Denitration catalyst for wide temperature window under high sulfur condition and preparation method thereof

A denitration catalyst, wide temperature technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as pipeline blockage and corrosion, and achieve good denitration activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

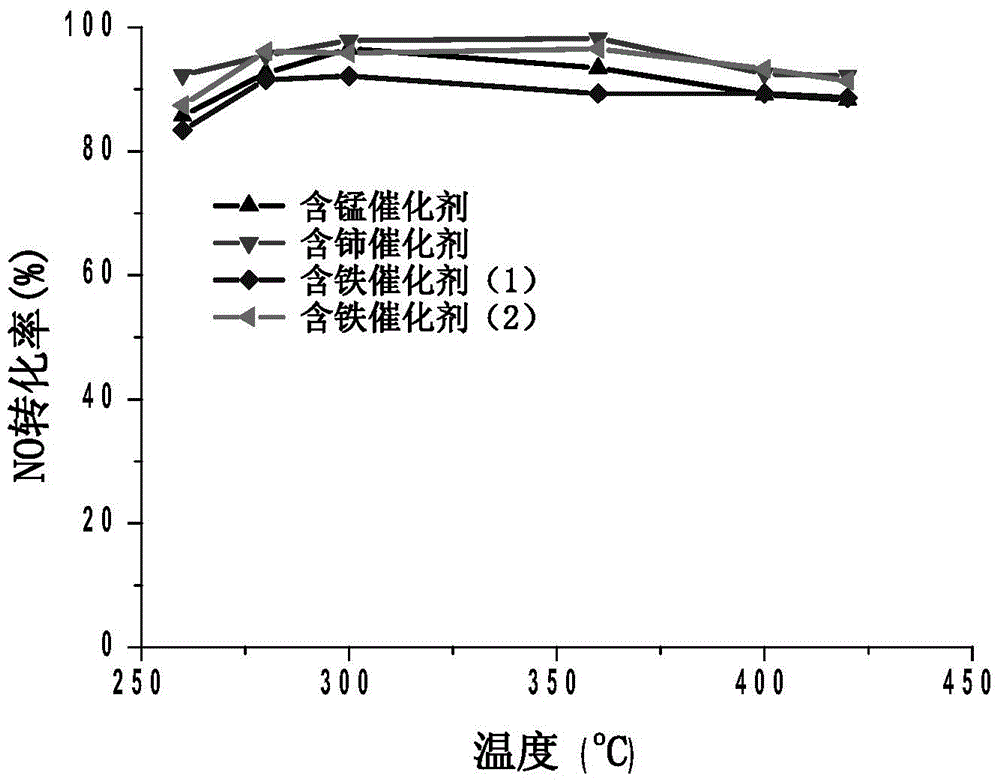

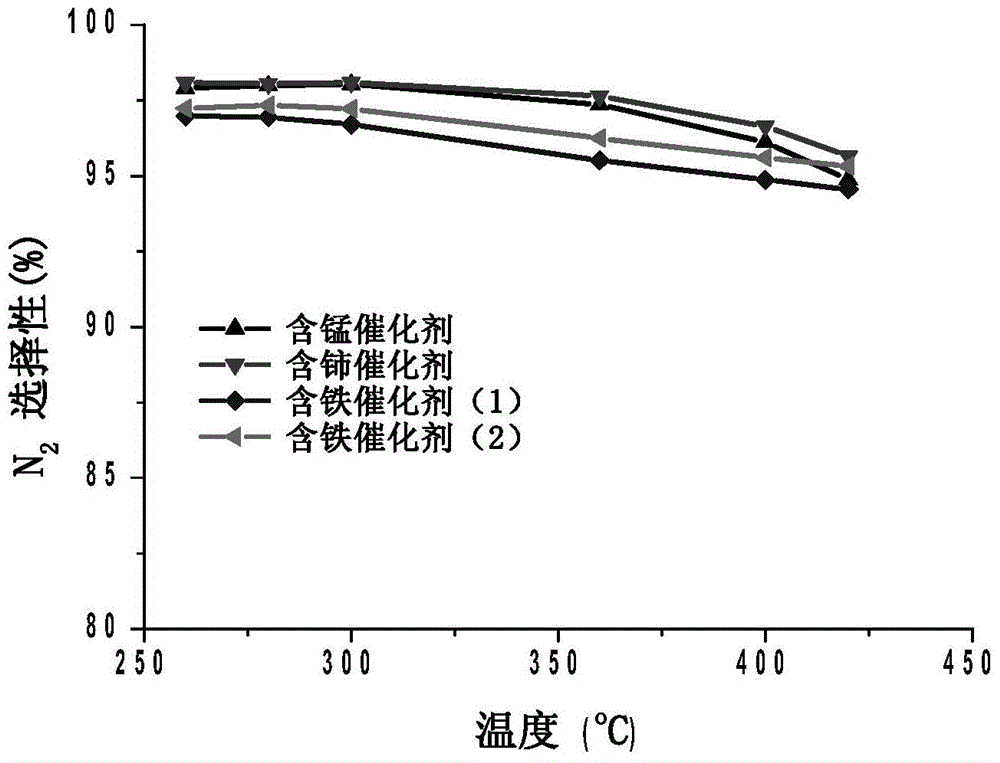

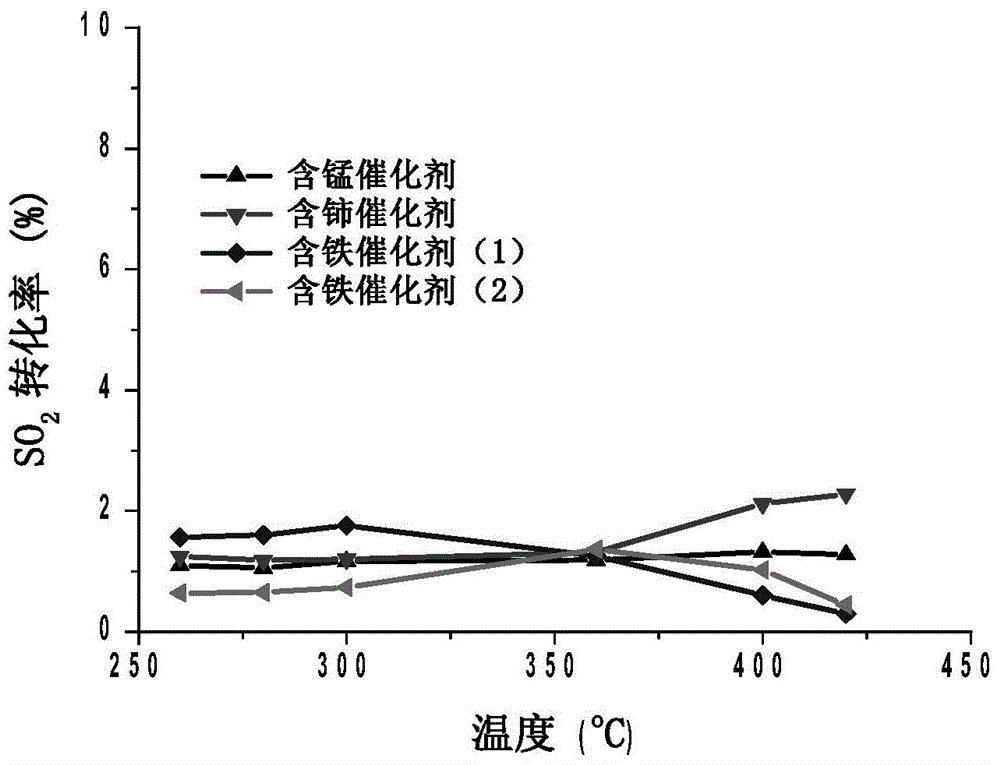

Embodiment 1

[0020] Example 1: Weigh 0.0428g of ammonium metavanadate and 0.3377g of ammonium paratungstate respectively, and dissolve them in 20ml of oxalic acid solution. Another 0.7040g of manganese acetate solution was added to 10ml of titanium dioxide suspension and fully stirred for 1 hour, then vanadium tungsten solution was added to continue heating and stirring until it became a paste, and dried at 100°C. The dried block was crushed and calcined in air at 550° C. for 5 hours to obtain a manganese-containing catalyst.

Embodiment 2

[0021] Example 2: Weigh 0.0428g of ammonium metavanadate and 0.3377g of ammonium paratungstate, and dissolve them in 20ml of oxalic acid solution. Another 0.6308g of cerium nitrate solution was added to 10ml of titanium dioxide suspension and fully stirred for 1 hour, then vanadium tungsten solution was added to continue heating and stirring until it became a paste, and dried at 100°C. Cerium-containing catalysts were obtained by crushing the dried blocks and calcining them in the air at 550° C. for 5 hours.

Embodiment 3

[0022] Example 3: Weigh 0.0428g of ammonium metavanadate and 0.3377g of ammonium paratungstate, and dissolve them in 20ml of oxalic acid solution. Another 1.2625g of ferric nitrate solution was added to 10ml of titanium dioxide suspension and fully stirred for 1 hour, then vanadium tungsten solution was added to continue heating and stirring until it became a paste, and dried at 100°C. The dried block was crushed and calcined at 550° C. in air for 5 hours to obtain the iron-containing catalyst (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com