Modified denitration catalyst and preparation method thereof

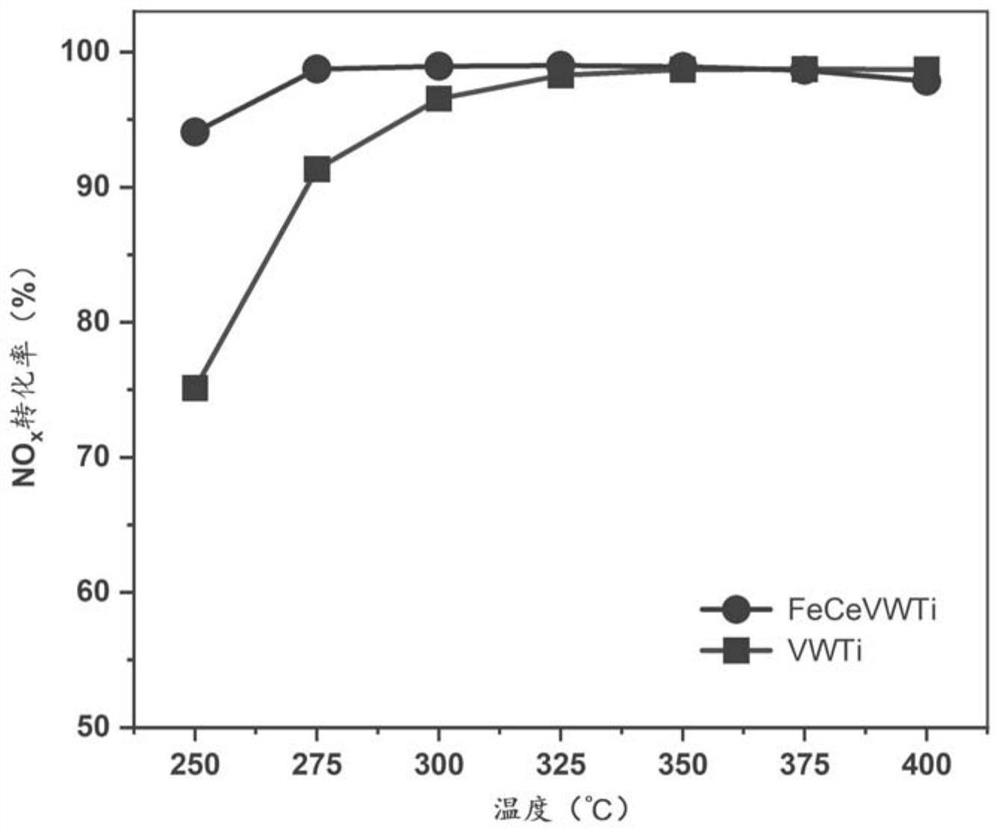

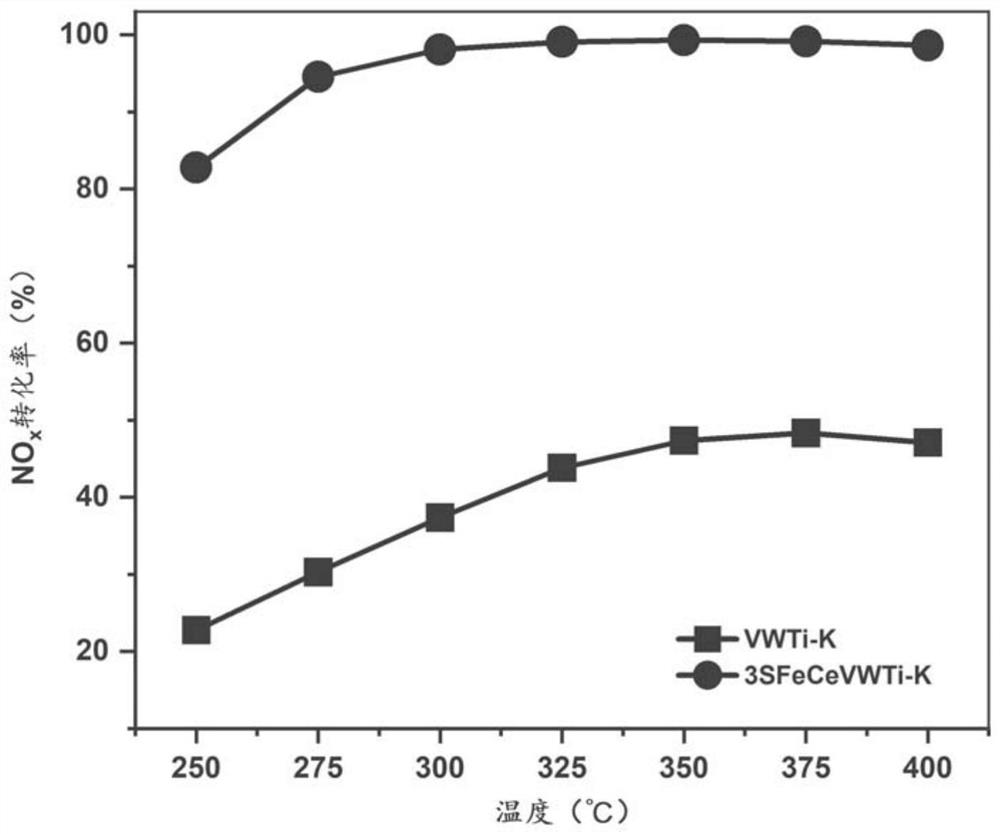

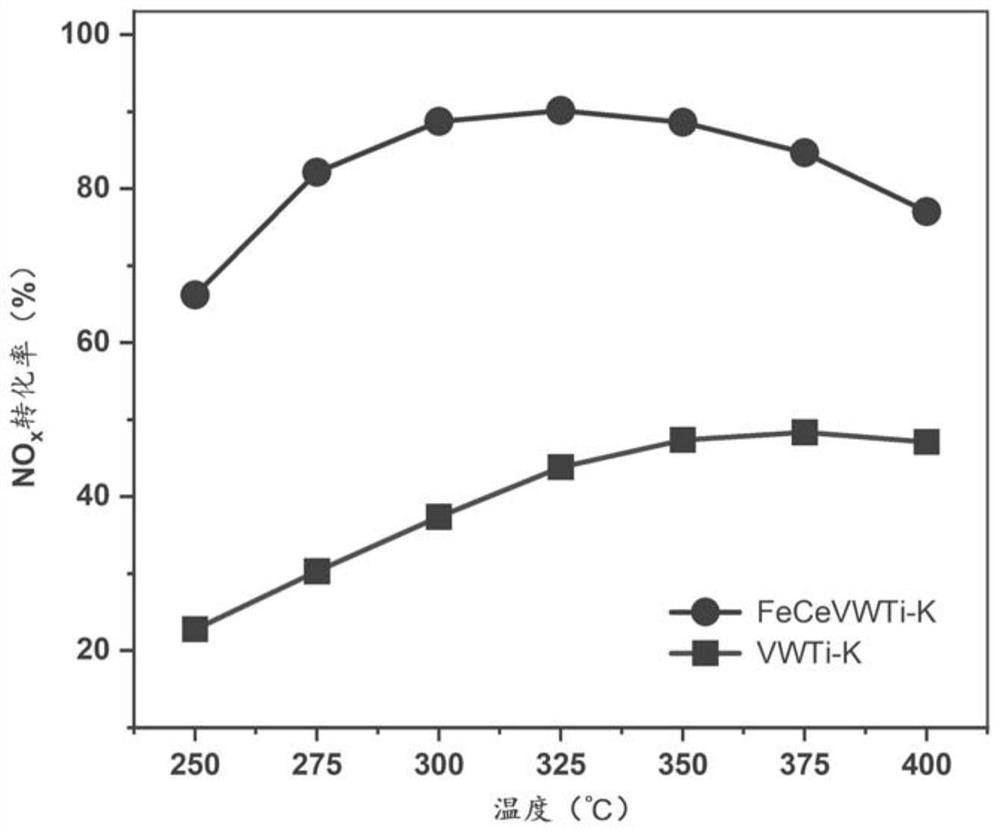

A denitrification catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of impact and unfavorable catalyst life, achieve high N2 selectivity, and the preparation process is non-toxic and non-toxic Harmful, strong anti-alkali metal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present application also provides a method for preparing a modified denitration catalyst. The modified denitration catalyst is the above-mentioned modified denitration catalyst. Specifically, the preparation method may include the following steps:

[0047] S1: Weigh the modifying element precursor salt according to the preset ratio and dissolve it to obtain solution A;

[0048] In the embodiment of the present application, the precursor salts include but are not limited to ferric nitrate, ferric sulfate, ferric acetate, ferric chloride, cerium nitrate, cerium sulfate, cerium acetate, cerium chloride, ammonium sulfate, ammonium bisulfate and sulfuric acid one or more of.

[0049] S2: Mix the vanadium-tungsten-titanium catalyst with the solution A, impregnate at room temperature to obtain the mixed solution B.

[0050] In some embodiments, the denitration catalyst includes one or more of powdery, granular, honeycomb, corrugated and flat vanadium-tungsten-titanium cat...

Embodiment 1

[0058] Preparation method of commercial denitration catalyst (3SFeCeVWTi) modified with iron, cerium and sulfate radical:

[0059] Select a commercially available honeycomb vanadium-tungsten-titanium catalyst, crush and grind it to powder, and analyze the mass content of each component of the vanadium-tungsten-titanium catalyst by X-ray fluorescence spectroscopy, wherein, V 2 o 5 1.144%, WO 3 3.458%, TiO 2 is 90.102%.

[0060] S1: The molar ratio of Fe to V is 0.05:1, the molar ratio of Ce to V is 1.5:1, and the molar ratio of S to V is 4.5:1. Take by weighing 0.0152 gram of iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 0.4916 grams of cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) and 0.4488 grams of ammonium sulfate ((NH 4 ) 2 SO 4 ) is a precursor salt, which is successively added to 8 milliliters of deionized water, ultrasonically treated and stirred until fully dissolved to obtain solution A;

[0061] S2: Add 6 grams of powdered vanadium-tungsten-titanium ...

Embodiment 2

[0067] Preparation method of commercial denitration catalyst (SFeCeVWTi) modified with iron, cerium and sulfate radical:

[0068] Select a commercially available honeycomb vanadium-tungsten-titanium catalyst, crush and grind it to powder, and analyze the mass content of each component of the vanadium-tungsten-titanium catalyst by X-ray fluorescence spectroscopy, wherein, V 2 o 5 1.144%, WO 3 3.458%, TiO 2 is 90.102%.

[0069] S1: The molar ratio of Fe to V is 0.01:1, the molar ratio of Ce to V is 0.1:1, and the molar ratio of S to V is 0.1:1. Take by weighing 0.0031 gram of iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 0.0328 grams of cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) and 0.0100 grams of ammonium sulfate ((NH 4 ) 2 SO 4 ) is a precursor salt, which is successively added to 8 milliliters of deionized water, ultrasonically treated and stirred until fully dissolved to obtain solution A;

[0070] S2: Add 6 grams of powdered vanadium-tungsten-titanium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com