Deep denitration process for supercritical carbon dioxide coal-fired boiler

A carbon dioxide, coal-fired boiler technology, applied in chemical instruments and methods, separation methods, lighting and heating equipment, etc., can solve the problems of lowering the temperature in the furnace and insufficient denitrification, so as to reduce the temperature in the furnace and reduce the thermal NOx. The effect of generating, good denitration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

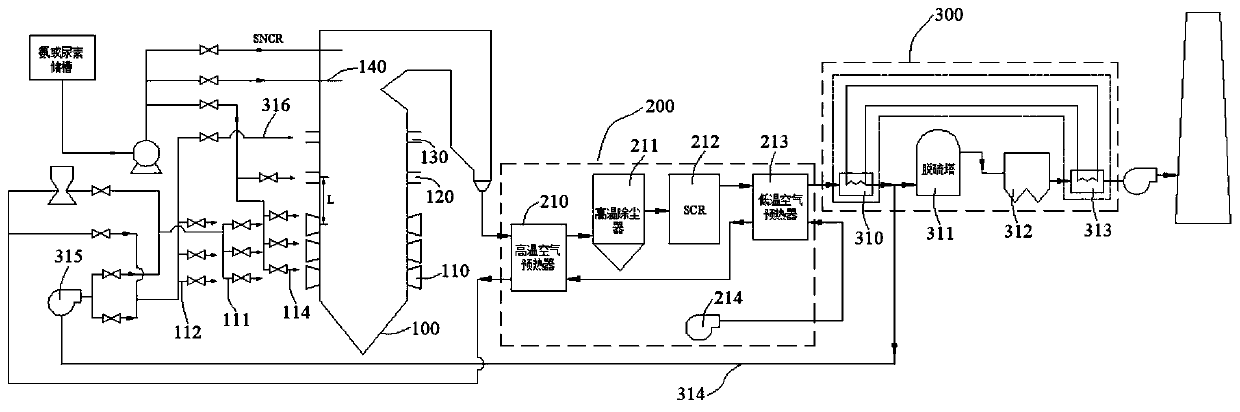

[0042] A supercritical carbon dioxide coal-fired boiler deep denitrification process in this embodiment, the boiler is a supercritical carbon dioxide coal-fired boiler, supercritical carbon dioxide has a higher energy density than water vapor, so the flame temperature in the high-temperature zone produced by it is also higher than that of ordinary water For steam boilers, the NOx content in the furnace is also higher than that of ordinary boilers.

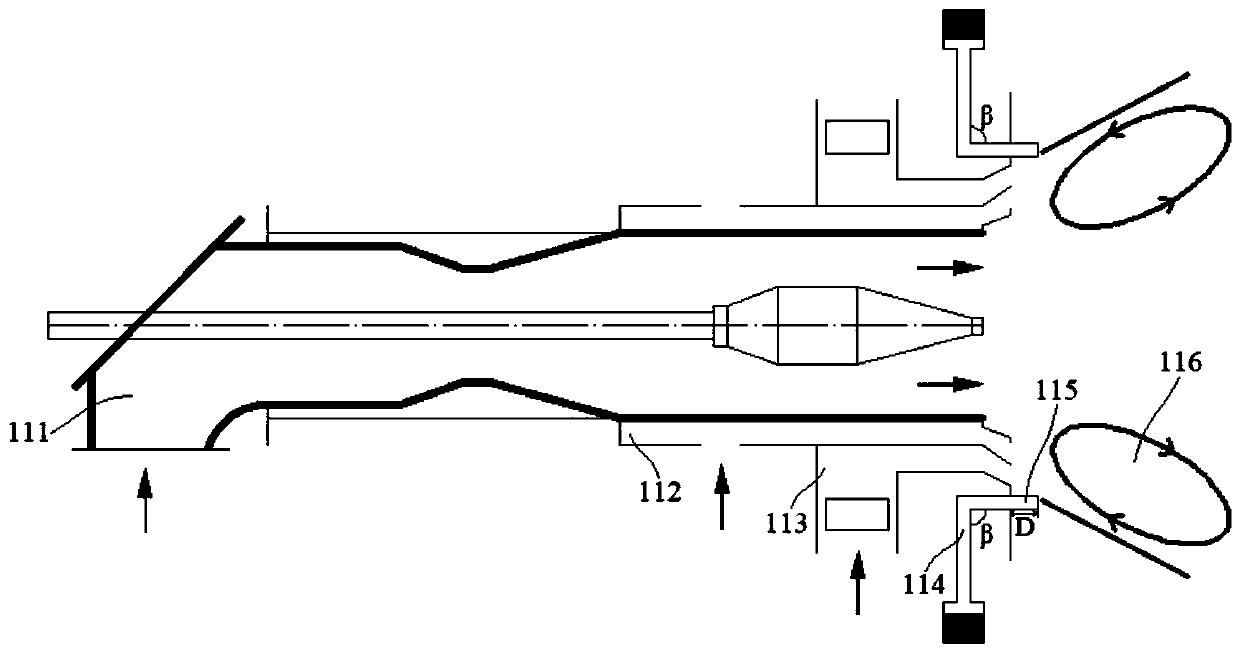

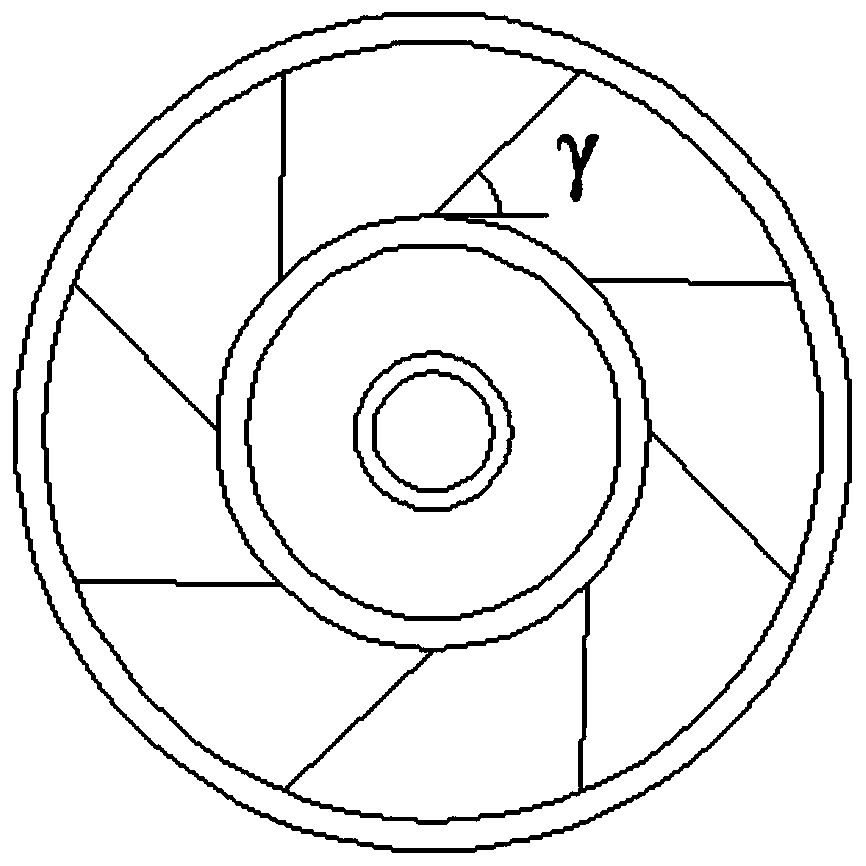

[0043] combine figure 1 The three-stage ammonia injection denitrification process in this embodiment is specifically: use the ammonia injection burner 110 to inject fuel and amino reducing agent into the main combustion area of the burner in the supercritical carbon dioxide coal-fired boiler, and form a temperature of 850-1400 ° C Ring-shaped high-temperature and low-oxygen reduction zone 116, where amino reducing agent and flue gas in the furnace undergo a reduction reaction to achieve primary denitrification; secondary ammonia ...

Embodiment 2

[0061]A supercritical carbon dioxide coal-fired boiler deep denitrification process in this embodiment, its steps are basically the same as in Embodiment 1, further, in this embodiment, after the three-stage denitrification in the furnace, the dust removal and denitrification unit 200 and the temperature is 350-400 °C The flue gas is subjected to high-temperature dust removal treatment, and the flue gas after dust removal is then subjected to SCR deep denitrification. Preferably, the dust removal and denitrification unit 200 in this embodiment performs two-stage air preheating and cooling treatment on the flue gas after the three-stage denitrification in the furnace. The two-stage air preheating process includes high-temperature air preheating before high-temperature ceramic dust removal and SCR deep denitrification After the low temperature air is preheated.

[0062] Specifically in this embodiment, the dedusting and denitration unit 200 includes a high-temperature air prehea...

Embodiment 3

[0068] A supercritical carbon dioxide coal-fired boiler deep denitrification process in this embodiment, its steps are basically the same as in Embodiment 1, further, the desulfurization unit 300 in this embodiment includes a heat recovery device 310, a wet desulfurization tower 311, Wet electrostatic precipitator 312 and reheater 313, heat recovery unit 310 and reheater 313 are also connected through circulating working fluid pipes, and the flue gas after SCR deep denitration is preheated by low-temperature air and then enters the heat recovery unit in desulfurization unit 300 Further cooling treatment in 310, the temperature of the flue gas after the cooling treatment is 70-90°C, at this time, entering the wet desulfurization tower 311 for desulfurization treatment can ensure the desulfurization effect.

[0069] After desulfurization treatment, the flue gas enters the wet electrostatic precipitator 312 for dust removal treatment. The heat absorbed by the heat recovery device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com