Patents

Literature

51results about How to "Wide reaction temperature window" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CO low-temperature oxidation catalyst and preparation method thereof

ActiveCN101485984AHigh activityHigh selectivityCarbon compoundsDispersed particle separationActive componentCerium

The invention provides a CO low-temperature oxidation catalyst. The catalyst is characterized in that the catalyst consists of a CeO2-TiO2 compound oxide carrier and an active component of CuO, and the loading capacity of the active component of CuO is 1 to 20 weight percent, wherein the range of the mol ratio of TiO2 to CeO2 is 0.1-4. The coprecipitation method is adopted to prepare the cerium-titanium compound oxide carrier, and a copper nitrate solution is steeped on the carrier. The catalyst prepared by the method has highly efficient catalytic activity, and can realize the complete removal of CO in the temperature range of between 80 and 170 DEG C, and the highest selectivity reaches 100 percent; moreover, the catalyst also has good waterproof and CO2 resistant performances. The method has the advantages of simple preparation conditions, low production cost, and the like.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

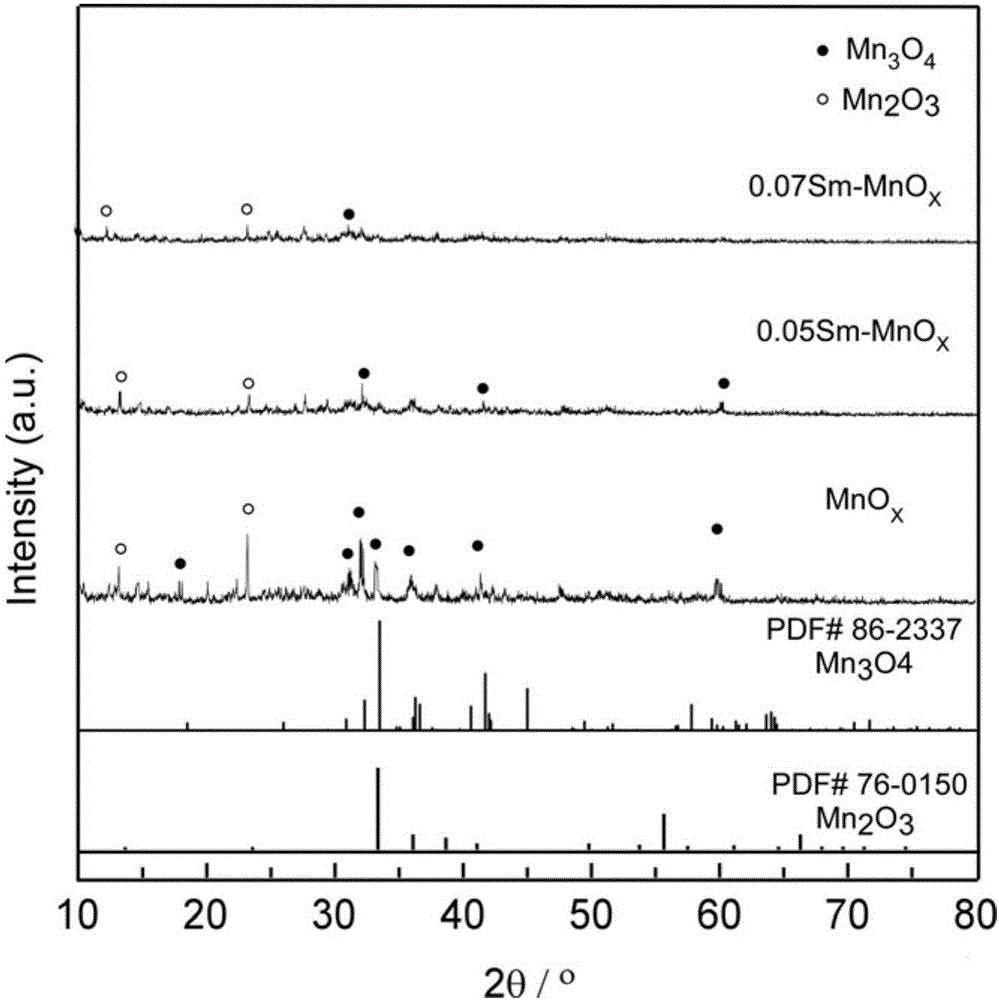

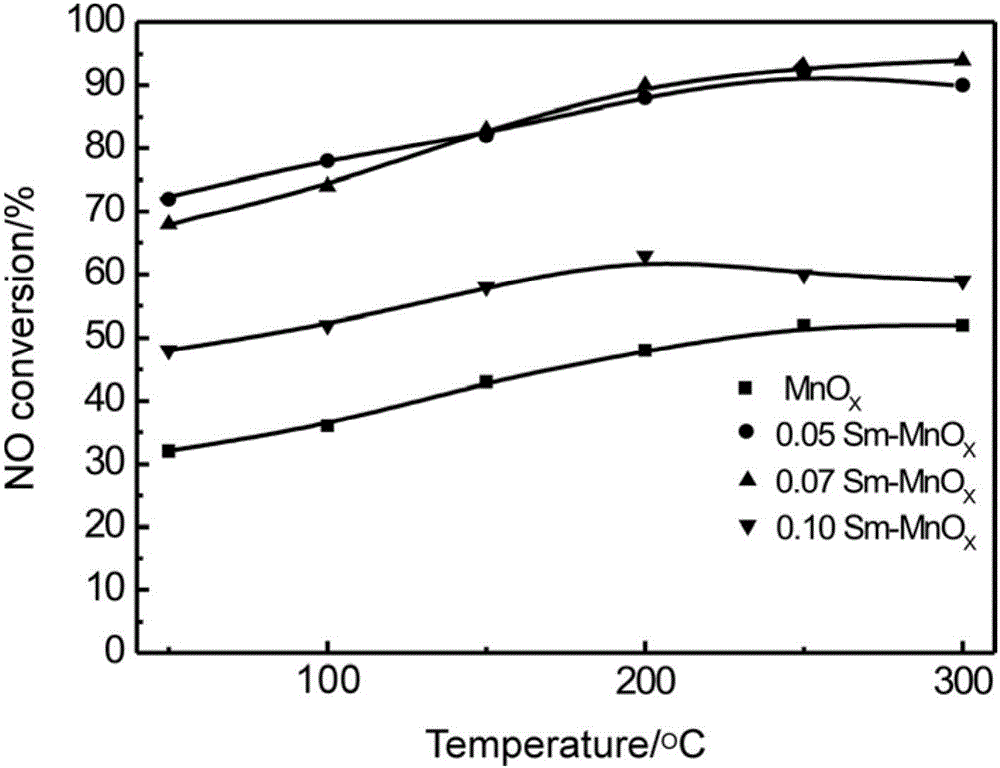

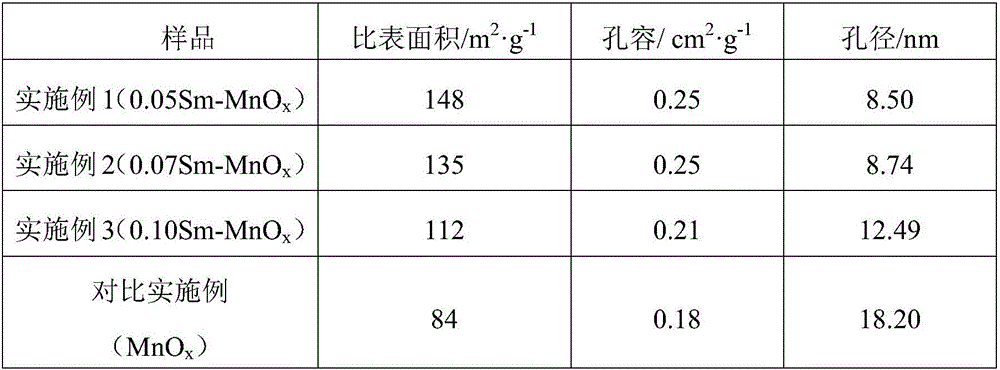

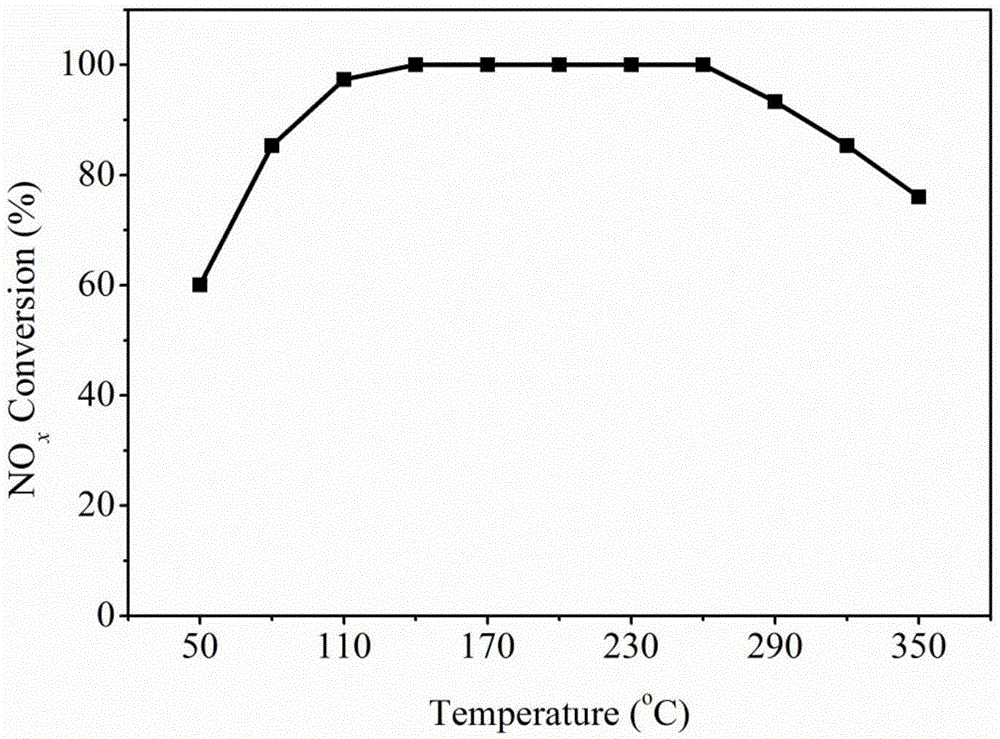

Samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as preparation method and application thereof

InactiveCN106268787ALarge specific surface areaSmall particle sizeHeterogenous catalyst chemical elementsDispersed particle separationDispersityMischmetal

The invention relates to a samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as a preparation method and application thereof. A proper amount of rare-earth metal samarium is doped into a manganese-based catalyst to obtain the samarium-doped MnOx low-temperature SCR catalyst; compared with a single manganese-based catalyst, the specific surface area of the catalyst is enlarged and the grain diameter of MnOx is reduced; the dispersity of manganese oxide in the catalyst is improved, and reaction activity of the MnOx at low temperature is effectively facilitated; an SCR denitration activity temperature window is expanded, and a modification effect on an MnOx catalyst is very good; the samarium-doped MnOx low-temperature SCR catalyst has relatively high catalytic activity at the low temperature.

Owner:WUHAN UNIV OF TECH

Catalyst for purification of waste incineration flue gas and preparation method of catalyst

ActiveCN109126773AHigh catalytic activityImprove adsorption capacityGas treatmentDispersed particle separationCarbon nanotubePlatinum oxide

The invention discloses a catalyst for purification of waste incineration flue gas. The catalyst takes vanadium oxide, platinum oxide and tungsten oxide as active components, gamma-alumina, titanium oxide and carbon nanotubes as carriers and one or more of manganese oxide, iron oxide, copper oxide, tin oxide and cerium oxide as active aids. The catalyst has the functions of decomposing dioxin andchlorobenzene compounds and functions of denitration and sulfur resistance and still has excellent removal capacity for dioxin and NOx at lower temperature. The invention also discloses a preparationmethod of the catalyst for purification of waste incineration flue gas. The preparation method has the advantages of being simple to operate, convenient, controllable and suitable for mass industrialproduction.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

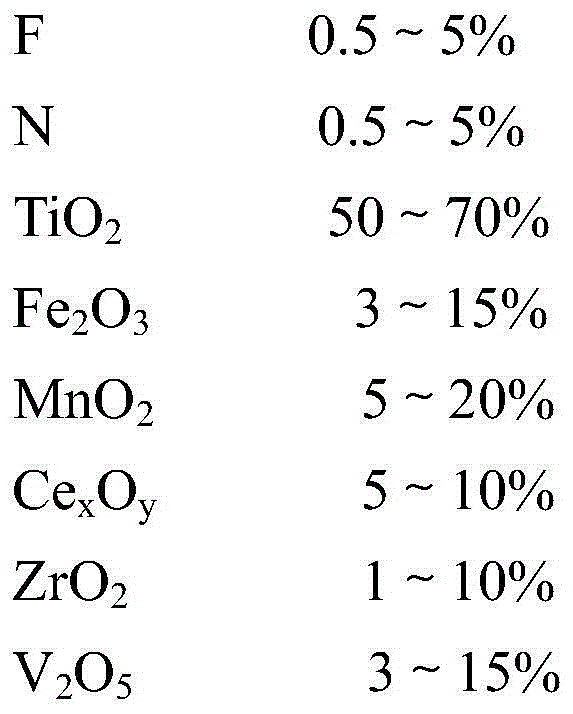

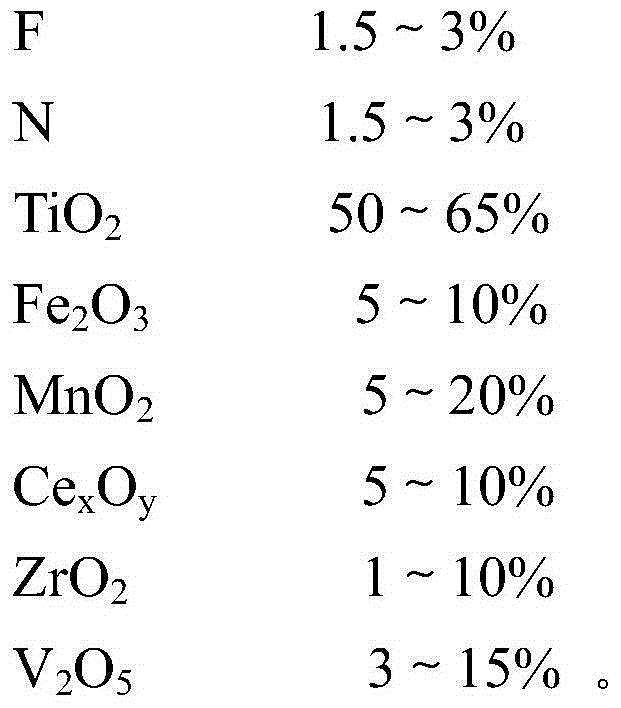

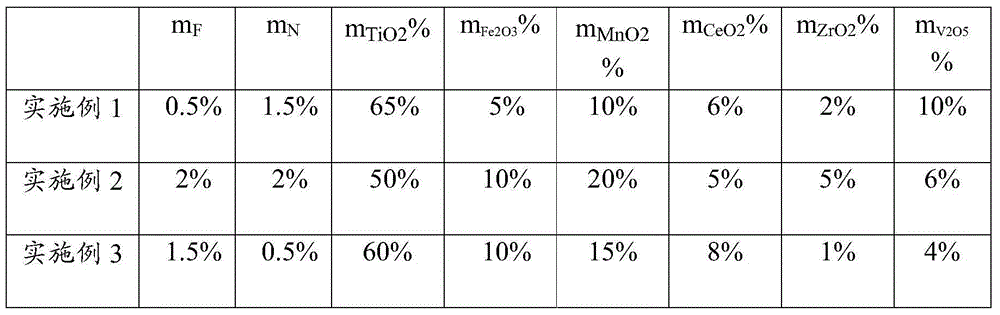

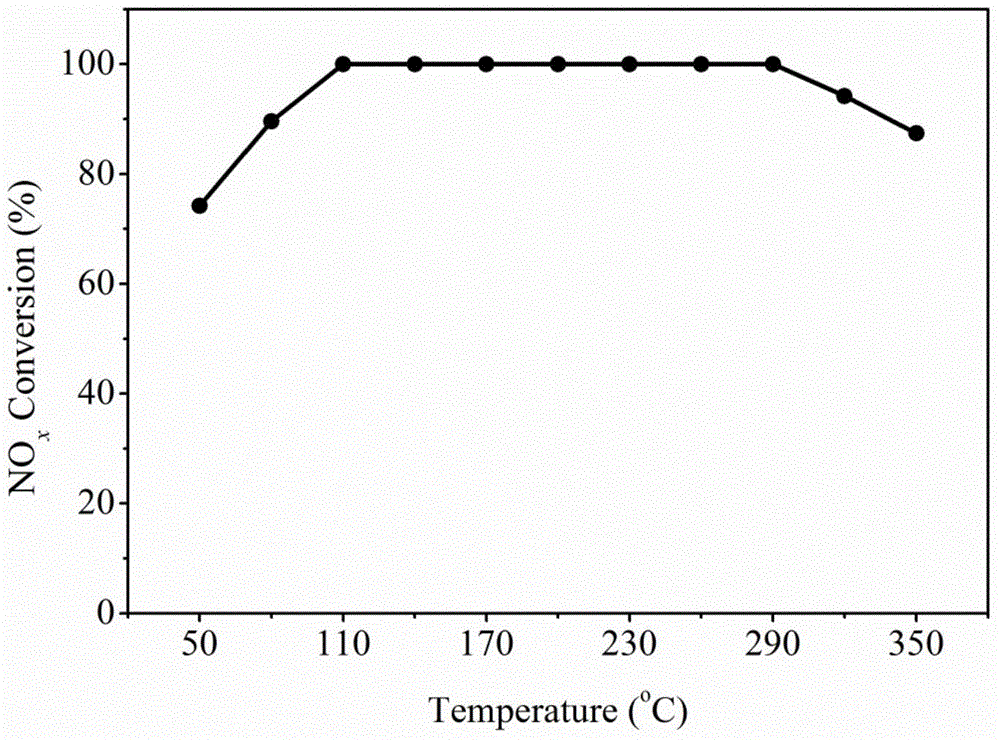

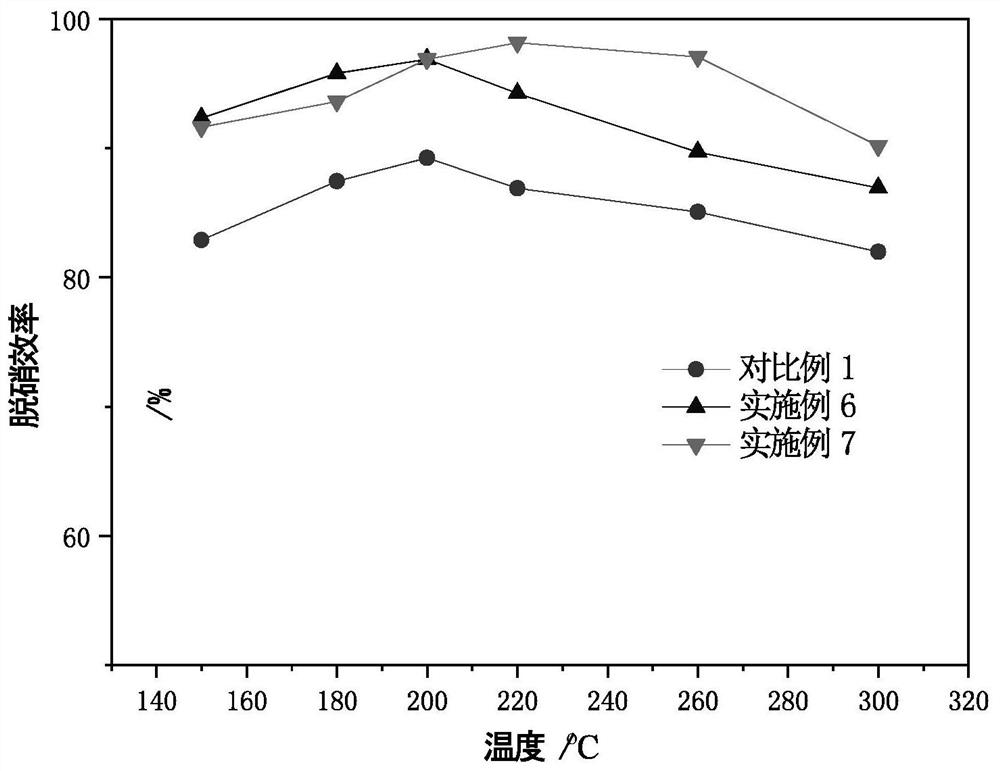

Non-metal-doped de-nitration catalyst and preparation method thereof

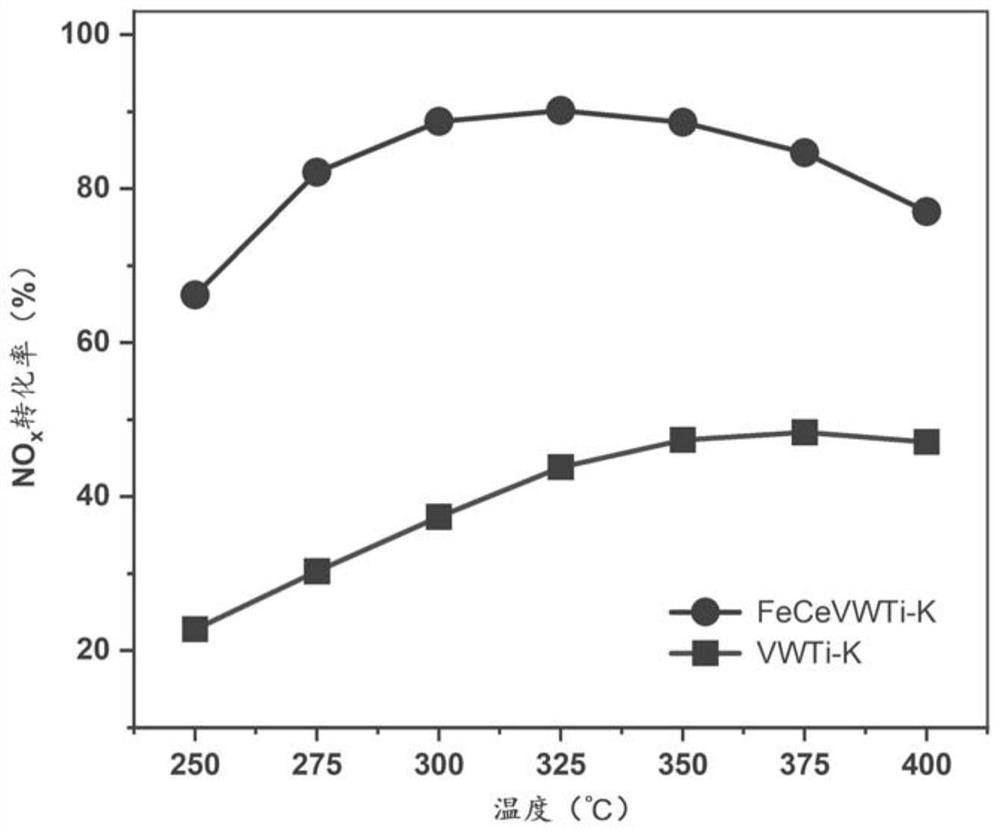

ActiveCN104588062AWide reaction temperature windowReaction temperature window widenedPhysical/chemical process catalystsDispersed particle separationActive componentNitration

The invention discloses a non-metal-doped de-nitration catalyst. The non-metal-doped de-nitration catalyst comprises a carrier and active components and also comprises non-metal F and N, wherein the carrier is TiO2; and the active components are Fe2O3, MnO2, CexOy, ZrO2 and V2O5. The invention also discloses a preparation method of the non-metal-doped de-nitration catalyst. The preparation method mainly comprises the following steps of carrying out dry-mixing raw materials, kneading, sieving with sieve plates, carrying out extrusion molding, drying and calcining. Since the de-nitration catalyst is doped with non-metal elements, the reaction temperature window of the catalyst is broadened, the catalytic activity of the catalyst is increased and in addition, the catalyst disclosed by the invention has better low temperature water resistance and good engineering application prospects.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

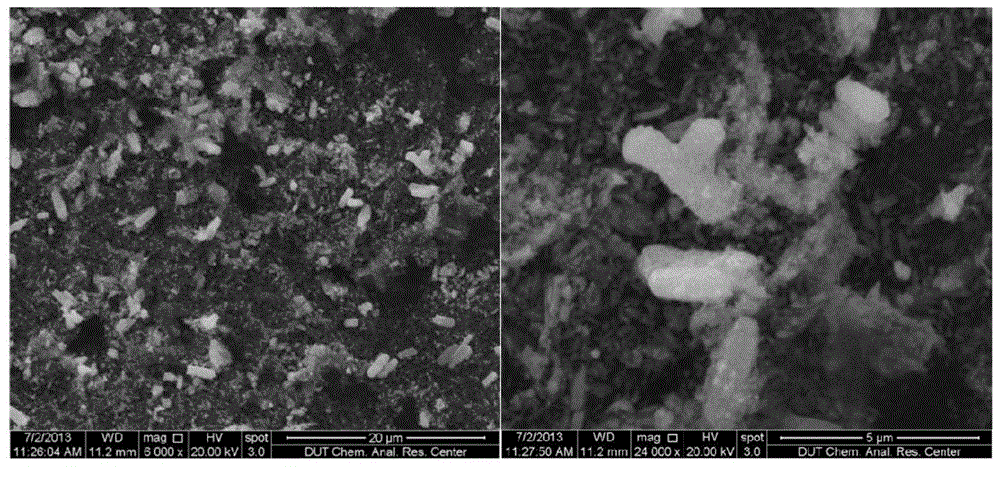

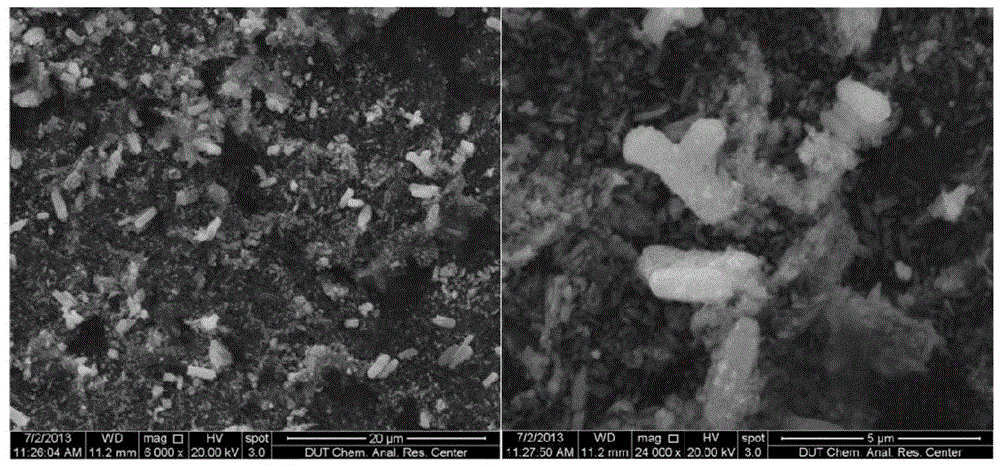

Preparation method of Mn-based rodlike microtopography composite oxide low-temperature denitrification catalyst

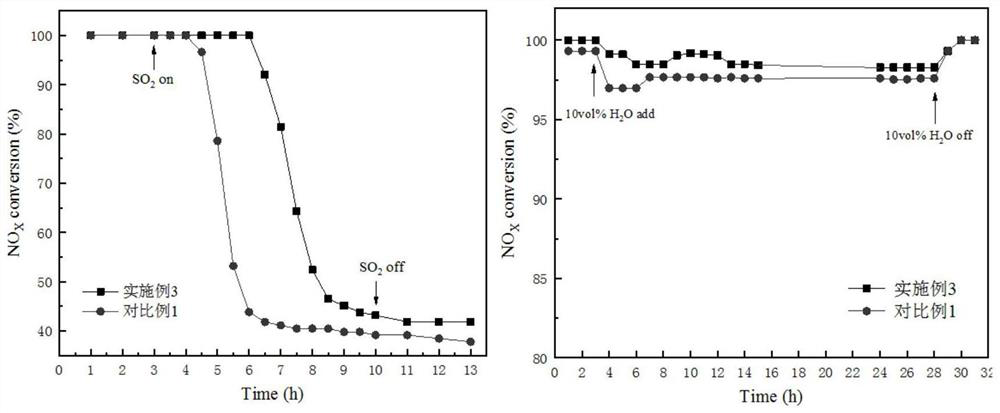

ActiveCN104624199AImprove water resistanceImprove sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureComposite oxide

The invention discloses a preparation method of a Mn-based rodlike microtopography composite oxide low-temperature denitrification catalyst, and belongs to the field of pollution control and techniques. The preparation method comprises the following steps of dissolving salt precursors of metal elements into distilled water to prepare a salt solution by taking MnOx as a catalyst and one or more of Ag, Cu, Fe, Ce and Co as additives, wherein NiOx is the important active component of the catalyst; and meanwhile, preparing a urea aqueous solution, mixing the salt solution and the urea aqueous solution uniformly, stirring and crystallizing at the reaction temperature of 50-120 DEG C for 4-12 hours, filtering, washing, drying, and forging and the like to prepare the Mn-based rodlike microtopography composite oxide low-temperature denitrification catalyst. The catalyst is applied to the selective catalytic reduction (NH3-SCR)NO by adopting NH3 as a reducing agent. The Mn-based rodlike microtopography composite oxide low-temperature denitrification catalyst has good low-temperature denitrification performance, is simple and convenient to prepare, is mild in condition, and has good application value in the denitrification field based on the NH3-SCR technique.

Owner:DALIAN UNIV OF TECH

High-efficiency denitration catalyst and preparation process thereof

InactiveCN106311212AReduce secondary pollutionEvenly dispersedGas treatmentHeterogenous catalyst chemical elementsAfter treatmentSulfur

The invention discloses a high-efficiency denitration catalyst and a preparation process thereof. The catalyst is a cerium bismuth aluminum composite oxide, wherein based on the molar ratio of metal elements, the molar ratio of cerium to aluminum is 0.1-1.0, and the molar ratio of bismuth to aluminum is 0.1-1.0. The catalyst is prepared by utilizing a treatment process of integrating a homogeneous co-precipitation method and a hydrothermal method, after-treatment is performed by utilizing the technical means of azeotropic distillation, and solid solution can be formed when the cerium and bismuth oxides are positioned in a highly dispersed state in the metal compound oxide. The high-efficiency denitration catalyst prepared by the invention can achieve excellent denitration activity, reaction stability, water resistance and sulfur tolerance in a temperature range of 200-400 DEG C.

Owner:王欧庭

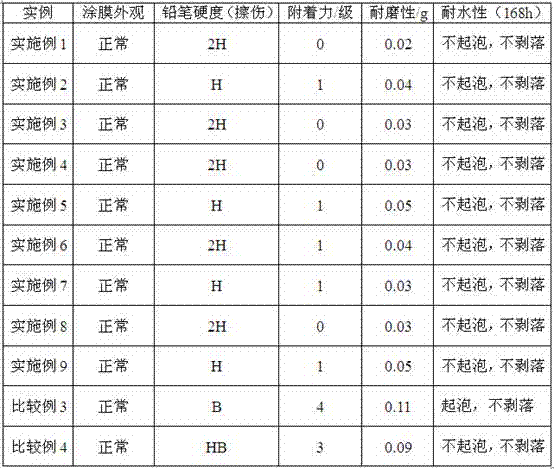

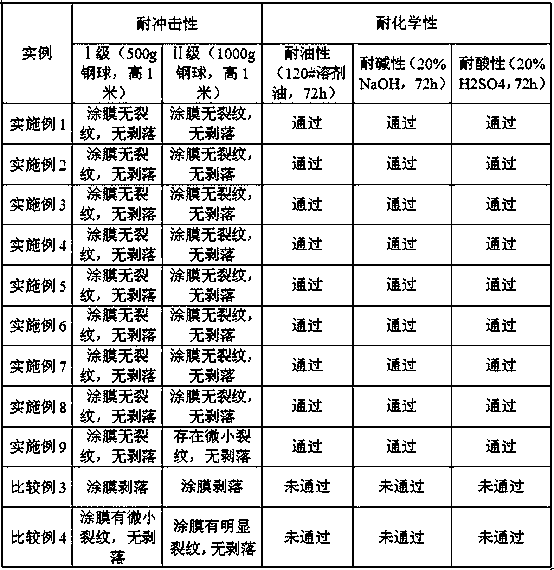

Tung oil-based aqueous polyurethane coating and preparation method thereof

ActiveCN107151520AHigh reactivityImprove hydrophobicityOrganic compound preparationCarboxylic acid esters preparationDistillationMoisture resistance

The invention discloses a preparation method of a tung oil-based aqueous polyurethane coating. The preparation method comprises the following steps: mixing tung oil, carboxylic acid, an acid catalyst and a hydroxylation reagent in proportion, and heating the obtained mixture to 35-45 DEG C; dropwise adding a hydrogen peroxide solution while intense stirring, controlling the dropwise adding speed to keep the reaction carried out at 40-65 DEG C, and keeping the reaction for 3-5 h after the dropwise addition is finished; standing and layering the obtained reaction solution after the reaction ends, separating the obtained water phase, neutralizing the water phase, washing the neutralized water phase with water, and carrying out reduced pressure distillation to obtain tung oil polyol; and uniformly mixing the tung oil polyol, a hydrophilic modifier and acetone in proportion, adding diisocyanate, carrying out a reaction at 50-70 DEG C for 2-5 h, cooling the obtained reaction product to room temperature, adding a neutralizer to form a salt, adding a diamine chain extender and deionized water mixed solution, carrying out a chain extension reaction until no free isocyanate radicals exist, and carrying out reduced pressure distillation to remove the acetone in order to obtain the tung oil-based aqueous polyurethane coating. The preparation method has the advantages of effective improvement of the hydrophobicity and the moisture resistance of the aqueous polyurethane coating, and renewable and nontoxic raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

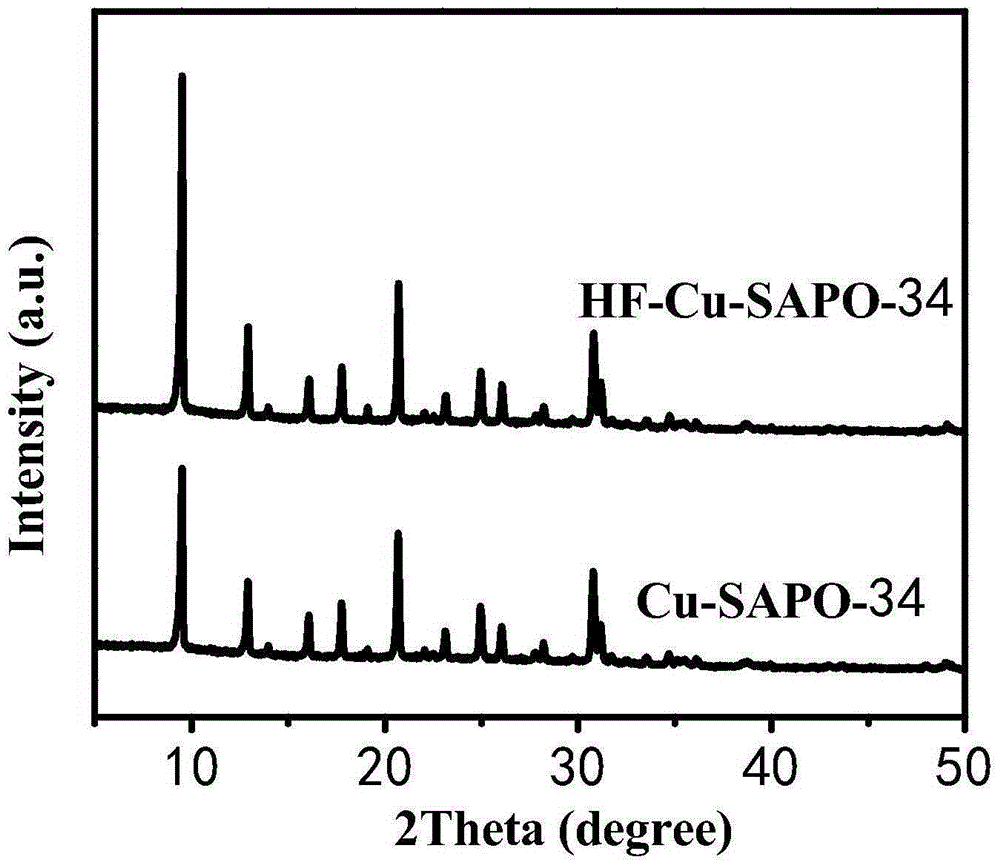

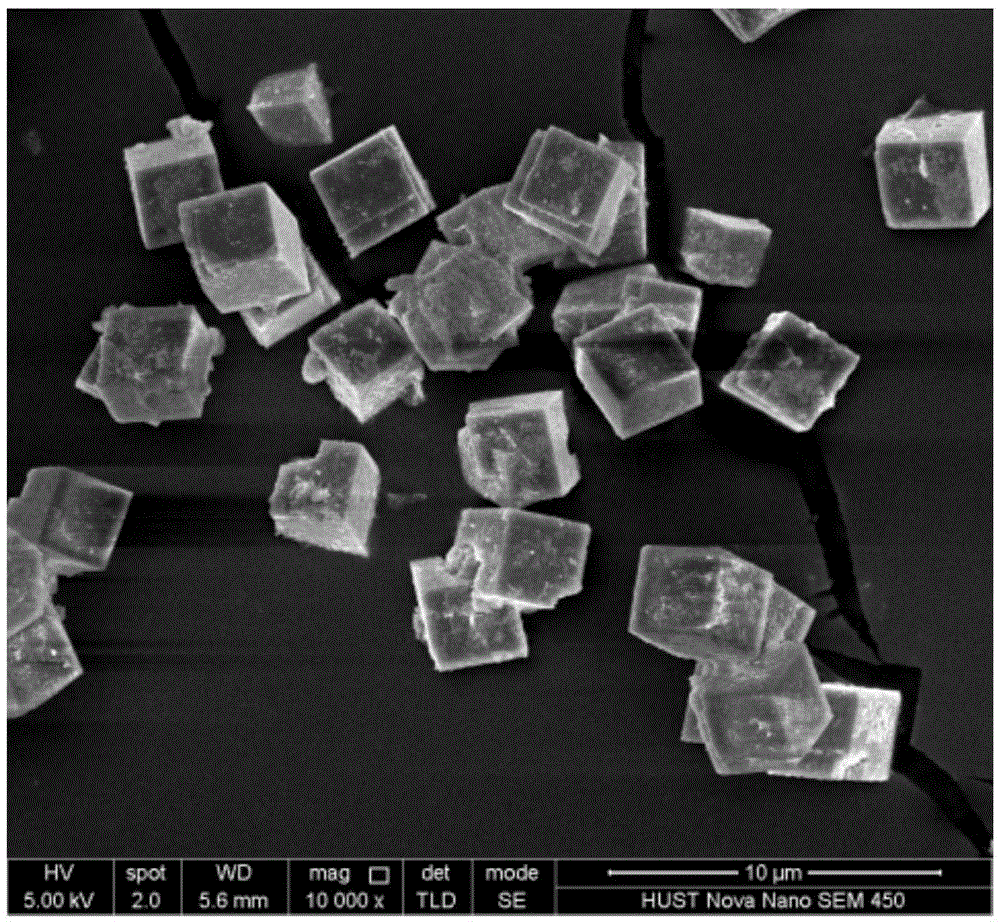

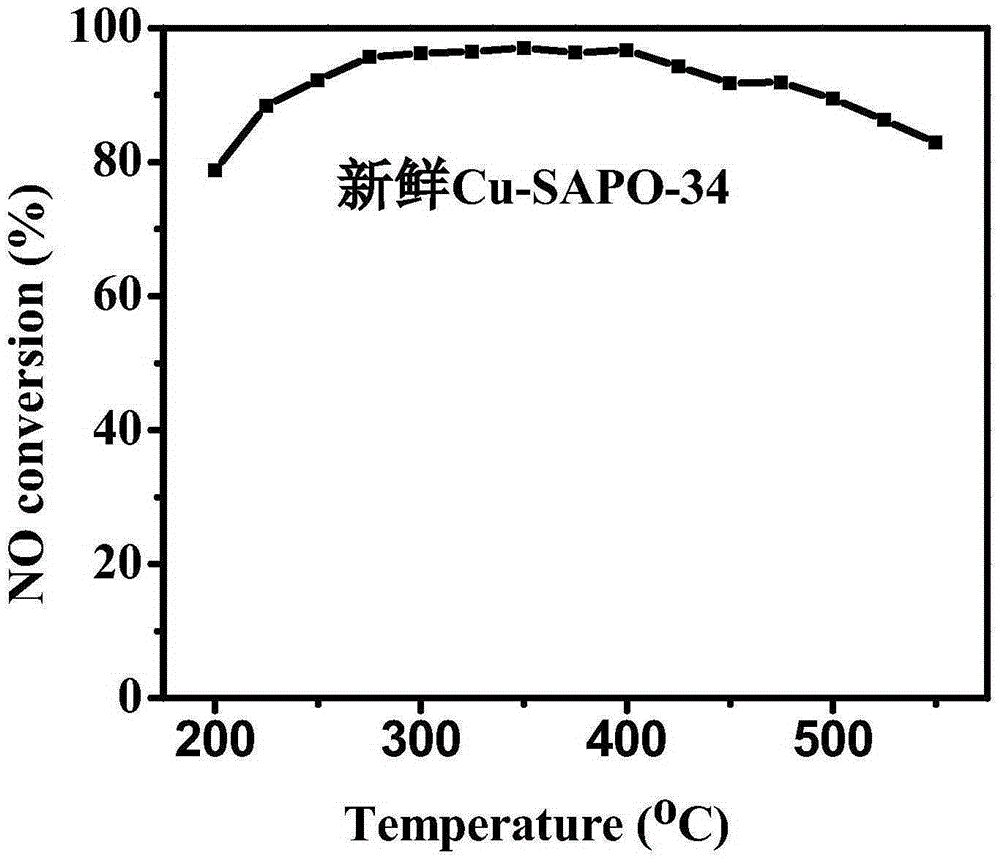

Preparation method for synthesizing Cu-SAPO-34 molecular sieve based catalyst through hydrogen fluoride modified one-step method

InactiveCN105251530AHigh crystallinityFast crystallizationInternal combustion piston enginesMolecular sieve catalystsMolecular sieveHydrogen fluoride

The invention provides a preparation method for synthesizing a Cu-SAPO-34 molecular sieve based catalyst through a hydrogen fluoride modified one-step method. The method comprises the steps that an aluminum source, orthophosphoric acid, a silicon source, copper sulfate, tetraethylenepentamine and hydrogen fluoride are sequentially added to deionized water to be fully stirred, gel is obtained and placed in a hydrothermal reaction kettle, reacting is carried out for 0.5-5 days at the temperature of 150 DEG C to 200 DEG C, and after cooling, filtering, washing and drying are carried out, calcination is carried out at the temperature of 550 DEG C to obtain the Cu-SAPO-34 molecular sieve based catalyst. Cu-SAPO-34 is synthesized in situ through the hydrogen fluoride modified one-step method, the degree of crystallinity of a molecular sieve is improved, SAPO-5 and other mixed crystals are prevented from being generated, the crystallization speed of the molecular sieve is increased, crystallization time is only 1 / 2-1 / 3 that of a molecular sieve without hydrogen fluoride, structure defect sites are reduced, the acid site density of the molecular sieve is increased, an NH3-SCR temperature window of the catalyst is widened, and the hydrothermal stability performance of the catalyst is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Mixed rare-earth denitration catalyst and preparation method thereof

InactiveCN107413350AHigh catalytic efficiencyWide reaction temperature windowDispersed particle separationCatalyst activation/preparationRare earthReaction temperature

The invention relates to a mixed rare-earth denitration catalyst and a preparation method thereof. An active component of the denitration catalyst is a double-active component composed of mixed rare-earth oxide and transition element oxide. The catalyst has the advantages of high catalytic efficiency, wide reaction temperature window and the like due to the synergistic effect between the mixed rare-earth oxide and between the rare-earth oxide and the transition element oxide. A preparation technology adopts an immersion method to manufacture and has the advantage of simple technology, wide raw material sources, low cost and the like. The mixed rare-earth oxide catalyst provided by the invention is mainly applied to the aspect of purifying industrial waste gas, and is especially used for the aspect of flue gas denitration. The mixed rare-earth denitration catalyst can be used for middle-temperature and low-temperature flue gas denitration of coal-fired power plants and can also be used for the field of low-temperature flue gas denitration of an industrial source.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Rare-earth-based iron-containing high-entropy solid solution catalyst and preparation method thereof

InactiveCN107930637AHigh catalytic efficiencyWide reaction temperature windowGas treatmentDispersed particle separationPtru catalystPhysical chemistry

The invention discloses a rare-earth-based iron-containing high-entropy solid solution catalyst. The rare-earth-based iron-containing high-entropy solid solution catalyst is prepared from the following components in percentage by weight: 6 percent to 10 percent of rare earth oxide, 12 percent to 30 percent of transition metal oxide, 7 percent to 16 percent of alkaline-earth metal oxide and the balance of trace components and a carrier. The invention further provides a preparation method and application of the rare-earth-based iron-containing high-entropy solid solution catalyst. The rare-earth-based iron-containing high-entropy solid solution catalyst disclosed by the invention has good catalytic efficiency and performance; the preparation cost and the utilization cost are reduced. The rare-earth-based iron-containing high-entropy solid solution catalyst disclosed by the invention is prepared by taking rare earth tailings as raw materials and tailing resources are effectively reutilized; the rare-earth-based iron-containing high-entropy solid solution catalyst has the advantages of simple technology, easiness for operation, less investment, low energy consumption and safety and environment protection; sustainable development of the society and industrial expanded application are easy to realize.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Conducting flue gas denitration catalyst and preparation method thereof

InactiveCN104148056AWith conduction heating functionWith low temperature denitrificationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The invention relates to a conducting flue gas denitration catalyst and a preparation method thereof. The conducting flue gas denitration catalyst is prepared from the following raw materials in percentage by weight: 60 to 90 percent of titanium dioxide, 3 to 9 percent of tungsten trioxide, 0.1 to 2 percent of vanadium pentoxide, 1 to 5 percent of silicon dioxide, 1 to 5 percent of rare earth, 3 to 10 percent of C fibers and the balance of a forming agent. The conducting flue gas denitration catalyst has a wire function, implements low-temperature catalysis, has high denitration efficiency, a low SO2 / SO3 conversion rate, a low ammonia escape rate, wear resistance, high intensity, a long chemical service life and a long mechanical service life and has low output of domestic sewage.

Owner:SHANDONG AIREP ENVIRONMENTAL TECH CO LTD

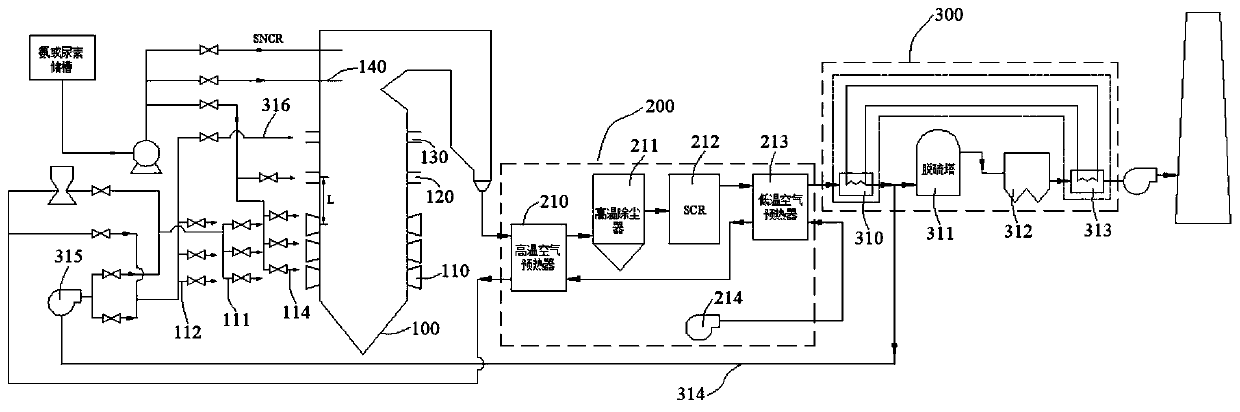

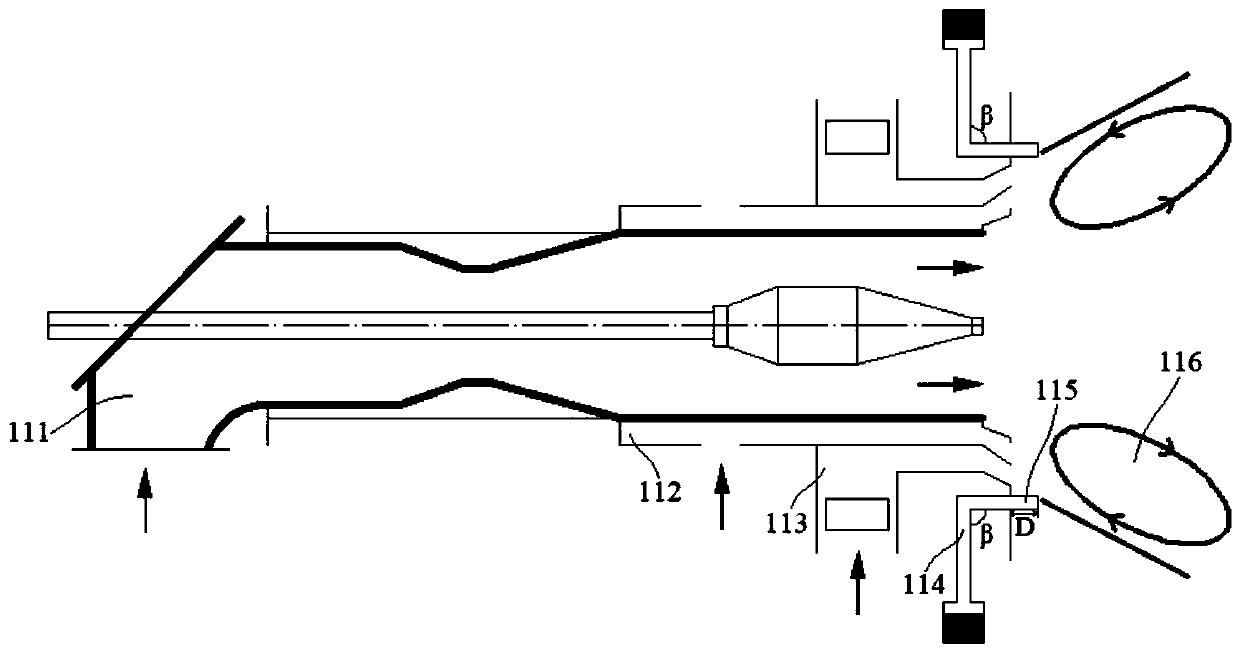

Deep denitration process for supercritical carbon dioxide coal-fired boiler

ActiveCN111450682ALower furnace temperatureReduce thermal NOx generationGas treatmentLighting and heating apparatusProcess engineeringFlue gas

The invention discloses a deep denitration process for a supercritical carbon dioxide coal-fired boiler, belonging to the technical field of NOx emission reduction. The deep denitration process comprises the following steps: three-stage ammonia injection denitration, wherein an ammonia injection combustor is used for injecting a fuel and an amino reducing agent into a main combustion area of a combustor in a boiler to form an annular high-temperature low-oxygen reduction area with a temperature of 850-1400 DEG C, and a reduction reaction is carried out in the annular high-temperature low-oxygen reduction area to achieve first-stage denitration, and a second-stage ammonia injection device and a third-stage ammonia injection device are used for respectively injecting an amino reducing agentto a main combustion area at the upper part of the high-temperature low-oxygen reduction area and a burnout area behind burnout air to realize second-stage denitration and third-stage denitration; anddedusting, desulfurization and denitrification, wherein SCR denitrification is conducted on the flue gas in a dedusting and denitrification unit, and then the flue gas is cooled to 70-90 DEG C and then sent into the boiler for circular denitrification treatment. The defect that the denitration degree is insufficient due to the fact that the temperature of the supercritical carbon dioxide coal-fired boiler is high in the prior art is overcome, deep staged denitration in the boiler is achieved through the three-stage ammonia injection denitration process, the temperature in the boiler is effectively reduced through low-temperature flue gas recirculation combustion, generation of thermal NOx is reduced, and deep denitration of the supercritical carbon dioxide coal-fired boiler is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A nitrogen oxide degradation film and its preparation method

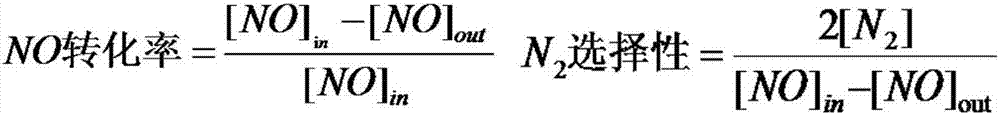

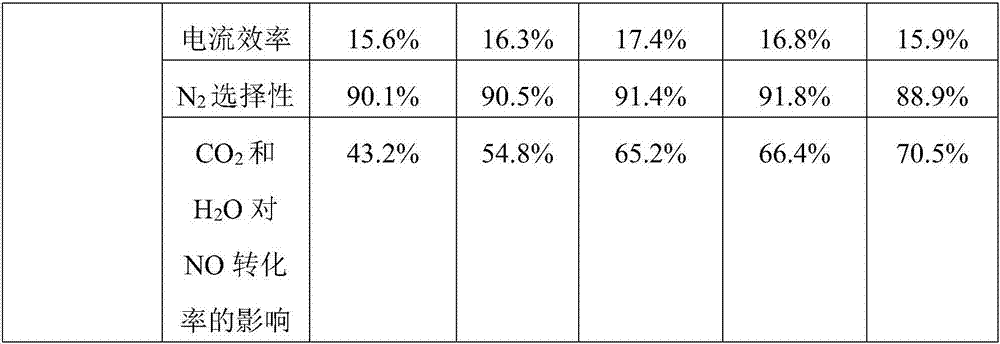

ActiveCN105478152BImprove reduction efficiencyHigh selectivityPhysical/chemical process catalystsDispersed particle separationNitrogen oxidesPotassium fluoride

The present invention provides a nitrogen oxide degradation membrane and a preparation method thereof. The raw material components of the degradation membrane mainly consist of cerium acetylacetonate, barium acetylacetonate, potassium fluoride, melamine and graphene, wherein cerium acetylacetonate and barium acetylacetonate are , potassium fluoride and melamine through a sol-gel method to prepare F and N co-doped BaCeO3, a precursor powder is obtained by mixing graphene with F and N co-doped BaCeO3, and the nitrogen is obtained by a casting film forming method Oxide degradation film. Thus, a non-metal modified inorganic degradation membrane is prepared through the sol-gel method, which has a more efficient and stable current utilization rate and is suitable for highly selective electrocatalytic degradation of nitrogen oxides.

Owner:广州爱科琪盛塑料有限公司

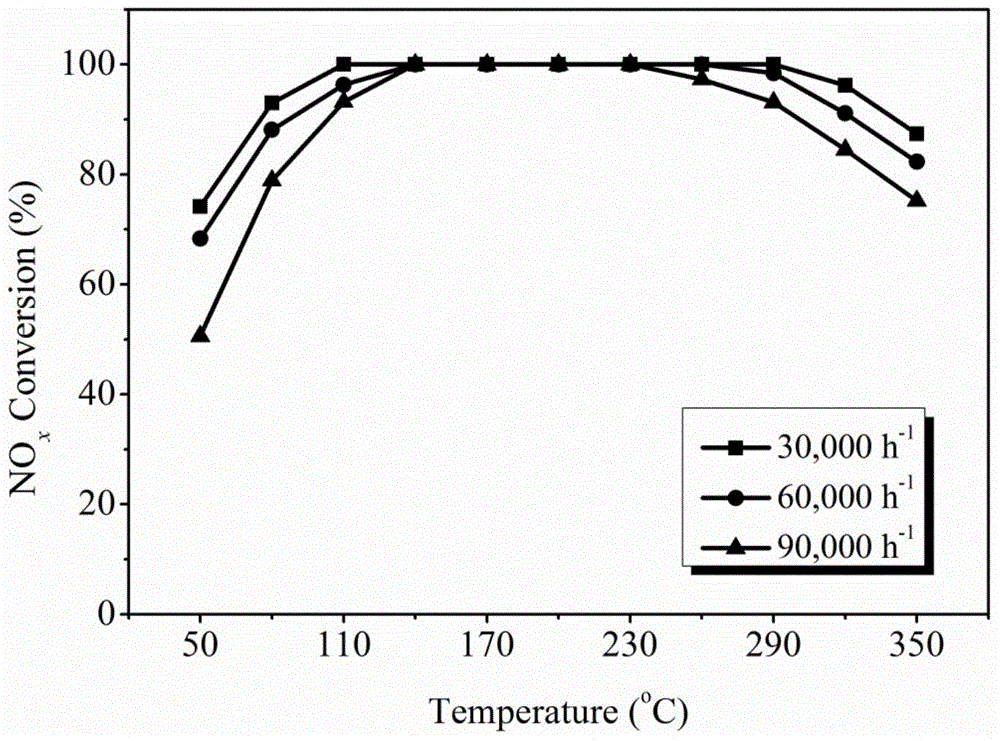

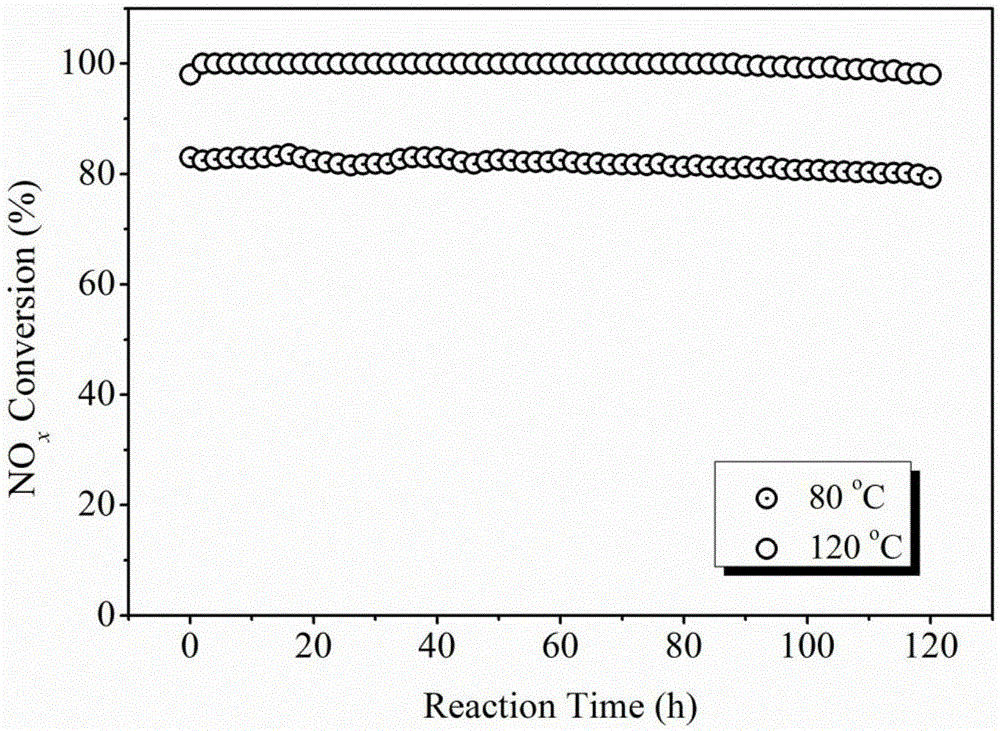

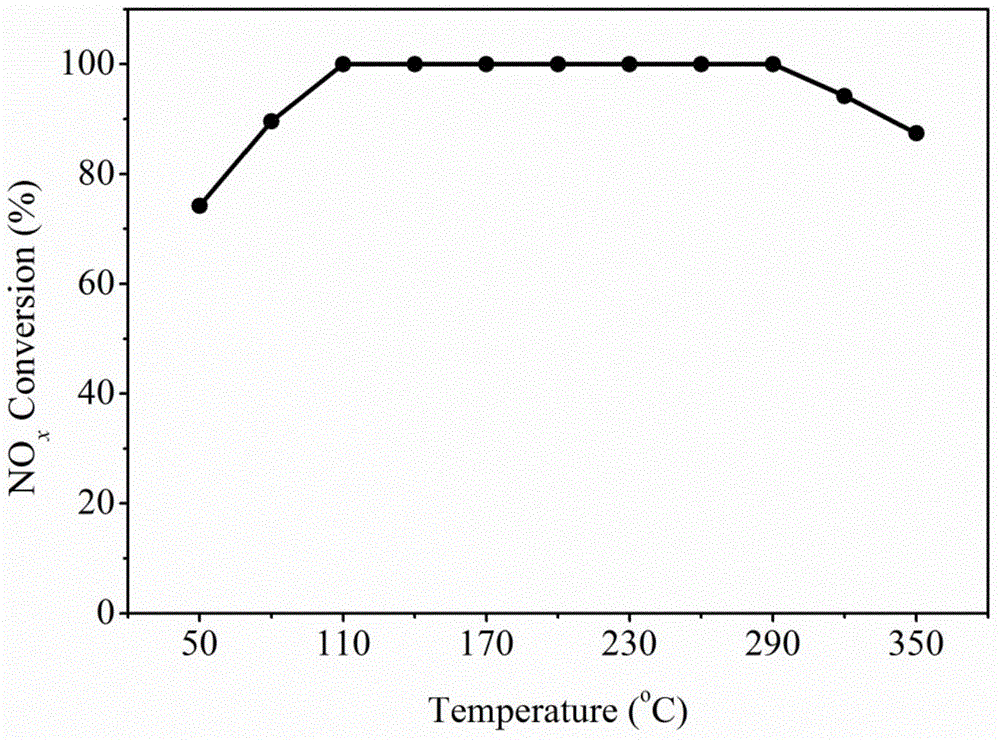

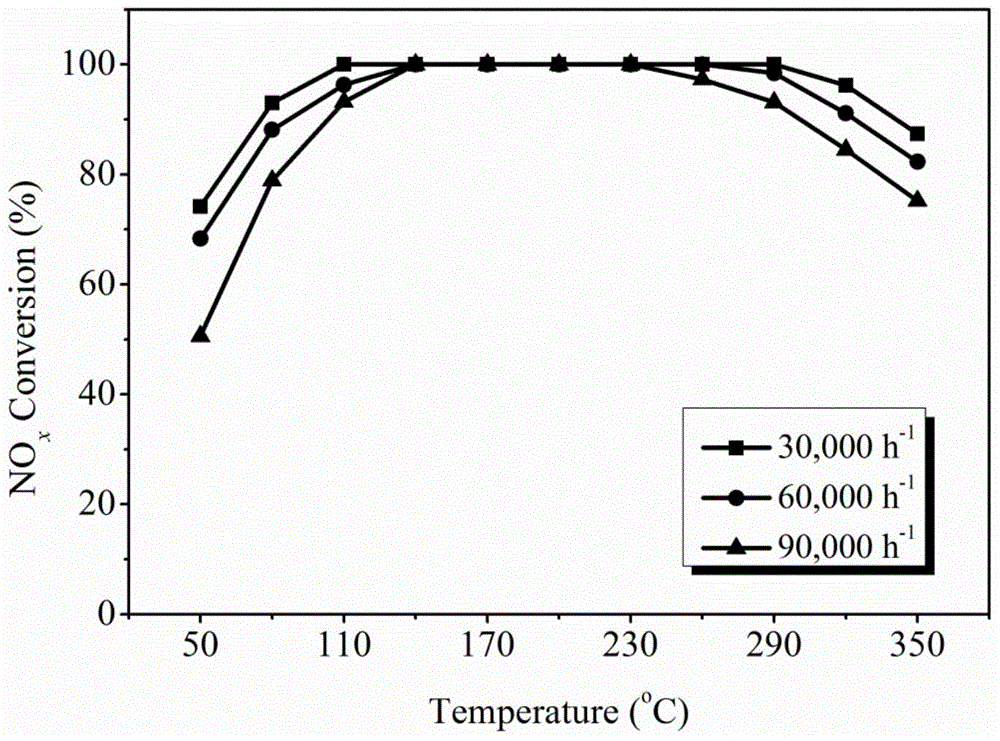

Preparation method and application of low temperature denitration Ni-based composite oxide cellular monolithic catalyst

ActiveCN105396598ALow temperature denitrification performance wideGood water and sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryComposite oxide

The invention provides a preparation method and application of a low temperature denitration Ni-based composite oxide cellular monolithic catalyst, and belongs to the technical field of environment catalysis and purification. The cellular monolithic catalyst mainly comprises an active component, a binding agent and an extrusion aid. The active component is a Ni-based composite metal oxide, the binding agent is prepared from pseudo-boehmite, a silicon oxide and dilute nitric acid, and the extrusion aid is sesbania powder. The monolithic catalyst has the good low temperature denitration performance and wide temperature operation window, the NOx conversion rate can reach 80% or above in the temperature range of 80-320 DEG C, and the catalyst has the high operation stability, good sulfur and water resistance and high application value and application prospect.

Owner:DALIAN UNIV OF TECH +1

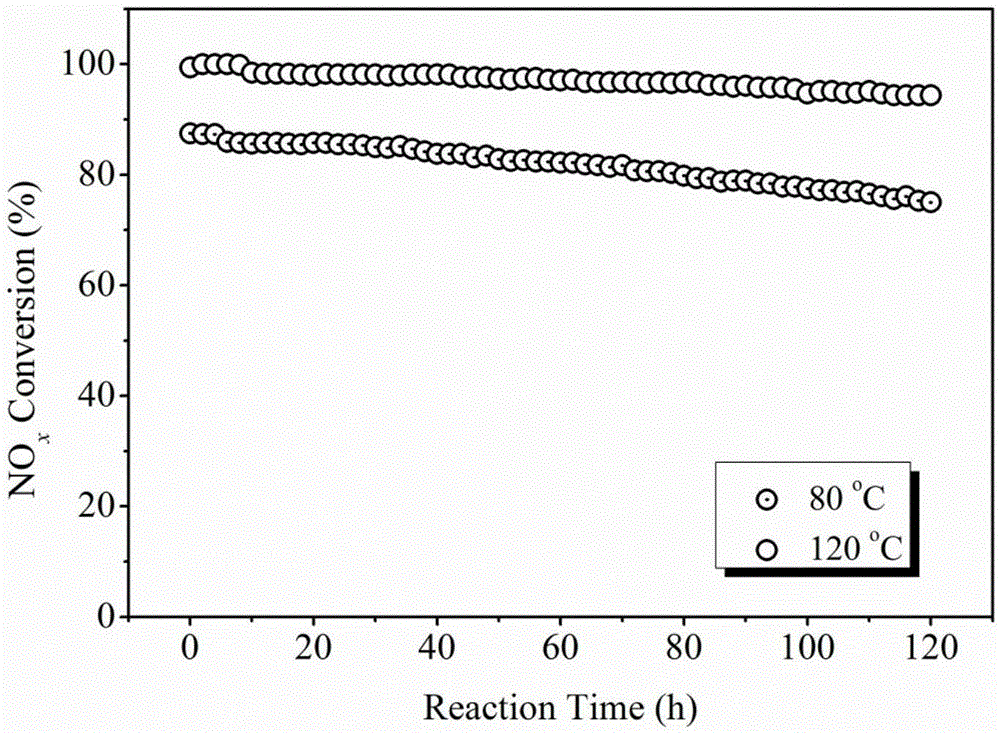

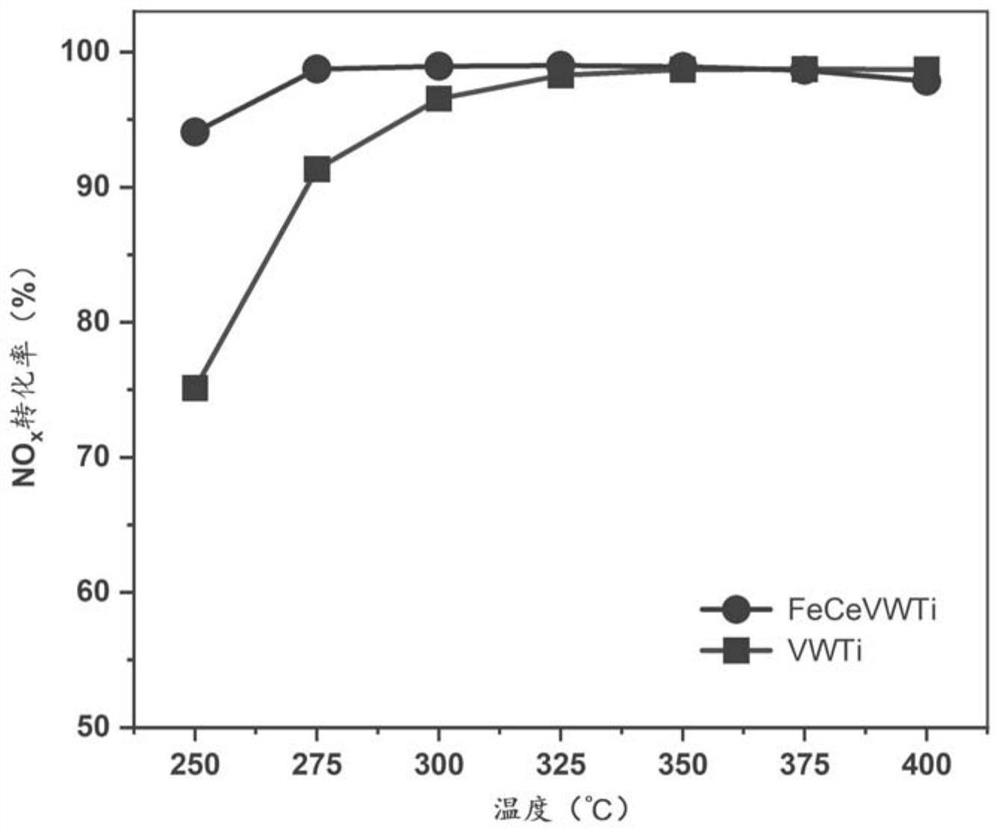

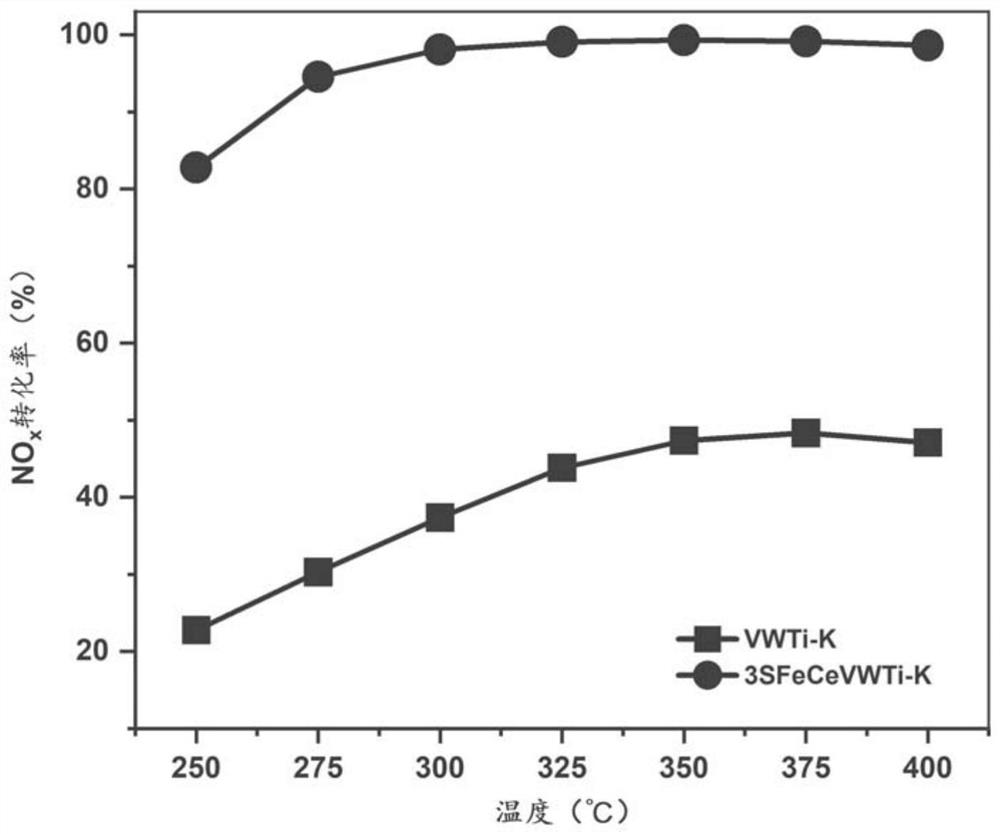

Modified denitration catalyst and preparation method thereof

PendingCN114515568AImprove denitrification activityExtended service lifeGas treatmentHeterogenous catalyst chemical elementsAlkaline earth metalPtru catalyst

The invention discloses a modified denitration catalyst, which takes a denitration catalyst as a carrier and adopts at least one of iron, cerium and sulfate radical as a modification component to improve the components and surface properties of the denitration catalyst, and adopts an impregnation method to improve the components and surface properties of the catalyst on the premise of ensuring that the macroscopic form of the existing denitration catalyst is not changed. The preparation process is mild, non-toxic and harmless. According to the improved catalyst, the denitration activity of the catalyst is improved, the reaction temperature window is widened, the catalyst has high N2 selectivity, the modified commercial denitration catalyst has higher alkali metal, alkaline earth metal and heavy metal poisoning resistance, and the service life of the catalyst is effectively prolonged.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Copper-iron-containing bimetal porous catalyst and preparation method thereof

InactiveCN108067288AGood purification effectWide reaction temperature windowGas treatmentMolecular sieve catalystsReaction temperatureIon exchange

The invention discloses a copper-iron-containing bimetal porous catalyst and a preparation method thereof. The catalyst composition is expressed as CuFezSixAlO2(x+), z is equal to 0.1 to 5 percent, x / is equal to 1 to 50, z / is equal to 0.1 to 1. The preparation method comprises the following steps: taking a Y molecular sieve as a carrier and taking copper iron bimetallic salt as an active ingredient precursor to prepare an aqueous solution; introducing the copper iron bimetallic active ingredient by using a liquid phase ion exchange method, and regulating the weight percentage of copper ironbimetal to 0 to 5 percent by controlling exchange times and time; drying and calcining samples to form catalyst powder; then carrying out direct high-pressure extruding molding or coating on the powder to the substrate surface with a fixed shape to obtain an integral catalyst. When the copper-iron-containing bimetal porous catalyst is used in the reaction of selective catalytic reduction of nitrogen oxide by ammonia, the reaction temperature is 150 to 500 DEG C, the ammonia is used as a reducing agent, the total flow of gas is controlled at 100 to 400ml / min and the airspeed is 10000 to 128000h<-1>. The purification efficiency of the nitrogen oxide is 90 to 100 percent.

Owner:中瑞天净环保科技(天津)有限公司

A preparation method of Mn-based rod-shaped microscopic composite oxide low-temperature denitration catalyst

ActiveCN104624199BImprove water resistanceImprove sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureMicro morphology

Owner:DALIAN UNIV OF TECH

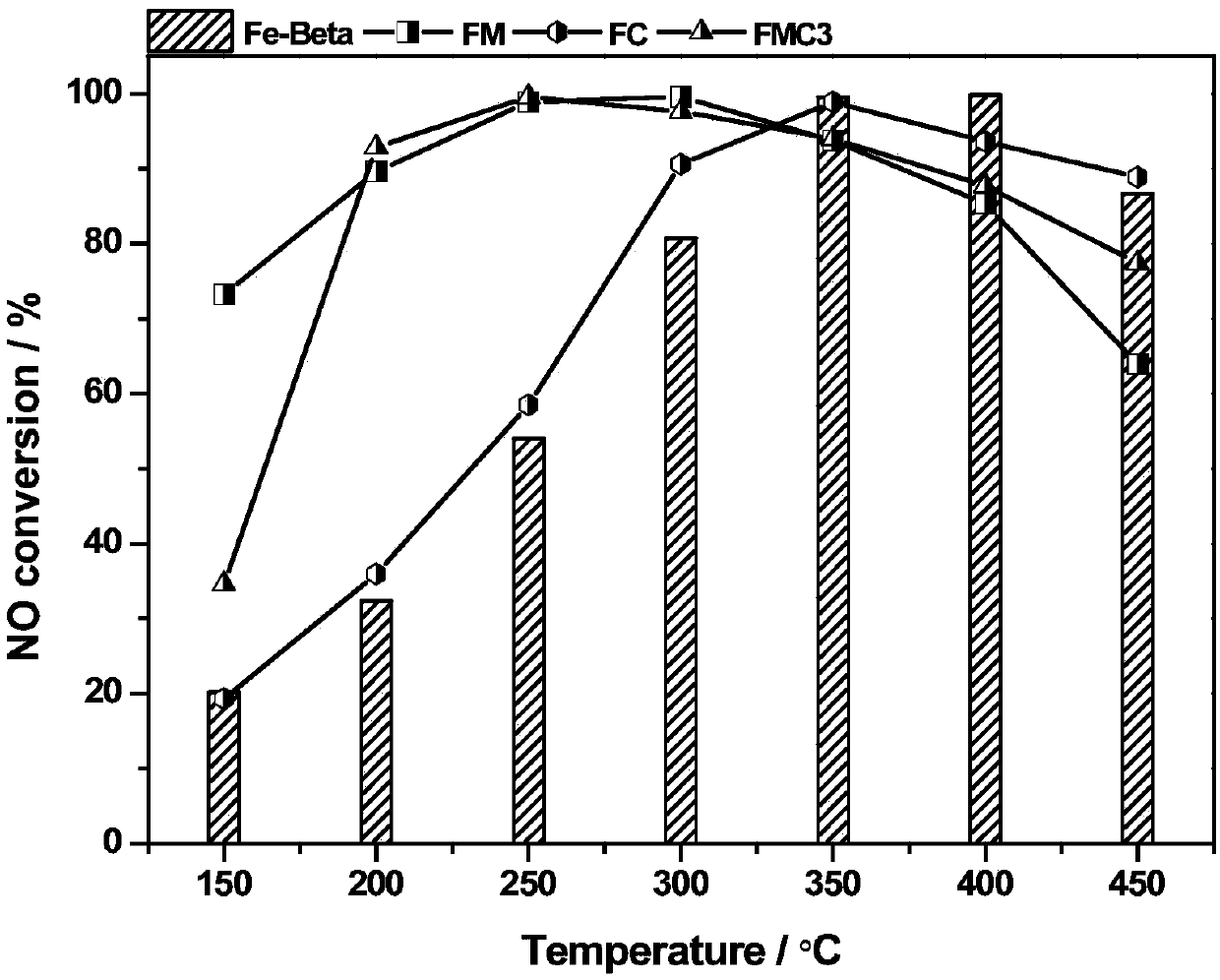

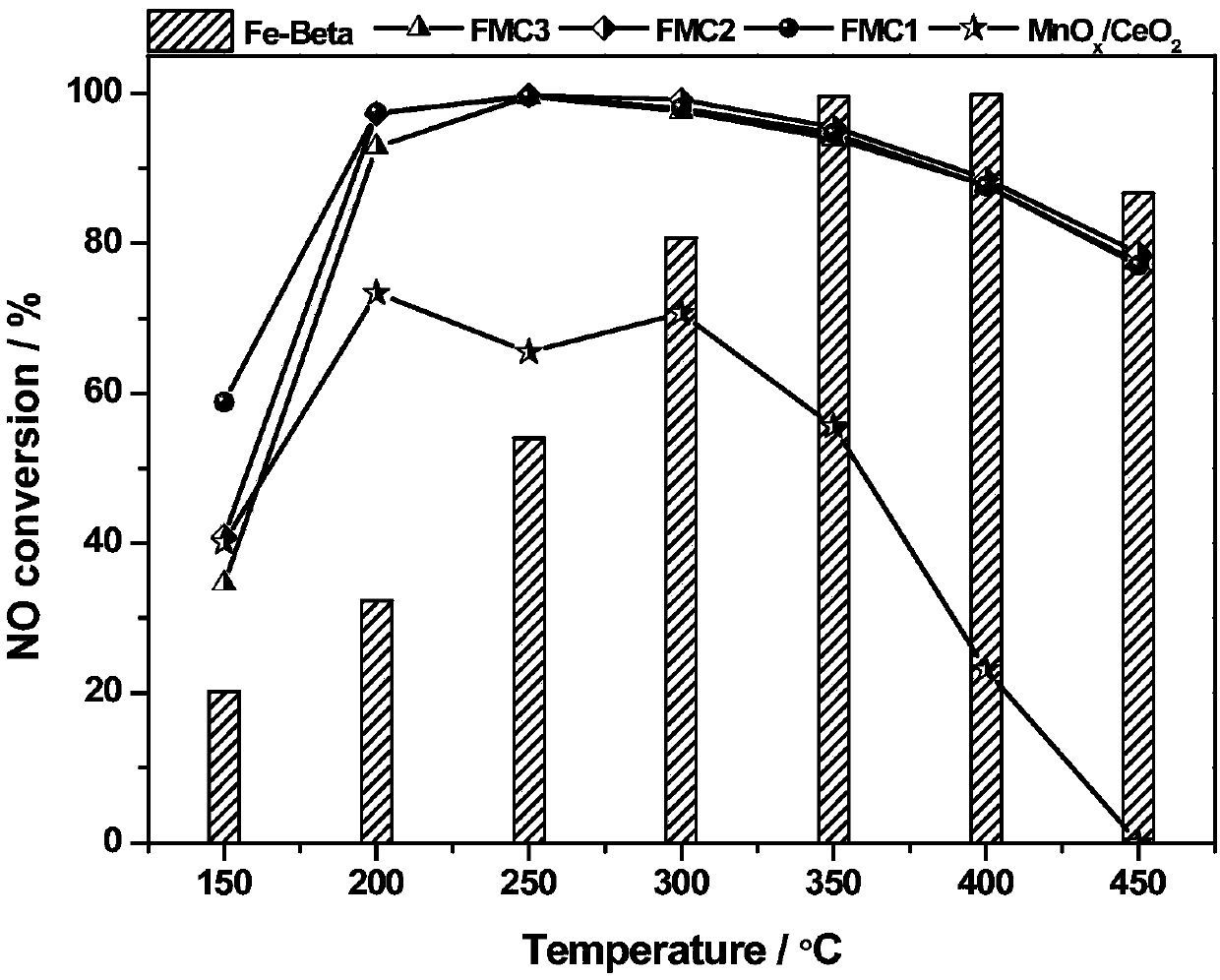

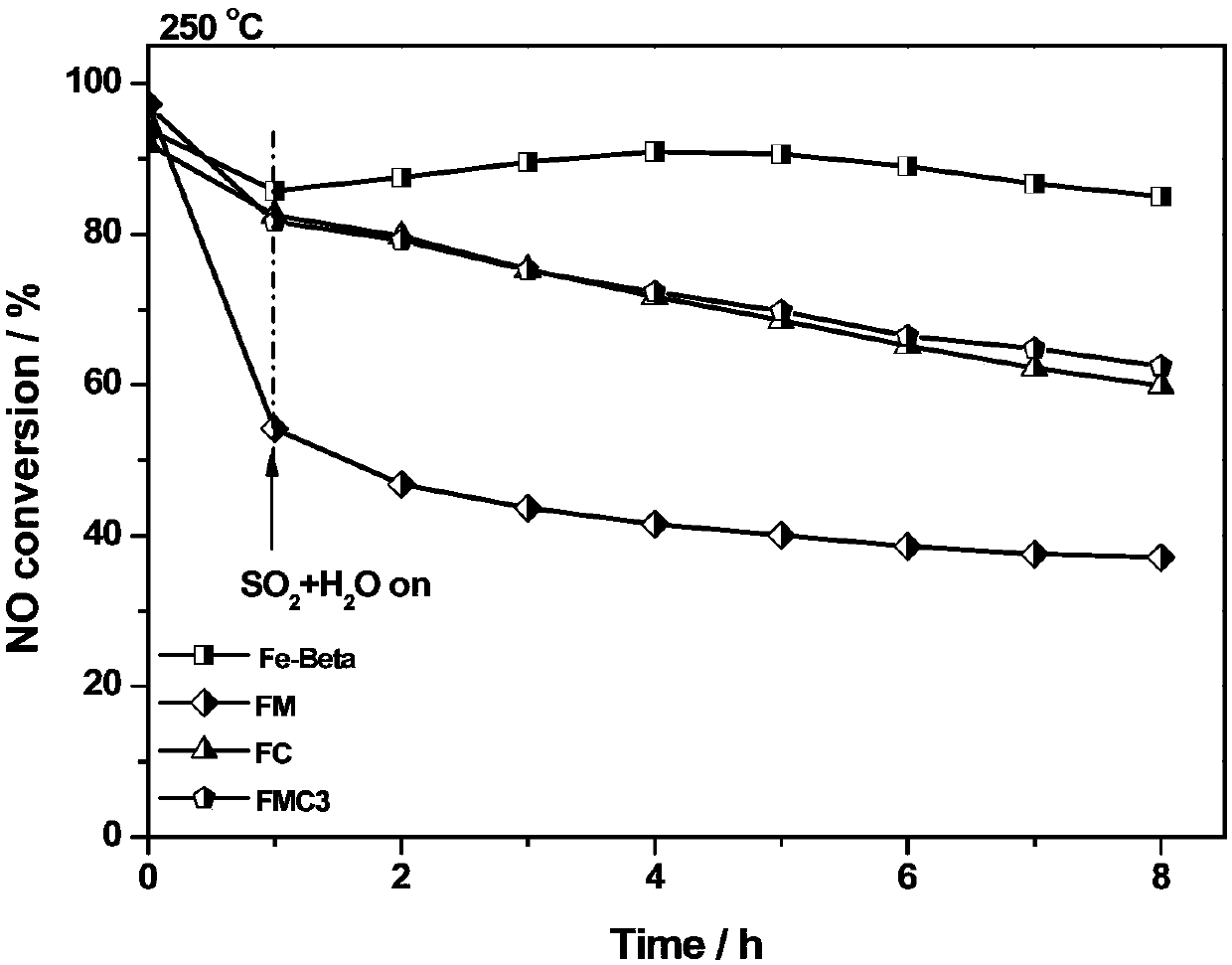

Preparation method of Beta-type molecular sieve resistant to propylene poisoning

ActiveCN108993586AHigh resistance to propylene poisoningDifferent active effectsMolecular sieve catalystsInternal combustion piston enginesHigh resistanceMolecular sieve

The invention discloses a preparation method of a Beta-type molecular sieve resistant to propylene poisoning. The preparation method comprises the following steps: taking a Fe-supported Beta-type molecular sieve with the pore diameter of 6.3-6.8 angstrom as a substrate; adding an oxide auxiliary agent into the molecular sieve substrate, stirring uniformly, and grinding for 40-90 min; roasting a sample after the mechanical mixing and grinding for 4 h at a heating rate of 2-5 DEG C / min in the air of 500 DEG C, wherein the oxide auxiliary agent is selected from the group comprising MnOx, CeO2 orMnOx / CeO2, and the loading amount of MnOx is 50% in the MnOx / CeO2. When being applied to a propylene-containing NH3-SCR reaction in the atmosphere, the prepared catalyst has the characteristics of high activity and high resistance to sulfur-poisoning property, and makes up for the defects that the conventional catalyst is poor in resistance to propylene poisoning performance or poor in resistanceto sulfur-poisoning property.

Owner:DALIAN UNIV OF TECH

CO low-temperature oxidation catalyst and preparation method thereof

ActiveCN101485984BHigh activityHigh selectivityCarbon compoundsDispersed particle separationActive componentCerium

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

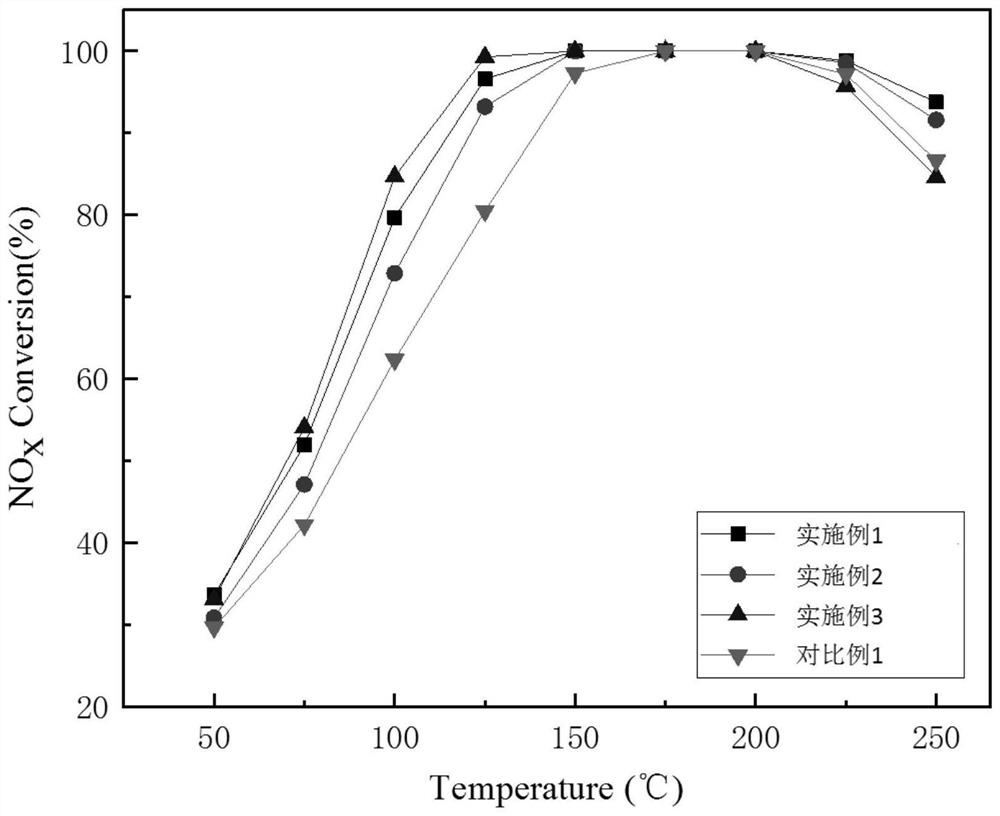

Low-temperature denitration catalyst and preparation method and application thereof

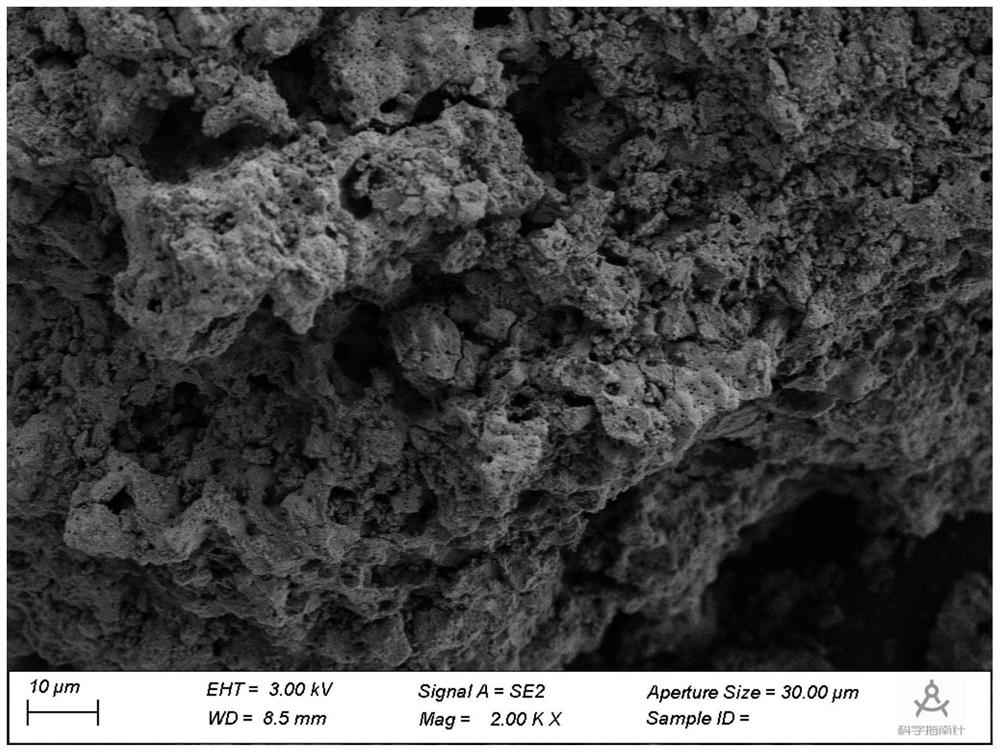

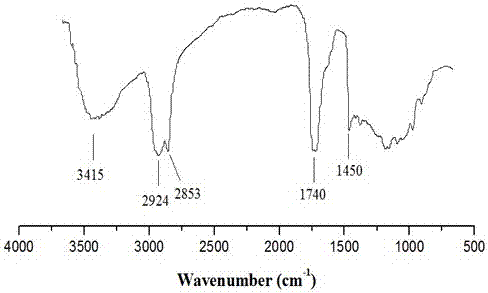

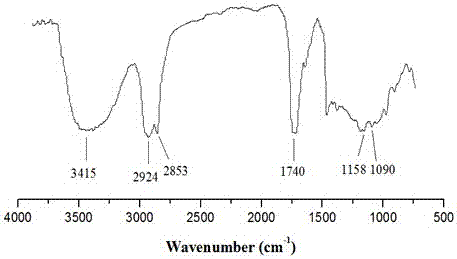

PendingCN112473655AGood low temperature denitrification activityWide reaction temperature windowGas treatmentHeterogenous catalyst chemical elementsCombustion chamberTitanium oxide

The invention relates to a low-temperature denitration catalyst and a preparation method and application thereof, and the method comprises the following steps: (1) dissolving manganese nitrate, ceriumnitrate and fuel in deionized water to obtain a mixed solution; (2) adding titanium dioxide into the mixed solution, and uniformly stirring to obtain a product; and (3) placing the obtained product in a pre-preheated combustion chamber for rapid combustion, then continuously roasting for a certain time, and finally grinding to obtain the Mn-Ce-Ox / TiO2 low-temperature denitration catalyst which isused for NH3-SCR reaction. Compared with the prior art, the preparation method has the advantages that the operation is simple, the prepared catalyst is porous and fluffy, the low-temperature denitration activity is better, the reaction temperature window is wider, the water resistance and sulfur resistance are better, and the like.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Preparation method of Mn-Ce/SBA-15 mesoporous molecular sieve catalyst containing active coating

ActiveCN109529913ALarge specific surface areaReduce areaGas treatmentMolecular sieve catalystsMolecular sieveFlue gas

The invention relates to the technical field of denitration, in particular to a preparation method of an Mn-Ce / SBA-15 mesoporous molecular sieve catalyst containing an active coating. The method comprises the steps of preparing an SBA-15 mesoporous molecular sieve; preparing an Mn-Ce / SBA-15 mesoporous molecular sieve, preparing a catalyst precursor, and preparing a catalyst finished product. The catalysis performance of the catalyst is high; the medium-low temperature denitration efficiency is high; the active temperature window is wide; the H2O poisoning resistant performance and SO2 poisoning resistant performance are good; the catalyst service life reduction due to the influence of SO2 in the flue gas is not liable to occur.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Mixed rare earth catalytic natural gas combustion catalyst and preparation method thereof,

PendingCN110898843ASimple preparation processExtensive sources of raw materialsHeterogenous catalyst chemical elementsGaseous fuelsPtru catalystPhysical chemistry

The invention provides a mixed rare earth catalytic natural gas combustion catalyst and a preparation method thereof, wherein the catalyst is prepared from the following components in percentage by weight: 5-15% of mixed rare earth, 1-3% of Fe2O3 and the balance of gamma-Al2O3 or a cordierite honeycomb ceramic carrier. According to the invention, the mixed rare earth catalytic combustion catalystprepared by an impregnation method and comprising double active ingredients of the mixed rare earth oxide and the transition metal oxide can be used for catalytic combustion of medium and low temperature natural gas stoves of resident users, can further be used for catalytic combustion of natural gas combustors of industrial sources, and solves the problems of low energy utilization rate, easy pollution generation and the like in flame combustion.

Owner:内蒙古智萃科技信息咨询有限公司

Low hydroxyl value tung oil polyol and preparation method thereof

ActiveCN107151212AIncrease concentrationReduce the amount of feedOrganic compound preparationCarboxylic acid esters preparationDistillationReaction temperature

The invention discloses a low hydroxyl value tung oil polyol preparation method, which comprises: (1) mixing tung oil, carboxylic acid, a catalyst and a hydroxylating reagent according to a certain ratio, heating to a temperature of 35-45 DEG C, adding a hydrogen peroxide solution in a dropwise manner under a vigorous stirring condition, maintaining the reaction temperature at 40-65 DEG C, maintaining the reaction temperature for 3-5 h after completing the adding, carrying out standing layering after completing the reaction, separating to obtain a water phase, neutralizing, carrying out water washing, and carrying out pressure reducing distillation to obtain tung oil polyol; and (2) mixing the tung oil polyol prepared in the step (1) and an alkaline catalyst according to a certain ratio, heating to a temperature of 90-140 DEG C, adding an epoxide, carrying out a polymerization reaction, and after completing the reaction, carrying out acid neutralizing, water washing and pressure reducing distillation to obtain the low hydroxyl value tung oil polyol. According to the present invention, the prepared low hydroxyl value tung oil polyol has the hydroxyl value of 30-100 mgKOH / g, the acid value of less than 1.0 mgKOH / g, the moisture content of less than 0.1 wt% and the yield of more than 90%, and is suitable for the preparation of polyurethane soft foam materials, polyurethane elastomers, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tung oil-based polyol and synthesis method thereof

ActiveCN107151217AIncrease concentrationReduce the amount of feedOrganic compound preparationCarboxylic acid esters preparationEpoxyCross-link

The invention discloses a tung oil-based polyol synthesis method, which comprises: mixing tung oil and a hydroxylating reagent according to a certain ratio, and heating to a temperature of 35-45 DEG C; mixing a hydrogen peroxide solution accounting for 40-60% of the total adding amount, carboxylic acid and an inorganic acid catalyst under vigorous stirring, adding the obtained mixture to the reaction system in a dropwise manner, slowly adding the remaining hydrogen peroxide solution in a dropwise manner after completing the adding of the mixture, maintaining the reaction temperature at 40-65 DEG C by controlling the adding rate, and maintaining the reaction temperature for 3-5 h after completing the adding; and carrying out standing layering after completing the reaction, separating to obtain a water phase, neutralizing, carrying out water washing, and carrying out pressure reducing distillation to obtain the tung oil-based polyol. According to the present invention, the conjugated double bond of tung oil can improve the reactivity of the epoxy group, such that the hydroxylating reagent is added while the epoxidation is performed so as to effectively avoid the occurrence of the cross-linking side reaction and efficiently synthesize the tung oil-based polyol product; and the prepared tung oil-based polyol has the hydroxyl value of 120-270 mgKOH / g, the acid value of less than 1.0 mgKOH / g, the moisture content of less than 0.1 wt% and the yield of more than 92%, and can be used for the preparation of polyurethane materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

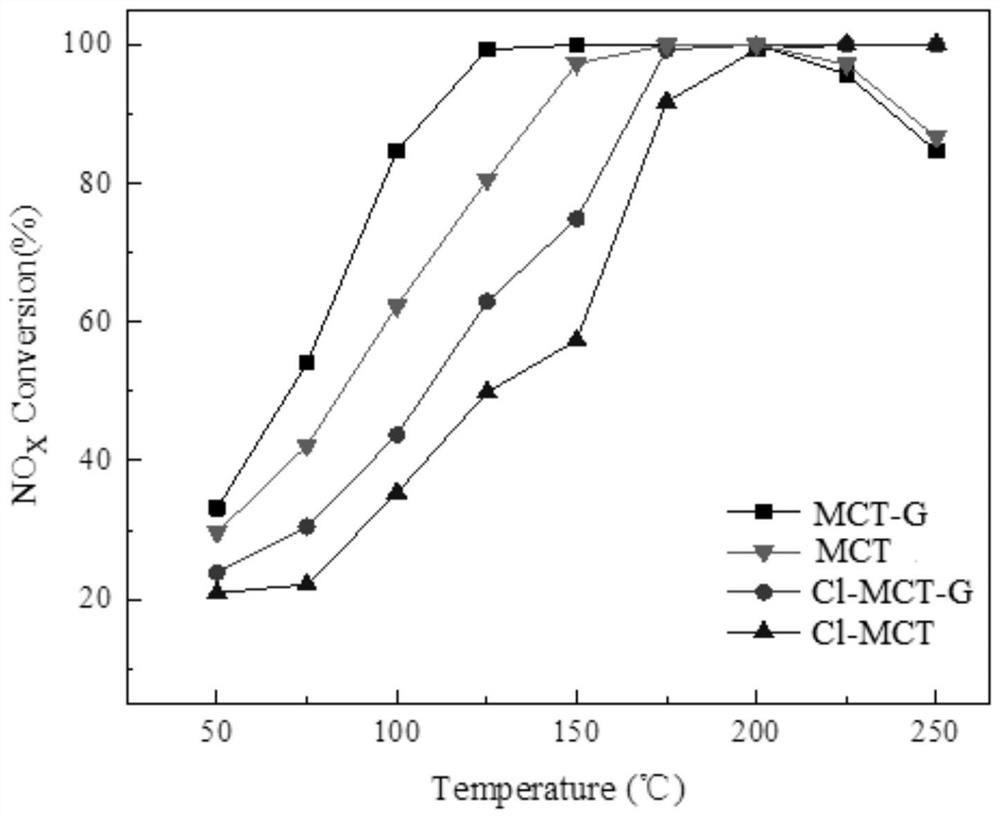

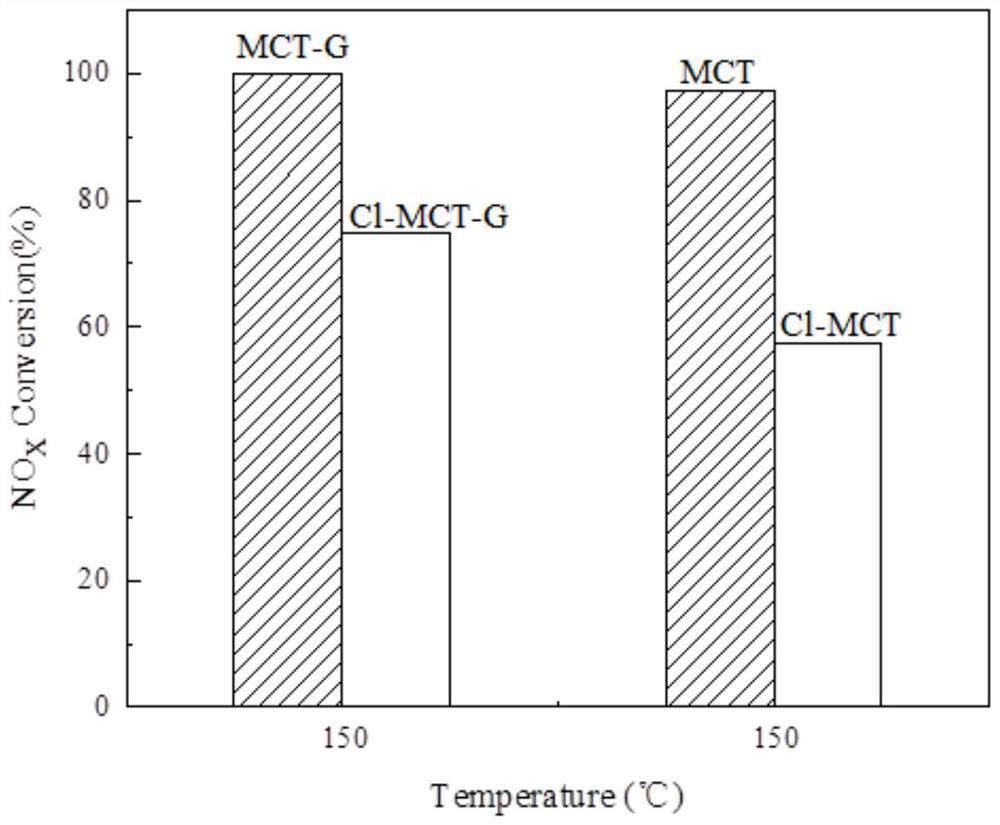

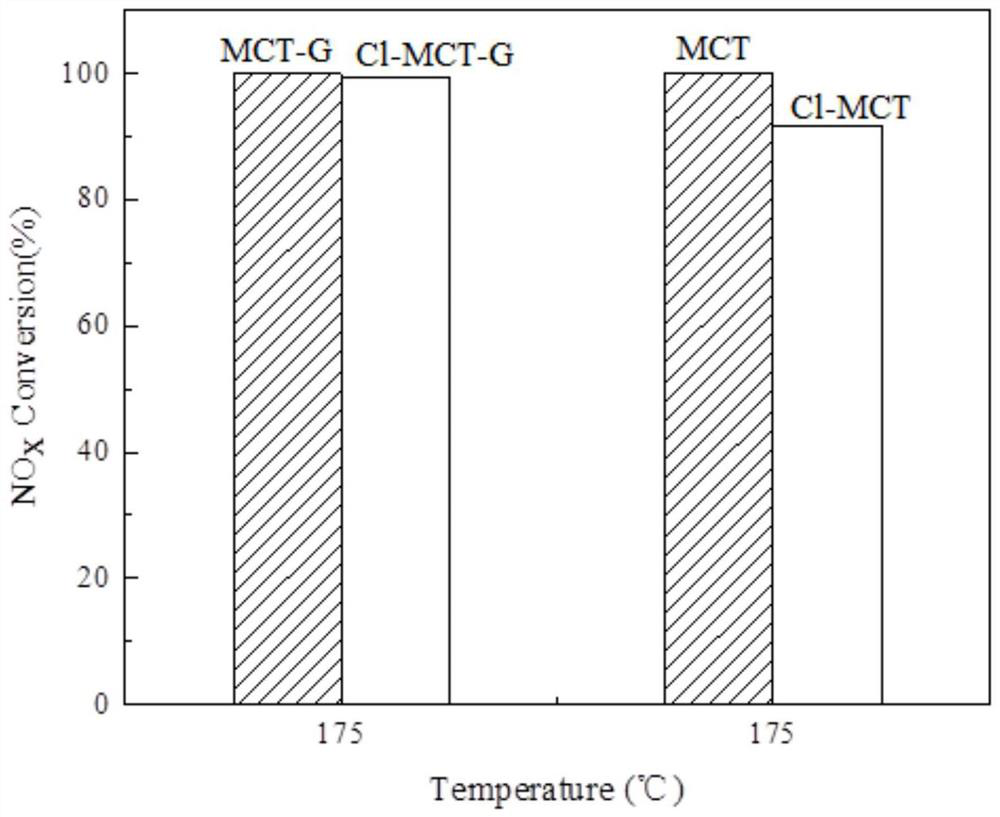

Low-temperature denitration catalyst capable of resisting halogen element Cl poisoning and preparation method and application of low-temperature denitration catalyst

PendingCN113457670AGood low temperature denitrification activityWide reaction temperature windowHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystCombustion chamber

The invention relates to a low-temperature denitration catalyst capable of resisting halogen element Cl poisoning and a preparation method and application thereof. The catalyst is prepared through a surface impregnation combustion method, and the preparation method comprises the following steps: (1) dissolving manganous nitrate, cerous nitrate and fuel in deionized water to obtain a mixed solution; (2) adding titanium dioxide into the mixed solution, and uniformly stirring to obtain a precursor product; and (3) burning the precursor product in a combustion chamber, continuously roasting, and grinding the obtained solid reaction product to obtain the target product. The catalyst is used for NH3-SCR reaction. Compared with a catalyst prepared by a traditional impregnation method, the Mn-Ce-Ox / TiO2 low-temperature denitration catalyst prepared by the preparation method disclosed by the invention has relatively good low-temperature denitration activity and halogen element Cl poisoning resistance, and the reduction amplitude of the NOx conversion rate of the catalyst is relatively small in a temperature range of 100-200 DEG C; equipment required in the preparation process is simple, the cost of raw materials is low, the combustion reaction is mild, and the method is a simple, safe and reliable new method.

Owner:SHANGHAI INST OF TECH

Catalyst for cleaning waste incineration flue gas and preparation method thereof

ActiveCN109126773BHigh catalytic activityImprove adsorption capacityGas treatmentDispersed particle separationChlorobenzenePtru catalyst

The invention discloses a catalyst for purifying waste incineration flue gas. The catalyst uses vanadium pentoxide, platinum oxide and tungsten oxide as active components, γ-alumina, titanium dioxide and carbon nanotubes as carriers, and manganese oxide One or more of , iron oxide, copper oxide, tin oxide, and cerium oxide are coagents. The catalyst of the invention not only has the function of decomposing dioxins and chlorobenzene compounds, but also has the function of denitrification and anti-sulfur, and still has excellent removal ability for dioxins and NOx at relatively low temperature. The invention also discloses a preparation method of the catalyst for purifying waste incineration flue gas. The preparation method has the advantages of simple operation, convenience and controllability, and is suitable for large-scale industrial production.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Low-temperature water-resistant SCR denitration catalyst and preparation method thereof

PendingCN111774054AReduce catalytic activityHigh catalytic activityHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystReaction temperature

The invention discloses a low-temperature water-resistant SCR denitration catalyst and a preparation method thereof. The catalyst takes titanium dioxide as a carrier, takes a manganese oxide as an active ingredient, and takes a holmium oxide, a cerium oxide and a transition metal oxide as cocatalysts; wherein the transition metal oxide is one or more of an iron oxide, a cobalt oxide, a copper oxide and a vanadium oxide, and the molar ratio of titanium to manganese to holmium to cerium to the transition metal is 1: (0.01-0.25): (0.001-0.01): (0.001-0.02): (0.01-0.03). The invention discloses apreparation method of the low-temperature water-resistant SCR denitration catalyst. According to the invention, oxides of various rare earth elements and transition metal elements are added; the low-temperature water-resistant SCR denitration catalyst is prepared by reasonably setting the mass ratio of the active component manganese to the auxiliary components in the catalyst and adopting an ultrasonic-enhanced auxiliary means, has the characteristics of low activation temperature, high catalytic activity and wider reaction temperature window, has higher water resistance, and is wider in application range.

Owner:SOUTHEAST UNIV

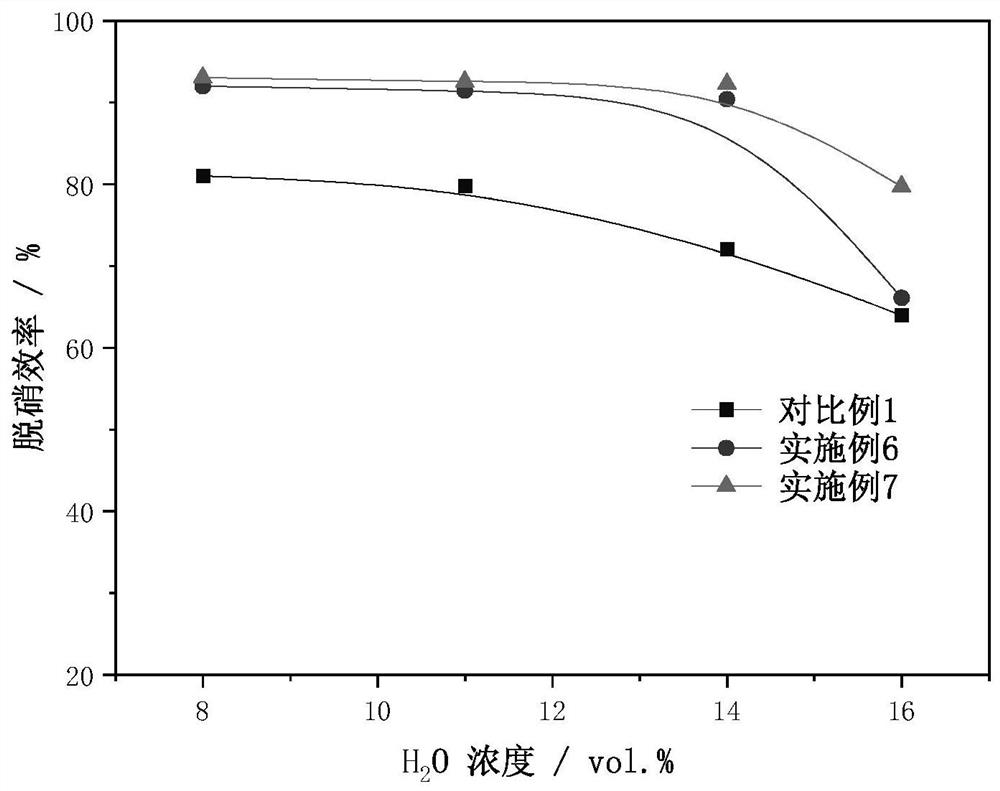

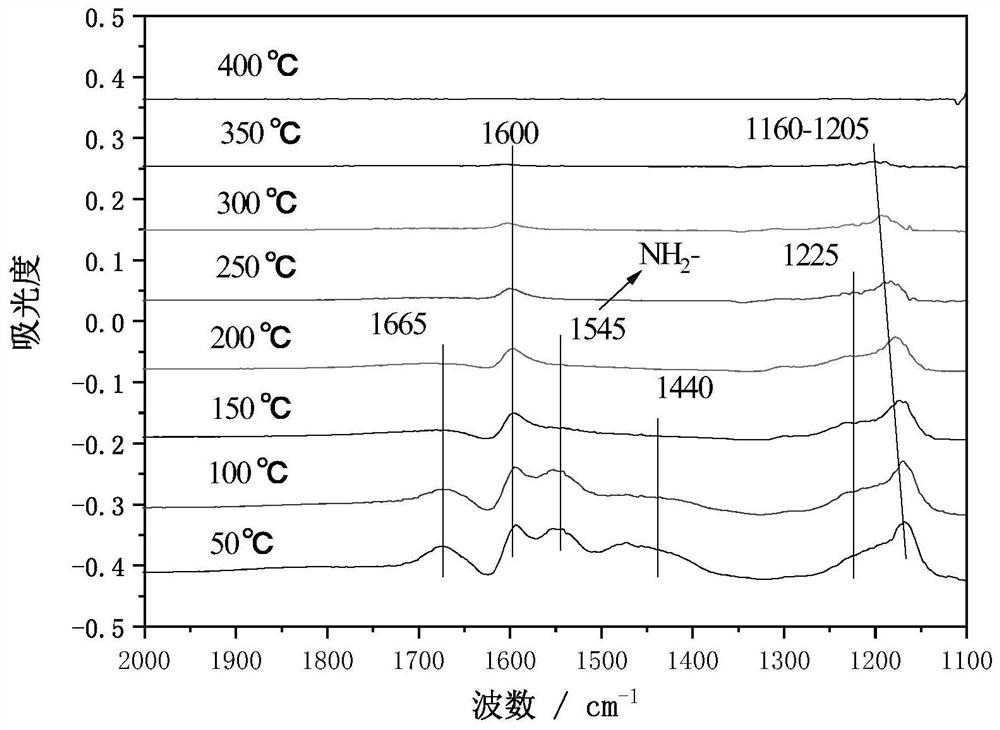

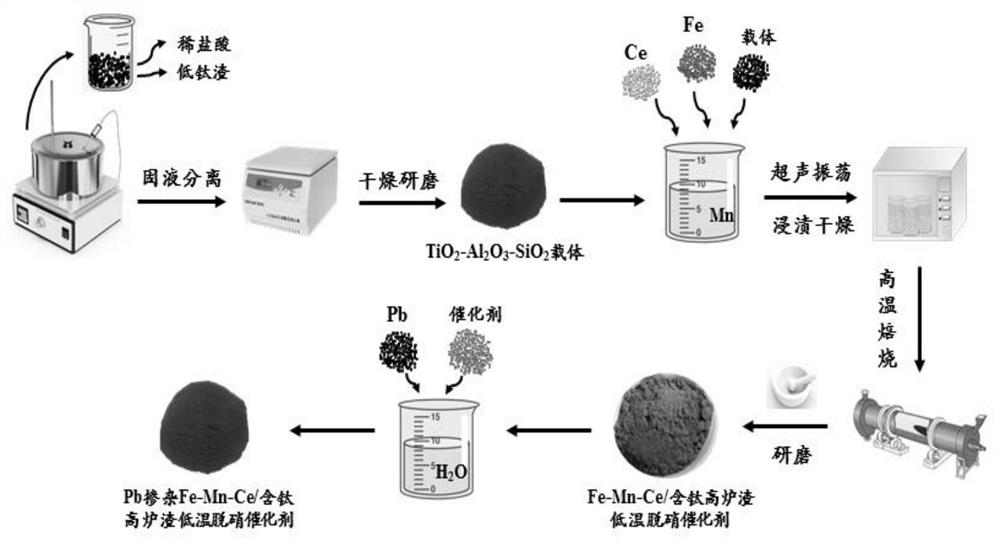

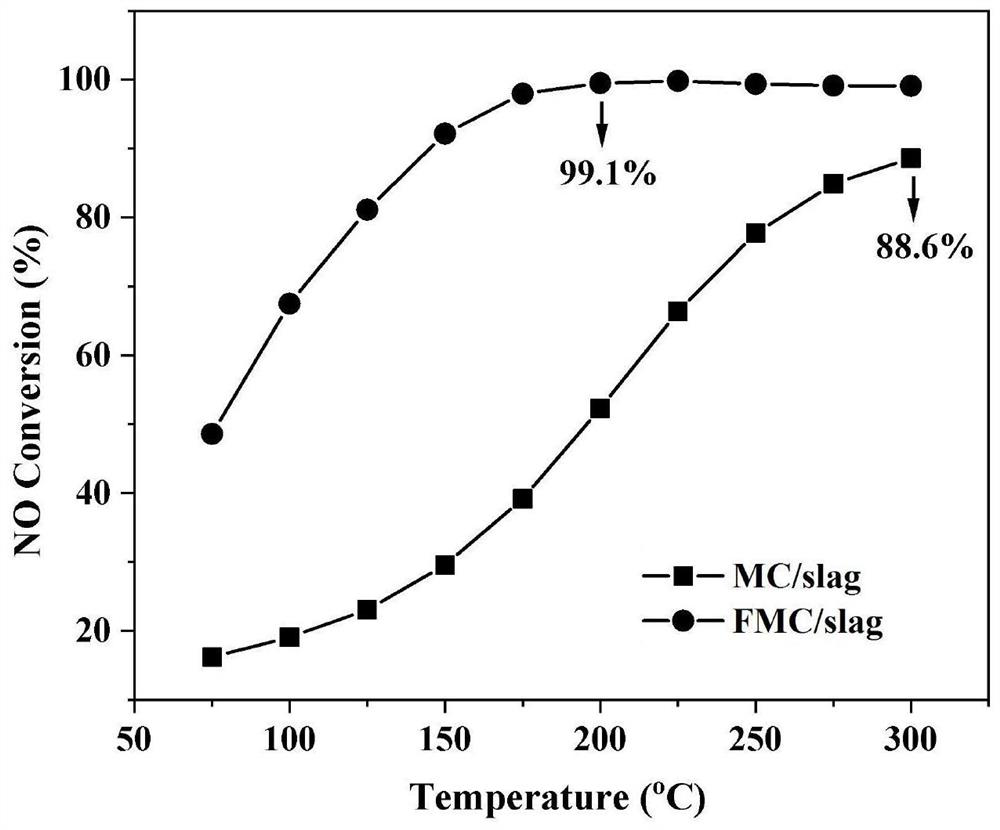

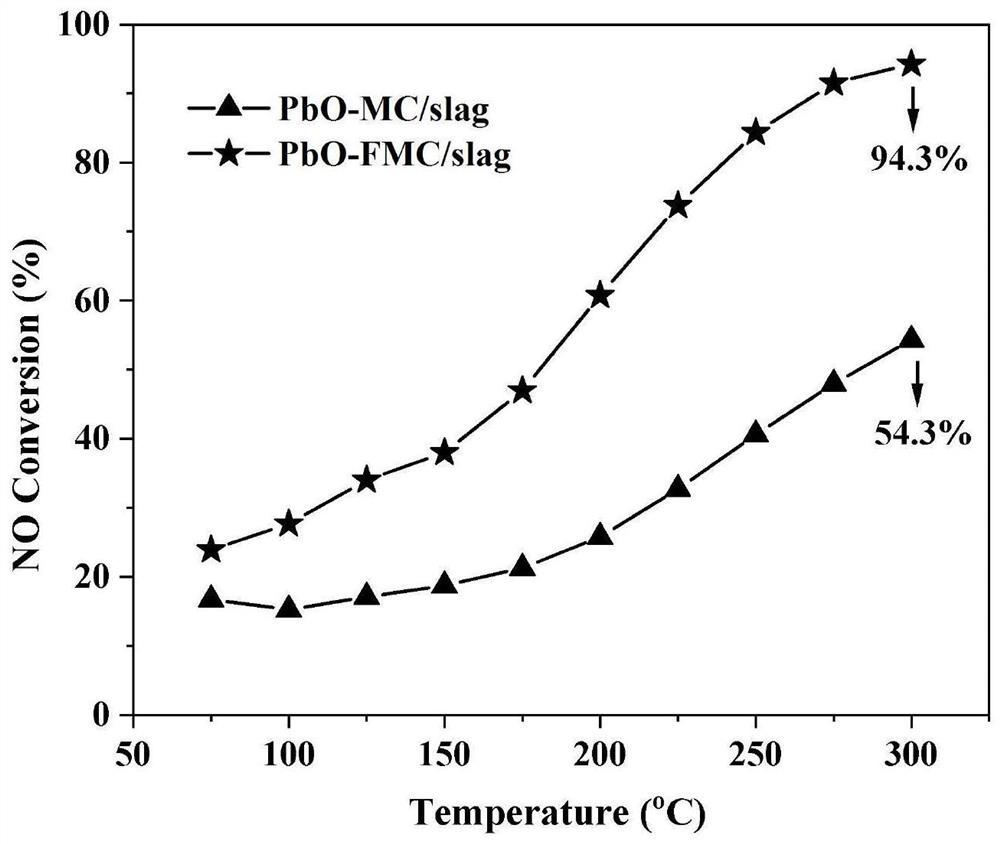

Lead poisoning resistant Fe-Mn-Ce/titanium-containing blast furnace slag denitration catalyst

PendingCN113786841AGood catalytic activity at low temperatureWide reaction temperature windowCatalyst carriersGas treatmentSlagFlue gas

The invention provides a Fe-Mn-Ce / titanium-containing blast furnace slag denitration catalyst . The Fe-Mn-Ce / titanium-containing blast furnace slag denitration catalyst provided by the invention has the characteristics of excellent low-temperature catalytic activity, wide reaction temperature window and the like, the price cost of the used raw materials is lower, and compared with a rare earth metal-based catalyst, the Fe-Mn-Ce / titanium-containing blast furnace slag denitration catalyst has obvious advantages. The Fe-Mn-Ce / titanium-containing blast furnace slag denitration catalyst provided by the invention has an obvious anti-poisoning effect on heavy metals such as PbO, PbCl2 or PbSO4. When the catalyst is applied to the field of selective catalytic reduction flue gas denitration, the actual service life of the catalyst can be prolonged, and the use cost is reduced. And the idea of turning waste into wealth is adopted, so that the blast furnace by-product titanium-containing blast furnace slag can be utilized to a greater extent, resources are saved, the pollution to the environment is reduced, and good social benefits are achieved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

A kind of tung oil-based waterborne polyurethane coating and preparation method thereof

ActiveCN107151520BInhibit synthesisReduce concentrationOrganic compound preparationCarboxylic acid esters preparationDistillationMoisture resistance

The invention discloses a preparation method of a tung oil-based aqueous polyurethane coating. The preparation method comprises the following steps: mixing tung oil, carboxylic acid, an acid catalyst and a hydroxylation reagent in proportion, and heating the obtained mixture to 35-45 DEG C; dropwise adding a hydrogen peroxide solution while intense stirring, controlling the dropwise adding speed to keep the reaction carried out at 40-65 DEG C, and keeping the reaction for 3-5 h after the dropwise addition is finished; standing and layering the obtained reaction solution after the reaction ends, separating the obtained water phase, neutralizing the water phase, washing the neutralized water phase with water, and carrying out reduced pressure distillation to obtain tung oil polyol; and uniformly mixing the tung oil polyol, a hydrophilic modifier and acetone in proportion, adding diisocyanate, carrying out a reaction at 50-70 DEG C for 2-5 h, cooling the obtained reaction product to room temperature, adding a neutralizer to form a salt, adding a diamine chain extender and deionized water mixed solution, carrying out a chain extension reaction until no free isocyanate radicals exist, and carrying out reduced pressure distillation to remove the acetone in order to obtain the tung oil-based aqueous polyurethane coating. The preparation method has the advantages of effective improvement of the hydrophobicity and the moisture resistance of the aqueous polyurethane coating, and renewable and nontoxic raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

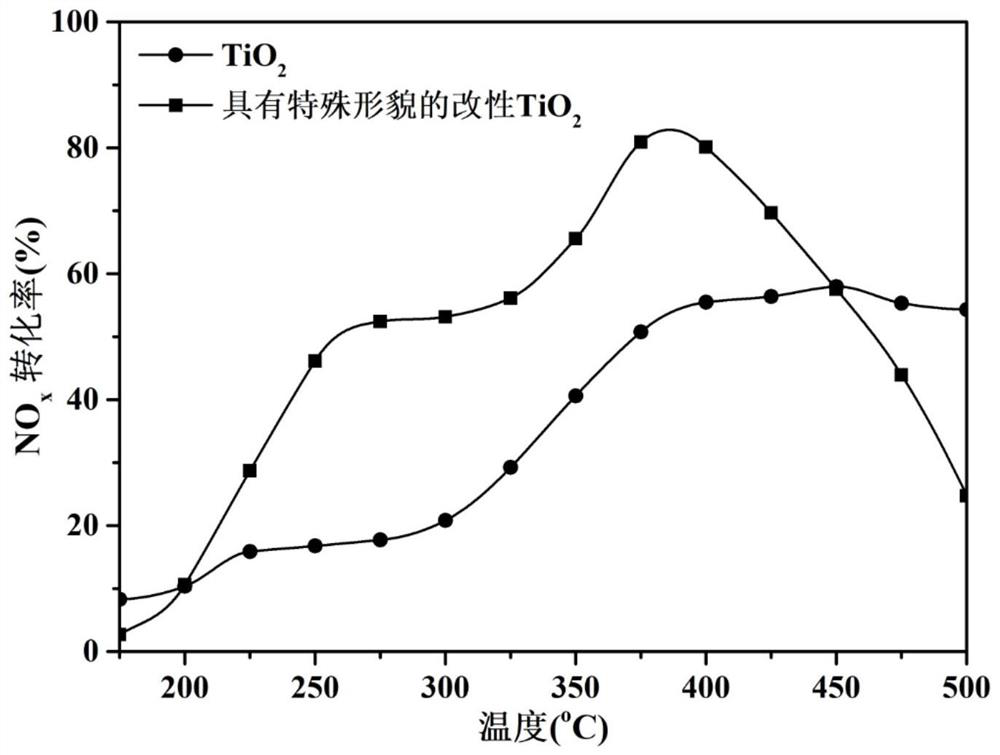

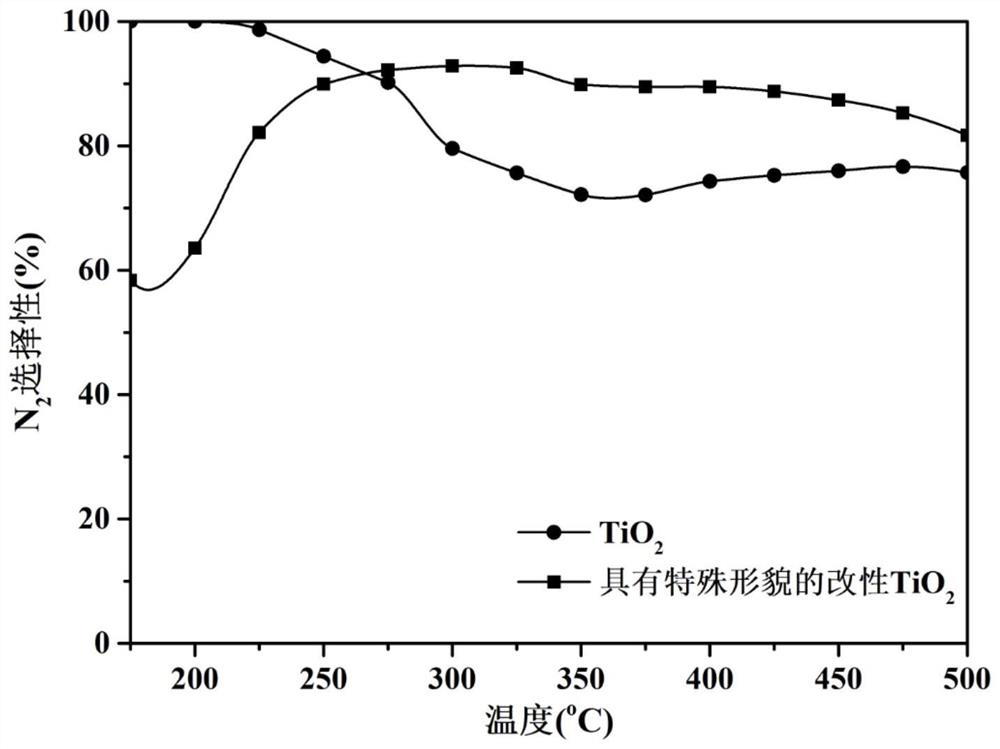

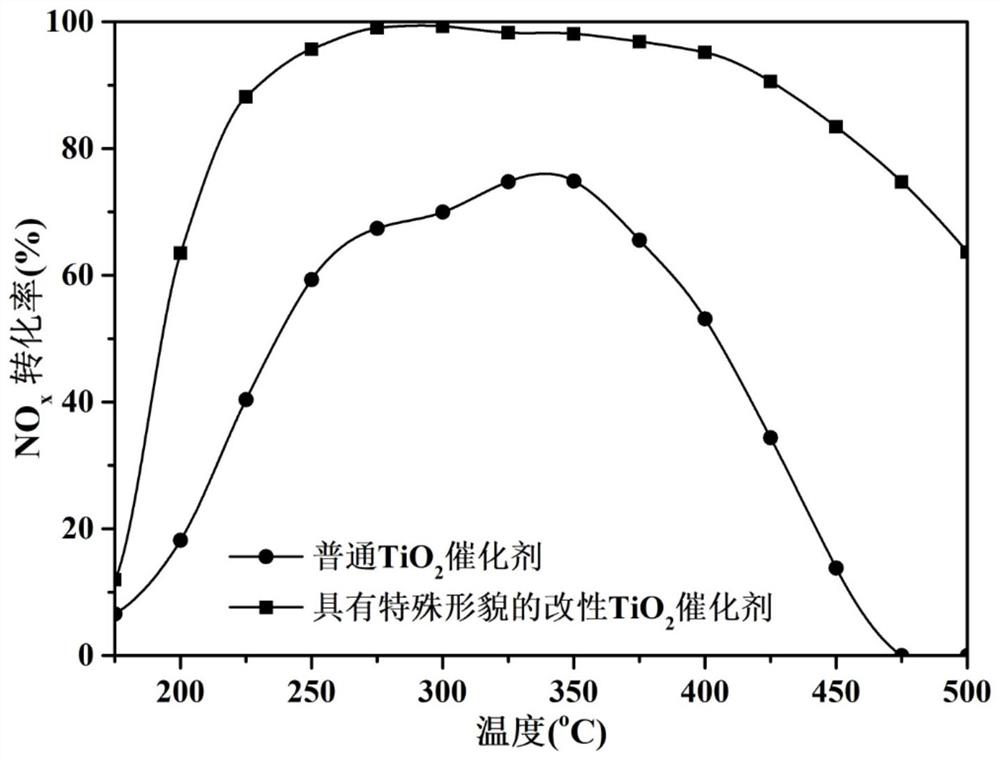

Modified titanium dioxide catalyst with special morphology and its preparation method and application

ActiveCN111001398BLower synthesis costHigh catalytic efficiencyCatalyst carriersDispersed particle separationPtru catalystTitanium isopropoxide

The invention discloses a modified titanium dioxide catalyst with special morphology and its preparation method and application. The method comprises: mixing diethylenetriamine, titanium tetraisopropoxide, niobium pentachloride and isopropanol High-temperature hydrothermal reaction is carried out, and the catalyst carrier is obtained after the product is separated, washed, dried and calcined. Subsequently, the active component is doped with active metal nitrate to prepare a modified titanium dioxide catalyst with special morphology. The catalyst prepared by the invention can be applied to the selective catalytic reduction of nitrogen oxides by ammonia. The catalyst exhibits high nitrogen oxide conversion, nitrogen selectivity, wide reaction temperature window, and excellent resistance to sulfur dioxide, water vapor, and alkali metal poisoning. The special morphology / structure can effectively reduce the amount of modifying elements, The production cost is well reduced, and the catalytic system is non-toxic to the environment and the human body, and has good industrial application prospects.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com