Domestic garbage smokeless oil-free vertical pyrolysis gasification furnace

A technology of pyrolysis gasification and domestic waste, applied in the direction of incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of secondary pollution flue gas, etc., to prolong the life of the furnace, strong usability, and less pollution emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

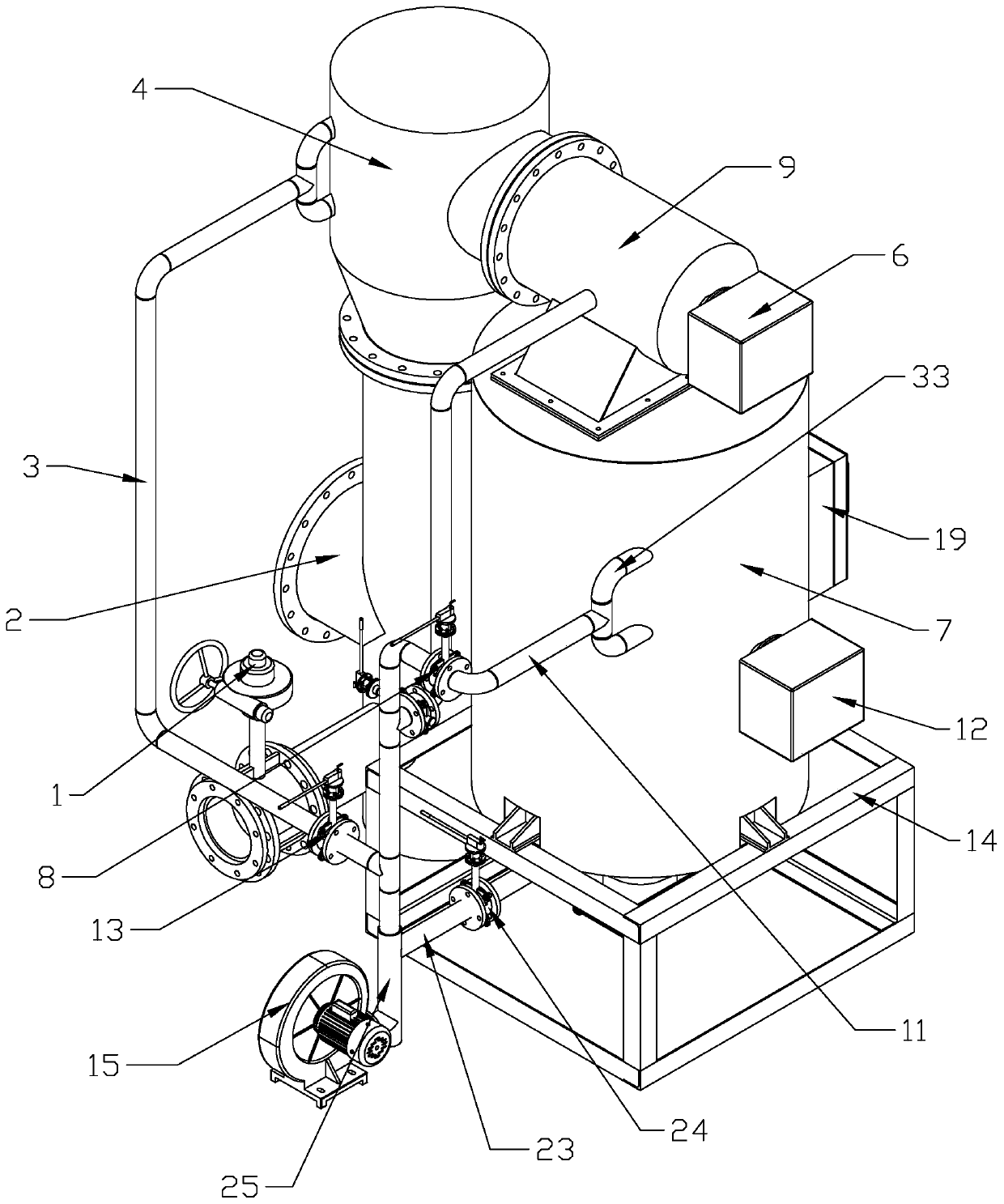

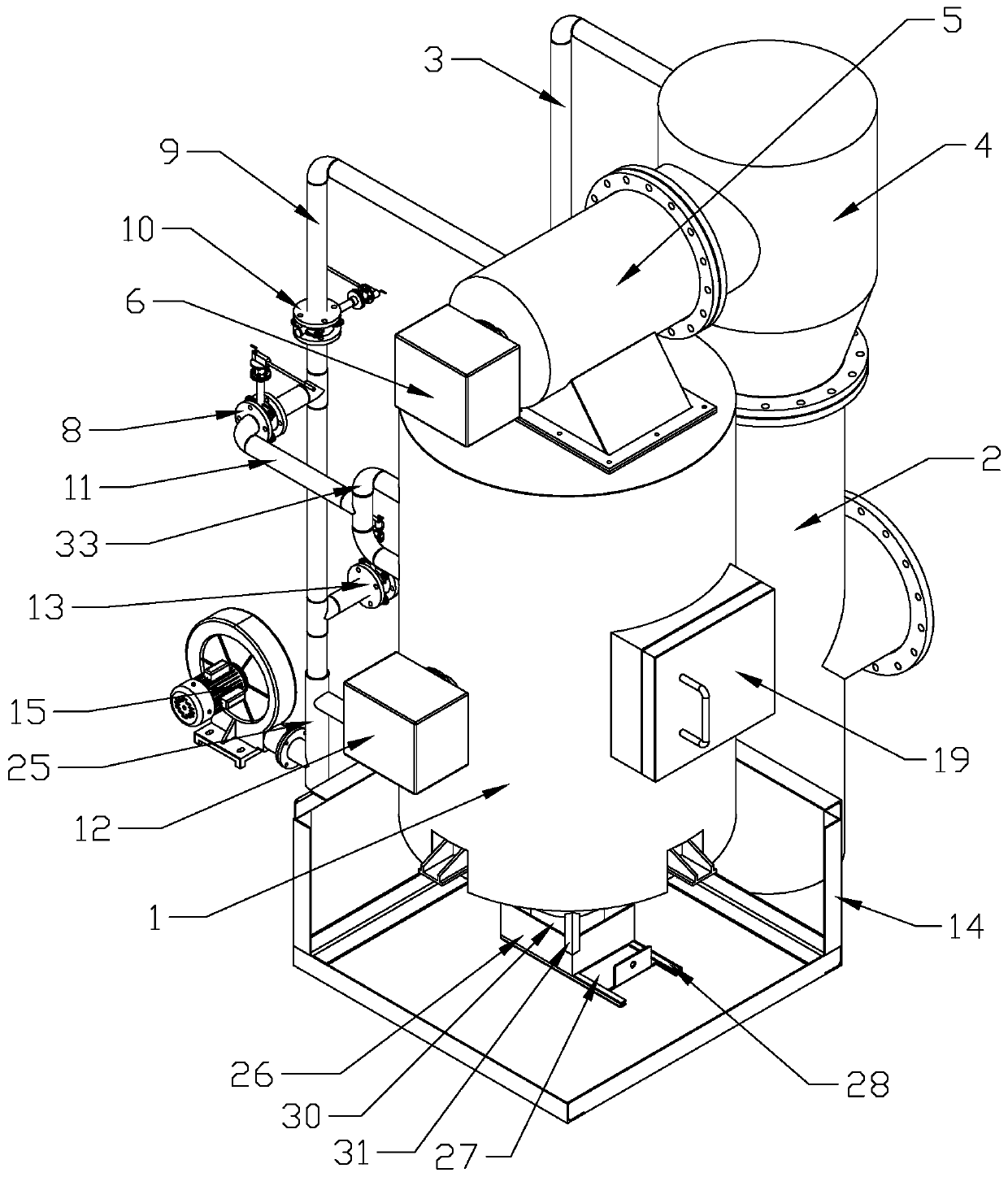

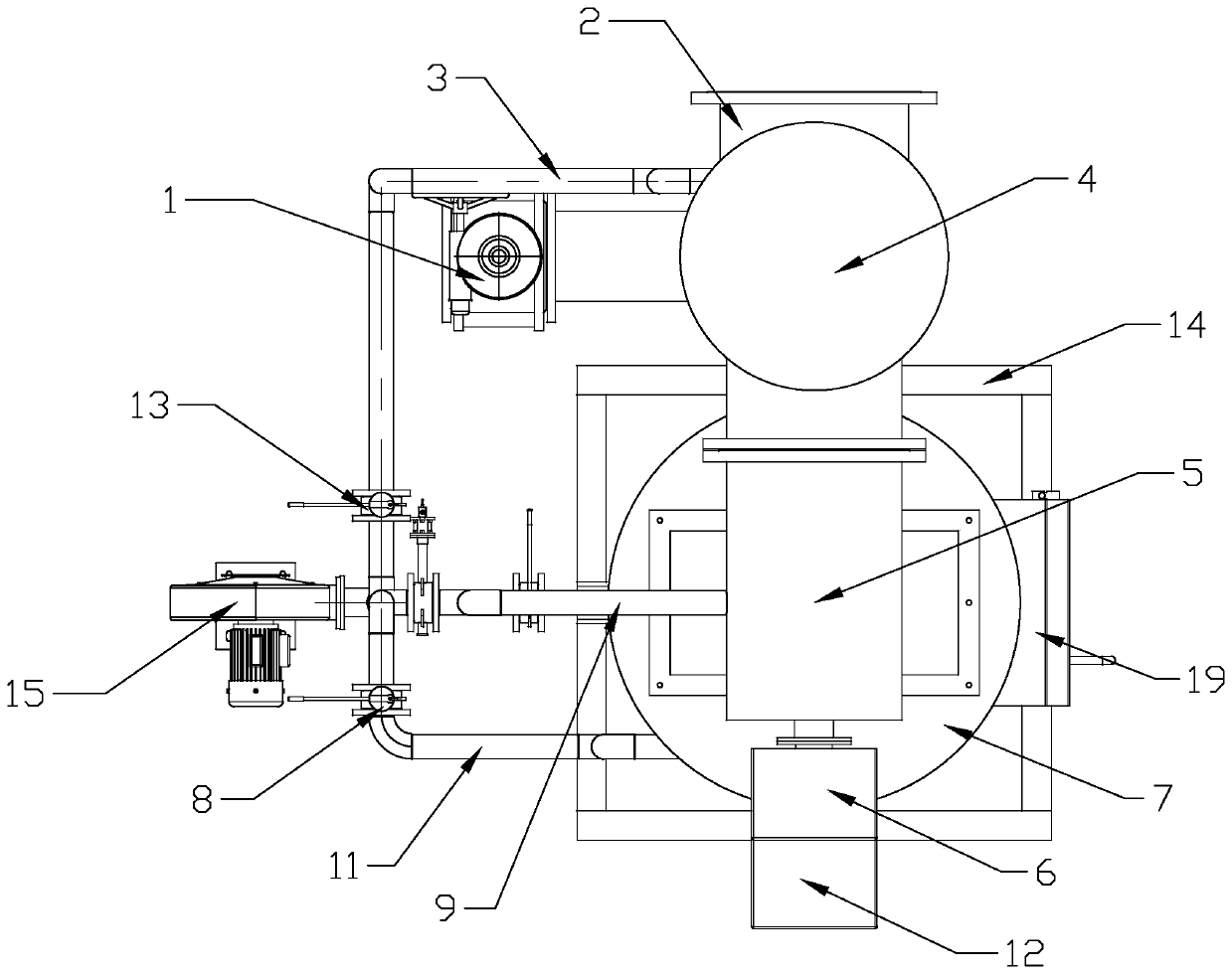

[0014] like figure 1 - As shown in 5, a smokeless and oil-free vertical pyrolysis gasifier for domestic waste, including a furnace body and an air pipeline, the air pipeline includes a second combustion air pipeline 11 arranged up and down and communicated with the furnace body and a second A combustion-supporting air pipeline 23, the wind blown by the blower 15 is sent into the first combustion-supporting air pipeline 23 and the second combustion-supporting air pipeline 11 respectively, wherein the first combustion-supporting air pipeline 23 extends into the bottom of the furnace body and passes through the air distributor 18 communicates with the bottom of the furnace body, and the second combustion-supporting air pipeline 11 communicates with the middle part of the upper half of the first combustion chamber 7 of the furnace body through the middle part of the U-shaped hollow pipe 33, and the U-shaped hollow pipe 33 is fixed on the first combustion chamber 7 On the tangent l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com