A denitrification treatment method for exhaust gas from an ethylene cracking furnace

A technology of ethylene cracking furnace and treatment method, which is applied in the field of environmental protection waste gas treatment, can solve the problems such as further improvement of denitrification activity, and achieve the effect of ensuring long-term stable operation, high denitrification efficiency and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

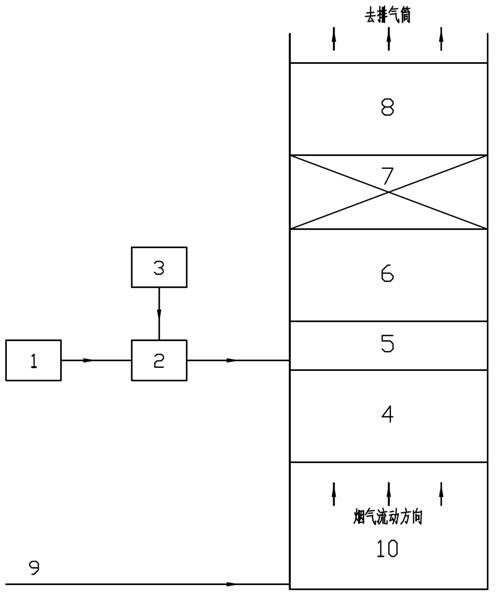

Method used

Image

Examples

Embodiment 1

[0032] The cross-sectional size of the honeycomb denitration catalyst monomer in the embodiment is 150×150 mm, the pore diameter is 6-12 mm, and the wall thickness is 0.8-2.2 mm. The catalyst preparation process is:

[0033] (1) Add carbon black powder and cerium nitrate to the ethanol solution containing tetraethyl orthosilicate (wherein the solid-liquid mass ratio is 1:8, cerium nitrate is CeO 2 The mass ratio of meter to carbon black powder is 3:1 orthoethyl silicate to SiO 2 The mass ratio of meter to carbon black powder is 2:1), under the condition of ultrasonic dispersion (the energy density of ultrasonic dispersion is 0.6kW / L, the temperature of ultrasonic dispersion is 40°C, and the time of ultrasonic dispersion is 1 hour), mix well, filter, Dry the solid phase at 50°C for 2 hours, and dry to obtain carbon black powder modified by silicon and cerium sources;

[0034] (2) Add 54g of carbon black powder obtained in step (1) (based on the weight of carbon black powder),...

Embodiment 2

[0044] The cross-sectional size of the honeycomb denitration catalyst monomer in the embodiment is 150×150 mm, the pore diameter is 6-12 mm, and the wall thickness is 0.8-2.2 mm. The catalyst preparation process is:

[0045] (1) Add carbon black powder and cerium nitrate to the ethanol solution containing tetraethyl orthosilicate (wherein the solid-liquid mass ratio is 1:8, cerium nitrate is CeO 2 The mass ratio of meter to carbon black powder is 3:1, and ethyl orthosilicate is SiO 2 The mass ratio of meter to carbon black powder is 2:1), under the condition of ultrasonic dispersion (the energy density of ultrasonic dispersion is 0.6kW / L, the temperature of ultrasonic dispersion is 40°C, and the time of ultrasonic dispersion is 1 hour), mix well, filter, Dry the solid phase at 50°C for 2 hours, and dry to obtain carbon black powder modified by silicon and cerium sources;

[0046] (2) Add 54g of carbon black powder obtained in step (1) (by weight of carbon black powder), 600g...

Embodiment 3

[0056] The cross-sectional size of the honeycomb denitration catalyst monomer in the embodiment is 150×150 mm, the pore diameter is 6-12 mm, and the wall thickness is 0.8-2.2 mm. The catalyst preparation process is:

[0057] (1) Add carbon black powder and cerium nitrate to the ethanol solution containing tetraethyl orthosilicate (wherein the solid-liquid mass ratio is 1:8, cerium nitrate is CeO 2 The mass ratio of meter to carbon black powder is 3:1 orthoethyl silicate to SiO 2 The mass ratio of meter to carbon black powder is 2:1), under the condition of ultrasonic dispersion (the energy density of ultrasonic dispersion is 0.6kW / L, the temperature of ultrasonic dispersion is 40°C, and the time of ultrasonic dispersion is 1 hour), mix well, filter, Dry the solid phase at 50°C for 2 hours, and dry to obtain carbon black powder modified by silicon and cerium sources;

[0058] (2) Add 54g of carbon black powder obtained in step (1) (based on the weight of carbon black powder),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com