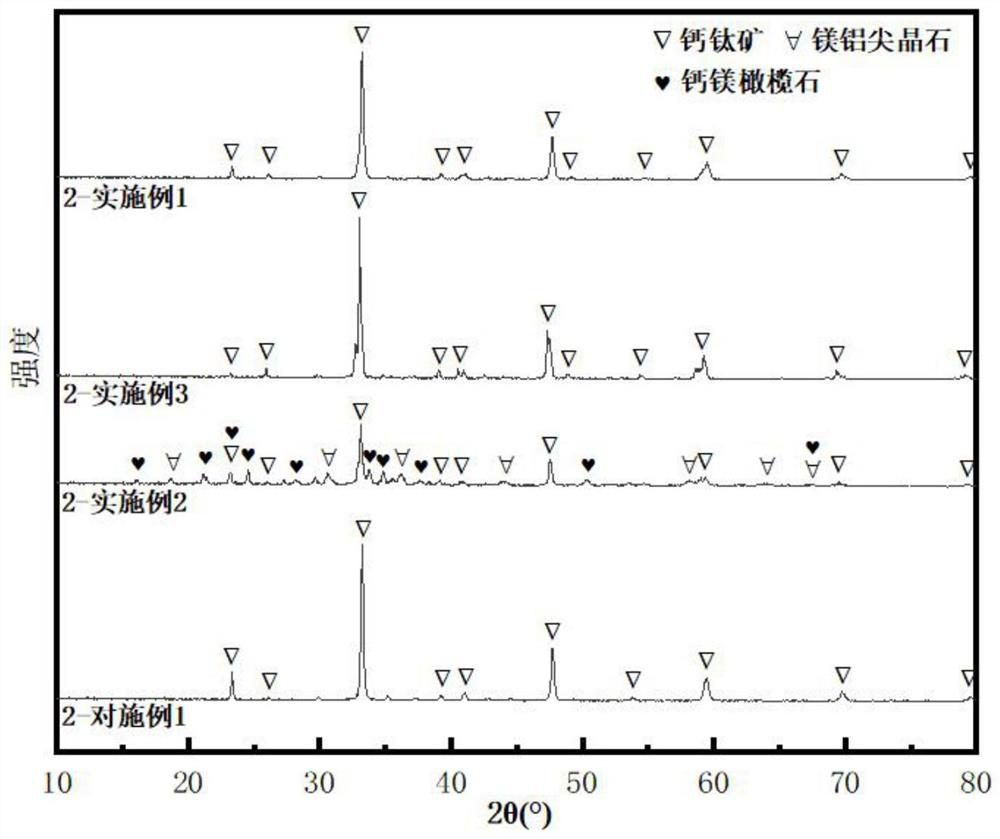

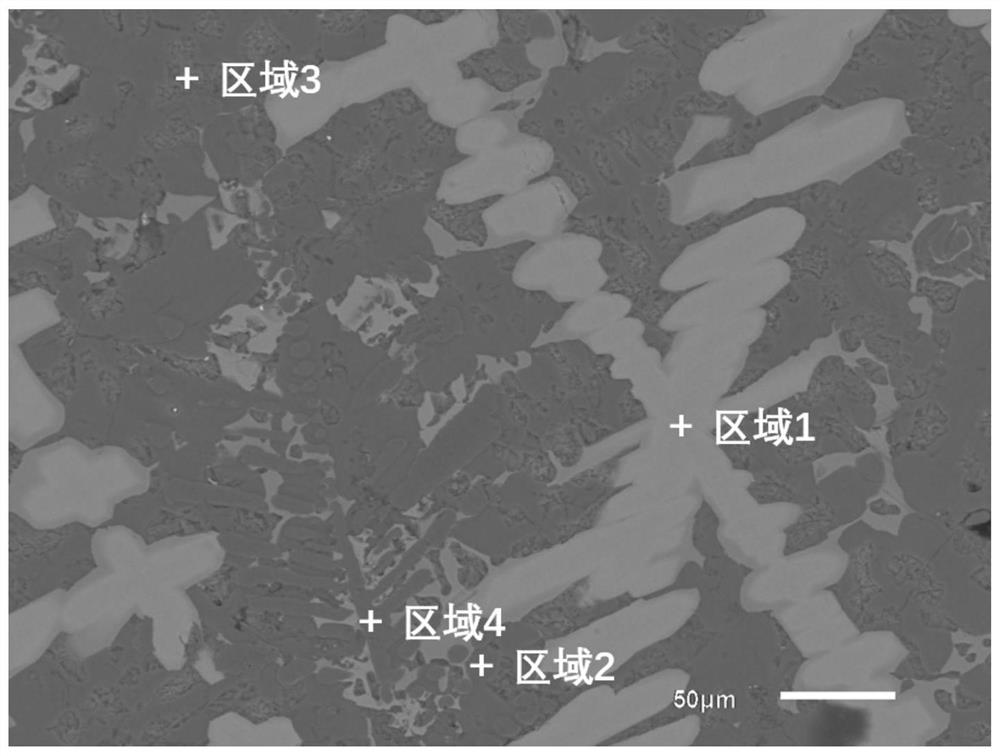

[0055] The blocky titanium-containing blast furnace slag was crushed and dried, placed in a grinding tank for grinding for 60 seconds, and then 100 g of titanium-containing blast furnace slag powder was mixed with 5 g of analytically pure CeO 2 , 10g analytically pure MnO 2 and 34.5g NaOH particles were mixed and ground evenly and placed in a magnesia crucible, first heated to 350°C for 1 hour to remove bound water and volatile impurities, and then heated to 1500°C in a muffle furnace at a heating rate of 5°C / min Insulated for 1h and cooled to room temperature with the furnace to obtain Ce, Mn-based optimized reconstruction slag, which is denoted as 1-embodiment 1, and its X-ray diffraction image is as follows figure 1 , scanning electron microscope images such as image 3 , X-ray energy spectrum analysis is shown in Table 1.

[0056] Table 1: X-ray energy spectrum analysis of 1-embodiment 1 in embodiment 1 (at%, combine image 3 )

[0057]

[0058] Then 1-Example 1 was...

Embodiment 2

[0062] The blocky titanium-containing blast furnace slag was crushed and dried, placed in a grinding tank for grinding for 60 seconds, and then 100 g of titanium-containing blast furnace slag powder was mixed with 1 g of analytically pure CeO 2 , 1g analytically pure MnO 2 and 5.1g of NaOH particles were mixed and ground evenly and placed in a magnesia crucible, first heated to 250°C for 0.5h to remove bound water and volatile impurities, and then heated to 1350°C in a muffle furnace at a heating rate of 3°C / min ℃ for 2 hours and cooled to room temperature with the furnace to obtain Ce, Mn-based optimized reconstruction slag, which is recorded as 1-Example 2, and its X-ray diffraction image is as follows figure 1 .

[0063] Then 1-Example 2 was crushed and ground, then placed in a ball mill jar for ball milling for 20 hours, after suction drying and grinding, 16 g was poured into 80 ml of 1% HCl solution and leached for 2 hours to strip off non-target components, and then Dilu...

Embodiment 3

[0065] The blocky titanium-containing blast furnace slag was crushed and dried, placed in a grinding tank for grinding for 60 seconds, and then 100 g of titanium-containing blast furnace slag powder was mixed with 10 g of analytically pure CeO 2 , 30g analytically pure MnO 2 and 21g of NaOH particles were mixed and ground evenly and placed in a magnesia crucible, first heated to 300°C for 1 hour to remove bound water and volatile impurities, and then heated to 1500°C in a muffle furnace at a heating rate of 10°C / min. 1h is cooled to room temperature with furnace, obtains Ce, Mn base optimization reconstruction slag, is recorded as 1-embodiment 3, and its X-ray diffraction image is as follows figure 1 .

[0066] Then 1-Example 3 is crushed and ground, then placed in a ball mill jar for ball milling for 12 hours, after suction drying and grinding, 16 g is poured into 400 ml of 20% HCl solution and leached for 1 hour to strip off non-target components, and then Dilute the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com