Tung oil-based aqueous polyurethane coating and preparation method thereof

A technology of water-based polyurethane and tung oil, which is applied in the field of polyurethane materials, can solve the problems of prone to side reactions, high reactivity of epoxy groups, and inability to use polyurethane, so as to avoid cross-linking side reactions, improve moisture resistance, and improve hydrophobicity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

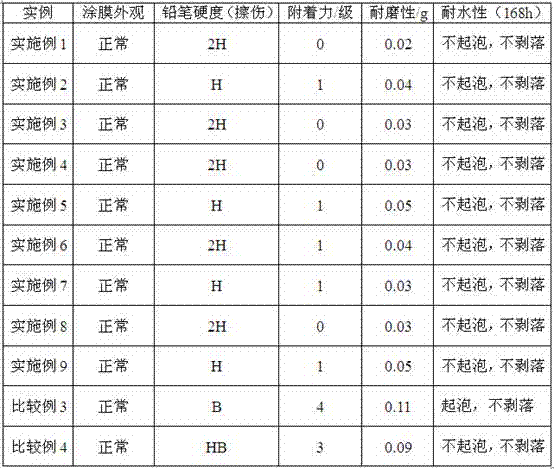

Examples

Embodiment 1

[0029] Add 500g of tung oil, 80g of formic acid (85wt% solution), 0.5g of concentrated sulfuric acid, and 150g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 40°C and stir well. Then, 325g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the rate of addition was controlled to keep the reaction temperature at about 50°C. After standing until the reaction system was separated, the water phase was removed, the oil phase was washed with 10wt% sodium bicarbonate aqueous solution to neutrality, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0030] Add 30 g of the above-prepared tung oil polyol, 2 g of dimethylol propionic acid, and 15 g of acetone into the reaction kettle and mix evenly, then slowly add 15 g of toluene diisocyanate, and react at 60° C. for 2.5 h. After the reaction, the material was cooled to roo...

Embodiment 2

[0032] Add 500g of tung oil, 55g of formic acid (85wt% solution), 4g of concentrated sulfuric acid, and 100g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 45°C and stir well. Then, 285g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the dropping rate was controlled to keep the reaction temperature at about 65°C. After standing until the reaction system was separated, the water phase was removed, the oil phase was washed with 10wt% sodium bicarbonate aqueous solution to neutrality, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0033] Add 30 g of the above-prepared tung oil polyol, 2.4 g of dimethylol propionic acid, and 15 g of acetone into the reaction kettle and mix well, then slowly add 17 g of diphenylmethane diisocyanate, and react at 60° C. for 2 h. After the reaction, the material was cooled to ro...

Embodiment 3

[0035] Add 500g tung oil, 100g formic acid (85wt% solution), 0.25g concentrated sulfuric acid, and 250g n-hexanoic acid into a 2000mL three-neck flask, heat up to 35°C and stir well. Then, 380g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the dropping rate was controlled to keep the reaction temperature at about 40°C. After the reaction system was separated into layers, the water phase was removed, and the oil phase was washed with 10 wt% sodium bicarbonate aqueous solution until neutral, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0036] Add 30 g of the above-prepared tung oil polyol, 1.6 g of dimethylol butyric acid, and 15 g of acetone into the reaction kettle and mix evenly, then slowly add 14 g of isophorone diisocyanate, and react at 60° C. for 5 h. After the reaction, the material was cooled to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com